Blue Diamond PICKUP BROOM 2 Series User manual

Operation and Maintenance Manual

Pickup Broom

Series 2

888-376-7027 | BlueDiamondAttachments.com

Register your

WARRANTY

within 30 days

of purchase

60” – 116512

72” – 116517

84” – 116522

96” – 116527

G B – 116555

Blue Diamond® Attachments2

Thank you for your decision to purchase a Blue Dia-

mond® Series 2 Pickup Broom. To ensure maximum

performance of your equipment, it is mandatory that you

thoroughly study the Operator’s manual and follow the

recommendations. Proper operation and maintenance

are essential to maximize equipment life and prevent

personal injury.

Operate and maintain this equipment in a safe man-

ner and in accordance with all applicable local, state,

and federal codes, regulations and /or laws. Follow all

on-product labeling and instructions.

Make sure that all personnel have read this Operator’s

Manual and thoroughly understand safe and correct

operating, installation and maintenance procedures.

Blue Diamond is continually working to improve its

products. Blue Diamond reserves the right to make any

improvements or changes as deemed practical and pos-

sible without incurring any responsibility or obligation

to make any changes or additions to equipment sold

previously.

Although great care has been taken to ensure the

accuracy of this publication, Blue Diamond makes no

warranty or guarantee of any kind, written or expressed,

implied or otherwise with regard to the information

contained within this manual. Blue Diamond assumes

no responsibility for any errors that may appear in this

manual and shall not be liable under any circumstances

for incidental, consequential or punitive damages in con-

nection with, or arising from the use of this manual.

Keep this manual available for frequent reference. All

new operators or owners must review the manual before

using the equipment and annually thereafter. Contact

your Blue Diamond Attachments Dealer for assistance,

information, or additional copies of the manual. Contact

www.bluediamondattachments.com or call 888-376-

7027 for a complete list of dealers in your area.

Serial Number Location:

Please record attachment information in the space pro-

vided for future reference.

Model Number:_____________________________

Serial Number: _____________________________

Dealer Name: ______________________________

Dealer Number:_____________________________

Date of Purchase:___________________________

The serial number plate is located on the right side, just

forward of the attachment mounting plate.

Always use your serial number when requesting infor-

mation or when ordering parts.

NOTE: The directions left, right, front and rear, as

mentioned throughout this manual, are as viewed from

the operator’s position.

Introduction: Owner Information

Revision Date: 11.09.2022

3Blue Diamond® Attachments

Table of Contents

1. Safety ............................................................................................4-5

1.1 General Safety Information......................................................4

1.2 Qualified Operators................................................................. 5

1.3 Mandatory Safety Shutdown Procedure ............................ 5

2. Operation ....................................................................................6-8

2.1 Setup........................................................................................... 6

2.2 Operating Tips..........................................................................7

3. Maintenance ............................................................................. 9-10

3.1 General....................................................................................... 9

3.2 Lubrication................................................................................ 9

3.3 Checking & Adjusting Broom Pattern................................. 9

3.4 Broom Wafers .........................................................................10

3.5 Removing and Replacing Motor .........................................10

3.6 Removing and Replacing Bearing......................................10

4. Parts...........................................................................................11-24

4.1 Main Parts Breakdown ............................................................11

4.2 Main Hood Breakdown.........................................................13

4.3 Adjustments ............................................................................15

4.4 Stopping and Disconnecting...............................................16

4.5 Transporting............................................................................ 17

4.6 Start Up ....................................................................................18

4.7 Operation Instructions...........................................................19

4.8 Adjustments ............................................................................21

4.9 Stopping and Disconnecting..............................................22

4.10 Transporting.......................................................................... 24

5. Specifications ..............................................................................25

5.1 Torque Specifications............................................................25

6. Warranty ....................................................................................... 27

Blue Diamond® Attachments4

1.1 General Safety Information • Read and follow instructions in this manual

and the machine’s Operators Manual before

operating.

• The manual must always remain with the

machine. In case of loss or damage, request

a new copy from your dealer or from Blue

Diamond.

• Strictly follow all rules prescribed by the safety

pictograms/decals applied to the machine.

Ensure that all safety pictograms/decals are

legible. If pictograms/decals are worn, they

must be replaced with new ones obtained

from Blue Diamond and placed in the position

indicated by this manual.

• Pay maximum attention to avoid any accidental

contact with rotating parts of the machine.

• During operation, adjustment, maintenance,

repairing, or transportation of the machine, the

operator must always use appropriate Personal

Protective Equipment (PPE) including but not

limited to safety glasses, gloves, and hearing

protection.

• Do not operate the attachment or machine

while wearing loose fitting clothing that can be

entangled or caught in parts of the machine.

• Do not operate the implement when tired, not

in good condition, or under the influence of

alcohol or drugs.

Entering and Leaving the Operator’s

Position

Get on or o the loader only at locations equipped

with hand holds and steps. Keep the steps and

handholds clean and inspect for damage. Make

necessary repairs as needed.

Maintain 3 point contact and face the loader and

attachment when entering and leaving.

DO NOT get on a moving or operating loader or

attachment.

NEVER jump on or o a running loader or

attachment.

1. Safety

CAUTION

The signal word CAUTION on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

WARNING

The signal word WARNING on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

The signal word DANGER on the machine and in

the manuals indicates a hazardous situation which,

if not avoided, will result in death or serious injury.

SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL identifies important

safety messages on the equipment and in the

owner’s manual. When you see this symbol, be

alert to the possibility of personal injury and

carefully read the message that follows.

IMPORTANT

The signal word IMPORTANT identifies procedures

which must be followed to avoid damage to the

machine.

