Blue Ice Azzurri Classico CM632 User manual

Service Manual

Intelligent Fresh Ground Coffee Machine

www.blueicecreammachine.co.uk

English

KLM1601

Service Manual

Intelligent Fresh Ground

Coffee Machine

AZZURRI CLASSICO

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Contents

1. Introduction 4

6

2. Structure

15

3. Troubleshooting

37

4. Repair

2.1 Overview

2.2 Description of internal components

2.3 Water circuit

2.4 Schematic circuit diagram

2.5 Technical data

General warnings

Symbol description

4

5

6

8

9

9

10

11

12

13

14

3.1 Troubleshooting check list

3.2 Check list for minor failure

15

32

2.3.1 Overview of water circuit

2.3.2 Water circuit for making coffee

2.3.3 Water circuit for making steam

2.3.4 Water circuit for making hot water

4.1 Tools preparation

4.2 General disassembly

37

38

38

41

42

43

43

44

44

45

46

47

48

49

49

50

4.2.1 Disassemble exterior parts

4.2.2 Disassemble power cord

4.2.3 Disassemble brew unit

4.2.4 Disassemble valve support group

4.2.5 Disassemble flowmeter

4.2.6 Disassemble solenoid valve group

4.2.7 Disassemble grinder group

4.2.8 Disassemble control panel group

4.2.9 Disassemble dispenser valve group

4.2.10 Disassemble drainage valve group

4.2.11 Disassemble pump group

4.2.12 Disassemble PCBA

4.2.13 Disassemble dispenser valve 2W

4.2.14 Disassemble dispenser valve 3W group

Contents

AZZURRI CLASSICO

76

82

50

51

53

53

56

58

61

65

76

76

76

78

78

79

5. Function test and maintenance

6. Explosive view

4.3 Precautions for maintenance and installation

Precautions for assembling

5.1 Function test and test standards

5.2 Coffee machine maintenance

4.2.15 Disassemble thermoblock group

4.2.16 Disassemble ground coffee container lid switch group

4.3.1 Brew unit group

4.3.2 Dispenser valve 6W

4.3.3 Grinder group

4.3.4 Control panel group

5.2.1 Coffee machine decalcifying

5.2.2 Rinse the brew unit

5.2.3 Rinse the foam milk unit

5.2.4 Wipe the coffee machine

Contents

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Contents

1. Introduction 4

6

2. Structure

15

3. Troubleshooting

37

4. Repair

2.1 Overview

2.2 Description of internal components

2.3 Water circuit

2.4 Schematic circuit diagram

2.5 Technical data

General warnings

Symbol description

4

5

6

8

9

9

10

11

12

13

14

3.1 Troubleshooting check list

3.2 Check list for minor failure

15

32

2.3.1 Overview of water circuit

2.3.2 Water circuit for making coffee

2.3.3 Water circuit for making steam

2.3.4 Water circuit for making hot water

4.1 Tools preparation

4.2 General disassembly

37

38

38

41

42

43

43

44

44

45

46

47

48

49

49

50

4.2.1 Disassemble exterior parts

4.2.2 Disassemble power cord

4.2.3 Disassemble brew unit

4.2.4 Disassemble valve support group

4.2.5 Disassemble flowmeter

4.2.6 Disassemble solenoid valve group

4.2.7 Disassemble grinder group

4.2.8 Disassemble control panel group

4.2.9 Disassemble dispenser valve group

4.2.10 Disassemble drainage valve group

4.2.11 Disassemble pump group

4.2.12 Disassemble PCBA

4.2.13 Disassemble dispenser valve 2W

4.2.14 Disassemble dispenser valve 3W group

Contents

www.blueicecreammachine.co.uk

1. Introduction

The manufacturer reserves the right to make product improvements. We guarantee that this manual respects the

technological status at the time the machine is supplied.

We are open to any suggestions from technicians which may improve the product and the manual.

General warnings

Once the packaging has been removed make sure the appliance is in good condition; if you have any doubts,

check the fault and contact the retailer or manufacturer directly.

Packaging must not be left where children can reach it as it is a potential hazard source.

The appliance must be installed in compliance with the safety standards in force in the country of use.

This appliance is completely safe only when it is connected to an effective earthing system that complies with

the safety standards. Make sure that the mains power is sufficient for the energy required for the machine.

