4

L.P. GAS CYLINDER

Gas cylinders manufactured today have mechanisms to provide worry

free barbequing year round:

Q.C.C.1 or Type 1-Quick Connect Coupling Valve, ensure fast tank hook-

ups requiring only hand tightening. The redundant valve system inhibits

the flow of gas to the burner if the connection is not 100% correct.

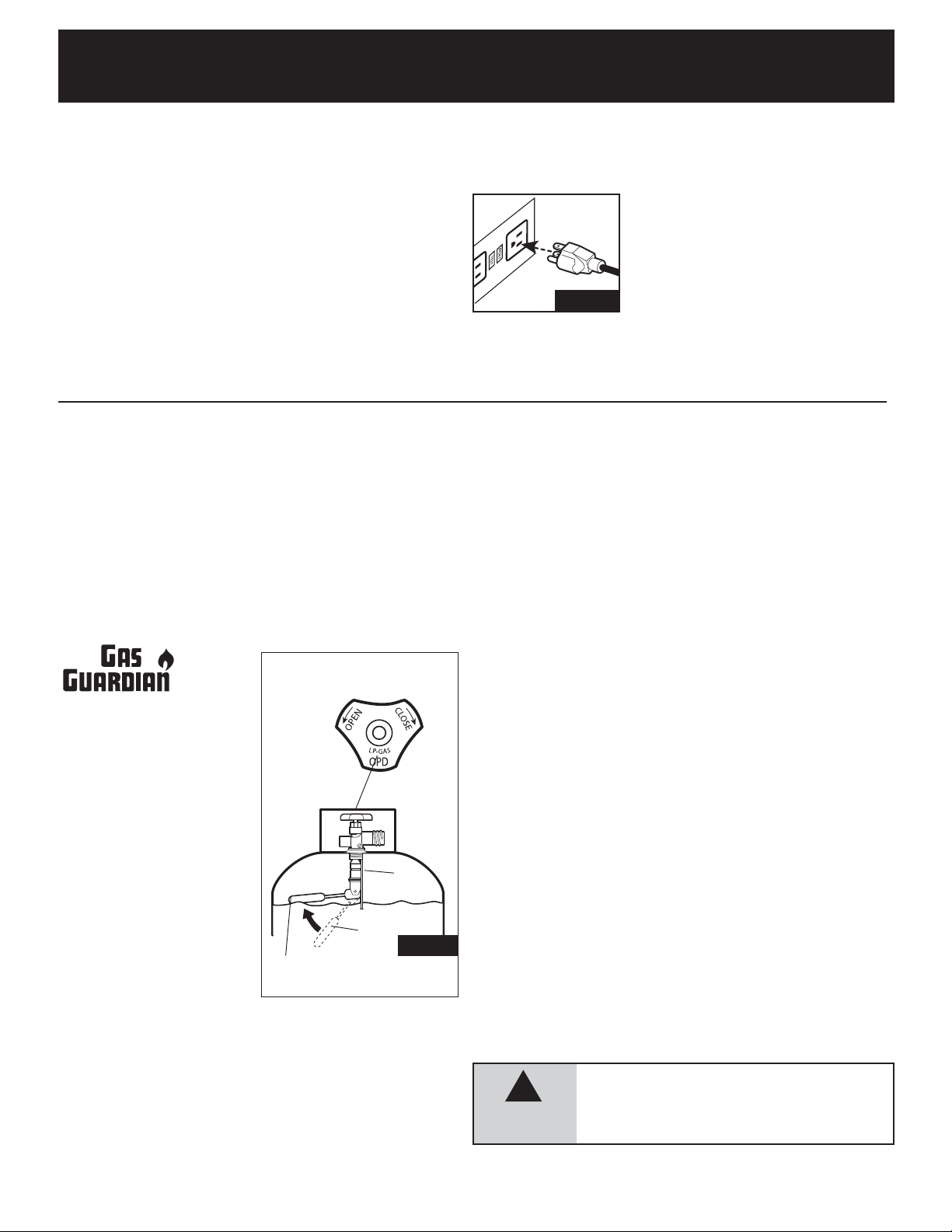

O.P.D. or Overfill Protection Device prevents accidental gas leaks

caused by cylinder “over pressurization”, the leading cause of cylinder

gas leaks. The float in the tank will automatically stop filling at 80%

capacity, leaving a 20% area for the expansion of liquid. Without this safety

feature, the relief valve may open and discharge propane, creating a

potential safety hazard. An O.P.D. cylinder is easily distinguished by its

triangular hand wheel valve. Figure 3)

Look for the Gas Guardian symbol

to easily identify propane cylinders

with these safety features.

