BKI LGF User manual

Gas Pressure Fryer

MODELS LGF, LGF-F, & LGF-FC

Service Manual

Serial Numbers 126732 and higher

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The "Company") warrants to the original purchaser that at time of shipment from the Company

factory, this equipment will be free from defect in materials and workmanship. Written notice of a claim

under this warranty must be received by the Company within ONE YEAR from the date of installation, but

no longer than ONE YEAR AND THREE MONTHS from date of shipment from the factory. Defective

conditions caused by abnormal use or misuse, lack of or improper maintenance, damage by third parties,

alterations by unauthorized personnel, acts of God, failure to follow installation and/or operating

instructions, or any other events beyond the reasonable control of the Company will NOT be covered

under this warranty. The obligation of the Company under this warranty shall be limited to repairing or

replacing (at the option of the Company) any part, with the exception of lamps, fuses, and glass (which

are not covered under warranty), which is found defective in the reasonable opinion of the Company. Any

part found defective by the Company will be repaired or replaced without charge F.O.B. factory,

Simpsonville, South Carolina or F.O.B. authorized BKI Distributor. The Company and/or its authorized

representatives will assume the normal replacement labor expense for the defective part for the period of

the warranty as stated above, excluding travel and/or other expenses incidental to the replacement of the

defective part, where replacement work is performed during standard business hours and not subject to

overtime, holiday rates, and/or any additional fees. IN NO EVENT SHALL THE COMPANY BE LIABLE

FOR LOSS OF USE, LOSS OF REVENUE OR LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT

OR CONSEQUENTIAL DAMAGES INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR

PRODUCT LOSS. WARRANTY DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS

EXCLUSIVE AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

REPLACEMENT PARTS

Any appliance replacement part, with the exception of lamps, fuses, and glass, which proves to be

defective in material or workmanship within ninety (90) days of installation will be replaced without charge

F.O.B. Factory, Simpsonville, SC or F.O.B. authorized BKI Distributor. The user shall have the

responsibility and expense of removing and returning the defective part to the Company as well as the

cost of reinstalling the replacement or repaired part.

The purchaser must post, in a prominent location, instructions to be followed in

the event the user smells gas. This information shall be obtained by consulting

the local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operation

and maintenance instructions thoroughly before installing or servicing

this equipment.

Gas Pressure Fryer Table of Contents

1

Table of Contents

Table of Contents .................................................................................................................................................... 1

Introduction.............................................................................................................................................................. 2

Safety .................................................................................................................................................................... 2

Safety Signs and Messages ............................................................................................................................. 2

Specific Precautions ......................................................................................................................................... 3

Equipotential ground plane........................................................................................................................... 3

Full Disconnection ........................................................................................................................................ 3

Safe Work Practices ......................................................................................................................................... 4

Safety Labels .................................................................................................................................................... 9

Maintenance........................................................................................................................................................... 11

Scheduled Maintenance...................................................................................................................................... 11

Safety Pop Valve Procedure........................................................................................................................... 12

Filtering Procedure.......................................................................................................................................... 13

LGF-F and LGF-FC .................................................................................................................................... 13

LGF............................................................................................................................................................. 14

Boil-Out Procedure ......................................................................................................................................... 15

Filter Pad Replacement .................................................................................................................................. 17

Troubleshooting................................................................................................................................................... 18

Replacement Parts ................................................................................................................................................ 19

Assemblies.......................................................................................................................................................... 19

Accessories......................................................................................................................................................... 42

Components........................................................................................................................................................ 43

Wiring Diagrams.................................................................................................................................................... 44

Gas Pressure Fryer Introduction

2

Introduction

The LGF Pressure Fryer is compact, attractive and functional in design. It is constructed of a stainless steel fryer

pot for cleaning ease. Exclusive BKI patented features and safety devices offer flexibility, efficiency and reliability

plus PERFECTION IN PRESSURE FRYING!

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has been

built with care and dedication -- using the best materials available. Attention to the operating instructions

regarding proper installation, operation, and maintenance will result in long lasting dependability to insure the

highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please contact your BKI Distributor. If they are unable to answer your

questions, contact the BKI Technical Service Department, toll free: 1-800-927-6887.

Outside the U.S., call 1-864-963-3471.

Safety

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you

see this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify specific

areas where potential hazards exist and special precautions should be taken. Know and understand the meaning

of these instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other

persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

This message is used when special information, instructions or identification are required

relating to procedures, equipment, tools, capacities and other special data.

Gas Pressure Fryer Introduction

3

Specific Precautions

Lids for LGF Pressure Fryers manufactured prior to May 27, 1980 (or units with

serial numbers lower than 3613) could be manually opened while under pressure

resulting in serious injury or death. If you have one of these units, please contact

the BKI Technical Services Department toll-free at 1-800-927-6887 for urgent

update information.

Risk of fire exists if the oil level drops below 5mm of the maximum oil level.

Use of oil/shortening older than the manufacturers recommendations for life of

the oil is prone to surge boiling and flash fires. Follow the oil manufacturers

guidelines for the life cycle of oil/shortening.

Do not open the drain valve or the fill valve while the fryer is under pressure.

Serious burns may result.

Follow instructions regarding effects of surge boiling of over-wet foods and

proper load size.

This unit incorporates components that contain Mercury. The use of Mercury

relays is an industry standard.

Equipotential ground plane

When a high current flows through a conductor, differences in potential appear

between the conductor and nearby metallic surfaces near the appliance. As a

result, sparks may be produced between the appliance and surrounding metal

surfaces. These sparks could cause serious injury, damage, or fire.