5Blue Diamond® Attachments

1.2 Qualified Operators

Safe Operation Needs Qualified Operators

Operator Training

• Check the rules and regulations at your

location. The rules may include an employer’s

work safety requirements. Regulations may

apply to local driving requirements or use

of a Slow Moving Vehicle (SMV) emblem.

Regulations may identify a hazard such as a

utility line.

• The new operator must start in an area without

bystanders and use all the controls until he or

she can operate the machine safely under all

conditions of the work area.

1.3 Mandatory Safety

Shutdown Procedure

BEFORE cleaning, adjusting, lubricating,

or servicing this unit, ALWAYS follow the

MANDATORY SAFETY SHUTDOWN PROCEDURE:

1. Lower loader arms and roll attachment forward

until it is flat on level ground.

2. Apply loader parking brake and stop the loader

engine.

3. Cycle controls to relieve pressure within the

auxiliary hydraulics lines.

4. Remove loader key and keep with you while

working on the attachment.

5. Disconnect auxiliary hydraulic lines from

loader.

1. Safety

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators can

cause serious injury or death.

For an operator to be qualified, he or she must

not use drugs or alcoholic drinks which impair

alertness or coordination while working. An

operator who is taking prescription drugs must

get medical advice to determine if he or she can

safely operate a machine and the equipment.

DANGER WARNING

Before operating this equipment, read and

understand all information in this manual and

the machine operator’s manual. Each individual

working with the equipment should be familiar

with all safety precautions.

WARNING

Failure to follow the safety procedures before

cleaning, adjusting, lubricating, or servicing this

unit could result in serious injury or death.

Blue Diamond® Attachments6

2.1 Setup

Although the broom attachment is supplied

fully assembled, some simple checks should be

performed before operation begins.

Safety Decals

The safety decals existing on the attachment

should be clearly readable and always followed.

Hydraulic Couplers

The broom may have been shipped without the

required hydraulic quick couplers. Obtain the

correct brand and size and install them on the

hoses.

Hoses / Fittings

Hydraulic fittings are used to connect all

attachment hoses. All fittings should be tight

and free of leaks. Hoses must be free of crimps

or cuts that might result in leakage. Check your

attachment before operation to make sure all hose

routings are kink-free and allow for movement

during the sweeping and dumping operations.

Wire Harness

The wiring harness to the optional water spray

kit pump should be routed to prevent catching

or pinching during the sweeping and dumping

operations.

Connecting Attachment to the Machine

To attach the broom to the loader:

1. Start the loader engine and rotate the coupler

out. Retract the coupler pins.

2. Move the loader forward and align the coupler

between the outer mounting bracket plates.

Pick up the attachment with the top bar.

3. Rotate the attachment back and engage

the coupler pins. Ensure coupler pins are

completely down and engaged. Always refer to

operating instructions in the skid steer manual.

4. Engage loader parking brake and stop the

engine. Cycle the controls to remove pressure

in the auxiliary hydraulic lines. Exit loader.

5. Clean quick couplers if dirty. Connect hydraulic

hoses to the skid steer quick couplers.

NOTE: While attachment is on the ground, visually

inspect quick coupler to ensure pins are extended.

6. Connect the wiring harness.

Safe Broom Operation

• Always follow the safety and operating

information in this manual.

• Only operate the attachment from the seat of

the loader.

• Always follow the weight limitations of the

loader.

• Do not remove guards and shields.

• Do not sweep near or toward people, vehicles,

or buildings that may be injured or damaged

by flying debris.

• Wear eye protection around the attachment.

• Carry the attachment low to the ground.

• DO NOT carry passengers.

2. Operation

WARNING

The following precautions must be observed for

the safety of the operator and bystanders.

WARNING

Never crawl under raised loader arms or

attachment.

7Blue Diamond® Attachments

2.2 Operating Tips

Sweeping

Only use broom on compatible loaders. Loader

flow must not exceed 25 gallons per minute. DO

NOT USE high flow hydraulics. Loader relief

pressure must not exceed 3500 PSI. Consult

loader manual for flow and pressure specifications.

Do not engage the broom hydraulics with the

loader engine at high speed. Engage hydraulics at

low engine speed and gradually increase engine

speed.

Do not reverse sweeping direction without

stopping broom hydraulics.

Limit forward and reverse travel speed to 5 mph.

Adjust brush to give a 2”- 4” wide pattern. (See

maintenance section)

Adjust rubber front and side skirts to be within 1/2”

of the ground.

Slow down in heavy material. Allow time for the

broom to sweep.

Avoid excessive down pressure on the broom.

Carry bucket so bolt-on edge is 1” above ground

line. Bucket should not contact ground, only

broom.

