Black Max BM25CSEDG User manual

OPERATOR’S MANUAL

MANUAL DEL OPERADOR

25cc TRIMMER/EDGER COMBO

JUEGO COMBINADO RECORTADORA/

RECORTADORA BORDES 25 cc

BM25CSEDG

To register your Black Max product,

please visit:

www.blackmaxtools.com

Para registrar su producto de Black

Max, por favor visita:

www.blackmaxtools.com

SAVE THIS MANUAL

FOR FUTURE REFERENCE GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

WARNING: To reduce the risk of injury, the user

must read and understand the operator’s manual before

using this product.

TABLE OF CONTENTS

General Safety Rules ............................................................2-3

Specific Safety Rules...............................................................3

Symbols ...................................................................................4

Features ...................................................................................5

Assembly ..............................................................................5-6

Operation ..............................................................................7-9

Maintenance .....................................................................10-13

Troubleshooting................................................................13-14

Parts Ordering/Service............................................. Back Page

ADVERTENCIA: Para reducir el riesgo de

lesiones, el usuario debe leer y comprender el manual

del operador antes de usar este producto.

ÍNDICE DE CONTENIDO

Reglas de seguridad generales ............................................2-3

Reglas de seguridad específicas.............................................3

Símbolos ..................................................................................4

Características .........................................................................5

Armado .................................................................................5-6

Funcionamiento ..................................................................7-10

Mantenimiento ..................................................................10-13

Solución de problemas.....................................................14-15

Pedidos de piezas/servicio................................. Pág. posterior

ii

Fig. 1

A - Bump feed string head (cabezal del hilo con

alimentación por golpe)

B - Drive shaft housing (alojamiento del eje de

impulsión)

C - Coupler (acoplador)

D - Front handle (mango delantero)

E - Strap hanger (colgador para la correa)

F - Stop switch (interruptor de parada)

G - Trigger lock-out (seguro del gatillo)

H - Starter grip and rope (mango del arrancador

y cuerda)

L

F

G

A

B

N

M

C

D

I

H

J

K

P

I - Primer bulb (bomba de cebado)

J - Fuel cap (tapa del tanque)

K - Rear handle (mango trasero)

L - Throttle trigger (gatillo del acelerador)

M

- Knob (perilla)

N - Curved shaft grass deflector (deflector de

pasto del eje curvo)

O - Straight shaft grass deflector (deflector de

pasto para eje recto)

P - Muffler (silenciador)

Q - Edger attachment (accesorio para cortar

bordes)

R - Blade guard (protección de la cuchilla)

S - Gear head (cabezal de engranajes)

T - Blade (cuchilla)

U - Guide wheel (rueda guía)

V - Blade guide (guía para bordillos)

W- Debris flap (aleta protectora)

X

- Adjusting knob (perilla de ajuste)

Y

- Holding pin (pasador de retención)

Z

- Hanger cap (tapa de brazo de suspensión)

See this fold-out section for all the figures

referenced in the operator’s manual.

Vea esta sección de la página desplegable para

todas las figuras mencionó en el manual del operador.

E

Y

Z

Q

T

X

R

S

U

W

V

iii

Fig. 2

A - Button (botón)

B - Guide recess (hueco guía)

C - Coupler (acoplador)

D - Power head shaft (eje del cabezal motor)

E - Knob (perilla)

F - Positioninghole(orificiodeposicionamiento)

G - Trimmer attachment (aditamento para

recortar)

AB

CD

E

F

G

A - Bolt (perno)

B - Front handle (mango delantero)

C - Wing nut (tuerca de mariposa)

A

B

C

Fig. 5

A - Straight shaft grass deflector (deflector de

pasto para eje recto)

B - Slot (ranura)

C - Tab (orejeta)

D - Bolt (perno)

A

BC

D

D

A - Stop switch (interruptor de parada)

B - Trigger lock-out (seguro del gatillo)

C - Throttle trigger (gatillo del acelerador)

D - Starter grip and rope (mango del arrancador

y cuerda)

Fig. 6

A

B

C

Fig. 4

A - Bolt (perno)

B - Bracket (placa)

C - Wing nut (tuerca de mariposa)

D - Curved shaft grass deflector (deflector de

pasto del eje curvo)

A

B

C

D

A - Stop switch (interruptor de parada)

B - Trigger lock-out (seguro del gatillo)

C - Primer bulb (bomba de cebado)

D - Throttle trigger (gatillo del acelerador)

Fig. 7 A

B

C

D

Fig. 8

A - Choke lever in FULL CHOKE position

[palanca del anegador en posición de FULL

CHOKE (anegación máxima)]

B - Choke lever in HALF CHOKE position

(palanca del anegador en posición de HALF

CHOKE (anegación media)]

C - Choke lever in RUN position [palanca del

anegador en posición de RUN (marcha)]

A

B

C

Fig. 3

iv

PROPER OPERATING POSITION

POSICIÓN CORRECTA PARA EL MANEJO

DE LA HERRAMIENTA

Fig. 9

A - Curved shaft trimmer (recortadora de eje

curvo)

B - Dangerous cutting area (área peligrosa de

corte)

C - Direction of rotation (sentido de rotación)

D - Best cutting area (mejor área de corte)

Fig. 10 A

B

C

D

A - Eyelet (ojillo)

B - Arrows (flechas)

C - Pull strings (tira del hilo)

D - Rotate the bump knob (gire a la derecha el

perilla percusiva)

Fig. 16

B

A - Straight shaft trimmer (recortadora de eje

recto)

B - Dangerous cutting area (área peligrosa de

corte)

C - Best cutting area (mejor área de corte)

D - Direction of rotation (sentido de rotación)

Fig. 11

B

A

C

D

A - Straight shaft trimmer cut-off blade (cuchilla

de corte de hilo de la recortadora de eje

recto)

B - Curved shaft trimmer cut-off blade (cuchilla

de corte de hilo de la recortadora de eje

recto)

Fig. 12

B

A

A

D

C

Fig. 13

Fig. 14

BC

A

BA

C

D

A - To increase depth (para aumentar la

profundidad)

B - Adjusting knob (perilla de ajuste)

C - Wheel arm (brazo de la rueda)

D - To decrease depth (para disminuir la

profundidad)

Fig. 15

A - To blade depth (profundidad de la cuchilla)

B - Curb guide (guía para bordillos)

C - Blade (lame, cuchilla)

Fig. 14

v

A - String head housing (alojamiento del cabezal

de hilo)

B - Depress tabs (presione los orejetas)

Fig. 21

B

D

A - Latch (pestillo)

B - Air filter (filtro de aire)

C - Air filter cover (tapa del filtro de aire)

D - Slots (ranuras)

E - Tabs (lengüetas)

A

E

Fig. 19

A - Idle speed screw (tornillo de marcha lenta)

A

Fig. 20

A

B

A - Latch (pestillo)

B - Air filter cover (tapa del filtro de aire)

Fig. 17

B

B

A

Fig. 18

A - Upper string head housing (alojamiento del

cabezal de hilo superior)

B - Tabs (lengüetas)

C - Lower string head housing (alojamiento del

cabezal de hilo inferior)

D - Spool (carrete)

E - Bump knob (perilla percusiva)

F - Spool slots (ranuras de carrete)

G - Knob ribs (costillas de la perilla)

BA

D

F

G

EC

B

C

Fig. 22

A - Flange washer (arandela de la brida)

B - Slots (ranuras)

C - Flange (brida)

D -Gear case (caja de engranajes)

A

D

C

B

Fig. 23

A - Blade (hoja)

B - Blade nut (tuerca de la cuchilla)

C - Lower flange washer (arandela de la brida

inferior)

D -Holding pin inserted into aligned slots

(sujetando el pasador introducido en las

ranuras alineadas)

E - Flange (brida)

D

BA

C

E

Fig. 24

A

A - 1/2 in. socket wrench (llave de boca tubular

de 13 mm [1/2 pulg.])