BKI provides an Equipotential ground terminal for the connection of a bonding

conductor after the installation of the appliance per lEC60417-1. This terminal is

located on the inside of the Power Entry Supply box near the Earth connection

and is marked with this symbol.

Full Disconnection

In accordance with Local and/or National wiring codes, the installer must provide

a means of full disconnection under over voltage Category III conditions. An IEC

approved cord and plug combination will meet this requirement.

Units not provided with a cord and plug do not meet this requirement. In

accordance with Local and/or National wiring codes, the installer must provide

the means of full disconnection.

The fryer is designed to hold a maximum of 35lbs (15.9KG) of oil/shortening.

Gas Pressure Fryer Introduction

4

Safe Work Practices

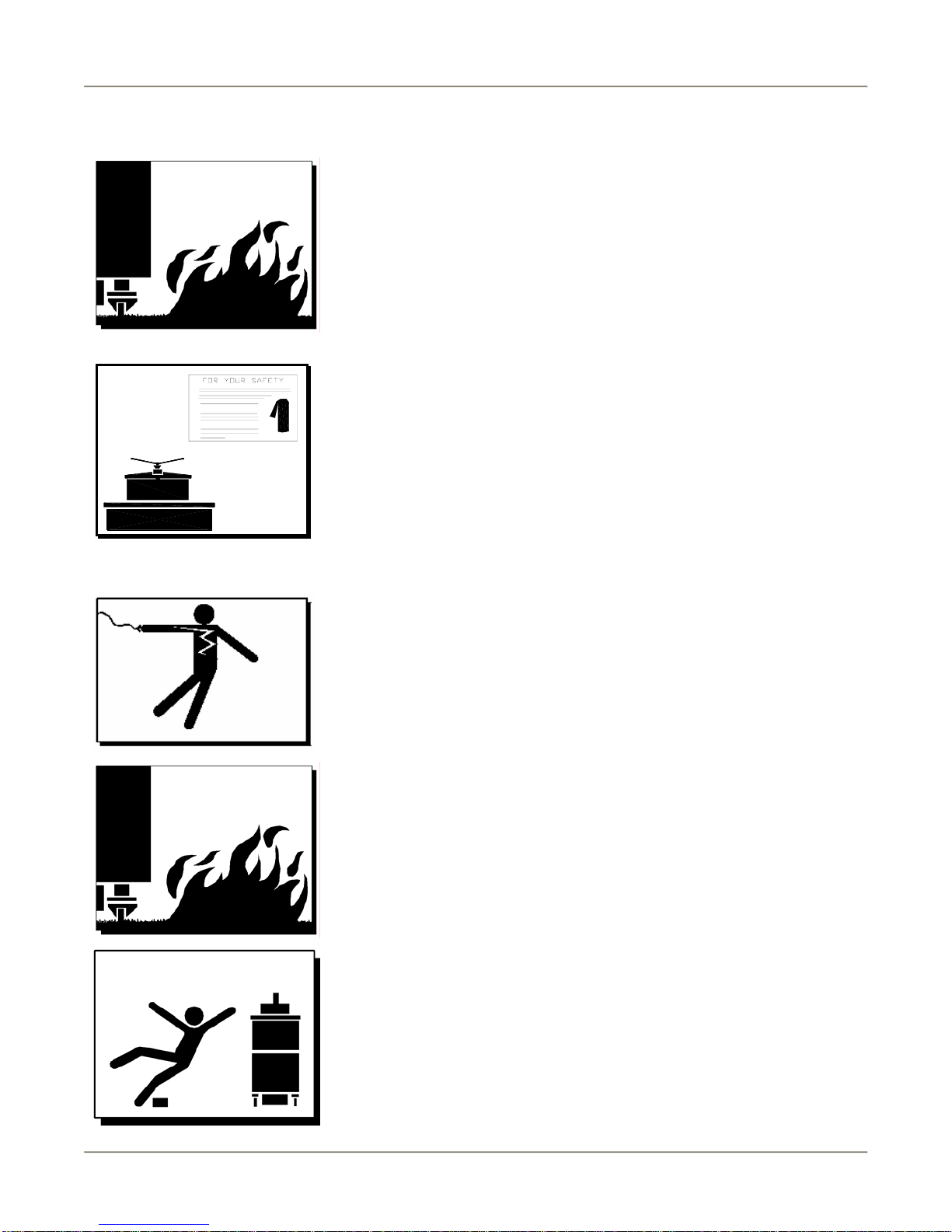

Do Not Store Or Use Anything Flammable Near

The Fryer

Your pressure fryer is powered by either natural gas or LP gas. Do not

store or use gasoline or any flammable liquids or vapors near this or any

other appliance. Flammable materials will burn easily. Letting any

flammable liquid or vapor get too close to the fryer could cause an

explosion or fire. Serious injury could result. Examples of flammables that

you should not store near the fryer are gasoline, paint, thinners or

removers, gas tanks, and cleaning materials.

Use Gas Safely-- Avoid Danger

Gas can be a dangerous fuel if not handled safely.

Make sure to ventilate the fryer properly. If the fryer is not properly

ventilated, carbon monoxide can be released around the fryer.

Asphyxiation or suffocation can occur if gas is not ventilated properly.

Before using this appliance for the first time, contact your local gas supplier

for instructions about what to do if you smell gas. Post those instructions

somewhere near the fryer, so that everyone who uses or works near the

fryer knows what to do if they smell gas.

