ii

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WHEN USING ELECTRICAL APPLIANCES, THE FOLLOWING

BASIC SAFETY PRECAUTIONS SHOULD BE STRICTLY ADHERED TO:

WARNING!!

To reduce the risk of burns, electric shock, fire, injury to persons or exposure to excessive

microwave energy:

7. Read all instructions before using the appliance.

8. Read and follow the specific PRECAUTIONS TO AVOID POSSIBLEEXPOSURE TOEXCESSIVE

MICROWAVE ENERGY found on page iii.

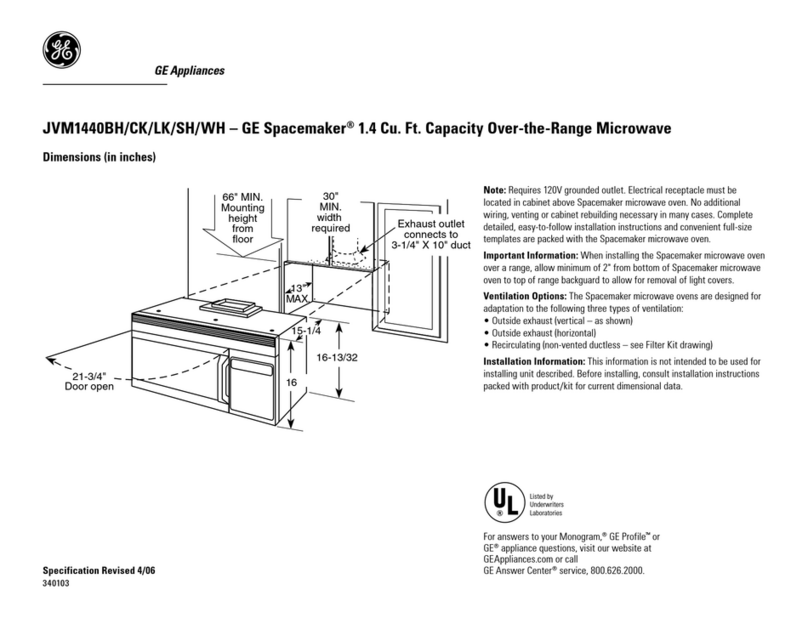

9. This appliance must be grounded. Connect onlyto properlygrounded outlet. See GROUNDING

INSTRUCTIONS found on page iv.

10. Install or locate this appliance only in accordance with the provided installation instructions.

11. Some productssuchaswhole eggs and sealed containers --- for example, closed glass jars --- may

explode and SHOULD NOT be heated in this oven.

12. Use this appliance only for its intended use as described in the manual. DO NOT use corrosive

chemicals or vapors in this appliance. This type of oven is specifically designed to heat, cook, or

dry food. It is NOT designed for industrial or laboratory use.

13. Children SHOULD NOT use this appliance.

14. DO NOT operate this appliance if it has a damaged cord or plug, if it is not working properly, or if

it has been damaged or dropped. See POWER SUPPLY CORD REPLACEMENT found on page

iv.

15. This appliance should be serviced only by qualified service personnel. Contactthe nearest autho-

rized service facility for examination, repair or adjustment.

16. DO NOT cover or block any openings on the appliance.

17. DO NOT store this appliance outdoors. DO NOT use this product near water --- for example, near

a kitchen sink, in a wet basement, or near a swimming pool.

18. DO NOT immersecordorpluginwater.

19. Keep cord away; from heated surfaces.

20. DO NOT letcordhangoveredgeoftableorcounter.

21. DO NOT useawaterjetforcleaning.

22. See the Maintenance section of this manual.

23. To reduce the risk of fire in the oven cavity:

a.) DONOTovercook food. Carefully attend applianceif paper, plastic, orother combustible mate-

rials are placed inside the oven to facilitate cooking.

b.) Removewiretwist---tiesfrompaperorplasticbaginoven.

c.) If materials inside theovenshouldignite, keep oven door closed, turn oven off, and disconnect

thepowercord,orshutoffpoweratthefuseorcircuitbreakerpanel.

d.) DONOTusethecavityforstoragepurposes.DONOTleavepaperproducts, cookingutensils,

or food in the cavity when not in use.