B - Indicator hole (orificio indicador)

A

B

Fig. 25

A - Hanger cap (tapa de suspensión)

B - Hole (orificio)

C - Button (botón)

D -Secondary hole (orificio secundario)

C

B

A

D

Page 2 — English

WARNING:

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below may result

in electric shock, fire and/or carbon monoxide poisoning

which will cause death or serious personal injury.

READ ALL INSTRUCTIONS

For safe operation, read and understand all instructions

before using this product. Follow all safety instructions.

Failure to follow all safety instructions listed below, can

result in serious personal injury.

Do not allow children or untrained individuals to use this

unit.

Do not start or operate the engine in a confined space,

building, near open windows, or in other unventilated

space where dangerous carbon monoxide fumes can

collect. Carbon monoxide, a colorless, odorless, and

extremely dangerous gas, can cause unconsciousness

or death.

Clear the work area before each use. Remove all objects

such as rocks, broken glass, nails, wire, or string which

can be thrown or become entangled in the cutting line

or blade.

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

Wear heavy, long pants, long sleeves, boots, and gloves.

Do not wear loose fitting clothing, short pants, sandals,

or go barefoot. Do not wear jewelry of any kind.

Heavy protective clothing may increase operator fatigue,

which could lead to heat stroke. During weather that is

hot and humid, heavy work should be scheduled for early

morning or late afternoon hours when temperatures are

cooler.

Never operate this unit on the operator’s left side.

Secure long hair above shoulder level to prevent entangle-

ment in moving parts.

Keep all bystanders, children, and pets at least

50 ft. away. Bystanders should be encouraged to wear

eye protection. If you are approached, stop the engine

and cutting attachment. In the case of bladed units, there

is the added risk of injury to bystanders from being struck

with the moving blade in the event of a blade thrust or

other unexpected reaction of the saw.

Do not operate this unit when you are tired, ill, upset, or

under the influence of alcohol, drugs, or medication.

Do not operate in poor lighting.

Keep firm footing and balance. Do not overreach. Over-

reaching can result in loss of balance or exposure to hot

surfaces. Keep cutting attachment below waist.

Do not use on a ladder or unstable support. Stable foot-

ing on a solid surface enables better control of the unit

in unexpected situations.

Keep all parts of your body away from any moving part.

To avoid hot surfaces, never operate the unit with the

bottom of the engine above waist level.

Do not touch area around the muffler or cylinder of the

unit, these parts get hot from operation. Contact with hot

surfaces could result in possible serious personal injury.

Always stop the engine and remove the spark plug wire

before making any adjustments or repairs except for

carburetor adjustments.

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace any damaged parts before use.

Never use blades, flailing devices, wire, or rope on trim-

mer attachment. Never use flailing devices, wire, or rope

on any attachment.

The cutting attachment should never rotate at idle during

normal use. The cutting attachment may rotate at idle

during carburetor adjustments.

It has been reported that vibrations from hand-held tools

may contribute to a condition called Raynaud’s Syndrome

in certain individuals. Symptoms may include tingling,

numbness, and blanching of the fingers, usually apparent

upon exposure to cold. Hereditary factors, exposure to

cold and dampness, diet, smoking, and work practices

are all thought to contribute to the development of these

symptoms. It is presently unknown what, if any, vibrations

or extent of exposure may contribute to the condition.

There are measures that can be taken by the operator to

possibly reduce the effects of vibration:

a) Keep your body warm in cold weather. When operat-

ing the unit wear gloves to keep your hands and wrists

warm. It is reported that cold weather is a major factor

contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to

increase blood circulation.

c) Take frequent work breaks. Limit the amount of

exposure per day.

d) Keep the product well maintained, fasteners

tightened and worn parts replaced.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician

about these symptoms.

Mix and store fuel in a container approved for gasoline.

Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 30 ft. away from refueling

site before starting engine. Slowly remove the fuel cap

after stopping engine. Do not smoke when refueling.

Stop the engine and allow to cool before refueling or

storing the unit.

GENERAL SAFETY RULES

Page 3 — English

Allow the engine to cool; empty the fuel tank into a con-

tainer approved for gasoline and secure the unit from

moving before transporting in a vehicle.

Wear your protective equipment and observe all safety

instructions. Be sure the cutting attachment stops turning

when the engine idles. When the unit is turned off make

sure the cutting attachment has stopped before the unit

is set down.

We recommend taking your equipment to a qualified

service center for repair, as service performed by

inexperienced or unqualified persons may damage the

equipment, create unsafe conditions, injury to user and/

or void your warranty.

GENERAL SAFETY RULES

SPECIFIC SAFETY RULES

TRIMMER

Inspect before use. Replace damaged parts. Make sure

fasteners are in place and secure. Check for fuel leaks.

Replace string head if cracked, chipped, or damaged

in any way. Be sure the string head is properly installed

and securely fastened. Failure to do so can cause serious

injury.

Make sure all guards, straps, deflectors, and handles are

properly and securely attached.

Use only recommended or equivalent replacement line in

the cutting head. Do not use any other cutting attachment.

To install any other type of replacement line or cutting

head to this string trimmer can result in serious personal

injury. Never use, for example, wire or wire-rope, which

can break off and become a dangerous projectile.

Never operate unit without the grass deflector in place

and in good condition.

Maintain a firm grip on both handles while trimming. Keep

string head below waist level. Never cut with the string

head located over 30 in. or more above the ground.

This product is intended for infrequent use by homeown-

ers and other occasional users for such general applica-

tions as trimming light and heavy vegetation, etc. It is not

intended for prolonged use. Prolonged periods of opera-

tion can cause circulatory problems in the user’s hands

due to vibration. For such use, it may be appropriate to

use a product having an anti-vibration feature.

EDGER

Replace dull or worn blade; do not attempt to sharpen.

Use this edger for edging along sidewalks, driveways,

flower beds, and similar areas. Do not use for any other

purpose.

Be thoroughly familiar with the controls. Know how to

stop the unit and disengage the controls quickly.

Do not use the edger on or near graveled surfaces.