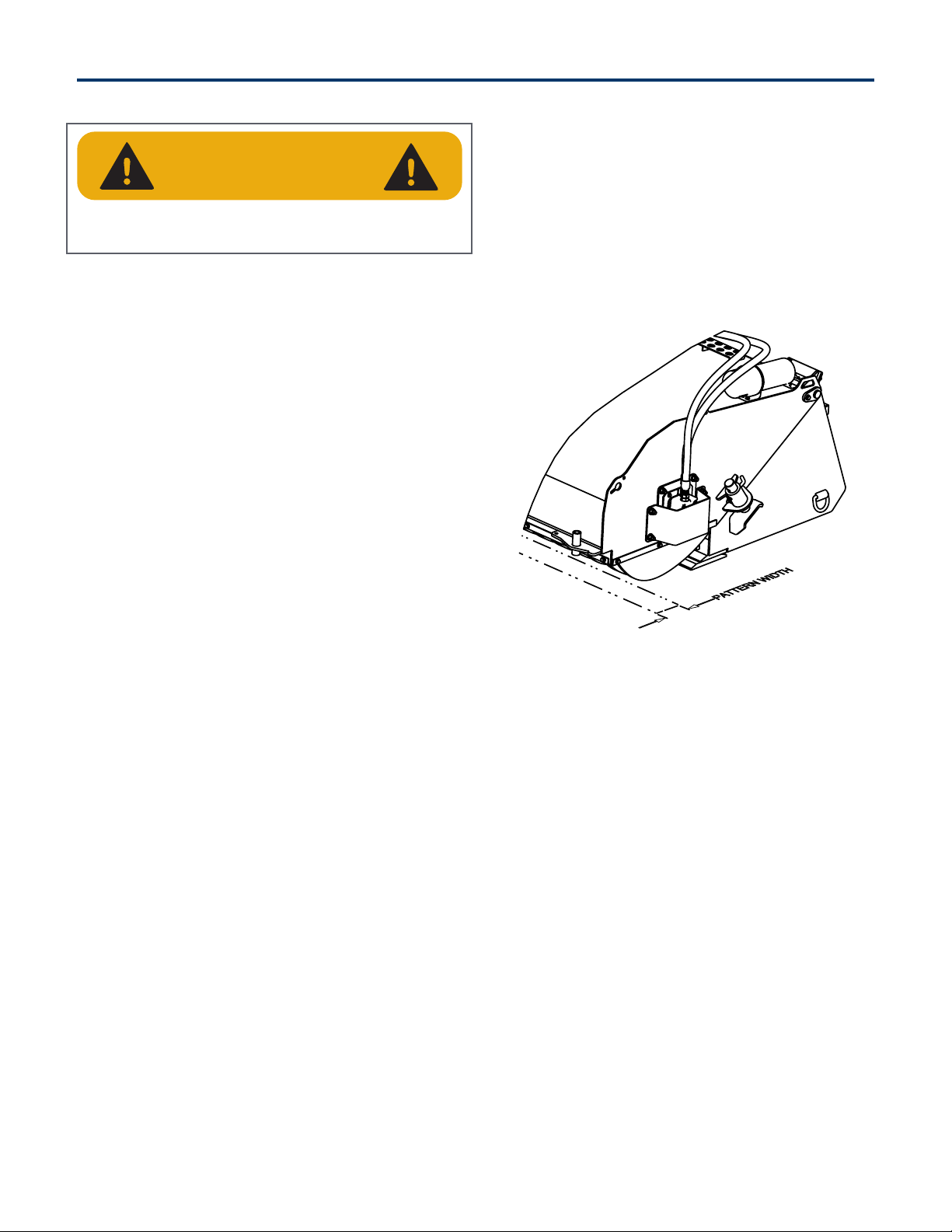

When sweeping forward, rotate the brush so

material is pushed away from the loader and over

the broom into the bucket. See Figure 1.

Figure 1

When sweeping backward, rotate the brush so

material is pushed toward the loader and into the

bucket. See Figure 2.

Figure 2

Dumping

STAY AWAY FROM POWER LINES.

Always check clearances before lifting broom.

Carry loaded bucket low to dump site.

Raise bucket slowly to the required dump height,

roll broom forward to dump bucket.

Optional Water Kit

Check the strainer bowl daily for dirt and debris.

This debris can plug the nozzles.

Check nozzles daily for debris. Remove and clean

plugged nozzles.

2. Operation

TRAVEL

BRUSH

DIRECTION

ROTATION

TRAVEL

BRUSH

DIRECTION

ROTATION

WARNING

The following precautions must be observed for

the safety of the operator and bystanders.

Blue Diamond® Attachments8

2.2 Operating Tips Cont’d

Optional Gutter Brush Kit

Only use gutter brush in forward direction.

Adjust height using retention chain so the gutter

brush bristle tips are touching the ground.

When not in use for a short period of time, raise

the gutter brush 1 – 2” above the ground with the

retention chain. Use the shut–o valve to stop

bristle rotation when the gutter brush is raised.

When not in use for long periods of time, remove

the gutter brush and connect the primary broom

motor directly to the loader hydraulics.

Storage

Follow the loader manufacturer’s instructions to

remove the broom attachment.

DO NOT store the polypropylene brush wafers in

direct sun light. The material can deteriorate.

Raise broom housing and take weight o of broom

wafers. Store broom with bucket stop pins in the

lowest position to relieve ground pressure on

broom core.

2. Operation

9Blue Diamond® Attachments

3.1 General

Proper maintenance of the attachment will result

in longer life and more productive and cost

eective operation. There are two basic categories

of maintenance, lubrication, and broom wafer

maintenance.

3.2 Lubrication

Grease the following lube points weekly. Lubricate

all grease zerks with an EP Lithium NLGL No. 2

grade grease. One example is Mobilux EP2.

• Broom shaft bearing zerk. This zerk is located

on the right side of the broom shroud. It can be

accessed through the wafers.

• Broom shroud pivot zerks. These two zerks

are located at the top rear of each side of the

bucket and should be greased weekly.

• Right side bearing. These two zerks are

located on the bearing located on the right

side of the broom. Grease either of the two

zerks, both do not need to be greased.

