Blejzyk MEFISTO User manual

MEFISTO - Building Guide

Welcome and congratulations on your purchase. We hope that our product

will provide you with many enjoyable flying hours as well as being a pleasure

to build.

Please treat this manual as a guide only. Your own modifications to the building

process are welcome.

We believe that the following steps are essential in achieving success with the

model:

-Before commencing with the assembly read the entire manual.

-Trial fit all parts.

-All glued parts (and their mating components) should be sanded using ≈240

sandpaper. This applies mainly to all plywood reinforcements in fuselage, tow

hook and inner nose cone.

-Accurately and neatly finished models usually fly better.

Kit Contents

Fibreglass Fuselage, Inner Nose Cone, Sheath nose

Pre-hinged V-tail Stabiliser & Mount

Sheeted and Sanded Wing Halves

Wing Hardwood blocks (4)

Closing Rib Plywood

Ballast Compartment Plywood

Wing Plate Plywoods (2 pieces)

Tail Reinforcement Plywood

Tail M3 Nylon Bolts & Brass Nuts (2)

Wing M4 Nylon Bolts & Nuts (4)

Wing Joiner System – Carbon Bar & Brass Tube

Auxiliary Wing Joiners (2)

Tow Hook

Aileron Control Horns (2)

V-Tail Control Horns (2)