Make yourself familiar with the area you are edging. Be

aware of uneven sidewalks and holes in the terrain as well

as other similar hazardous conditions (example: wire or

wire rope which can break off and become a dangerous

projectile). Always push the edger attachment slowly over

rough ground.

Do not attempt to remove cut material nor hold material

to be cut when the motor is running or when the cutting

blade is moving.

Keep hands and feet away from the cutting area.

Always keep your right hand on the rear handle and your

left hand on the front handle when the blade is rotating.

A coasting blade can cause injury while it continues to

spin after the motor is stopped or throttle trigger released.

Maintain proper control until the blade has completely

stopped rotating.

Check blade nut for tightness before operating the

attachment.

Improper assembly can create a dangerous situation.

Never stand or have any part of your body in line with the

path of the edger blade.

If the edger strikes any type of foreign object:

a) Stop the edger and remove the spark plug wire or

disconnect from the power supply.

b) Inspect for damage to the edger attachment.

c) Correct damage before using the edger attachment.

Failure to do so can cause serious injury.

Always stop the engine or motor and remove the spark plug

wire or disconnect from the power supply before attempt-

ing to remove any obstruction caught or jammed in the

blade, installing attachment, or making any adjustments.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this product. If you

loan someone this product, loan them these instructions

also to prevent misuse of the product and possible injury.

Page 4 — English

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning for safe

operation of this product.

SYMBOL NAME EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual To reduce the risk of injury, user must read and under-

stand operator’s manual before using this product.

Eye and Hearing Protection

Always wear eye protection with side shields marked to

comply with ANSI Z87.1 along with hearing protection

when operating this equipment.

Wear Gloves Wear non-slip, heavy-duty protective gloves when

handling this equipment.

Wear Safety Footwear Wear non-slip safety footwear when using this

equipment.

Keep Bystanders Away Keep all bystanders at least 50 ft. away.

Ricochet Thrown objects can ricochet and result in personal injury

or property damage.

No Blade Do not install or use any type of blade on a product dis-

playing this symbol.

Cutting Hazard Failure to keep hands and feet away from the blade will

result in serious personal injury.

Hot Surface To reduce the risk of injury or damage, avoid contact

with any hot surface.

Gasoline and Lubricant

Use unleaded gasoline intended for motor vehicle use

with an octane rating of 87 [(R + M) / 2] or higher. This

product is powered by a 2-cycle engine and requires

pre-mixing gasoline and 2-cycle lubricant.

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER: Indicates a hazardous situation, which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a hazardous situation, that, if not avoided, may result in minor or

moderate injury.

NOTICE: (Without Safety Alert Symbol) Indicates information considered important, but

not related to a potential injury (e.g. messages relating to property damage).

Page 5 — English

PACKING LIST

Curved Shaft Trimmer Assembly

Edger Attachment

Front Handle with Hardware

Curved Shaft Grass Deflector

.095 in. Pre-Cut Line, 16 ft.

Bottle of 2-Cycle Lubricant

Hanger Cap

Holding Pin

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

UNPACKING

This product requires assembly.

Carefully remove the items from the box. Make sure that

all items listed in the Packing List are included.

WARNING:

Do not use this product if any parts in the Packing List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the unit carefully to make sure no damage oc-

curred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

1-800-726-5760 for assistance.

FEATURES

ASSEMBLY

PRODUCT SPECIFICATIONS

Engine displacement ......................................................................................................................................................25cc

String Trimmer

Cutting width............................................................................................................................................................17 in.

Line diameter ......................................................................................................................................................0.095 in.

Edger

Blade Length ...............................................................................................................................................................9 in.

Edging Depth...............................................................................................................Adjustable from 1/2 in. to 2-3/4 in.

KNOW YOUR PRODUCT

See Figure 1.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

BUMP FEED STRING HEAD

The bump feed string head allows easy line advance during

trimmer operation.

ERGONOMIC DESIGN

The design of the trimmer provides for easy handling. It is

designed for comfort and ease of grasp when operating in

different positions and at different angles.

GRASS DEFLECTOR

The product includes a grass deflector that helps protect

you from flying debris.

TOP-MOUNTED ENGINE

The top-mounted engine improves balance and is located

away from the dust and debris of the cutting area.

Page 6 — English

WARNING:

Do not attempt to modify this product or create acces-

sories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

INSTALLING THE POWER HEAD TO THE

ATTACHMENT

See Figure 2.

WARNING:

Never install, remove, or adjust any attachment while

power head is running. Failure to stop the engine can

cause serious personal injury.

The attachment connects to the power head by means of

a coupler device.

Stop the engine and disconnect the spark plug wire.

Loosen the knob on the coupler of the power head shaft.

Push in the button located on the trimmer attachment.

Align the button with the guide recess on the power head

coupler and slide the two shafts together. Rotate the trim-

mer attachment until the button locks into the positioning

hole.

NOTE: If the button does not release completely in the

positioning hole, the shafts are not locked into place.

Slightly rotate from side to side until the button is locked

into place.

Tighten the knob securely.

WARNING:

Be certain the knob is fully tightened before operating

equipment; check it periodically for tightness during use

to avoid serious personal injury.

REMOVING THE ATTACHMENT FROM THE

POWER HEAD

Stop the engine and disconnect the spark plug wire.

Loosen the knob.

Push in the button and twist the shafts to remove and

separate ends.

ATTACHING THE FRONT HANDLE

See Figure 3.

Remove wing nut and bolt from the front handle.

Install the front handle onto the top side of the power

head shaft in the area indicated by the label.

Place the bolt through the front handle.

NOTE: The hex bolt head fits inside the hex recess

molded into one side of the handle.

Reinstall the wing nut.

Tighten wing nut securely.

ATTACHING THE GRASS DEFLECTOR

WARNING:

The line cutting blade on the grass deflector is sharp.

Avoid contact with the blade. Failure to avoid contact

can result in serious personal injury.

TO ATTACH THE CURVED SHAFT GRASS

DEFLECTOR

See Figure 4.

Remove bolt and wing nut from grass deflector.

Press the grass deflector onto the bottom of the curved

shaft as shown.

Insert the bolt through the grass deflector and the bracket

on the curved shaft.

Place the wing nut on the bolt and tighten securely.

ASSEMBLY

Page 7 — English

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

WARNING:

Never use blades, flailing devices, wire, or rope on this

product. Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

NOTICE:

The spark arrestor on this product has not been evalu-

ated by the USDA Forest Service and cannot be used

on U.S. forest lands. In addition, product users must

comply with Federal, State, and local fire prevention

regulations. Check with appropriate authorities. Contact

customer service or a qualified service center to purchase

a replacement spark arrestor.

NOTICE:

Before each use, inspect the entire product for damaged,

missing, or loose parts such as screws, nuts, bolts, caps,

etc. Tighten securely all fasteners and caps and do not

operate this product until all missing or damaged parts

are replaced. Please contact customer service or a quali-

fied service center for assistance.