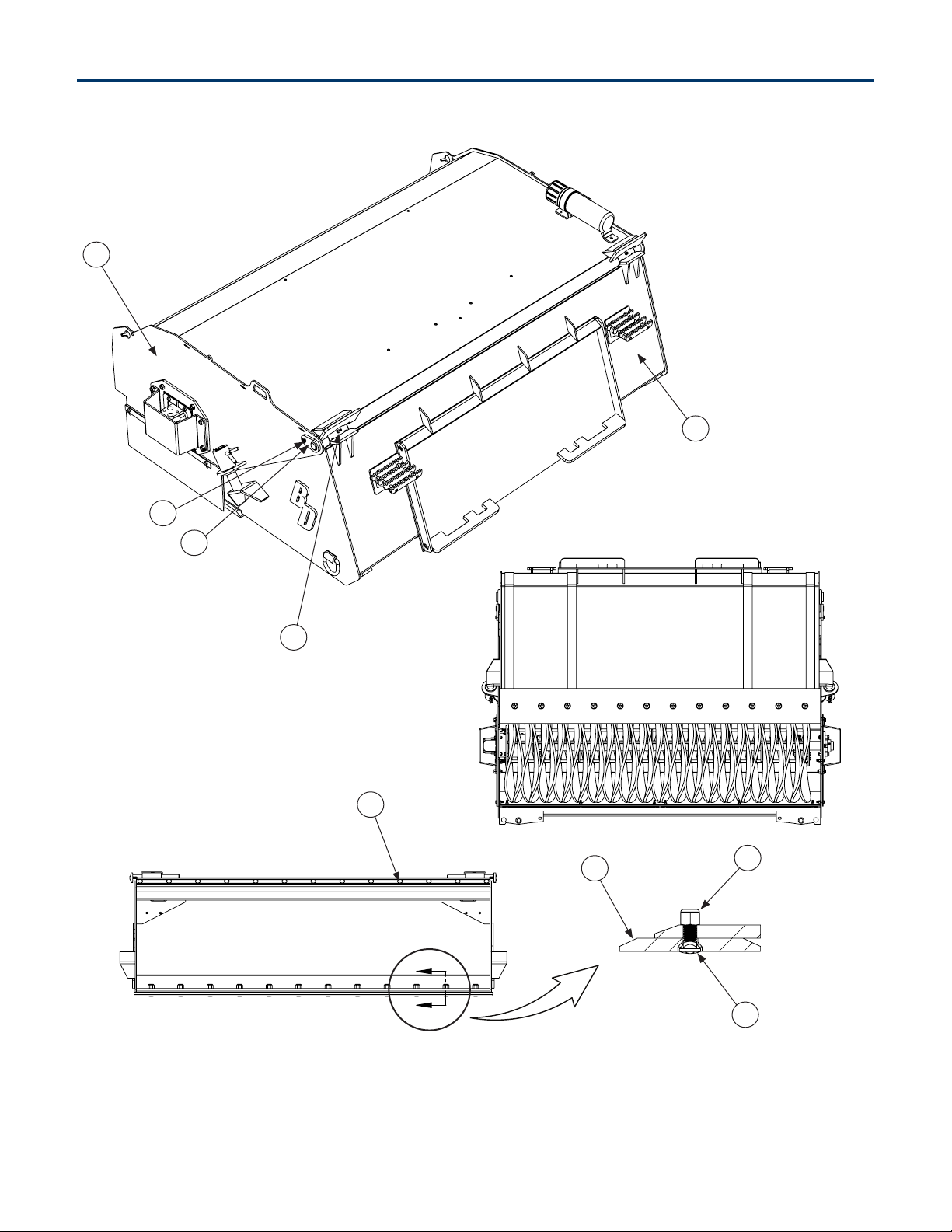

3.3 Checking and Adjusting

Broom Pattern

The brush pattern should be checked and adjusted

every 8 hours or daily. To check and adjust pattern:

1. Move the broom to a dusty flat surface.

2. With the loader at low throttle, start the broom

motor.

3. Slowly lower the broom until it is in the

operating position. (bolt-on edge is 1” o of

ground).

4. Keep the broom in this position for 10 seconds.

Do not move loader.

5. Raise broom, stop the broom motor, and move

the loader back several feet. Lower broom to

ground, set loader brake and exit loader.

6. Measure pattern width left by broom. Pattern

should be 2”–4” wide.

7. To adjust pattern, carefully prop up the broom

shroud assembly. Remove the two bent leg

pins.

8. Move the two stop pins to a dierent hole

location and replace the two bent pins. To

widen the pattern move the stop pins up; to

narrow the pattern move the stop pins down.

See Figure 3.

Figure 3

3. Maintenance

WARNING

The following precautions must be observed for

the safety of the operator and bystanders.

Blue Diamond® Attachments10

3.4 Broom Wafers

Removing Broom Wafers

See parts diagram for pictures.

1. Place broom on ground and perform

mandatory shutdown procedure (see section

1.3 Mandatory Safety Shutdown Procedure on

page 3).

2. Remove side rubber skirt retainers.

3. Remove motor guard hardware and motor

guard plate.

4. Remove bearing guard hardware and bearing

guard plate.

5. Remove motor plate to broom housing

hardware and remove motor subassembly.

6. Remove bearing plate to broom housing

hardware.

7. Using hoist, raise broom housing o of broom

core. Roll broom core away from bucket.

8. Remove end retainer from one broom

core

end

.

9. Remove wafers.

Replacing Broom Wafers

See parts diagram for pictures.

1. Place broom drum on end with one retaining

plate assembled. Place retaining plate on ground

.

2. Install a new wafer making sure wafer retention

pins are trapped on broom drum bar.

3. Install more wafers. Alternate steel and poly

wafers if using both types. The retention pins

on consecutive wafers should alternate 180°

and be trapped by opposite bars.