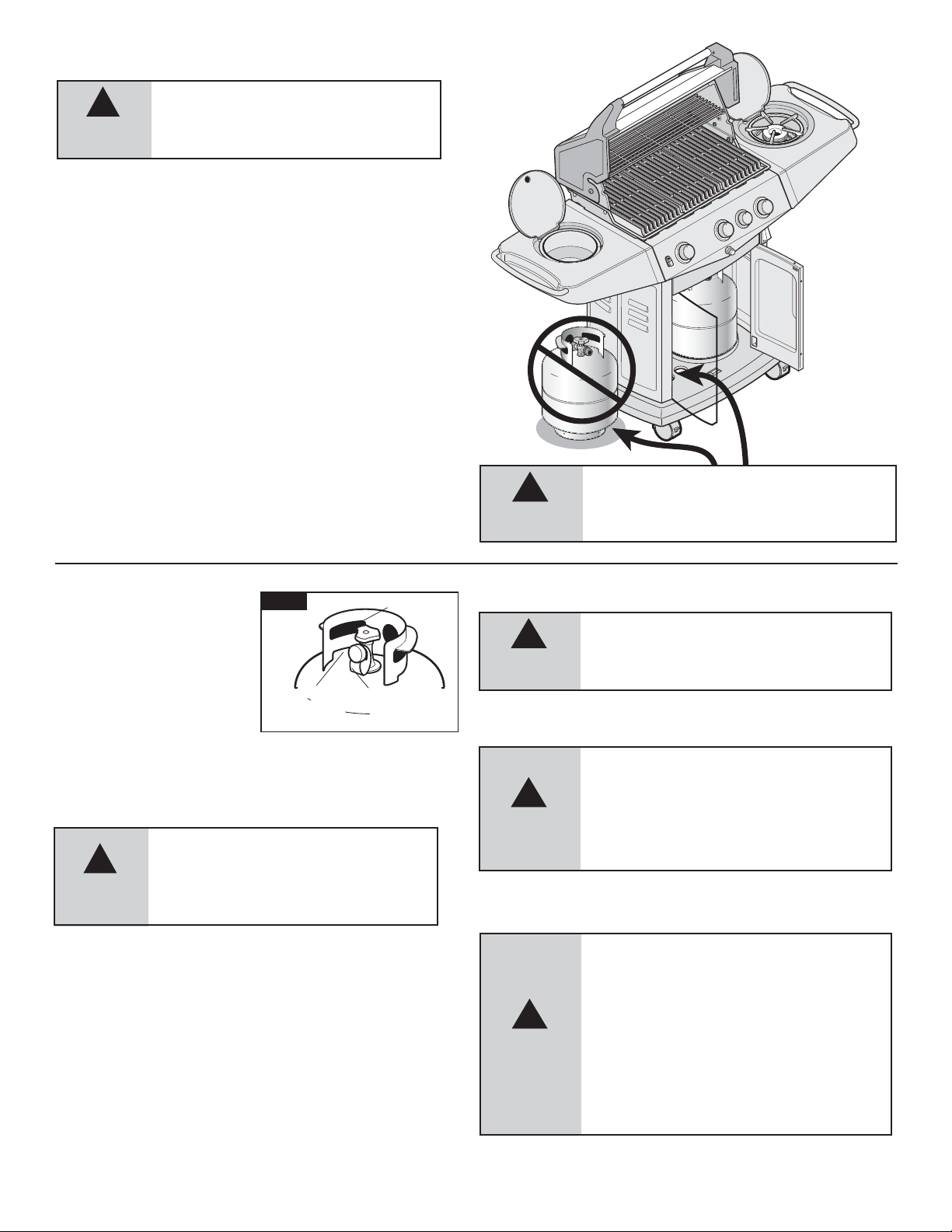

1. SPECIFICATIONS

Self-contained propane gas

barbeque systems are designed to

be used only with a 9.1 kg (20 lb)

propane cylinder, equipped with a

Type 1 cylinder valve and

incorporating an overfill protection

device (O.P.D). This barbeque

cannot be connected to an existing

#510 P.O.L. type valve (ones with left-

hand threads). The cylinder for your

gas barbeque must be constructed

and marked in accordance with the

specifications of L.P. gas cylinders:

In Canada: The National Standards of Canada CAN/CSA-B339,

Cylinders, Spheres and Tubes for Transportation of Dangerous Goods;

and Commission.

In the U.S.: U.S. Department of Transportation (D.O.T.)

DO NOT CONNECT TO A PROPANE GAS CYLINDER EXCEEDING THIS

CAPACITY, OR USE A CYLINDER WITH ANY OTHER TYPE OF VALVE

CONNECTION DEVICE. The Type 1 valve is recognizable by the large

FILLING STOPS AT 80%

NEW OPD

HANDWHEEL

Fig. 3

O.P.D.

FLOAT

SAFETY:

• Always turn off the cylinder valve tightly when your barbeque is not in use.

• Handle tank valves with care.

• Never connect an unregulated L.P. gas cylinder to your barbeque.

• Never store a spare cylinder under or near your barbeque when in use.

• Never subject any cylinder to excessive heat or direct sunlight.

• Always keep your in-use cylinder securely fastened in an upright position.

• Do not insert any foreign objects into the valve outlet. You may damage

the back-check. A damaged back-check can be the source of a leak. Leaking

propane may result in explosion, fire, severe personal injury or death.

• Never fill the cylinder beyond 80% full.