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you or any

untrained or unauthorized person installs, services, or repairs this

equipment. Always Use an Authorized Service agent to Service Your

Equipment.

Use the Fryer On Noncombustible Floors Only

Make sure your floor is noncombustible. Do not operate your fryer on floors

that are wood, carpeted or have rubber mats. Placing your fryer on a

combustible floor could cause a fire. Serious injury could result. Examples

of noncombustible floors where you can safely place your fryer are

concrete, tile, and ceramic.

Keep The Area Around Your Fryer Uncluttered

Make sure to keep the area around your fryer clear of any obstacles.

Serious injury can occur if you trip or fall near the fryer. You could be

burned by hot shortening that splashes out of the fryer or by falling against

the hot metal of the fryer.

Gas Pressure Fryer Introduction

5

Keep The Floor Around Your Fryer Clean Of

Shortening

Make sure to keep the floor around your fryer clean of shortening and

other liquids. Serious injury can occur if you slip near your fryer. You could

be burned by hot shortening that splashes out of the fryer or by falling

against the hot metal of the fryer.

Keep The Lid Closed When The Fryer Is Not In

Use

Hot shortening can splash if someone moves the fryer or bumps into it.

Serious injury can occur if hot shortening splashes out of the fryer.

Do not lean, sit or stand on the fryer or perform any maintenance or

cleaning duties while the fryer or the shortening is hot. You could be

burned.

Keep The Casters Locked

To avoid spilling shortening, keep the casters locked. If any shortening

spills near your fryer, clean it up immediately.

Do Not Overfill The Fryer With Shortening

Hot shortening and steam may escape and burn you if you put too much

shortening in the fryer. Fill the fryer to approximately one inch below the fill

marks that are inside the fryer pot. Heat the shortening. If needed, carefully

add more shortening to bring the level to the fill marks.

Do Not Let Any Water Get Into The Fryer

Always remove excess moisture from food before placing it into the fryer

basket. Water will cause the hot shortening to spatter. You could be

burned.

Do Not Overload The Basket With Food

Hot shortening and steam may escape and burn you if you place too much

food in the basket.

Gas Pressure Fryer Introduction

6

Always Make Sure The Lid Hook Is Latched When

Closing The Fryer

To make sure the lid hook is latched properly, press down the lid until the

hook snaps shut. Hot shortening and steam can escape if the lid hook is

not latched properly. You could be burned.

Always Tighten The Spin Handle When Closing

The Fryer

Hot shortening and steam can escape if you do not tighten the spin handle

properly. You could be burned. Line up the orange knobs on the fryer lid

handle and the front hook when tightening.

Do Not Over-Tighten The Spin Handle

You could damage the fryer.

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling the fryer basket or touch

any hot metal surfaces. You received a pair of insulated mitts with your

fryer. If you lose or damage your mitts, you can buy new ones at your local

restaurant equipment supply store or from your local BKI Distributor.

Always wear non-skid shoes when working around the fryer or any other

equipment that uses shortening. Never wear loose clothing such as

neckties or scarves while operating your fryer. Keep loose hair tied back or

in a hair net while operating your fryer.

Always wear appropriate personal protection equipment during the filtering

process to guard against possible injury from hot oil.

Always wear appropriate personal protection equipment during the boil-out

process to guard against possible injury from hot cleaning solution.

Never Loosen The Spin Handle Until The

Pressure Gauge Is At Zero

Steam may escape suddenly if you loosen the spin handle before the

gauge is at zero. If steam escapes suddenly, you could be burned.

After the pressure gauge is at zero, wait 5 seconds. Then loosen the spin

handle slowly to open the lid of the fryer. By doing this, the steam will

escape slowly and you will not be burned.

Seal The Safety Valve Properly

To seal the safety valve, lift the arm on the side of the valve. Then release

it. The valve should snap closed. Hot steam can escape from the valve

and you could be burned if you do not seal the valve properly.

Gas Pressure Fryer Introduction

7

Keep Away From The Vent

Hot steam escapes from the vent continuously when you are using your

fryer. You could be burned if you get too close to the vent.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near