It is unadvisable to use extension leads or electrical adaptors for multiple sockets. If it is essential to use them, use

only single adaptors or leads that comply with the current safety standards. Never exceed the capacity

indicated on the adaptor or leads, or the maximum power indicated on the adaptor.

This appliance should only be used for what it has been designed. Any other use is considered improper and

consequently dangerous. The manufacturer cannot be held responsible for any damages caused due to an

erroneous or irrational use. The technician must remind the user about the safety standards to ensure correct

operation of the appliance.

The use of an electrical appliance is subject to the safety standards.

If the customer decides not going to use the appliance for a long time, the power cable must be disconnected

from the mains and empty the water container.

To guarantee that the coffee-maker works properly and efficiently, it is essential to follow the manufacturer’s

instructions, and carrying out periodical maintenance and check of all the safety devices.

Always make sure that hands, or other parts of the body, never come within the range of the coffee dispensing

spouts or those of steam and hot water so as not to be scalded.

The maintenance technician must inform the retailer or manufacturer promptly of any problems when installing

or using the appliance.

The coffee machine must be used at the temperature between 5℃and 40℃.

●

●

●

●

●

●

●

●

●

●

●

●

Introduction

4Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

AZZURRI CLASSICO

Introduction

5

Symbol description

Non-compliance with the operation, may cause electric

shock, and threat to life.

Non-compliance with the operation may cause coffee

machine damaged, or personal injury.

Non-compliance with the operation, may cause scalded or

burned.

This symbol, if prompted, please carefully read information

with it.

This symbol, if prompted, represents recycle.

www.blueicecreammachine.co.uk

1. Introduction

The manufacturer reserves the right to make product improvements. We guarantee that this manual respects the

technological status at the time the machine is supplied.

We are open to any suggestions from technicians which may improve the product and the manual.

General warnings

Once the packaging has been removed make sure the appliance is in good condition; if you have any doubts,

check the fault and contact the retailer or manufacturer directly.

Packaging must not be left where children can reach it as it is a potential hazard source.

The appliance must be installed in compliance with the safety standards in force in the country of use.

This appliance is completely safe only when it is connected to an effective earthing system that complies with

the safety standards. Make sure that the mains power is sufficient for the energy required for the machine.

It is unadvisable to use extension leads or electrical adaptors for multiple sockets. If it is essential to use them, use

only single adaptors or leads that comply with the current safety standards. Never exceed the capacity

indicated on the adaptor or leads, or the maximum power indicated on the adaptor.

This appliance should only be used for what it has been designed. Any other use is considered improper and

consequently dangerous. The manufacturer cannot be held responsible for any damages caused due to an

erroneous or irrational use. The technician must remind the user about the safety standards to ensure correct

operation of the appliance.

The use of an electrical appliance is subject to the safety standards.

If the customer decides not going to use the appliance for a long time, the power cable must be disconnected

from the mains and empty the water container.

To guarantee that the coffee-maker works properly and efficiently, it is essential to follow the manufacturer’s

instructions, and carrying out periodical maintenance and check of all the safety devices.

Always make sure that hands, or other parts of the body, never come within the range of the coffee dispensing

spouts or those of steam and hot water so as not to be scalded.

The maintenance technician must inform the retailer or manufacturer promptly of any problems when installing

or using the appliance.

The coffee machine must be used at the temperature between 5℃and 40℃.

