BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Burlington, VT 05402

Toll Free: (800) 331-5842 • Phone: (802) 860-3700 • Fax: (802) 864-0183

Project

Item No.

Quantity

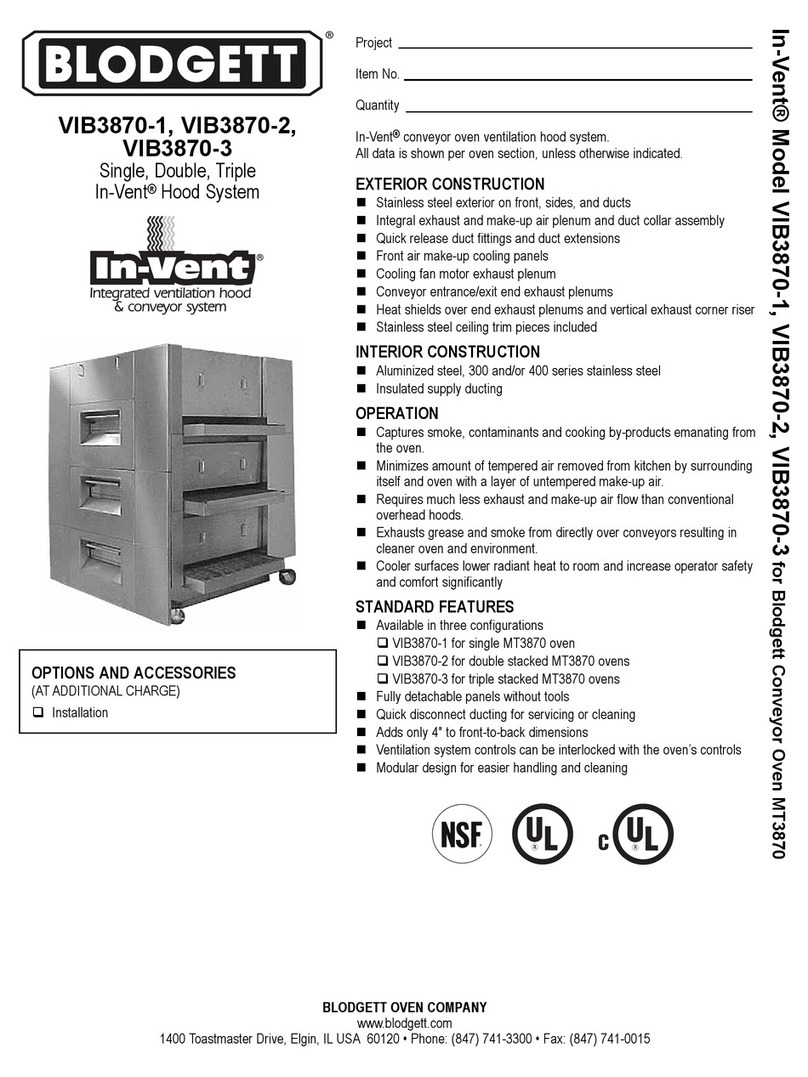

In-Vent®conveyor oven ventilation hood system.

All data is shown per oven section, unless otherwise indicated.

EXTERIOR CONSTRUCTION

!Stainless steel exterior on front, sides, and ducts

!Integral exhaust and make-up air plenum and duct collar assembly

!Quick release duct fittings and duct extensions

!Front air make-up cooling panels

!Cooling fan motor exhaust plenum

!Conveyor entrance/exit end exhaust plenums

!Heat shields over end exhaust plenums and vertical exhaust corner riser

!Stainless steel ceiling trim pieces included

INTERIOR CONSTRUCTION

!Aluminized steel, 300 and/or 400 series stainless steel

!Insulated supply ducting

OPERATION

!Captures smoke, contaminants and cooking by-products emanating from

the oven.

!Minimizes amount of tempered air removed from kitchen by surrounding

itself and oven with a layer of untempered make-up air.

!Requires much less exhaust and make-up air flow than conventional

overhead hoods.

!Exhausts grease and smoke from directly over conveyors resulting in

cleaner oven and environment.

!Cooler surfaces lower radiant heat to room and increase operator safety

and comfort significantly

STANDARD FEATURES

!Available in three configurations (all ovens must have remote mounted

controls)

"VIB3240-1 for single SG3240

"VIB3240-2 for double stacked SG3240

"VIB3240-3 for triple stacked SG3240

!Fully detachable panels without tools

!Quick disconnect ducting for servicing or cleaning

!Adds only 6" to front-to-back dimensions

!Ventilation system controls can be interlocked with the oven’s remote

mounted controls

!Modular design for easier handling and cleaning

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

"Installation

VIB3240-1, VIB3240-2,

VIB3240-3

Single, Double, Triple

In-Vent®Hood System

In-Vent® Model VIB3240-1, VIB3240-2, VIB3240-3 for Blodgett Conveyor Oven SG3240 with remote mount controls

VIB3240-2 In-Vent®is shown on

Double Stacked Blodgett Model SG3240 Conveyor Oven

which is sold separately.