for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not understand that

this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

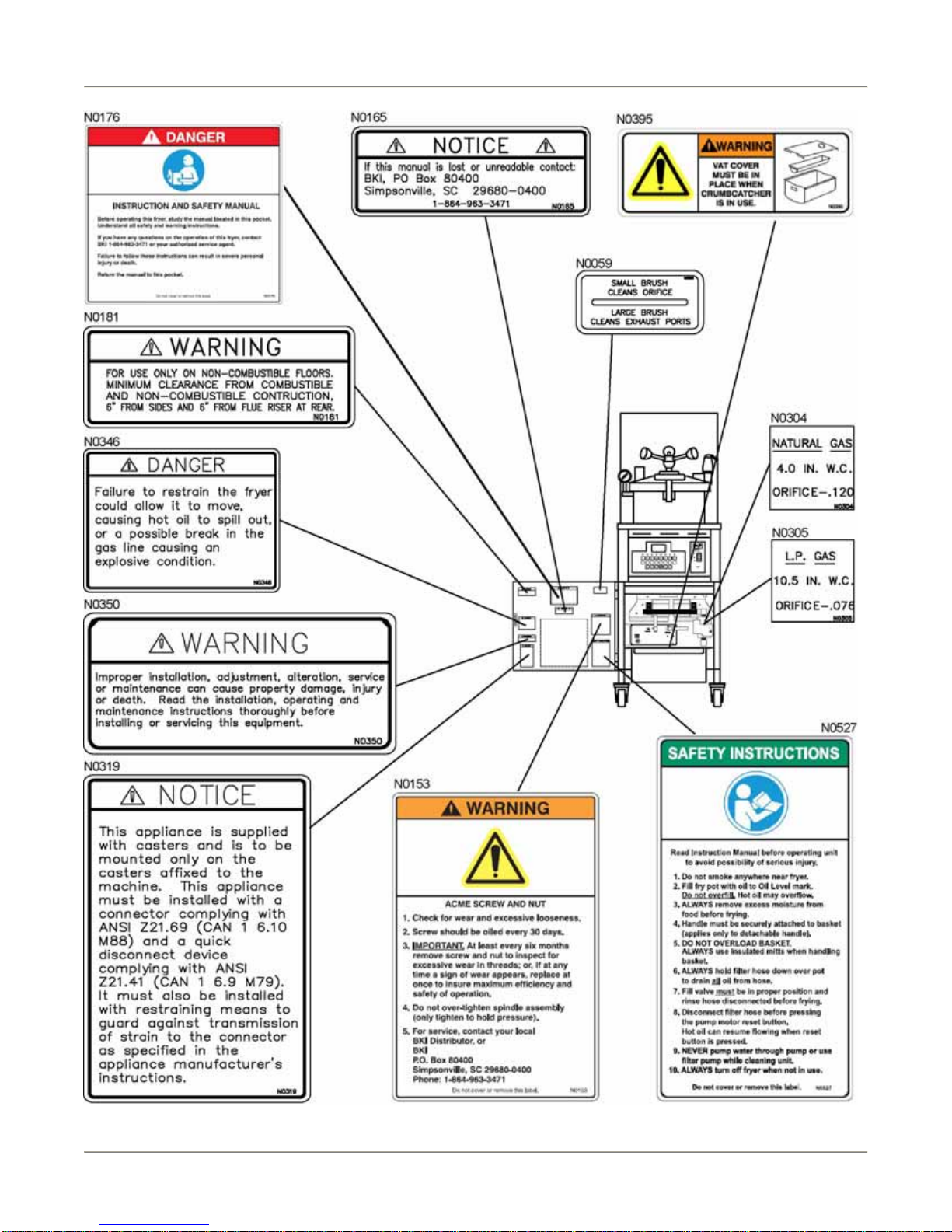

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all

safety labels clean and in good condition. Replace any damaged or

missing safety labels. Refer to the Safety Labels section for illustration and

location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific label

illustrated on page 9, then contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Gas Pressure Fryer Introduction