●

●

●

●

●

●

●

●

●

●

●

●

Introduction

4Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

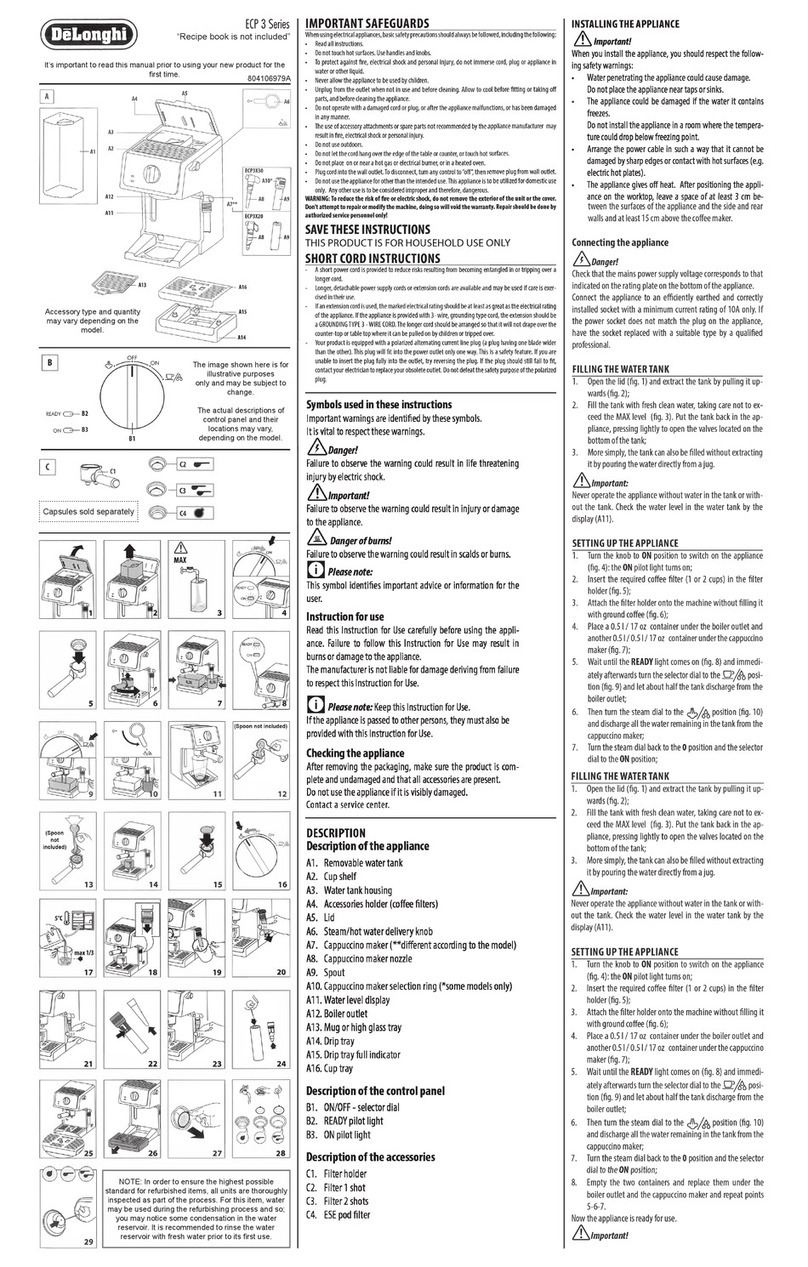

2. Structure

2.1 Overview

Bean container lid

Top cover

Water tank cover

Water tank ornament cover

Water tank

Support elect

Power button

Front cover left

Cup support

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

9

10

11

12

13

14

15

16

17

18

Structure

6Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Front cover right

Touch screen

Rotary

Clean button

Decorative plate

Handle

Drip tray decoration cover

Drip tray cover

Drip tray

AZZURRI CLASSICO

19

22

23

28

29

30

31

32

20

21

24

25

26

27

Bean container

Grinder adjustment

knob

Ground coffee

container lid

19

20

21

Back cover

Logo

Right side section

28

29

30

Left side section

Power line

31

32

Hot water export

Coffee export

Milk connector

Foam rubber

Light for coffee

Milk and foam export

22

23

24

25

26

27

Structure

7

www.blueicecreammachine.co.uk

2. Structure

2.1 Overview

Bean container lid

Top cover

Water tank cover

Water tank ornament cover

Water tank

Support elect

Power button

Front cover left

Cup support

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

9

10

11

12

13

14

15

16

17

18

Structure

6Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Front cover right

Touch screen

Rotary

Clean button

Decorative plate

Handle

Drip tray decoration cover

Drip tray cover

Drip tray

2.2 内部组件说明

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Structure

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

21

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Thermoblock

Dispenser valve 3W

Geared motor

Dispenser valve 2W

Dispenser valve

Condensator

Support

PCBA

Pump

Drainage valve

Line pencil connector

Transformer

Base

Brew unit

Solenoid valve

Drip tray microswitch

Reed sensor

Flowmeter

Valve support

Control panel

Grinder group

AZZURRI CLASSICO

2.3 Water circuit

2.3.1 Overview of water circuit

Structure

9

1

2

3

4

5

8

6

79

10

11

12

13

15

14

12

3

45

6

Water tank

Sieve

Flowmeter

Condensator

Pump

Pressure maintaining valve

Steam thermoblock

Dispenser valve 3W

1

2

3

4

5

6

7

8

Coffee thermoblock

Dispenser valve 2W

Drainage valve

Brew unit

Beverage export