4. Install last wafer and install broom drum

retaining plate. Carefully lay the core on its side

.

5. Move core under broom housing and lower

housing on core.

6. Replace bearing plate and motor plate

hardware. Tighten hardware.

7. Replace motor and bearing guard plates and

hardware. Tighten hardware.

8. Reinstall rubber skirting and side skirting

retainers.

9. Tighten hardware.

3.5 Removing and Replacing

Motor

See parts diagram for pictures.

1. Place broom the ground and perform

mandatory shutdown procedure (see section

1.3 Mandatory Safety Shutdown Procedure on

page 3).

2. Remove left side rubber skirt retainer.

3. Remove and cap motor hoses.

4. Remove motor guard hardware and motor

guard plate.

5. Remove motor subassembly from broom

housing.

6. Remove coupler bolt and loosen coupler set

screw. Remove coupler from motor shaft.

7. Remove motor gasket plate hardware, gasket

plates, and gasket.

8. Remove motor can hardware and remove motor.

9. Reassemble in reverse order.

3.6 Removing and Replacing

Bearing

See parts diagram for pictures.

1. Place broom the ground and perform

mandatory shutdown procedure (see section

1.3 Mandatory Safety Shutdown Procedure on

page 3).

2. Remove right side rubber skirt retainer.

3. Remove bearing guard hardware and bearing

guard plate.

4. Remove bearing plate to broom housing

hardware.

5. Loosen bearing lock collar with a drift punch

and hammer. Counter clockwise loosens collar.

6. Remove bearing and bearing plate.

7. Remove bearing plate to bearing hardware to

remove bearing.

8. Reassemble in reverse order. To tighten

bearing lock collar, use hammer and drive

punch. Clockwise movement tightens collar.

3. Maintenance

11Blue Diamond® Attachments

4. Parts

4.1 Main Parts Breakdown

2

5

4

3

1

9

8

6

7

Blue Diamond® Attachments12

ITEM PART NUMBER DESCRIPTION QTY 60”

316580

QTY 72”

316538

QTY 84”

316586

QTY 96”

316589

1

216370-60

Bucket Weldment - 60" 1 — — —

216380-60*

216370-72

Bucket Weldment - 72" — 1 — —

216380-72*

216370-84

Bucket Weldment - 84" — — 1 —

216380-84*

216370-96

Bucket Weldment - 96" — — — 1

216380-96*

2

216371-60

Hood Weldment - 60" 1 — — —

216381-60*

216371-72

Hood Weldment - 72" — 1 — —

216381-72*

216371-84

Hood Weldment - 84" — — 1 —

216381-84*

216371-96

Hood Weldment - 96" — — — 1

216381-96*

3 216465 Hood Pivot Pin 2 2 2 2

4 299426 3/8 x 1 1/4" Bolt 2 2 2 2

5

299016 Pivot Grease Fitting 2 2 2 2

297005*Pivot Grease Fitting 2 2 2 2

6

216560 Bolt-On Edge - 60" 1 — — —

216562 Bolt-On Edge - 72" — 1 — —

216564 Bolt-On Edge - 84" — — 1 —

216566 Bolt-On Edge - 96" — — — 1

7 216570 3/4 x 2" Plow Bolt 10 12 14 16

8 299657 3/4" Nylock Nut 10 12 14 16

9 216375 Black Push-In Rivets for 3/8" Hole 11 13 15 17

*For serial numbers 144361, 151397, 151398, 151839-151844, 153113

4.1 Main Parts Breakdown Cont’d

4. Parts

13Blue Diamond® Attachments

4. Parts

4.2 Main Hood Breakdown

8

20

4

54

11 2

3

6

7

109

1

Blue Diamond® Attachments14

ITEM PART NUMBER DESCRIPTION QTY 60”

316580

QTY 72”

316538

QTY 84”

316586

QTY 96”