8

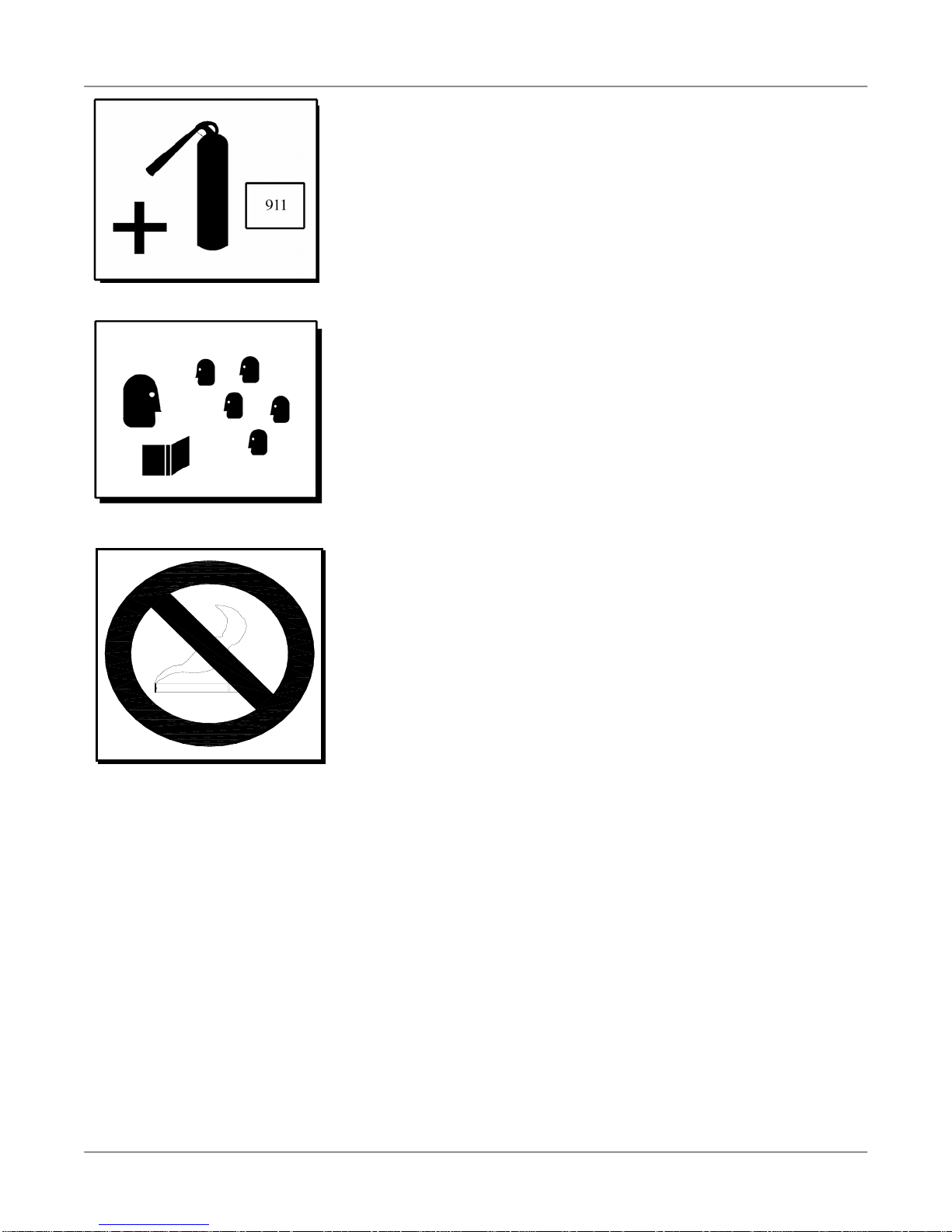

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must

use a 40-pound Type BC fire extinguisher and keep it within 25 feet of your

equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and

the fire department near your telephone.

Know your responsibilities as an Employer

•Make certain your employees know how to operate the equipment.

•Make certain your employees are aware of the safety precautions on

the equipment and in this manual.

•Make certain that you have thoroughly trained your employees about

operating the equipment safely.

•Make certain the equipment is in proper working condition. If you make

unauthorized modifications to the equipment, you will reduce the

function and safety of the equipment.

Do Not Smoke Near The Fryer.

Gas Pressure Fryer Introduction

9

Safety Labels

Gas Pressure Fryer Introduction

10

Gas Pressure Fryer Maintenance

11

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Do not over-tighten the spindle assembly. (Only tighten to hold pressure.)

Your fryer will need periodic maintenance and servicing. We strongly suggest that you

use only a service company that is authorized by BKI to do this work.

The restraining device must always be connected when the appliance is in service.

Disconnect for movement, such as servicing or cleaning. Reconnect the restraint when

fryer has been returned to its normal position.

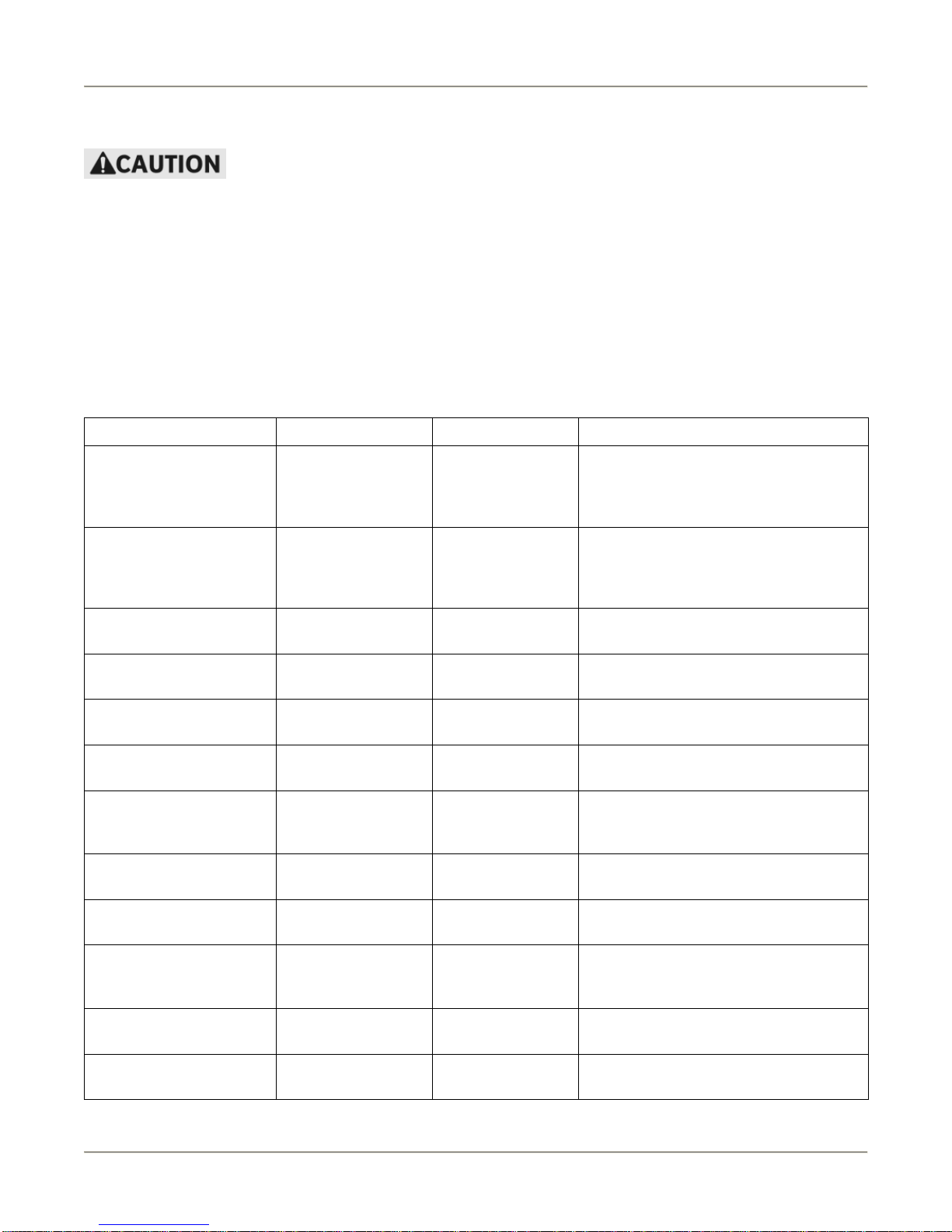

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

FREQUENCY PERFORMED BY PART ACTIVITY

Each Fry Cycle User Pressure Gauge Check for proper display of cooking vat

pressure. Contact authorized BKI

service agent if adjustment or

replacement is required.