Reversing valve

Solenoid valve

9

10

11

12

13

14

15

www.blueicecreammachine.co.uk

2.2 内部组件说明

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Structure

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

21

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Thermoblock

Dispenser valve 3W

Geared motor

Dispenser valve 2W

Dispenser valve

Condensator

Support

PCBA

Pump

Drainage valve

Line pencil connector

Transformer

Base

Brew unit

Solenoid valve

Drip tray microswitch

Reed sensor

Flowmeter

Valve support

Control panel

Grinder group

2.3.2 Water circuit for making coffee

Structure

10

1

10

2

3 7 4

5

69

8

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Valve support

Flowmeter

Condensator

Pump

Dispenser valve 3W

Coffee thermoblock

Dispenser valve 2W

Drainage valve

Brew unit

Export

1

2

3

4

5

6

7

8

9

10

AZZURRI CLASSICO

Valve support

Flowmeter

Condensator

Pump

Dispenser valve 3W

Steam thermoblock

Dispenser valve

Solenoid valve

Foam rubber

1

2

3

4

5

6

7

8

9

2.3.3 Water circuit for making steam

Structure

11

1

9

8

2

7 3

6

5

4

www.blueicecreammachine.co.uk

2.3.2 Water circuit for making coffee

Structure

10

1

10

2

3 7 4

5

69

8

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Valve support

Flowmeter

Condensator

Pump

Dispenser valve 3W

Coffee thermoblock

Dispenser valve 2W

Drainage valve

Brew unit

Export

1

2

3

4

5

6

7

8

9

10

2.3.4 Water circuit for making hot water

Structure

12

1

8

2

7 3 4

5

6

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Valve support

Flowmeter

Condensator

Pump

Dispenser valve 3W

Coffee thermoblock

Dispenser valve

Export

1

2

3

4

5

6

7

8

AZZURRI CLASSICO

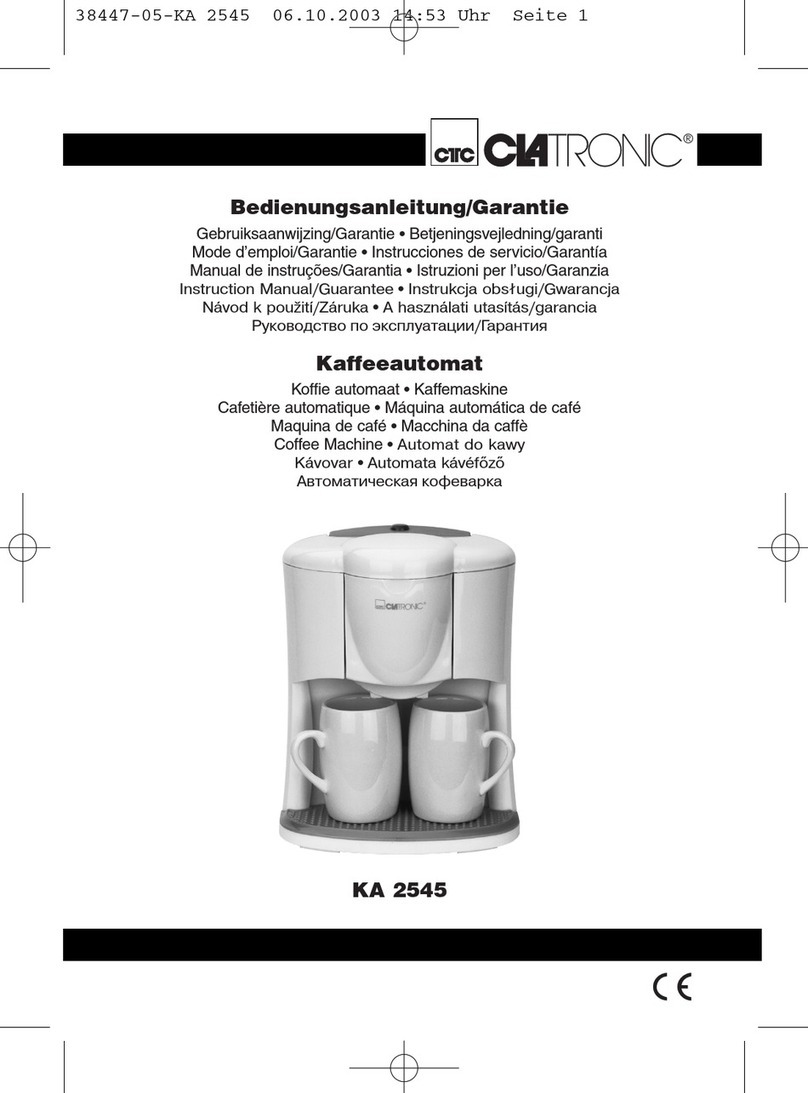

2.4 Schematic circuit diagram

Structure

13

N

L

24

3

1

UU

LN

Neutral LineTransPump

Power

Steam

Coffee

Coffee

Steam

P7

SWV

Brew

Step

NTC

Brew

SWV

BinWaterMilk Bin Water Flow

Coffee Lamp

HMI

-++

-

+-

16

17

26

24

25

18

23

1

2

3

4

22

21

20

19

5

8 9 10

11

12

13

14

15

6

7

1

2

3

4

5

6

7

8

9

10

11

12

13

Power switch

OLED screen

HMI

Rotary PCB

NTC

Feedback device

Microswitch

Stepper motor

Motor for dispenser valve

Geared motor

Transformer

Steam fused-cord

Coffee fused-cord

14

15