ETHANOL-BLENDED FUELS

NOTICE:

Do not use E15 or E85 fuel in this product. It is a viola-

tion of federal law and will damage the unit and void

your warranty. Only use unleaded gasoline containing

up to 10% ethanol.

NOTE: To improve performance when using oxygenated

fuels, we recommend the use of Ethanol Shield 2-cycle

lubricant.

FUELING AND REFUELING THE TRIMMER

WARNING:

Gasoline and its vapors are highly flammable and explo-

sive. To prevent serious personal injury and property

damage, handle it with care. Keep away from ignition

sources and open flames, handle outdoors only, do not

smoke and wipe up spills immediately.

FUEL MIXTURE

This product is powered by a 2-cycle engine and requires

pre-mixing gasoline and 2-cycle lubricant. Pre-mix unleaded

gasoline and 2-cycle engine lubricant in a clean container

approved for gasoline. DO NOT mix quantities larger than

usable in a 30-day period.

Recommended fuel: This engine is certified to operate on

unleaded gasoline intended for automotive use.

NOTE: We recommend you use Ethanol Shield 2-cycle

lubricant or an equivalent high-quality synthetic 2-cycle

lubricant in this product. Mix at 2.6 oz. per gallon (US).

Do not use automotive lubricant or 2-cycle outboard

lubricant.

HIGH QUALITY 2-CYCLE ENGINE LUBRICANT

GASOLINE LUBRICANT

1.0 gal. (US) (3.8 liter) 2.6 oz. (76 ml)

2.5 gal. (US) (9.5 liter) 6.4 oz. (189 ml)

FILLING TANK

Clean surface around fuel cap to prevent contamination.

Loosen fuel cap slowly. Rest the cap on a clean surface.

Carefully pour fuel mixture into the tank. Avoid spillage.

Prior to replacing the fuel cap, clean and inspect the

gasket.

Immediately replace fuel cap and hand tighten. Wipe up

any fuel spillage.

NOTE: It is normal for smoke to be emitted from a new

engine after first use.

WARNING:

Always shut off engine before fueling. Never remove

fuel cap or add fuel to a machine with a running or hot

engine. Make sure the unit is sitting on a flat, level sur-

face and only add fuel outdoors. If the engine is hot, let

the unit cool for at least five minutes before adding fuel.

After fueling, immediately replace fuel cap and tighten

securely. Move at least 30 ft. from refueling site before

starting engine. Do not smoke and stay away from open

flames and sparks! Failure to follow these instructions

could result in a fire and cause serious personal injury.

OPERATION

Page 8 — English

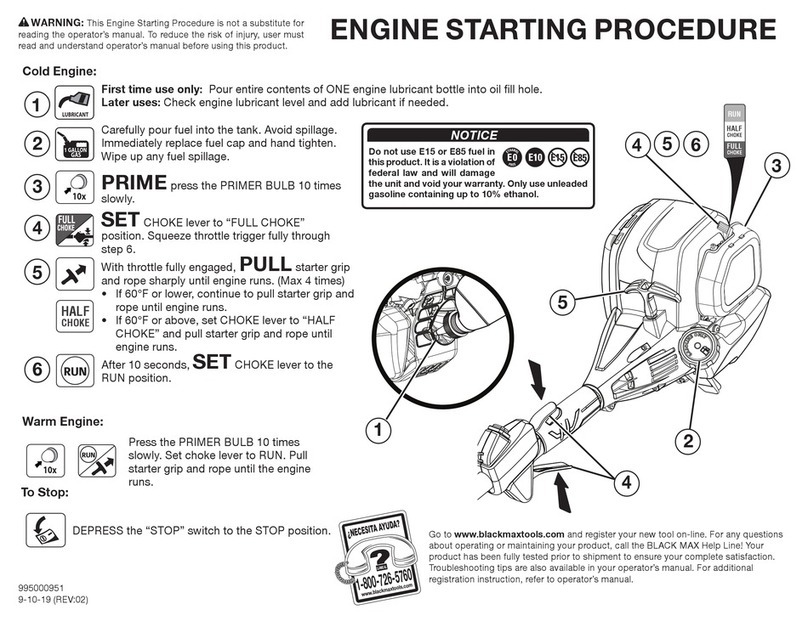

STARTING AND STOPPING

See Figures 6 - 8.

Trimmer should be on a flat, bare surface for starting.

To start a cold engine:

Lay the product on a flat, bare surface.

Push the primer bulb approximately ten times.

Set the choke lever to FULL CHOKE.

Depress lock-out button and squeeze throttle trigger

fully and pull starter grip and rope sharply until engine

attempts to start (no more than 4x).

Set the choke lever to HALF CHOKE.

Pull starter grip and rope until engine runs, no more than

6 pulls.

Allow engine to run for 10 seconds, then set the choke

lever to RUN.

NOTE: In cooler environments, additional pulls of the

starter grip and rope may be required with the choke

lever in the FULL CHOKE position.

To start a warm engine:

Lay the product on a flat, bare surface.

Push the primer bulb up to ten times.

Set the choke lever to RUN.

Depress lock-out button and squeeze throttle trigger fully,

pull the starter cord.

NOTE: If the product does not start, repeat the previous

steps.

To stop the engine:

To stop the engine, depress the STOP switch to the stop

position “ ”.

IF ASSISTANCE IS REQUIRED FOR THIS PRODUCT:

Do not return this product to the retail store where it was

purchased. Please call our Customer Service Department

for any issues you may have.

For Help Call: 1-800-726-5760

OPERATING THE TRIMMER

See Figure 9.

WARNING:

Engine housing can become hot during trimmer opera-

tion. Do not rest or place your arm, hand, or any body

part against the engine housing during trimmer operation.

Only hold the trimmer as shown in figure 9 with all body

parts clear of engine housing. Extended contact with

the engine housing can result in burns or other injuries.

WARNING:

Always position the unit on the operator’s right side. The

use of the unit on the operator’s left side will expose the

user to hot surfaces and can result in possible burn injury.

WARNING:

To avoid burns from hot surfaces, never operate unit with

the bottom of the engine above waist level.

Hold the trimmer with your right hand on the rear handle

and your left hand on the front handle. Keep a firm grip with

both hands while in operation. Trimmer should be held at a

comfortable position with the rear handle about hip height.

Always operate trimmer in RUN position. Cut tall grass

from the top down. This will prevent grass from wrapping

around the shaft housing and string head which could cause

damage from overheating. If grass becomes wrapped around

the string head, STOP THE ENGINE, disconnect the spark

plug wire, and remove the grass. Prolonged cutting at partial

throttle will result in lubricant dripping from the muffler.

WARNING:

Always hold the string trimmer away from the body keep-

ing clearance between the body and the product. Any

contact with the housing or string trimmer cutting head

can result in burns and/or other serious personal injury.

TRIMMER OPERATING TIPS

See Figures 9 - 11.

Avoid hot surfaces by always keeping the tool away from

your body. (Proper operating position shown in figure 9.)

Keep the trimmer tilted toward the area being cut; this is

the best cutting area.