User Lid Gasket Check for unusual wear such as cracks

and deformation, and pressure leaks.

Contact authorized BKI service agent if

adjustment or replacement is required.

Daily User Dead Weight

Assembly Clean weight and orifices daily and

check for wear.

User Filter Pad Replace filter pad. Refer to the

procedure in this manual.

User Condensation

Pan Remove and drain.

User Filter system Filter the shortening using the

procedure in this manual.

Weekly User Safety Pop Valve Check for release of pressure and

proper seal. Refer to the procedure in

this manual.

User Fryer Pot Perform the boil-out procedure in this

manual.

Every 6 Months Authorized BKI

service agent Acme Screw and

Nut Check for wear on the threads.

Authorized BKI

service agent Solenoid Valve Check that the valve is holding and

releasing pressure when the timer or

computer activates it.

Authorized BKI

service agent Hook, Catch,

Spring Check for wear and ease of operation.

Authorized BKI

service agent Connections,

Fittings Check for leakage while oil is pumping.

Gas Pressure Fryer Maintenance

12

Safety Pop Valve Procedure

The safety pop valve should be blown under pressure periodically to prevent the seat from sticking.

Failure to use the insulated mitts will result in injury. Always use the insulated mitts when

handling the arm on the safety valve.

1. After the pressure is up during a cooking cycle, use the insulated glove to lift the arm on the edge of the

safety valve and let some steam escape. This will clean the valve.

2. Release the lever on the valve, and let it slam shut to seal the valve.

Gas Pressure Fryer Maintenance

13

Filtering Procedure

Breaded foods require frequent filtering. An excess amount of breading left in the fryer pot will reduce the life of

the shortening. We recommend the shortening be filtered after every three frying cycle loads. When the

shortening starts to show signs of foaming and has a bad taste, do not use it. The fryer pot should be cleaned

before refilling with new shortening. Best results for filtering are obtained while the shortening is hot. You should

filter at the end of every business day. You should also remove and drain the condensation pan daily.

Always wear appropriate personal protection equipment during the filtering process to

guard against possible injury from hot oil.

If the pump motor automatically shuts off while filtering, place the FILTER/OFF/FRY

switch in the OFF position, wait 15 minutes, press the pump motor reset button, then

follow the appropriate refill procedure below.

LGF-F and LGF-FC

1. Set the FILTER/OFF/FRY switch to OFF.

2. Remove the fryer basket.

3. Make certain that the filter pad is clean and not torn.

IMPORTANT: Make certain the vat cover is properly positioned underneath the drain valve. Also

make certain the filter vat and filter screen is under the main drain valve before starting the filtering

process.

4. Move the DRAIN handle slowly to the OPEN position so that the shortening starts to flow evenly. This

is to prevent excessive splashing of hot shortening.

5. When the pot is empty, place the DRAIN handle in the CLOSED position.

To refill the pot automatically, use the steps below:

Hot shortening may splash out of the pot causing severe injury when filling the pot if the

lid is not closed. To prevent shortening splashes, close the lid before filling.

•Close the lid to prevent shortening splashes.

•Place the FILL handle to the THRU POT position.

•Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into the

pot.

•After 1 minute carefully open the lid to check the level of the shortening.

•Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or until

air starts bubbling through the shortening.

•As soon as air is seen in the shortening, first place the FILL handle to the THRU HOSE position

then position the FILTER/OFF/FRY switch to OFF to prevent shortening degradation and prevent

the filter pump and lines from filling up with shortening.

•Add new shortening if the fill mark has not been reached.

Gas Pressure Fryer Maintenance

14

To refill the pot through the rinse hose, use the steps below:

•Make certain that the rinse hose is connected to rinse hose connector.

•Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the pot if the

lid is not held down over the hose nozzle. To prevent shortening splashes, hold the lid

down over the hose nozzle.

•Hold the lid down over the hose nozzle to prevent shortening splashes.

•Position the FILL lever in the THRU HOSE position.

•Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into the

pot.

•After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of the

shortening.

•Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or until

air starts bubbling through the shortening.

•As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to prevent

shortening degradation.

•Add new shortening if the fill mark has not been reached.

LGF

1. Set the FILTER/OFF/FRY switch to OFF.

2. Remove the fryer basket.

3. Make certain that the FKF filter unit or portable filter unit filter pad is clean and not torn.

4. Position the FKF filter unit or portable filter unit under the main drain valve and make sure it’s filter

screen is in place.

5. Ensure that the FKF filter unit or portable filter unit is powered.

6. Move the DRAIN handle slowly to the OPEN position until the shortening starts to flow evenly. This

will prevent excessive splashing of hot shortening.

7. When the pot is empty, place the DRAIN handle in the CLOSED position.

To refill the pot through the drain valve, use the steps below:

•Make certain that the braided hose (located on the drain valve) is connected to it’s mating part on

the FKF filter unit or portable filter unit.

Hot shortening may splash out of the pot causing severe injury when filling the pot if the

lid is not closed. To prevent shortening splashes, close the lid before filling.

•Close the lid to prevent shortening splashes.

Gas Pressure Fryer Maintenance

15

•Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into the

pot.

•After 1 minute carefully open the lid to check the level of the shortening.

•Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or until

air starts bubbling through the shortening.

•As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to prevent

shortening degradation and prevent the filter pump and lines from filling up with shortening.

•Add new shortening if the fill mark has not been reached.

To refill the pot through the rinse hose, use the steps below:

•Make certain that the rinse hose is connected to it’s mating part on the FKF filter unit or portable

filter unit.

•Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the pot if the

lid is not held down over the hose nozzle. To prevent shortening splashes, hold the lid

down over the hose nozzle.

•Hold the lid down over the hose nozzle to prevent shortening splashes.

•Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into the

pot.

•After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of the

shortening.

•Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or until

air starts bubbling through the shortening.

•As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to prevent

shortening degradation.

•Add new shortening if the fill mark has not been reached.

Boil-Out Procedure

Boil-outs remove microscopic particles of carbon that build up on the walls of the fryer pot. To avoid eventual

carbon build-up, off flavors, and shortening breakdown, boil-outs should be done once a week on each fryer

following these procedures.

Always wear appropriate personal protection equipment during the boil-out process to

guard against possible injury from hot cleaning solution.

1. Position the FILTER/OFF/FRY switch to OFF.

2. Drain the clean shortening into an adequate storage container. (Allow the shortening to cool to room

temperature before attempting storage.)

Gas Pressure Fryer Maintenance

16

3. CLOSE the drain and fill the fryer pot with HOT water to the shortening level fill mark. Do not overfill by

allowing the water level higher than the fill mark.

4. Add ½ cup (4 ounces) of BKI cleaner.

5. Wash down the inside of the pot and lid with the pot brush to loosen the sediment.

6. Set the temperature of the solution as follows:

•For an LGF or LGF-F – Position the FILTER/OFF/FRY switch to ON. Set the thermostat to a

temperature of 190º F.

•For an LGF-FC – Position the FILTER/OFF/FRY switch to ON. Press PROG (program), type 1733,

and press ENTER. The fryer pot will heat to a temperature of 190º F during the CLEAN cycle to allow

the CLEAN function to be performed. NOTE: The fryer pot must be below 255º F to enter the CLEAN

mode.

7. Bring the cleaning solution to a rolling boil and maintain the boil for 5 minutes.

8. Place the FILTER/OFF/FRY switch to OFF.

9. Scrub the inside of the fryer pot and inside of the lid again.

10. Before draining the cleaning solution, remove the filter bag, screen and pipe connections from the filter

vat. This must be done before draining the cleaning solution. NEVER pump water or detergent through

the filter system.

11. After 15 minutes, slowly open the drain valve. Drain the solution into the filter vat and discard.

12. Rinse the pot with hot water, using the pot brush to remove remaining sediment, drain and discard.

13. Close the drain and refill the fryer pot with hot water to the proper level.

14. Add approximately 4 to 6 ounces of distilled (white) vinegar to develop a neutralizing solution. Stir the

solution briefly. Leave in the pot for three to five minutes and discard. NOTE: Foaming of shortening

after boil-outs is caused by failure to follow proper neutralizing procedures.

15. Repeat steps 12 through 14 as needed to remove all traces of cleaning solution.

16. Rinse the pot again with Cool water, drain and discard.

Damage to the fryer could result if the fryer pot is not completely dry before filling with

shortening. Refill the fryer pot with shortening ONLY when it is completely dry.