external thread on the outlet part of the valve. Standard existing valves do

not have these exterior threads. Any attempt to connect a regulator, with other

than the:

i) Mating Type 1 connector (recognized by the large black coupling nut) or

ii) Standard #510 P.O.L. fitting,

by use of adapters or any other means, could result in damage, fire or injury

and may negate the important safety features designed into the Type 1

system. The connection of a #510 P.O.L. fitting will not provide the flow control

or temperature shut-off features built into the complete Type 1 system.

We strongly recommend use of a propane cylinder with Q.C.C.I and O.P.D.

safety features.

THE CYLINDER MUST ALSO BE EQUIPPED WITH:

a. A shut-off valve terminating in a proper cylinder valve outlet specified in

current standards:

• Canada: CAN/CGA - 1.6a - M98 - Outdoor Gas Grills - Amend.

• U.S.: ANSI Z 21.58a-1998 OUTDOOR COOKING APPLIANCES.

b. A listed overfilling protection device (O.P.D.).

c. A safety relief valve having direct communication with the vapor space of

the cylinder.

d. A collar to protect the tank shut off valve.

e. An arrangement for vapor withdrawal.

f. A bottom ring for securing to tank support assembly.

THE CYLINDER SHOULD NOT EXCEED 472 MM (18 1/2") IN HEIGHT AND 317

MM (12 1/2") IN DIAMETER.

ELECTRICAL CAUTION

• If any accessory installed on this barbeque requires an external

electrical power source, it must be electrically grounded in

accordance with local laws or in the absence of local laws, with

the Canadian Electrical Code CSA C22.1 or in the U.S., with the

National Electrical Code ANSI-NFPA 70.