The curved shaft trimmer cuts when passing the unit from

right to left. The straight shaft trimmer cuts when passing

the unit from left to right. This will avoid throwing debris at

the operator. Avoid cutting in the dangerous area shown

in illustration.

Use the tip of line to do the cutting; do not force string

head into uncut grass.

Wire and picket fences cause extra line wear, even break-

age. Stone and brick walls, curbs, and wood may wear

line rapidly.

Avoid trees and shrubs. Tree bark, wood moldings, siding,

and fence posts can easily be damaged by the line.

OPERATION

Page 9 — English

TO ADVANCE THE CUTTING LINE

Line advance is controlled by tapping the string head on

grass while running engine at full throttle.

Run engine at full throttle.

Tap the knob on ground to advance line. The line ad-

vances each time the knob is tapped. Do not hold the

knob on the ground.

NOTE: The line trimming cut-off blade on the grass deflector

will cut the line to the correct length.

NOTE: If the line is worn too short you may not be able to

advance the line by tapping it on the ground. If so, stop the

engine and manually advance the line.

To advance the cutting line manually:

Stop the engine and disconnect the spark plug wire.

Push the knob in while pulling on line(s) to manually ad-

vance the line.

GRASS DEFLECTOR LINE TRIMMING CUT-

OFF BLADE

See Figure 12.

The trimmer is equipped with a line trimming cut-off blade

on the grass deflector. For best cutting, advance line until it

is trimmed to length by the cut-off blade. Advance the line

whenever you hear the engine running faster than normal,

or when trimming efficiency diminishes. This will maintain

best performance and keep the line long enough to advance

properly.

USING THE EDGER ATTACHMENT

See Figure 13.

WARNING:

Engine housing on gas power heads may become hot

during edger operation. Do not rest or place your arm,

hand, or any body part against the engine housing during

edger operation. Only hold the edger as shown in figure

13 with all body parts clear of engine housing. Extended

contact with the engine housing can result in burns or

other injuries.

WARNING:

Always position the unit on the operator’s right side. The

use of the unit on the operator’s left side will expose the

operator to hot surfaces and can result in possible burn

injury.

WARNING:

To avoid burns from hot surfaces, never operate unit with

the bottom of the engine above waist level.

When using the edger attachment, hold the unit with your

right hand on the rear handle and your left hand on the front

handle. Keep a firm grip with both hands while in operation.

The edger should be held at a comfortable position with the

rear handle about hip height.

NOTE: When used with a gas power head, always operate

at full throttle. Prolonged cutting at partial throttle will result

in oil dripping from the muffler.

ADJUSTING DEPTH OF CUT

See Figures 14 - 15.

Stop the engine and disconnect the spark plug wire.

Loosen the adjusting knob and move the wheel arm up

to increase the depth or down to decrease the depth.

After adjustment is complete, tighten the adjusting knob

securely.

Replace the spark plug wire.

NOTE: Adjust the blade depth from 1/2 in. to 1 in. deep

initially. Make a shallow cut to test the cutting depth. If the

cutting depth needs adjusting, this should be done progres-

sively until the desired depth is reached.

EDGER OPERATING TIPS

The edger will edge along sidewalks, driveways, flower-

beds, curbs, and similar areas.

Use the arrow guide on the blade guard to align the blade

with the edging surface.

Cut at a steady pace. If the blade begins to bog down,

you are edging too fast; slow your pace. Do not force the

blade into ground.

Light contact of the blade against the sidewalk edge,

curb, etc., is acceptable and will not damage the edger.

Best appearance is obtained when grass is dry. Avoid

edging in wet soil or wet grass areas or the blade guard

might clog and result in an uneven edge. If the blade

guard becomes clogged, stop the engine, remove the

spark plug wire, disconnect from the power supply, or

remove the battery pack, then remove debris from the

blade guard.

OPERATION

Page 10 — English

MAINTENANCE

Normal maintenance, replacement or repair of emission con-

trol devices and systems may be performed by any qualified

repair establishment or individual with original or equivalent

parts. Warranty and recall repairs must be performed by a

authorized service center; please contact customer service

for assistance.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug wire and move it away from spark

plug. Failure to follow these instructions can result in

serious personal injury or property damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

WARNING:

When servicing, use only recommended or equivalent

replacement parts. Use of any other parts could create

a hazard or cause product damage.

NOTICE:

Periodically inspect the entire product for damaged,

missing, or loose parts such as screws, nuts, bolts, caps,

etc. Tighten securely all fasteners and caps and do not

operate this product until all missing or damaged parts

are replaced. Please contact customer service or a quali-

fied service center for assistance.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-

based products, penetrating lubricants, etc., come in con-

tact with plastic parts. Chemicals can damage, weaken or

destroy plastic which could result in serious personal

injury.

LINE REPLACEMENT

See Figure 16.

Use only .095 in. trimmer line. Use original manufacturer’s

replacement line for best performance.

Stop the engine and disconnect the spark plug wire.

Rotate the bump knob clockwise as necessary to align the

arrows on the bump knob with the arrows on the string

head housing.

Cut one piece of trimmer line 16 ft. long. Insert the line

into the eyelet on the string head housing. Push until the

end of the line comes out the other side of the housing.

Pull the line until equal amounts of line appear on both

sides of the housing.

NOTE: Line may jam if more than 16 ft. is loaded.

Rotate the bump knob clockwise to wind the line on the

spool until approximately 6 in. of line is showing on each

side.

Push the bump knob down while pulling on line(s) to

manually advance the line.

CLEARING LINE JAM AND/OR REPLACING

BUMP KNOB

See Figures 17 - 18.

Stop the engine and disconnect the spark plug wire.

Depress the tabs on the side of the string head housing

to remove the lower string head housing.

NOTE: The housing is spring loaded and will self eject

when the tabs are depressed. It is not necessary to re-

move the upper string head housing from the drive shaft.

Push the spool and bump knob through the string head

housing and remove the string from the spool.

If replacing the bump knob, remove the old knob from

the spool. Align the knob ribs with the spool slots and

place the new bump knob onto the spool. If you are not

replacing the bump knob, skip this step.

Insert the bump knob and spool assembly through the

opening in the string head housing.

Align the slots on the lower string head housing with the

tabs on the upper string head housing.

Push the housing together until the tabs snap into place.

NOTE: Hold the spool by the knob while completing the

installation.

Install line as described in Line replacement.

Page 11 — English

CLEANING THE EXHAUST PORT, MUFFLER,

AND SPARK ARRESTOR

NOTICE:

The spark arrestor on this product has not been evalu-

ated by the USDA Forest Service and cannot be used

on U.S. forest lands. In addition, product users must

comply with Federal, State, and local fire prevention

regulations. Check with appropriate authorities. Contact

customer service or a qualified service center to purchase

a replacement spark arrestor.