316589

1

216371-60

Hood Weldment - 60" 1 — — —

216381-60*

216371-72

Hood Weldment - 72" — 1 — —

216381-72*

216371-84

Hood Weldment - 84" — — 1 —

216381-84*

216371-96

Hood Weldment - 96" — — — 1

216381-96*

2 216450 Side Skirt Retainer Plate 2 2 2 2

3 216451 Side Skirt 2 2 2 2

4

216452 Front Skirt Retainer Plate - 60" 2 2 2 2

216454 Front Skirt Retainer Plate - 72" 2 2 2 2

216456 Front Skirt Retainer Plate - 84" 2 2 2 2

216458 Front Skirt Retainer Plate - 96" 2 2 2 2

5

216453 Front Skirt - 60" 1 1 1 1

216455 Front Skirt - 72" 1 1 1 1

216457 Front Skirt - 84" 1 1 1 1

216459 Front Skirt - 96" 1 1 1 1

6 216462 Pivot Stop Pin 2 2 2 2

7 216573 Bent Pull Clevis Pin 2 2 2 2

8 299423 Hood bolts - 3/8 x 1" 7 7 7 7

9 299426 Skirt Bolt - 3/8 x 1.25" 12 12 14 14

10 299724 Skirt Washer 12 12 14 14

11 299625 Skirt nut - 3/8" Nylock 12 12 14 14

*For serial numbers 144361, 151397, 151398, 151839-151844, 153113

4.2 Main Hood Breakdown Cont’d

4. Parts

15Blue Diamond® Attachments

4. Parts

ITEM PART NUMBER DESCRIPTION QTY

1

216372 Cover - Square Bearing 1

216382*Cover - Round Bearing 1

2

216373 Bearing Mount Plate - Square Bearing 1

216383*Bearing Mount Plate - Round Bearing 1

3

216590 Bearing - Square 1

216479*Bearing - Round 1

4

109177 Bearing Nuts - Square Bearing - 5/8" Stover 4

299618*Bearing Nuts - Round Bearing - 1/2" Nylock 4

5

299432 Cover Bolts - Square Bearing - 1/2 x 1.5" 4

299439*Cover Bolts - Round Bearing - 1/2 x 1.75" 4

6

299440 Bearing Bolts - Square Bearing - 5/8 x 1.75" 4

299433-2.25*Bearing Bolts - Round Bearing - 1/2 x 2.25" 4

*For serial numbers 144361, 151397, 151398, 151839-151844, 153113

4.3 Bearing Mount Breakdown

5

1

6

3

2

4

Blue Diamond® Attachments16

4. Parts

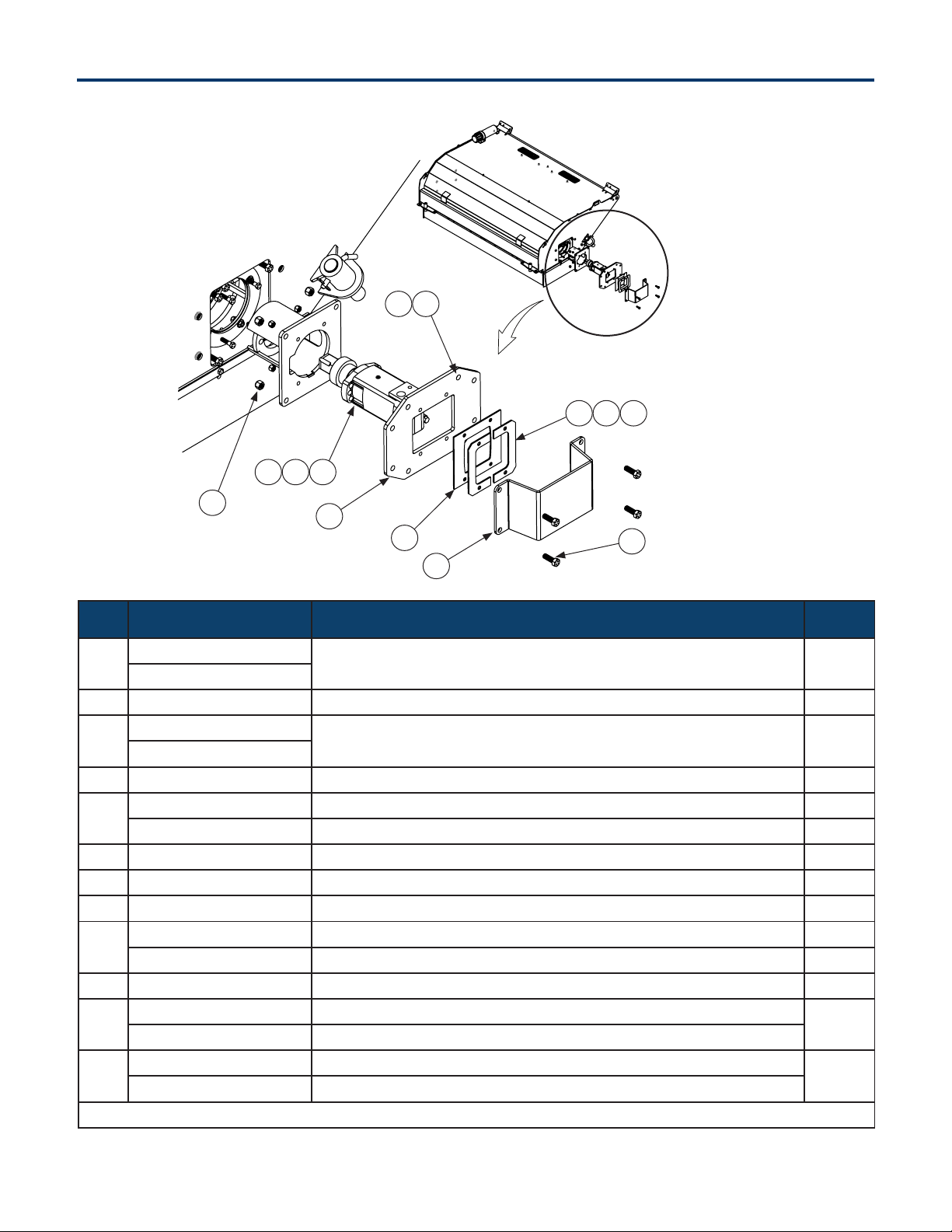

ITEM PART NUMBER DESCRIPTION QTY

1

216374

Left Side Motor Mount Plate 1

216384*

2 216377 Rubber Cover Retaining Plate 2

3

216372

Motor Cover 1

216382*

4 216376 Rubber Motor Cover 1

5

299432 Motor Cover Bolts - 1/2 x 1.5" 4

299439*Motor Cover Bolts - 1/2 x 1.75" 4

6 299618 Motor Mount Nut - 1/2" Nylock 2

7 299487 Rubber Motor Cover Bolts - 3/8 x 1.5" 4

8 299625 Rubber Motor Cover Nuts - 3/8" Nylock 4

9

299433 Motor Mount Bolt - 1/2 x 2" 2

299433-2.25*Motor Mount Bolt - 1/2 x 2.25" 2

10 See "Motor Assembly" Motor Assembly 1

11

299487 Motor Coupler Bolts - 3/8 x 1.5"

4

299439*Motor Coupler Bolts - 1/2 x 1.75"