• The three-prong plug provides protection against shock hazard

and should be plugged directly into a properly grounded

three-prong receptacle. Do not cut or remove the grounding

prong from this plug.

• To ensure continued protection against risk of electric shock,

connect to properly earthed outlets only.

• Ensure all electrical supply cords and fuel supply hoses are

kept well away from any heated surfaces.

CARING FOR YOUR EQUIPMENT

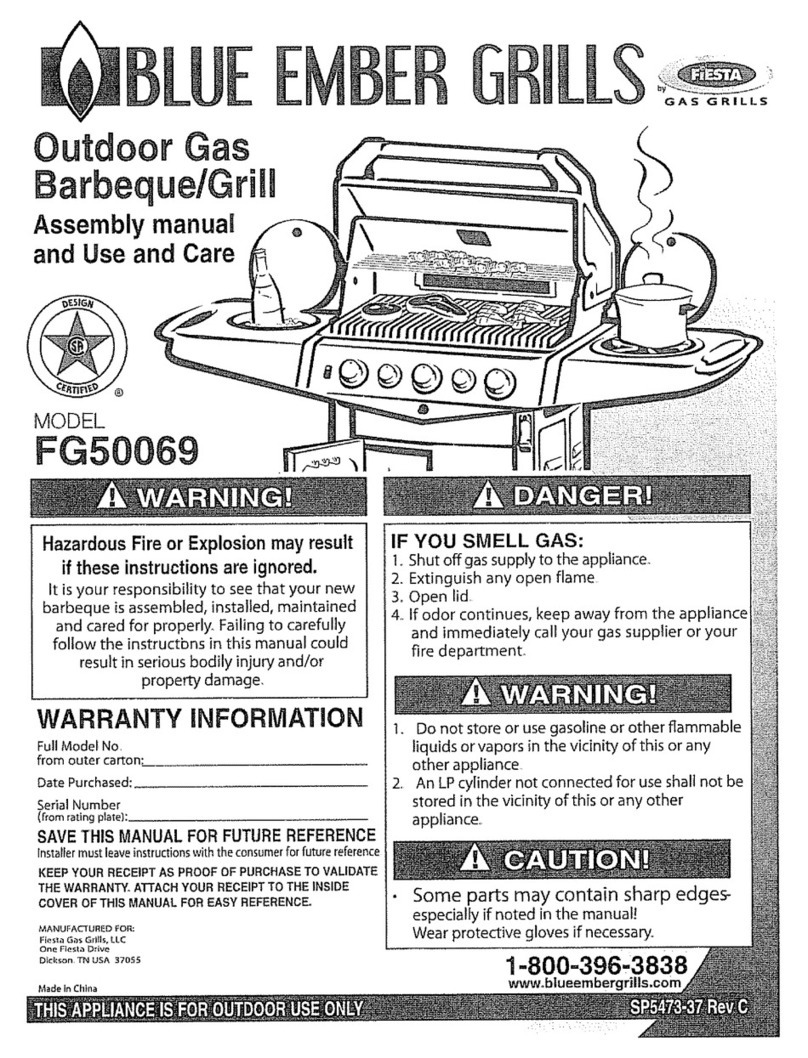

PROVIDING POWER TO YOUR BARBEQUE

To provide power to the barbecue, plug grounded electrical cord into

rear electrical box as shown. (Page 14, Fig.15)

Plug electrical cord into properly grounded

GFI (Ground Fault Interrupt) receptacle. If

use of an extension cord is required, be

sure that it is a minimum 16 AWG, 3 wire

well insulated cord, marked for OUTDOOR

USE ONLY and properly grounded. (Fig.14)

CAUTION: To ensure continued protection against risk of

electric shock, connect to properly earthed outlets only.

Fig. 14

WARNING

!

IF THE ABOVE INSTRUCTIONS

ARE NOT FOLLOWED EXACTLY,

A FIRE CAUSING DEATH OR

SERIOUS INJURY MAY OCCUR.