Fibreglass Cloth Strips

2

Wings

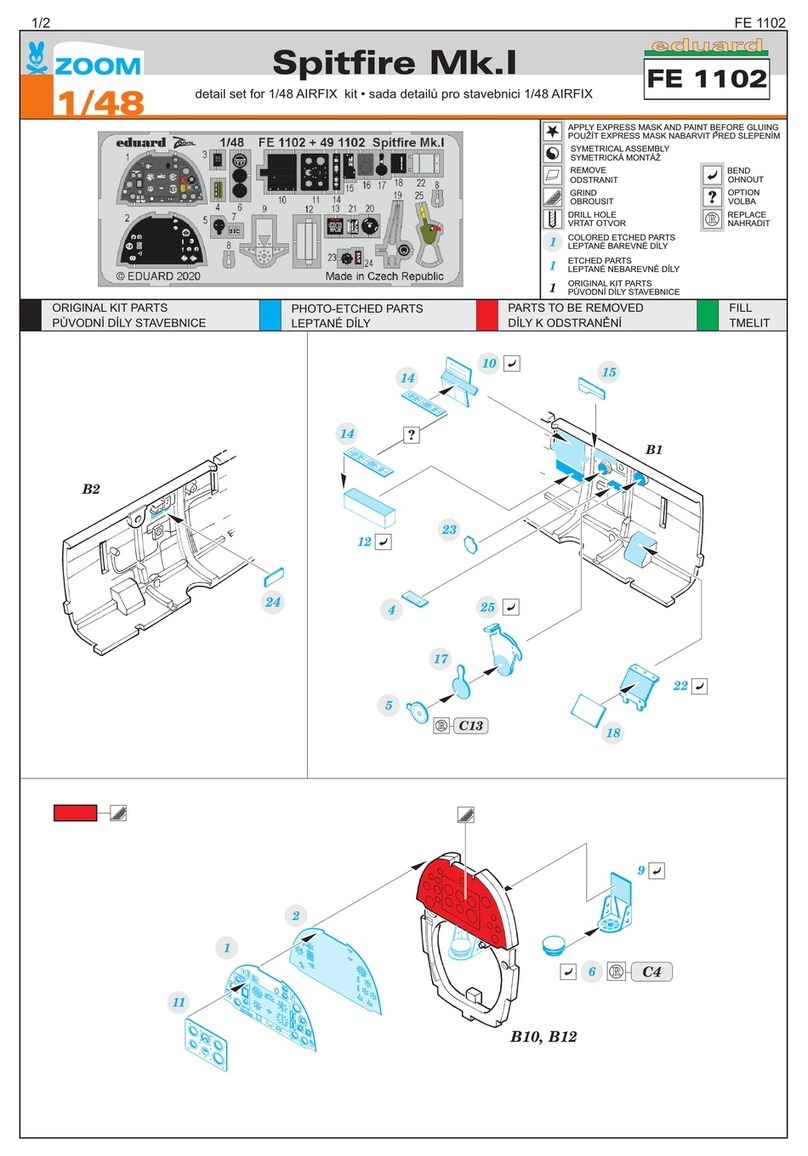

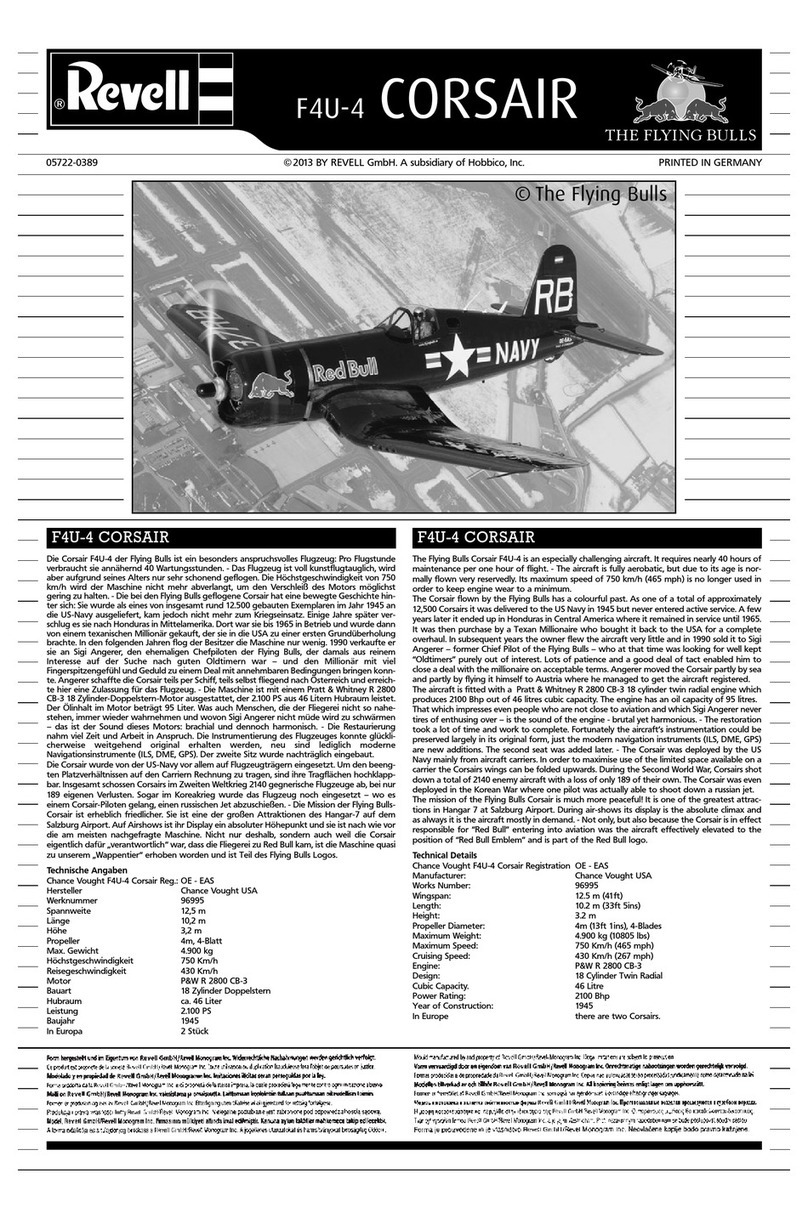

The wing joining system for this model consists of a carbon joiner bar and a brass

joiner tube. The carbon joiner bar is permanently glued into one wing, while the

brass joiner tube is permanently glued into the other wing, see Figure 1.

Rebore one wing root hole to φ7mm. Blank-off one end of the brass tube with a flat

piece of fibreglass soaked in resin. When completely cured and dry insert the carbon

joiner into the brass tube and trial fit them into the wing spars. The brass tube should

be fully inserted into one wing while the carbon joiner should be half inserted into the

brass tube, see Figure 1. Position one wing half flat on a building board and apply

50mm dihedral at the tip of the other half (the wings have been already sanded to the

correct dihedral). Pieces of balsa, books etc can be used to hold the required

dihedral. Separate the wings and remove the carbon bar and brass tube. Sand the

entire outside surface of the brass tube.

Figure 1

Lay down a piece of wax paper to protect your building board and cover the wing for

50mm or so to protect the veneer from any epoxy overspill. Smear the inside of the

wing holes with a slow curing epoxy (1hour) and insert the assembled brass tube

and carbon joiner into the wings. Using masking tape hold the two wing halves

together (with 50mm dihedral), making sure that both halves match each other. Be

careful not to glue the wings together. Allow the epoxy to cure.

Assemble the wing halves together and mark the position of the hardwood blocks on

the skin, as per the general arrangement drawing. Remove the foam to the depth of

the hardwood blocks and shape the blocks to achieve a loose fit. Cut the wing

closing ribs from the supplied ply. The ribs should be slightly bigger than the actual

root wing profile. Cut holes for the wing joiner and servo leads in both ribs.

Using a blunt tool (a piece of hardwood) push in the foam to a depth of approximately

1mm around the perimeter of the wing root. This operation will allow a stronger joint

with the closing ribs.

