8

Operation

Sequence of Operation

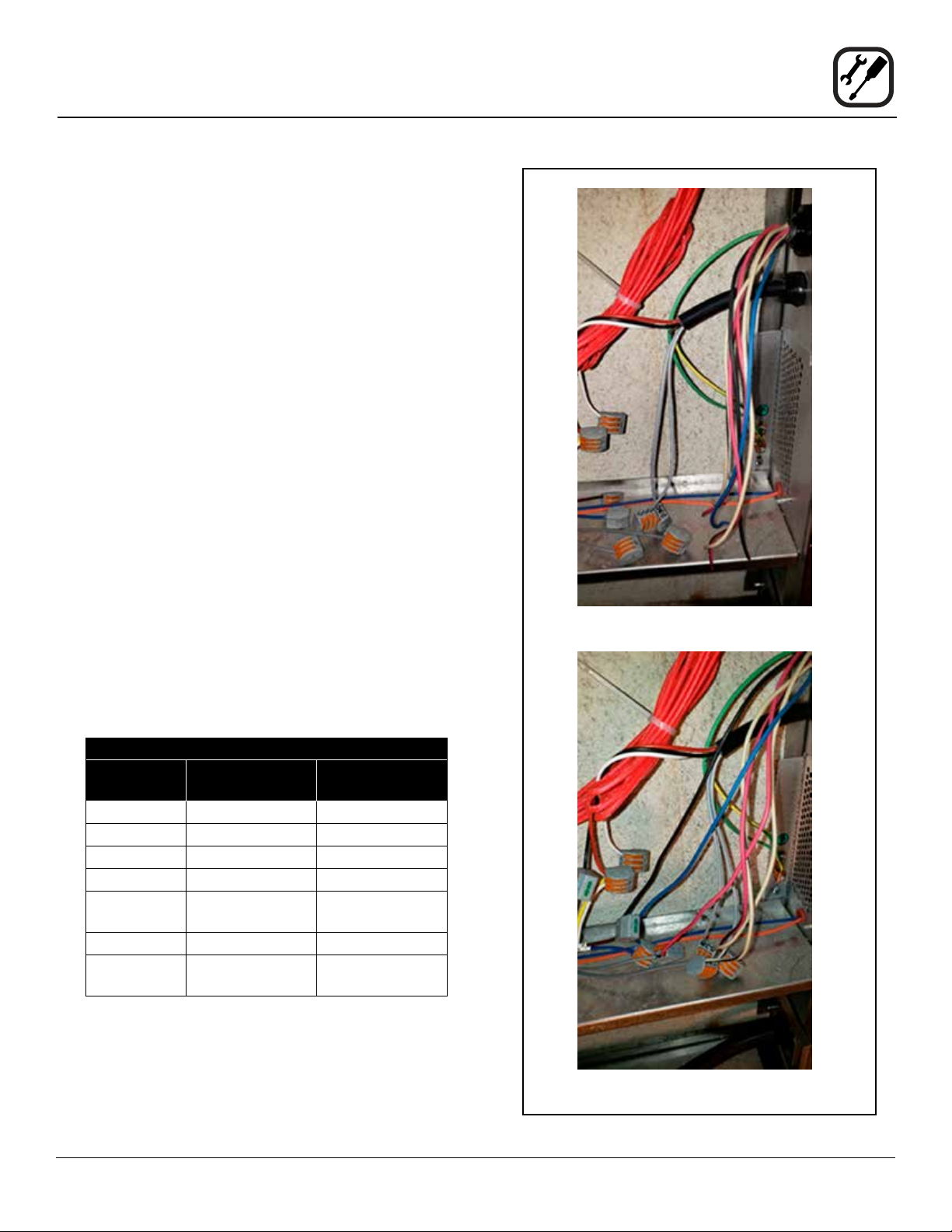

1. The VLF ventless hood receives power from the eld

wiring block of a single, or top of a double stack, vent-

less ready oven. This received power runs to the

front panel circuit breaker of the VLF and must be in

the ON position in order for the hood to operate.

2. The VLF has an interlock switch that engages when

the hood’s lter is properly installed. The lter inter-

lock switch must also be engaged in order for the

hood to operate.

3. Provided 1 and 2 above are satised, turning on ei-

ther the top or bottom ventless ready oven of a double

stack or the single ventless ready oven will start the

oven’s convection blower motor, closing the motor’s

proof of rotation switch which will turn on the hood’s

blower motor.

4. When the VLF blower turns on it creates a pressure

dierential between the plenum above and the ple-

num below the hood’s lter. The upper and lower

plenum pressure taps are connected to two pressure

switches, one has a pressure setpoint of 0.40”W.C.

and the other has a pressure setpoint of 0.25”W.C.

The 0.40”W.C. pressure switch is interlocked with the

oven’s call for heat. For a new lter, the dierential

pressure is low because airow is nearly uninhibited.

This very low pressure will cause no change in either

switch, which will allow the oven to heat and operate

normally.

5. As the VLF’s lter becomes obstructed through use,

the dierential pressure across the lter will rise.

When this dierential pressure reaches 0.25”W.C.,

the orange indicator light, labeled “Order New Filter”,

will illuminate on the front panel of the hood

6. As the VLF’s lter becomes further obstructed from

usage, the dierential pressure will continue to rise.

When this dierential pressure reaches 0.40”W.C.,

the red indicator light, labeled “Change Filter To Use

Oven”, will illuminate on the front panel of the hood.

Once the red indicator is illuminated the oven’s/ov-

ens’ call for heat will disengage. The oven(s) will still

operate but will not heat.