NOTE: Depending on the type of fuel used, the type and

amount of lubricant used, and/or your operating conditions, the

exhaust port, muffler, and/or spark arrestor screen may

become blocked with carbon deposits. If you notice a

power loss with your gas powered tool, you may need to

remove these deposits to restore performance. We highly

recommend that only qualified service technicians perform

this service.

The spark arrestor must be cleaned or replaced every 50

hours or yearly to ensure proper performance of your prod-

uct. Spark arrestors may be in different locations depending

on the model purchased. Please contact your nearest service

dealer for the location of the spark arrestor for your model.

IDLE SPEED ADJUSTMENT

See Figure 19.

WARNING:

The cutting head will move when adjusting the idle speed.

Wear all protective clothing and keep all bystanders,

children, and pets at least 50 ft. away. Make adjustments

with the unit supported by hand so that the blade/cutting

head does not contact the ground or any object. Keep

all parts of your body away from the cutting head and

muffler. Failure to follow these instructions could result

in serious personal injury.

If the cutting attachment turns at idle, the idle speed screw

needs adjusting on the engine. Turn the idle speed screw

counterclockwise to reduce the idle RPM and stop the cut-

ting attachment movement. If the cutting attachment still

moves at idle speed, contact a service dealer for adjustment

and discontinue use until the repair is made.

WARNING:

The cutting attachment should never turn at idle. Turn

the idle speed screw counterclockwise to reduce the

idle RPM and stop the cutting attachment, or contact a

service dealer for adjustment and discontinue use until

the repair is made. Serious personal injury could result

from the cutting attachment turning at idle.

CLEANING THE AIR FILTER

See Figures 20 - 21.

For proper performance and long life, keep air filter clean.

Remove the air filter cover by pushing down on the latches

while gently pulling off the cover.

Remove the air filter.

Clean the foam filter element with warm soapy water.

Rinse and let dry.

NOTE: If the foam filter element is damaged, it should be

replaced.

Apply a light coat of engine oil to the foam filter element,

then squeeze it out.

Reinstall the air filter.

NOTE: Make sure the filter is seated properly inside the

cover. Installing the filter incorrectly will allow dirt to enter

the engine, causing rapid engine wear.

Replace the air filter cover by placing the slots on the air

filter cover over the tabs on the housing, then push the

cover down until it snaps securely in place.

FUEL CAP, TANK, AND LINES

WARNING:

Check for fuel leaks. A leaking fuel cap, tank, or line is a

fire hazard and must be replaced immediately. If you find

any leaks, correct the problem before using the product.

Failure to do so could result in a fire that could cause

serious personal injury.

The fuel cap contains a non-serviceable filter and a check

valve. A clogged fuel filter will cause poor engine per-

formance. If performance improves when the fuel cap is

loosened, the check valve may be faulty or filter clogged.

Replace the fuel cap if required.

SPARK PLUG REPLACEMENT

The spark plug for this engine may be replaced using a

Torch L7RTC, Champion RCJ6Y or equivalent spark plug.

The spark plug gap should be set at .025 in. Use a recom-

mended or equivalent replacement and replace annually.

NOTICE:

Be careful not to cross-thread the spark plug. Cross-

threading will seriously damage the product.

MAINTENANCE

Page 12 — English

REPLACING THE EDGER BLADE

See Figures 22 - 24.

Replace blades when worn down to indicator hole on blade.

Use replacement blade model number AC04215.

Stop the engine and disconnect the spark plug wire.

Align the slot in the flange washer and gear case with the

slot in the flange; place the holding pin through all three

slots to secure in place.

Using a 1/2 in. socket wrench, turn the blade nut clock-

wise to loosen.

Remove the old blade from the edger shaft.

Clean debris from the edger shaft and flange washers.

Center the new blade on the flange washer, making sure

the blade sits flat.

Install the cupped washer with the hole off of the blade

surface.

Install the blade nut onto the edger shaft.

Using a 1/2 inch socket wrench, turn the blade nut coun-

terclockwise onto the edger shaft and tighten securely.

This replacement part is available from the place of pur-

chase, or by calling customer service.

NOTE: Always make sure the blade is correctly installed

and securely fastened before each use.

ATTACHING THE STORAGE HANGER

See Figure 25.

There are two ways to hang the attachment for storage.

To use the hanger cap, push in the button and place the

hanger cap over the end of the attachment shaft. Slightly

rotate the cap from side to side until the button locks into

place.

The secondary hole in the attachment shaft can be used

for hanging purposes as well.

STORING THE PRODUCT

Clean all foreign material from the product. Store idle unit

indoors in a dry, well-ventilated area that is inaccessible

to children. Keep away from corrosive agents such as

garden chemicals and de-icing salts.

Abide by all ISO and local regulations for the safe storage

and handling of gasoline.

When storing 1 month or longer:

Drain all fuel from tank into a container approved for

gasoline. Run engine until it stops.

HIGH ALTITUDE ENGINE OPERATION

Your engine is configured for operation below 2000 feet

altitude at the factory. Your engine must be re-configured

for operation above 2000 feet altitude. Operating the engine

with the wrong engine configuration at a given altitude may

increase its emissions, decrease fuel efficiency, degrade per-

formance and cause irreversible damage. Engines configured

for high altitude operation cannot be operated in standard

altitude conditions. A qualified service center should ensure

that your engine is properly configured for your location.

MAINTENANCE

This product has a Three-year Limited Warranty for personal, family,

or household use (30 days for business or commercial use).

For warranty details, visit www.blackmaxtools.com

or call (toll free) 1-800-726-5760.

Page 13 — English

MAINTENANCE

THIS PRODUCT WAS MANUFACTURED WITH A CATALYST MUFFLER

Congratulations! You have made an investment toward protecting the environment. In order to maintain this product’s

original emission level, please refer to the maintenance section below.

MAINTENANCE SCHEDULE

Inspect For Clean Replace Replace

Maintenance Damage Before Every Every 25 Hours Every

Part Each Use 5 Hours or Yearly 50 Hours

*CATALYTIC MUFFLER ASSEMBLY..................................................................................................................X

SPARK SCREEN ...............................................................................................................................................X

*AIR FILTER ASSY

includes:

Filter Screen ........................................................................ X

*CARBURETOR ASSY

includes:

Gaskets ........................................ X

*FUEL TANK ASSY

includes:

Fuel Lines..................................... X

Fuel Cap....................................... X

Fuel Filter................................................................................................................... X

*IGNITION ASSY

includes:

Spark Plug................................................................................................................. X

* NOTICE: THE USE OF EMISSION CONTROL COMPONENTS OTHER THAN THOSE DESIGNED FOR THIS UNIT

IS A VIOLATION OF FEDERAL LAW.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start No spark

No fuel

Engine is flooded

Clean or replace spark plug. Reset spark plug gap.

Refer to Spark Plug Replacement earlier in this

manual.

Push primer bulb until bulb is full of fuel. If bulb does

not fill, primary fuel delivery system is blocked. Contact

a qualified service dealer. If primer bulb fills, engine

may be flooded, proceed to next item.

Set the choke lever to the FULL CHOKE position.