Smear a slow curing epoxy (1 hour) with microballoons inside the holes and insert

the hardwood blocks. Make sure that the space between the hardwood blocks and

the top and bottom veneer is filled up with the epoxy. Apply the glue to the entire

3

wing root area and glue-in the closing ribs. Use masking tape to hold the ribs. Allow

the epoxy to cure.

Sand the closing ribs flush with the wing profile.

Drill two x φ4mm holes through the hardwood blocks in each wing half for the wing

bolts. The holes should be perpendicular to the top surface of the wing, see the

general arrangement drawing. Drill two horizontal φ2mm holes in the hardwood

blocks for the auxiliary wing joiners. Vertical and horizontal holes should be

staggered. Trial fit the auxiliary joiners. Adjustment can be made by reboring the

holes, but only those in which joiners will be glued in. Epoxy the auxiliary joiners into

the wing halves.

Cut out the ailerons with a sharp hobby knife. With a blunt tool push in the foam on

aileron and wing sides to a depth of 2-3 mm. Fill the voids with a mixture of 5min

epoxy and microballoons. Allow the epoxy to cure completely. Sand the sides

flush. Sand the bottom front edge of the aileron so that it can deflect down.

The position of the wing servos is marked on the wings. Cut out the veneer and

foam so that a servo fits very snugly inside the servo hole.

At this stage the wing should be sanded lightly with a fine sandpaper and sealed with

a clear varnish. Any type of a suitable, lightweight varnish can be used to protect the

wing and tail from moisture and aging. Although an epoxy was used to glue the

veneer to the wing cores, care should be taken when using non-water based

varnishes so as not to destroy the wing foam.

Ailerons can be attached with a clear tape. Start at the top surface and then turn the

aileron flat on the top of the wing. Tape the bottom surface.

Install the aileron horn directly in line with the servo arm.

TAIL

The edges of the tail have been already pre- sanded to the correct angle. Join all

three parts together using a 5min epoxy. We recommend using cardboard templates

to hold the V-tail while the glue cures. Reinforce the joints with pieces of the supplied

fibreglass cloth.

The tail can be permanently glued to the fuselage or alternatively attached using M3

bolts. The former method is quick and easy but can be problematic during transport.

Details of the bolted version are provided in the following section “Fuselage”

FUSELAGE

Wing position on top of the fuselage:

-HN1033 profile: as per drawing

4

-S6063 profile: move the wing forward by approximately the thickness of the

leading edge

Cut a hole in the wing seating so that a receiver can be inserted. Glue the wing

seating plates using 5min epoxy. The wing seating plates can be shaped to a slight

V angle to accommodate the wing dihedral.

Assemble the wing halves and drill φ4mm holes in the fuselage (and wing seating

plates) using the wing holes as guides. Double sided tape can be used to hold the

wing during this operation. Take off the wing and rebore the fuselage holes to

φ5.5mm and insert the provided nuts. Place the wing on top of the fuselage again

and trial fit the wing bolts. It is important for the nuts to fit tightly inside the fuselage

holes up to the collar. Lock the nuts in place using CA glue.

Should you have opted for a removable tail, glue the plywood reinforcement to the

tail seat (inside the fuselage). Drill 2 φ3mm holes in the V-tail mount. Place the tail

on top of the fuselage and drill φ3mm holes using the tail holes as guides. Make sure

that the tail is correctly aligned. Rebore the fuselage holes to φ5.5mm and insert the

provided nuts. Lock the nuts in place using CA glue. Install the supplied control

horns.

If required, install a tow hook using 2-3 layers of fibreglass as reinforcement.

Bowden cables can be glued at 2-3 places inside the fuselage using CA or epoxy

glues. Alternatively, they can be glued to a 3mm piece of balsa shaped to conform to

the inside contour of the fuselage. The entire assembly is then glued inside the

fuselage.

Cut a hole for the receiver battery in the inner nose part. Insert through this hole a

φ26mm plate cut from the supplied plywood. This plate will act as a closure for the

ballast compartment. Drill a hole on top of the ballast compartment so that small

pieces of lead can be inserted.

Cut holes for the servos. It is recommended to reinforce with plywood the areas

where the servos will be bolted down. Drill holes for the bowden cables.

Drill 4 x φ4mm holes around the circumference of the inner nose cone, 7 mm from

the edge. These holes will allow excess glue to drain away as well as provide a

better bond. Insert the inner nose cone deeply into the sheath nose. Trial fit it into

the fuselage. Light sanding may sometimes be required in order to obtain a good fit

inside the fuselage. Sand the outside of the inner nose cone and the inside of the

fuselage (the areas to be glued together) with a fine sandpaper. Smear the inside of

the fuselage with 5min epoxy and push in the sheath nose/inner nose assembly into

the fuselage. Carefully align the sheath nose with the fuselage and tape the joint

line. Use a liberal amount of epoxy for this operation but be careful not to glue the

sheath nose to the inner cone.