12

299625 Motor Coupler Nuts - 3/8 Nylock

4

299618*Motor Coupler Nuts - 1/2 Nylock

*For serial numbers 144361, 151397, 151398, 151839-151844, 153113

4.4 Motor Mount Breakdown

12

1

11

72 8

910 6

12

4

3

5

17Blue Diamond® Attachments

4. Parts

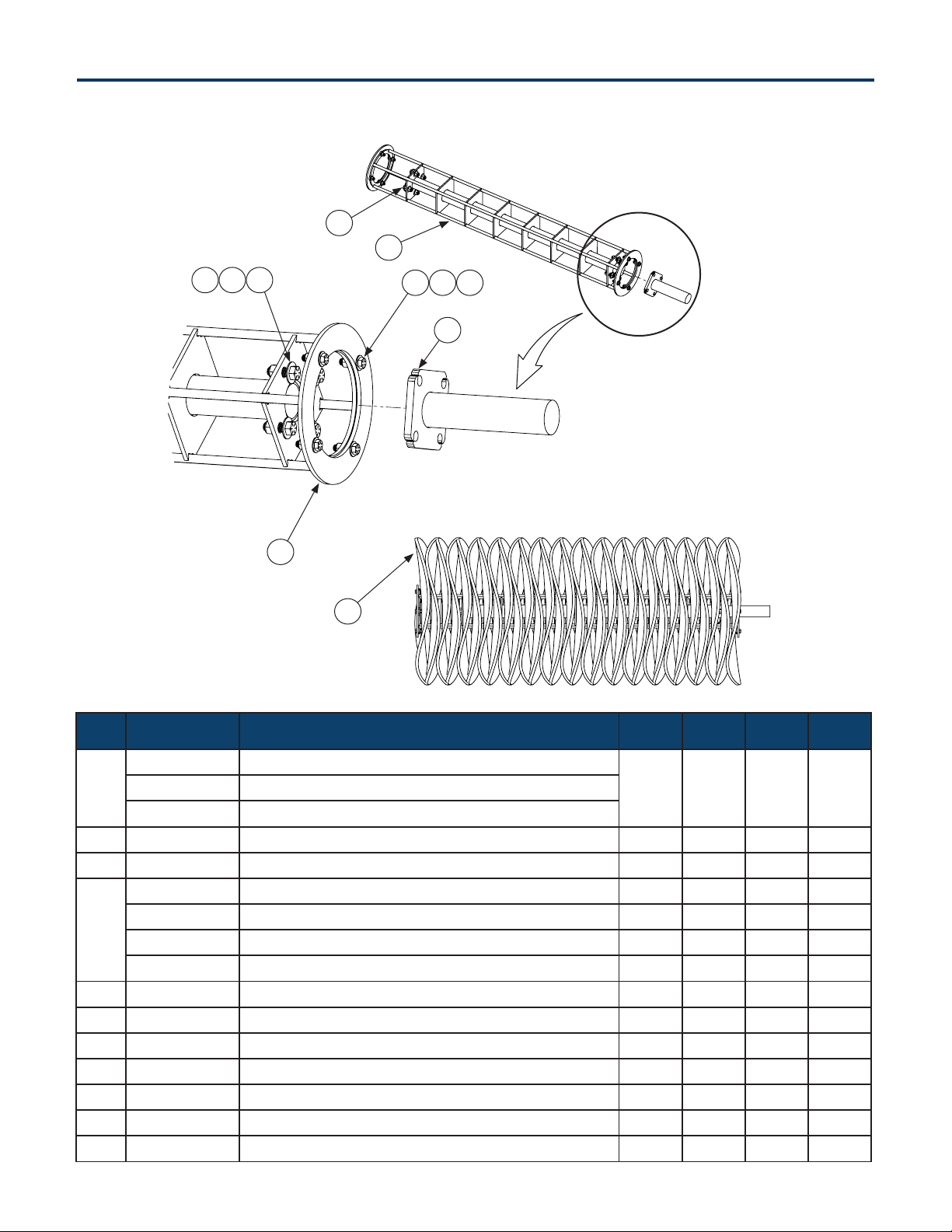

ITEM PART NUMBER DESCRIPTION QTY 60”

316580

QTY 72”

316538

QTY 84”

316586

QTY 96”