16

17

18

19

20

21

22

23

24

25

26

Coffee fused-cord

Steam fused-cord

Pump

Grinder motor

Terminal

LED×2

Valve

Reed sensor

Drip tray microswitch

Flowmeter

Line pencil connector( contains 10A fuse)

Power line

Power filter

www.blueicecreammachine.co.uk

2.3.4 Water circuit for making hot water

Structure

12

1

8

2

7 3 4

5

6

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Valve support

Flowmeter

Condensator

Pump

Dispenser valve 3W

Coffee thermoblock

Dispenser valve

Export

1

2

3

4

5

6

7

8

14

Structure

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

2.5 Technical data

Total voltage/power

China

Europe

220V/50HZ 1200W

230V/50HZ 1400W

Approvals CCC,CB,GS,CE

Power ratings

Thermoblock

Pump

Grinder motor

Drive motor

Dispenser valve motor

Solenoid valve

220V 1200W

230V/50HZ 48W ULKA EP4

DC 220V

DC 24V

DC 24V

DC 24V

Capacities

Water tank

Coffee grounds container

Coffee bean container

Coffee powder volume for brew unit

1.8L

15 Pieces

250g

MIN 5g; MAX 14g

Various data

Dimensions(length×width×height)

Cable Length

Net weight

450×302×370 mm

approx 1.5 m

approx 12.6kg

AZZURRI CLASSICO

76

82

50

51

53

53

56

58

61

65

76

76

76

78

78

79

5. Function test and maintenance

6. Explosive view

4.3 Precautions for maintenance and installation

Precautions for assembling

5.1 Function test and test standards

5.2 Coffee machine maintenance

4.2.15 Disassemble thermoblock group

4.2.16 Disassemble ground coffee container lid switch group

4.3.1 Brew unit group

4.3.2 Dispenser valve 6W

4.3.3 Grinder group

4.3.4 Control panel group

5.2.1 Coffee machine decalcifying

5.2.2 Rinse the brew unit

5.2.3 Rinse the foam milk unit

5.2.4 Wipe the coffee machine

Contents

www.blueicecreammachine.co.uk

14

Structure

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

2.5 Technical data

Total voltage/power

China

Europe

220V/50HZ 1200W

230V/50HZ 1400W

Approvals CCC,CB,GS,CE

Power ratings

Thermoblock

Pump

Grinder motor

Drive motor

Dispenser valve motor

Solenoid valve

220V 1200W

230V/50HZ 48W ULKA EP4

DC 220V

DC 24V

DC 24V

DC 24V

Capacities

Water tank

Coffee grounds container

Coffee bean container

Coffee powder volume for brew unit

1.8L

15 Pieces

250g

MIN 5g; MAX 14g

Various data

Dimensions(length×width×height)