17. Dry the fryer pot, lid, and filter vat COMPLETELY.

18. Close the main drain and fill with new shortening to the proper level.

Gas Pressure Fryer Maintenance

17

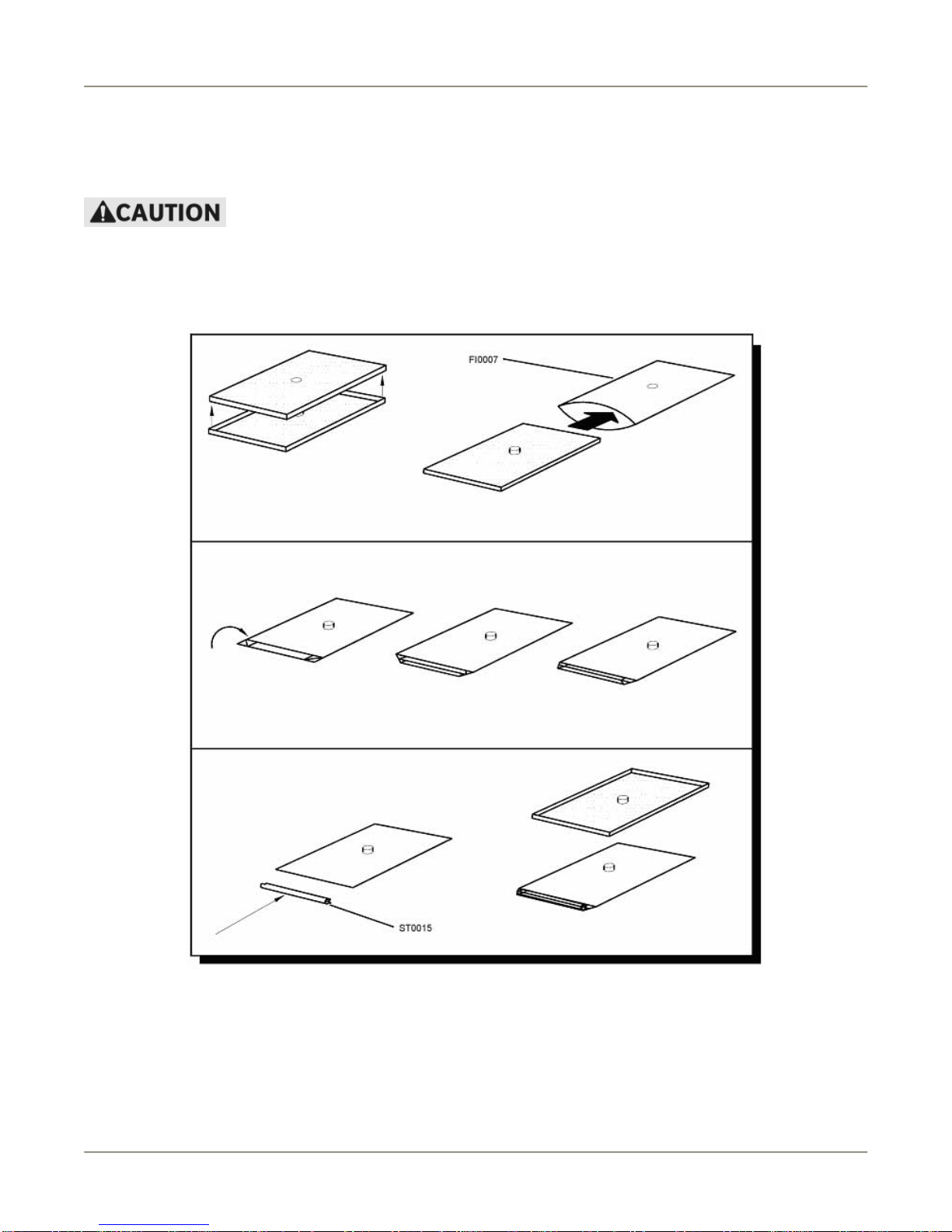

Filter Pad Replacement

The filter pad must be replaced daily. If the shortening has a milky color when it is pumped into the pot, the filter

pad should be replaced immediately.

If the filter pad is not properly closed, breading crumbs will get through the pad opening

and clog the pump. Ensure that the filter pad is properly closed upon replacement.

1. Place the filter screen inside the filter pad.

2. Fold the end of the pad and seal with the bag clip.

Gas Pressure Fryer Maintenance

18

Troubleshooting

Refer to the table below for troubleshooting information.

Problem Cause Possible Solution

Pressure Loss or Not Releasing

Pressure Dead Weight Valve Leaking Clean the weight and orifice. If problems

persist, contact an authorized BKI service

agent for corrective action.

Lid Gasket Leaking Contact an authorized BKI service agent

for corrective action.

Solenoid Valve Leaking or

Stuck After a period of time, it is possible that

the valve seat and/or plunger may stick or

wear. Activate the valve by starting a cook

cycle. You should hear a solid metallic

CLICK sound from the solenoid valve. If

you should hear no sound (or a slow

BUZZING CLICK), contact an authorized

BKI service agent for corrective action.

Safety Valve not seating Contact an authorized BKI service agent

for corrective action.

Shortening Heating Too Slowly Gas pressure is low or isn’t

adjusted properly Contact an authorized BKI service agent

for corrective action.

Bad thermostat or loose

wires Contact an authorized BKI service agent

for corrective action.

Filter System Not Working Uncertain Press the reset button on end of pump

and hi-limit reset button under control

panel. If problems persist, contact an

authorized BKI service agent for

corrective action.

Connections not tight Tighten the connections. If problems

persist, contact an authorized BKI service

agent for corrective action.

Filter valve not open Contact an authorized BKI service agent

for corrective action.

Filter paper on screen

clogged with crumbs Change filter paper. If problems persist,

contact an authorized BKI service agent

for corrective action.

Motor hums, but does not

pump Check for clogged pump. If problems

persist, contact an authorized BKI service

agent for corrective action.

Motor and pump coupling

worn Contact an authorized BKI service agent

for corrective action.

No power to control panel Make sure drain valve is completely

closed. If problems persist, contact an

authorized BKI service agent for

corrective action.

Computer Hangs Computer malfunction. Press and hold the Toggle/Clear button

while moving the FRY/OFF/FILTER

switch from FRY to OFF and back to

FRY. If problems persist, contact an

authorized BKI service agent for

corrective action.

Other manuals for LGF

3

This manual suits for next models

2

Table of contents

Other BKI Fryer manuals

Popular Fryer manuals by other brands

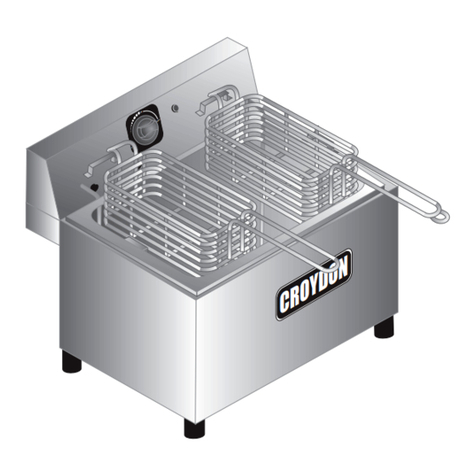

croydon

croydon F25 instruction manual

Tower Hobbies

Tower Hobbies T17056BLK manual

smith+nobel

smith+nobel IA3642 instruction manual

Paula Deen kitchen electrics

Paula Deen kitchen electrics PDAF2 Instructions & recipes

Emeril Lagasse

Emeril Lagasse DZEL24-01 owner's manual

Sunbeam

Sunbeam Cool-Zone DF5200S Instruction booklet