Squeeze the trigger and pull the starter grip and rope

repeatedly until the engine starts and runs.

NOTE: Depending on the severity of the flooding, this

may require numerous pulls of the rope.

TROUBLESHOOTING

Page 14 — English

PROBLEM POSSIBLE CAUSE SOLUTION

Engine does not reach full

speed and emits excessive

smoke

Incorrect lubricant/fuel mixture

Air filter screen is dirty

Spark arrestor screen is dirty

Spark plug fouled

Use fresh fuel and the correct 2-cycle lubricant mix.

(50:1).

Clean air filter screen. Refer to Cleaning the Air Filter

earlier in this manual.

Contact a qualified service dealer.

Clean or replace spark plug. Reset spark plug gap.

Refer to Spark Plug Replacement earlier in this

manual.

Engine starts, runs, and

accelerates but will not idle

Idle speed screw on carburetor

needs adjustment

Turn idle speed screw clockwise to increase idle

speed. See Figure 16.

Line will not advance Line is welded to itself

Not enough line on spool

Line is worn too short

Line is tangled on spool

Engine speed is too slow

Lubricate line with silicone spray.

Install more line. Refer to the applicable line replace-

ment section in this manual.

Pull lines while alternately pressing down on and

releasing bump knob.

Remove line from spool and rewind. Refer to the appli-

cable line replacement section in this manual.

Advance line at full throttle.

Spool retainer hard to turn Screw threads are dirty or dam-

aged.

Clean threads and lubricate with grease - if no

improvement, replace the spool retainer.

Grass wraps around drive

shaft housing and string head

Cutting tall grass at ground level

Operating trimmer at part throttle

Cut tall grass from the top down to prevent wrapping.

Operate trimmer at full throttle

Engine starts and runs but

string head does not turn

Shafts are incorrectly assembled. Reassemble shafts. Refer to Joining the Power

Head to the Trimmer or Edger Attachment in the

Assembly section of this manual.

If problem persists after trying the above solutions, contact customer service or a qualified service center for assistance.

NOTICE:

As the equipment owner, you are responsible for the performance of the required maintenance listed in the Maintenance

section. It is recommended that you retain all receipts covering maintenance on your equipment. Neglecting or failing to

perform the required maintenance may increase emissions, decrease fuel efficiency, degrade performance, cause irrevers-

ible engine damage and/or void your warranty.

TROUBLESHOOTING

Página 2 — Español

ADVERTENCIA:

LEA Y COMPRENDA TODAS LAS INSTRUCCIONES. El

incumplimiento de las instrucciones señaladas abajo puede

causar descargas eléctricas, incendios y lesiones corporales

serias.

LEA TODAS LAS INSTRUCCIONES

Para utilizar este producto de una forma segura, lea y

entienda todas las instrucciones antes de usarlo. Siga todas

las instrucciones de seguridad. La inobservancia de todas las

instrucciones de seguridad señaladas abajo puede causar

lesiones corporales graves.

No permita que utilicen esta unidad niños ni personas carentes

de la debida instrucción para su manejo.

No haga arrancar o funcionar el motor en un espacio confinado,

de edificio, cerca de ventana abiertas, o en otro área sin

ventilación donde se puedan recolectar las emanaciones

de monóxido de carbono. El monóxido de carbono, un gas

incoloro, inodoro y sumamente peligroso, puede causar la

pérdida de la conciencia o la muerte.

Despeje el área de trabajo cada vez antes de utilizar esta

herramienta. Retire todos los objetos tales como piedras, vidrios

rotos, clavos, alambre o cuerdas que pudiesen resultar lanzados

o enredados en el hilo de corte o cuchilla, según sea el caso.

Siempre utilice protección ocular con protección lateral con

la marca de cumplimiento de la norma ANSI Z87.1, como así

también protección auditiva cuando utilice este equipo. Si no

cumple esta advertencia, los objetos que salen despedidos

pueden producirle lesiones serias en los ojos.

Póngase pantalones, mangas largas, botas y guantes gruesos.

No se ponga ropa holgada o pantalones cortos, sandalias ni

ande descalzo. No se ponga joyas de ninguna clase.

La ropa protectora pesada puede aumentar la fatiga del

operador, lo cual puede originar un golpe de calor. En climas

cálidos y húmedos, el trabajo pesado debe programarse para

las primeras horas de la mañana o las últimas horas de la tarde,

cuando las temperaturas son más bajas.

Nunca utilice esta unidad colocándola al lado izquierdo de usted.

Recójase el cabello largo arriba del nivel de los hombros para

evitar que se enrede en las piezas móviles.

Mantenga a todas las personas presentes, niños y animales por

lo menos a 15 m (50 pies) de distancia. Debe exhortarse a los

circunstantes a ponerse protección para los ojos. Si alquien se

aproxima mientras usted está utilizando la herramienta, apague

el motor y el accesorio de corte. En el caso de las unidades

con cuchilla, existe el riesgo adicional de que las personas

presentes sufran lesiones al ser golpeadas con la cuchilla en

movimiento en caso de un contragolpe de la cuchilla u otra

reacción inesperada de la sierra.

No use esta unidad cuando se encuentre fatigado, enfermo,

molesto o bajo los efectos del alcohol, drogas o medicamentos.

No utilice este producto si no hay luz suficiente.

Mantenga los pies bien afirmados y el equilibrio. No trate de

alcanzar demasiado lejos. Al tratar de hacerlo puede perder el

equilibrio o exponerse al contacto con superficies calientes.

No utilice la unidad al estar en una escalera o en un

soporte inestable. Una postura estable sobre una superficie

sólida permite un mejor control de l’unidad en situaciones

inesperadas.

Mantenga todas las partes del cuerpo alejadas de toda pieza

móvil.

Para evitar tocar superficies calientes, al utilizar esta unidad

nunca coloque la parte inferior de la misma arriba del nivel

de la cintura.

No toque las áreas alrededor del silenciador o del

cilindro de la unidad, estas partes se calientan durante el

funcionamiento. Contacto con superficies calientes puede

causar lesiones serias.

Siempre apague el motor y retire el cable de la bujía antes

de realizar cualquier ajuste o reparaciones, excepto para los

ajustes del carburador.

Inspeccione cada vez la unidad antes de usarla para ver si

tiene tornillos flojos, fugas de combustible, etc. Reemplace

toda pieza dañada antes de utilizar la unidad.

Nunca utilice cuchillas, mayales, alambres ni cuerdas en el

accesorio para recortar. Nunca utilice mayales, alambres ni

cuerdas en en ninguna aditamentos.

El accesorio de corte nunca debe girar en marcha lenta

durante el uso normal. El accesorio de corte puede girar en

marcha lenta durante los ajustes del carburador.

Ha habido informes de que las vibraciones de las

herramientas motorizadas de mano pueden contribuir, en

ciertas personas, al desarrollo de una condición llamada

síndrome de Raynaud. Entre los posibles síntomas está el

hormigueo, el entumecimiento y la palidez de los dedos,

síntomas presentes normalmente con la exposición al frío.

