Dear Customer, Thank you for choosing our Fire Rolling Shutter with EW resistance

performance.

It was designed and built in compliance with:

CPR 305/2011 (Construction Products Regulation);

Machinery Directive 2006/42 / EC

Electromagnetic Compatibility Directive 2014/30 / EU

Low Voltage Directive 2014/35 / EU

RED Directive (Radio Equipment Directive) 2014/53 / UE

Directive 2011/65 / EU RoHS II - Restrictions on the use of hazardous substances

following the indications of the standards:

❖

UNI EN 13241: 2016 Industrial, commercial and garage doors and gates - Product

standard, performance characteristics;

❖

UNI EN 12604: 2017 Industrial, commercial and garage doors and gates - Mechanical

aspects - Requirements and test methods;

❖

UNI EN 12453: 2017 Industrial, commercial and garage doors and gates - Safety in use of

motorized doors - Requirements and test methods;

❖

UNI EN 16034: 2014 Pedestrian doors, industrial, commercial, garage doors and opening

windows - Product standard, performance characteristics - Fire resistance and / or smoke

control characteristics;

and tested according to the standards:

❖

UNI EN 1634-1: 2018 Test of fire resistance and control of smoke dispersion for doors and

closing systems, opening windows and their construction accessories - Part 1: Fire

resistance tests for doors and closing systems and opening windows ;

❖

UNI EN 1634-2: 2009 Fire resistance and smoke dispersion control tests for doors, closing

systems, opening windows and their construction components - Part 2: Resistance tests

for construction components;

❖

UNI EN 1363-2: 2001 Fire resistance tests - Alternative and additional procedures;

❖

UNI EN 15269-10: 2011 Extended application of the results of fire resistance tests and / or

control of smoke dispersion for doors, opening systems and windowsand their construction

components - Part 10: Fire resistance of steel roller shutters ;

In support, CE documents are issued consisting of:

•

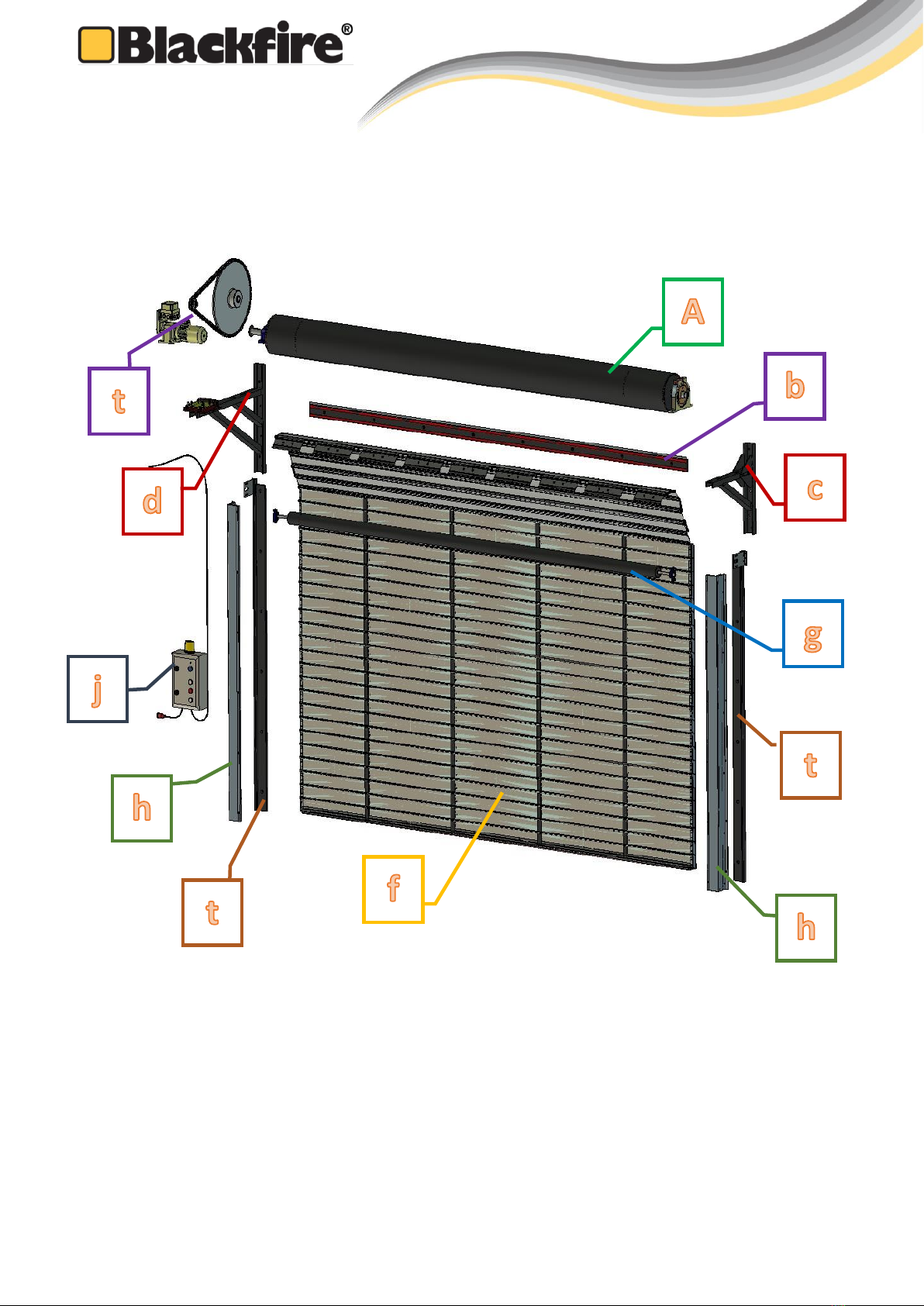

Installation, Use, Maintenance and Safety Manual;

•

Gearmotor Manual with relative declaration of incorporation issued by the

Manufacturer;

•

Control Panel Manual with relative declaration of incorporation issued by the

Manufacturer;

•

Safety device manuals with relative declarations of conformity issued by

manufacturers;

•

DOP (Declaration of Performance);

•

CE label.