Cable Length

Net weight

450×302×370 mm

approx 1.5 m

approx 12.6kg

16 Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Troubleshooting

Item Confirmation No. No. Cause Remedy RemarksProblem Prob-

ability

3.2

3.2.4

3.2.4.1

3.2.4.2

3.2.5.1

3.2.5.2

The following should be repaired or replaced water tank group

The following should be repaired or replaced powder container cover

The following should be repaired by dismatling the machine

3.2.6.1

3.2.6.2

3.3.1.1

3.3.1.2

3.3.1.3

3.3.1.4

3.2.5

3.2.6

3.3.13.3

Examine

the

external

movable

parts

Foam

rubber can

not be

installed

Wrong installation

for foam rubber

group

YES - confirm if the rubber foam

installed correct

NO - continue to 3.2.4.2

YES - replace 79000054 or

79000055

Replace or repair

damaged parts

according to foam

rubber explosive view

8810101022

Replace or repair

damaged components

according to water

tank explosive view

8810101020

Replace or repair

damaged components

according to bean

container explosive

view 8810101019

Disassemble and

replace components

according to 4.2.2

1. Disassemble control

panel according to

4.2.8;

2. Disassemble

microswitch and

replace according to

4.3.4

YES - move valve body in order to

make it reset

NO - continue to 3.2.5.2

YES - replace components

YES - clean the left coffee

powder

NO - continue to 3.2.6.2

YES - replace powder container

cover 79000123

YES - use proper voltage for the

machine

NO - continue to 3.3.1.2

YES - replug the powder cord to

the powder socket

NO - continue to 3.3.1.3

YES - replacepowder cord

NO - continue to 3.3.1.4

YES - replace microswitch

73000051

NO - continue to 3.3.1.5

Foam rubber is

damaged

Valve body is

stucked, can not

be reset

Components

damaged

Lots of coffee

powder left below

the powder

container cover

Powder container

cover deformed

Improper voltage

for the machine

Confirm if the

powder cord

connected

correct

Powder cord

damaged

Powder switch

damaged

Water

leakage

from the

bottom

when

taking out

water tank

or filling in

water tank

Powder

container

cover can

not be

covered

tightly

Machine

can not be

powered

on

Press

On/Off to

AUTO

CHECKIN

G and

then to

READY

AZZURRI CLASSICO

Troubleshooting

17

Item Confirmation No. No. Cause Remedy RemarksProblem Prob-

ability

The connector

between PCB and

powder switch

does not work

YES - connect or repair power

switch connector

NO - continue to 3.3.1.6

1. Disassemble control

panel according to

4.2.8;