Se cree que los factores hereditarios, la exposición al frío

y a la humedad, la dieta, el fumar y las prácticas de trabajo

contribuyen al desarrollo de estos síntomas. Actualmente

se desconoce qué tipo de vibraciones o cuánto tiempo de

exposición a las mismas, si tal es el caso, pueden contribuir

a la mencionada afección. Hay medidas de precaución que

puede tomar el operador para reducir posiblemente los

efectos de la vibración:

a) Mantenga caliente el cuerpo en tiempo frío. Al utilizar la

unidad use guantes para mantener calientes las manos y

las muñecas. Los informes médicos indican que el clima

frío es un factor importante que contribuye al síndrome

de Raynaud.

b) Despuésde cada períododeutilizaciónde la unidad, haga

ejercicio para aumentar la circulación de la sangre.

c) Tome descansos frecuentes durante el trabajo. Limite la

cantidad de exposición al día.

d) Mantengala herramienta biencuidada,con los elementos

desujecióndebidamenteapretadosysiemprecambiando

las piezas desgastadas.

Si sufre cualquiera de los síntomas propios de esta

condición, de inmediato interrumpa el uso de la unidad y

consulte a su doctor en lo concerniente a los mismos.

Mezcle y guarde el combustible en un recipiente aprobado

para gasolina.

REGLAS DE SEGURIDAD GENERALES

Página 3 — Español

Mezcle el combustible al aire libre, donde no haya chispas

ni llamas. Limpie todo derrame de combustible. Aléjese

por lo menos 9 m (30 pies) del sitio de reabastecimiento de

combustible antes de encender el motor. Afloje lentamente

la tapa del tanque de combustible después de apagarse el

motor. No fume durante el reabastecimiento.

Apague el motor y deje que se enfríe antes del reabastecimiento

de combustible o de guardar la unidad.

Deje que se enfríe el motor; vacíe el tanque de combustible en

un recipiente de uso aprobado para gasolina y fije la unidad

para inmovilizarla antes de transportarla en un vehículo.

Póngase equipo de protección y observe todas las

instrucciones de seguridad. Asegúrese de que el accesorio

de corte deje de girar al tenerse el motor en marcha lenta. Al

apagar la unidad, asegúrese de que el accesorio de corte se

haya detenido antes de dejarla en reposo.

Recomendamos que lleve la équipement a un centro de

servicio calificado para reparaciones, ya que todo servicio

realizado por personas sin experiencia o calificación puede

dañar la équipement, causar lesiones al usuario crear

condiciones de inseguridad, y anular la garantía.

REGLAS DE SEGURIDAD GENERALES

REGLAS DE SEGURIDAD ESPECÍFICAS

RECORTADORA

Inspeccione el producto cada vez antes usarlo. Reemplace

toda pieza dañada. Asegúrese de que todos los tornillos y

demás elementos de unión estén en lugar y bien firmes. Revise

la herramienta para ver si tiene fugas de combustible.

Reemplace el cabezal del hilo si estuviese agrietado, astillado

o dañado de alguna manera. Asegúrese de que el cabezal del

hilo, o cuchilla, según sea el caso, esté debidamente instalado

y firmemente asegurado. La inobservancia de esta advertencia

puede causar lesiones corporales serias.

Asegúrese de que todas las protecciones, correas, deflectores

y mangos estén firme y correctamente instalados.

En el cabezal de corte use únicamente hilo de repuesto

recomendadas o equivalents. No use ningún otro aditamento

de corte. Instalar cualquier otra tipo de hilo de corte o hilo de

repuesto en esta recortadora de hilo puede producir lesiones

corporales serias. Por ejemplo, nunca utilice alambre ni cable,

segmentos de los cuales pueden desprenderse y convertirse

en peligrosos proyectiles.

Nunca utilice la unidad si el deflector de césped no está en

posición y en buenas condiciones de funcionamiento.

Sujete firmemente ambos mangos al estar recortando.

Mantenga el cabezal del hilo por debajo del nivel de la

cintura. Nunca corte con el cabezal del hilo a más de

762 mm (30 pulg.) del suelo.

Este producto está diseñado para uso poco frecuente por parte

de propietarios y otros usuarios ocasionales para aplicaciones

generales como cortar vegetación ligera y pesada, etc. No es

para uso prolongado. Los períodos prolongados de manejo de

la unidad pueden causar problemas circulatorios en las manos

del operador debido a la vibración. Para tal uso puede convenir

utilizar una sierra dotada de características de antivibración.

RECORTAR BORDES

Si la hoja está desafilada o desgastada, cámbiela; no intente

afilarla.

Use esta recortadora de bordes a lo largo de aceras, caminos

de entrada, macizos de flores y áreas similares. No la use para

ningún otro propósito.

Familiarícese completamente con todos los controles. Aprenda

la forma de apagar la unidad y de desactivar los controles con

rapidez.

No utilice la recortar de bordes en la lluvia en superficies de

grava ni cerca de las mismas.

Familiarícese con el área donde está cortando los bordes.

Esté consciente del desnivel de las aceras, de todo agujero

existente en el terreno y de toda condición peligrosa similar (Por

ejemplo: alambre o cable, segmentos de los cuales pueden

desprenderse y convertirse en peligrosos proyectiles). En

terreno áspero siempre empuje lentamente el accesorio para

recortar bordes.

No intente retirar material cortado ni sujetar material por cortar

mientras esté funcionando el motor o esté girando la hoja de

corte.

Mantenga las manos y los pies alejados de las área de corte.

Cuando la hoja esté girando, mantenga siempre las manos en

el mango superior.

La hoja de corte puede causar lesiones en su giro de inercia

después de apagar el motor o de soltar el gatillo del acelerador.

Mantenga un control adecuado de la herramienta hasta que

se detenga por completo la hoja de corte.

Verifique que la tuerca de la hoja esté ajustada antes de utilizar.

Si no se monta la unidad correctamente, se puede producir

una situación peligrosa.

Nunca debe pararse ni colocar ninguna parte de su cuerpo en

la línea de corte de la hoja para cortar bordes.

Si la recortadora bordes toca cualquier objeto extraño:

a) Apague la recortadora de bordes y desconecte el cable de

la bujía o desconecte la unidad del suministro de corriente.

b) Inspeccione la para recortar bordes para ver si está dañado.

c) Corrija todo daño presente antes de utilizar la para cortar

bordes. La inobservancia de esta advertencia puede causar

lesiones corporales serias.

Siempre apague el motor y retire el cable de la bujía, o

desconecte la unidad del suministro de corriente, antes de

intentar retirar cualquier obstrucción atrapada o atorada en

la cuchilla, antes de instalar cualquier accesorio o de realizar

cualquier ajuste.

Guarde estas instrucciones. Consúltelas con frecuencia y

empléelas para instruir a otras personas que puedan utilizar

esta herramienta. Si presta a alguien esta herramienta, facilítele

también las instrucciones.

Table of contents

Languages:

Other Black Max Trimmer manuals