EQUIPMENT

5

This model can be flown with a rudder/elevator/aileron or just elevator/aileron.

Micro size servos should be used in the fuselage. Wing servos can be installed

using a small amount of silicon sealer. Before gluing the servos into the wings, wrap

them with electrical insulating tape.

Insert a 350-800mAh battery into the fuselage.

The receiver is positioned behind the servos and the aerial can be routed inside the

fuselage.

Recommended Control Throws:

Elevator – 9mm up/down

Aileron – 10 up, 6 down

Rudder – 9 left/right

These are only recommended initial throws and can be changed to suit individual

flying styles.

CG POSITION

For the first flights we recommend that the model should be balanced 74mm from the

leading edge, measuring in the CL of the fuselage. After the first flight the CG

position and wing incidence angle can be adjusted to suit individual flying styles.

ELECTRIC VERSION

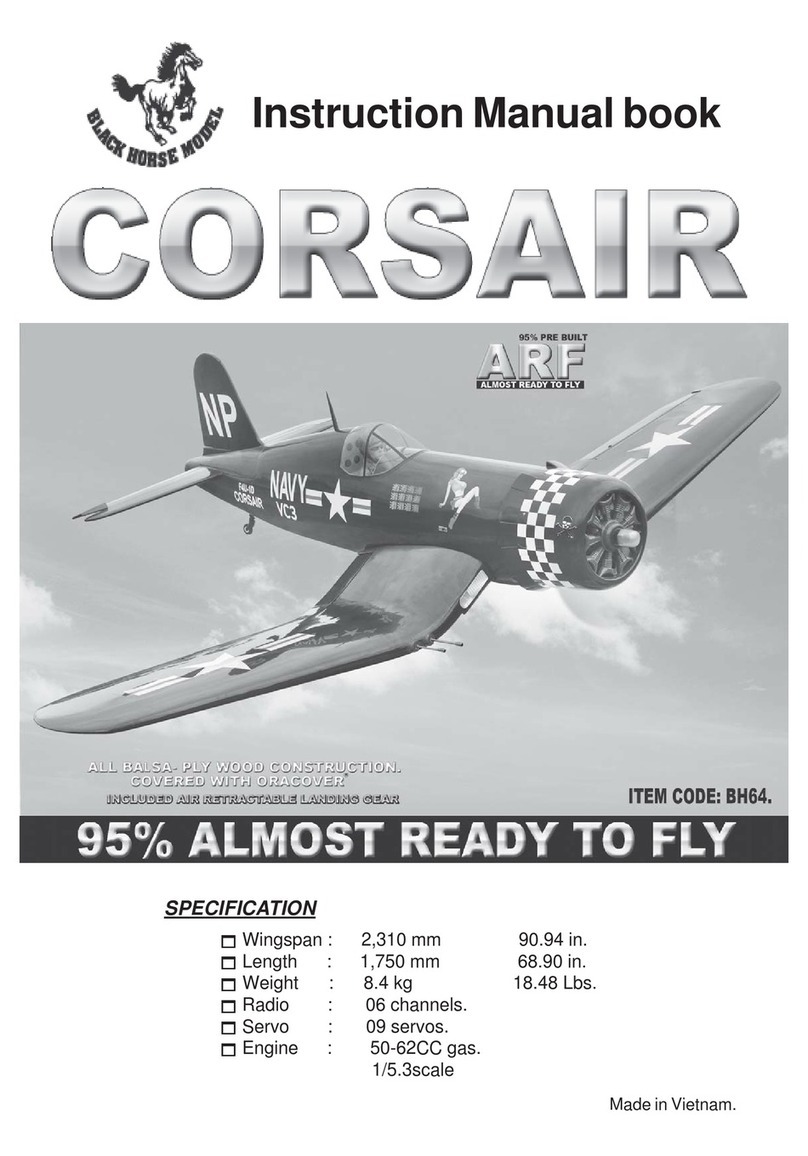

However, any suitable motor and reduction gear can be used. Cut the nose of the

electric fuselage at the diameter of the spinner. The fuselage CL is already set ≈2°

down, so no extra down thrust angle is required, see Figure 2. Just set the motor

mount parallel to the nose closing bulkhead. The motor mount can be made from a

plywood-epoxy board laminate, each approximately 1.6 mm thick. Cut the air vent

holes and drill holes for the motor fixing screws. Glue the motor mount using epoxy

and carbon fibre tows. Trim the inner nose cone to suit the motor/reduction gear

shape.

6

Figure 2

TAPE

CUT TO SUIT MOTOR

This manual suits for next models

1

Table of contents

Other Blejzyk Toy manuals