2. Disassemble control

panel,repair connection

line according to 4.3.4

Disassemble right side

section according to

4.2.1

Disassemble back cover

according to 4.2.1

Disassemble PCBA,

replace and repair

according to 4.2.12

YES - connct or repair the

transformer connector

NO - continue to 3.3.1.7

YES - replace the fuse inside the

line pencil connector

NO - continue to 3.3.1.8

YES - replace or repair PCBA,

item: 78000006

YES - fill in the water tank

NO - continue to 3.3.2.2

YES - place the water tank again

NO - continue to 3.3.2.3

YES - clean water tank, knock the

place near the ball in order to

make the ball move inside water

tank

NO - continue to 3.3.2.4

YES - replace water tank group,

item: 881010037

NO - continue to 3.3.2.5

YES - replace water tank group,

item: 8810101026

NO - continue to 3.3.2.6

YES - replace reed sensor,

item: 73000095

NO - continue to 3.3.2.7

YES - connect or repair power

switch connector

NO - continue to 3.3.2.8

Transformer

connector fell off

or damaged

Fuse inside the line

pencil connetor is

damaged

PCBA damaged

No water in the

water tank

The water tank

does not install in

place

The ball inside the

water tank is

sticked

The ball is fell off

Ball damaged

Reed sensor

damaged

Connector

damaged

3.3.1

3.3.1.5

3.3.1.6

3.3.1.7

3.3.1.8

3.3.2.1

3.3.2.2

3.3.2.3

3.3.2.4

3.3.2.5

3.3.2.6

3.3.2.7

3.3

Machine

can not be

power on

3.3.2 FILL WATER

TANK on

screen

Press

On/Off to

AUTO

CHECKIN

G and

then to

READY

The following should be replaced or repaired the water tank group

The following should be repaired by dismatling the machine

www.blueicecreammachine.co.uk

16 Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Troubleshooting

Item Confirmation No. No. Cause Remedy RemarksProblem Prob-

ability

3.2

3.2.4

3.2.4.1

3.2.4.2

3.2.5.1

3.2.5.2

The following should be repaired or replaced water tank group

The following should be repaired or replaced powder container cover

The following should be repaired by dismatling the machine

3.2.6.1

3.2.6.2

3.3.1.1

3.3.1.2

3.3.1.3

3.3.1.4

3.2.5

3.2.6

3.3.13.3

Examine

the

external

movable

parts

Foam

rubber can

not be

installed

Wrong installation

for foam rubber

group

YES - confirm if the rubber foam

installed correct

NO - continue to 3.2.4.2

YES - replace 79000054 or

79000055

Replace or repair

damaged parts

according to foam

rubber explosive view

8810101022

Replace or repair

damaged components

according to water

tank explosive view

8810101020

Replace or repair

damaged components

according to bean

container explosive

view 8810101019

Disassemble and

replace components

according to 4.2.2

1. Disassemble control

panel according to

4.2.8;

2. Disassemble

microswitch and

replace according to

4.3.4

YES - move valve body in order to

make it reset

NO - continue to 3.2.5.2

YES - replace components

YES - clean the left coffee

powder

NO - continue to 3.2.6.2

YES - replace powder container

cover 79000123

YES - use proper voltage for the

machine

NO - continue to 3.3.1.2

YES - replug the powder cord to

the powder socket

NO - continue to 3.3.1.3

YES - replacepowder cord

NO - continue to 3.3.1.4

YES - replace microswitch

73000051

NO - continue to 3.3.1.5

Foam rubber is

damaged

Valve body is

stucked, can not

be reset

Components

damaged

Lots of coffee

powder left below

the powder

container cover

Powder container

cover deformed

Improper voltage

for the machine

Confirm if the

powder cord

connected

correct

Powder cord

damaged

Powder switch

damaged

Water

leakage

from the

bottom

when

taking out

water tank

or filling in

water tank

Powder

container

cover can

not be

covered

tightly

Machine

can not be

powered

on

Press

On/Off to

AUTO

CHECKIN

G and

then to

READY

18

Troubleshooting

Service Manual

Intelligent Fresh Ground Coffee Machine

KLM1601

Item Confirmation No. No. Cause Remedy RemarksProblem Prob-

ability

YES - replace or repair PCBA,

item: 78000006

YES - clean rest coffee powder

NO - continue to 3.3.3.2

YES - take out coffee grounds

container, reinstall drip tray

NO - continue to 3.3.3.3

YES - replace coffee grounds

container frame item: 79000113

NO - continue to 3.3.3.4

YES - replace microswitch,

item: 73000088 (X3C306N2LB)

NO - continue to 3.3.3.5

YES - connect or repair

microswitch connector,

item: 78000022

NO - continue to 3.3.3.6

YES - replace or repair PCBA,

item: 78000006

YES - clean up the terminal

NO - continue to 3.3.4.2

YES - clean up the terminal

NO - continue to 3.3.4.3

YES - replace or repair PCBA,

item: 78000006

YES - power off the machine,

restart (drainage will be reset

when power on the machine)

NO - continue to 3.3.5.2

Disassemble PCBA,

replace and repair

according to 4.2.12

Replace or repair

damaged components

according to drip tray

explosive view

8810101017

Disassemble PCBA,

replace and repair

according to 4.2.12

Disassemble back

cover according to

4.2.1

Disassemble PCBA,

replace and repair

according to 4.2.12

FILL WATER

TANK on

screen

PCBA damaged

Lots of coffee

powder left on the

base

Brew unit does not

reset

Coffee grounds

container frame

damaged

Drip tray

microswitch

damaged

Drip tray

microswitch

connector does

not work

PCBA damaged

Drip tray terminal

is wet

Base terminal is

wet

PCBA damaged

Stepper motor in

drainage valve

does not reset(

stepper motor still

in the drainage

position when

making coffee)

3.3

3.3.3

3.3.4

3.3.5

3.3.2 3.3.2.8

3.3.3.1

3.3.3.2

3.3.3.3

3.3.3.4

3.3.3.5

3.3.3.6

3.3.4.1

3.3.4.2

3.3.4.3

The following should be repaired by dismatling the machine

The following should be repaired by disassembling or changing proper parts

The following should be repaired by dismatling the machine

3.3.5.1

Press

On/Off to

AUTO

CHECKIN

G and

then to

READY

INSTALL

TRAY on

screen

EMPTY TRAY

on screen

No water

comes from

coffee

export

when

CLEANING

AZZURRI CLASSICO

This manual suits for next models

1

Table of contents