316589

1

216415 Wafer - Poly

31 37 43 49216410 Wafer - Steel

216417 Wafer - Poly/Steel

2 216478 Motor to Shaft Flange 1 1 1 1

3 216480 Drum to Bearing Shaft and Flange 1 1 1 1

4

216481 Drum Shaft - 60" 1 — — —

216482 Drum Shaft - 72" — 1 — —

216483 Drum Shaft - 84" — — 1 —

216484 Drum Shaft - 96" — — — 1

5 216378 Bristle Retaining Ring 1 1 1 1

6 299426 Retaining Ring Bolts - 3/8 x 1.25" 8 8 8 8

7 299625 Retaining Ring Nuts - 3/8" Nylock 8 8 8 8

8 299724 Retaining Ring Washers 16 16 16 16

9 299432 Flange Bolts - 1/2 x 1.5" 8 8 8 8

10 299618 Flange Nuts 1/2" Nylock 8 8 8 8

11 299732 Flange Washers 16 16 16 16

4.5 Drum Shaft Breakdown

2

4

5

3

6

11

1

7 8

109

Blue Diamond® Attachments18

4. Parts

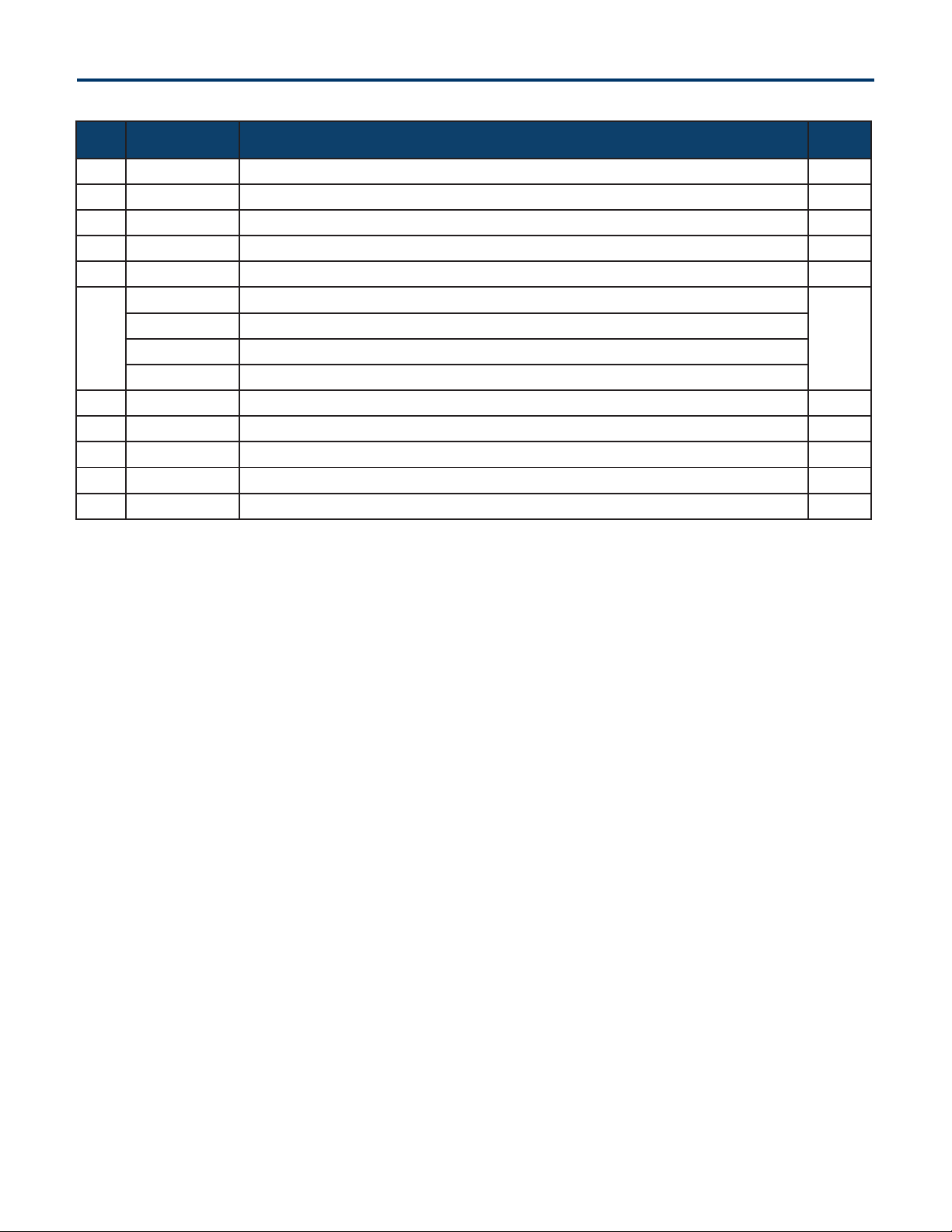

ITEM PART NUMBER DESCRIPTION QTY

1

216421-2

Motor Shaft Coupler

1

216386*1

2

216425

Motor

1

216385*1

3

299724

Motor Coupler Washer

1

N/A*—

4 299447 Motor Coupler Bolt - 3/8 x 4" 1

*For serial numbers 144361, 151397, 151398, 151839-151844, 153113

4.6 Motor Assembly

2

1

3

4

19Blue Diamond® Attachments

4. Parts

4.7 Water Kit Breakdown

5

3

2

4

8 1

10

96

7

316571 60” Water Kit

316573 72” Water Kit

316576 84” Water Kit

316579 96” Water Kit

Blue Diamond® Attachments20

4. Parts

4.7 Water Kit Breakdown Cont’d

ITEM PART NUMBER DESCRIPTION QTY

1 216673 Pump Mount Bracket 1

2 216539 Pump Hood 1

3 216540 Pump 1

4 216650 Pub Tank 1

5 216655 Tank Strap 2

6

316580 60” Spray Bar Kit

1

316583 72” Spray Bar Kit

316586 84” Spray Bar Kit

316589 96” Spray Bar Kit

7 116555 Gutter Brush Assembly 1

8 299426 Hex Bolt-Grade 8-3/8-16 X 1 2

9 299625 Grade 8 Locknut 3/8-16 2

10 299725 Washer 3/8 2

NS 216688 1/2 Water Hose (per foot) 9

Other manuals for PICKUP BROOM 2 Series

1

This manual suits for next models

5

Table of contents

Popular Floor Machine manuals by other brands

Ghibli & Wirbel

Ghibli & Wirbel S-TEAM 6 V instruction manual

Kunzle & Tasin

Kunzle & Tasin NEW GOLIA PLUS S User & maintenance manual

Nilfisk-Advance

Nilfisk-Advance Clarke SA40 Instructions for use

Century 400

Century 400 Ninja 411-222MO operating instructions

Tennant

Tennant T3 Operator's manual

Powr-Flite

Powr-Flite PAS20BA Operators manual & parts lists