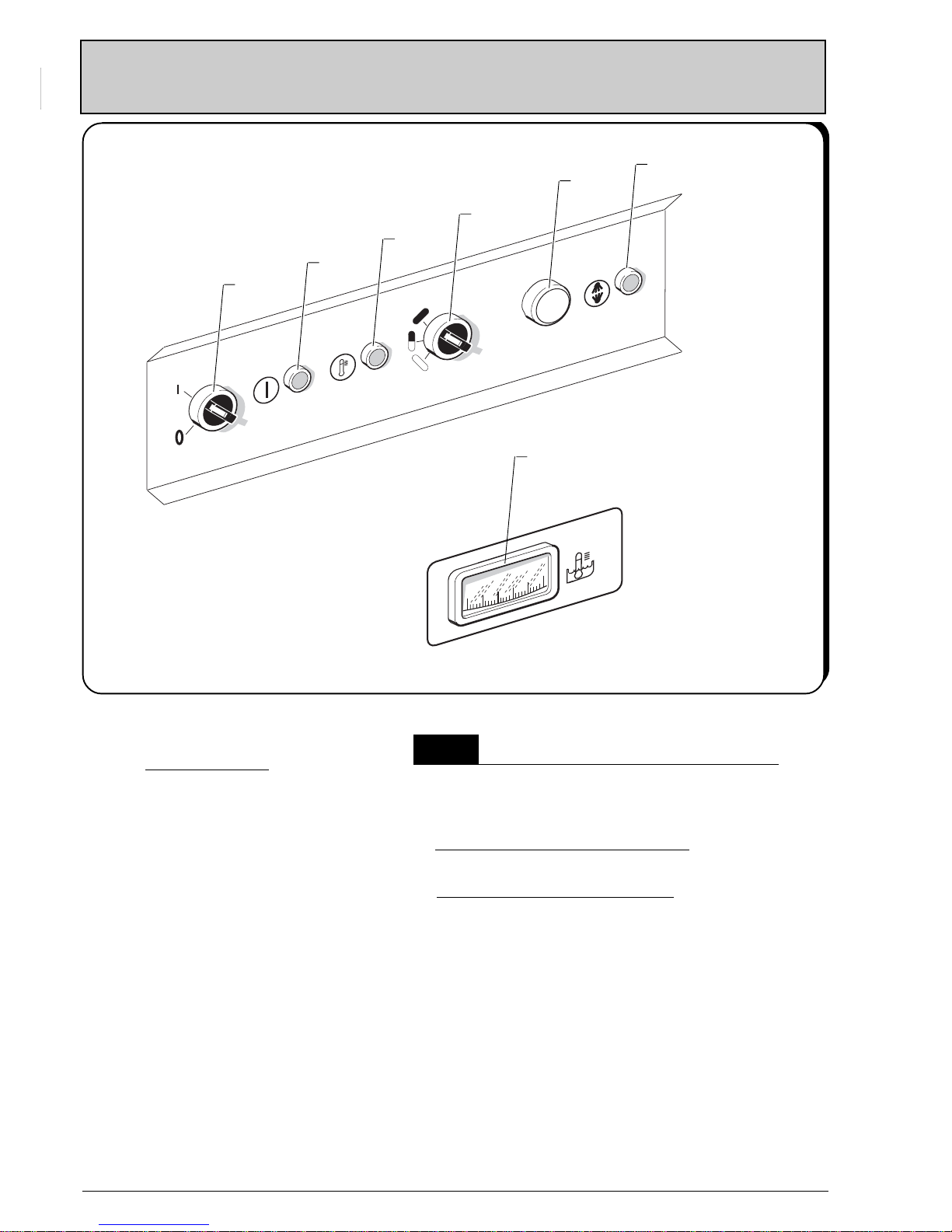

9

SMW 15

PARTICULAR RECOMMENDATIONS

FOR THE OPERATOR

-Do not operate the machine without having become fully

familiar with the contents of this manual and without having

acquired a comprehensive knowledge of the specific

techniques and machine controls.

-Checkthattheareainwhichthemachineistobeinstalledis

compatible with the dimensions of the machine itself before

installing this latter.

-Only use lifting and handling means as are adequate to the

weightofthemachinewhenthismustbeinstalledorremoved

either completely or in part.

-Never allow unauthorized or unqualified personnel to start,

adjust, operate or repair the machine. Always refer to this

manual for the necessary operations.

-The mechanical parts and electrical/electronic components

situated inside the machine are protected by entirely closed

panels.

-Always ensure that the main switch has been set to the

“OFF”positionbeforecleaningand/orservicingthemachine

and before removing any guard. This will disconnect the

power source during the operator’s intervention.

-The electrical powering system must be equipped with an

automatic release system prior to the main machine switch

and with a suitable grounding system that complies with all

the requisites established by industrial provisions for the

prevention of accidents.

-Always disconnect the power source if work must be carried

out on the main switch or in its vicinity.

-Allinspectionsandmaintenanceoperationsrequiringremoval

of the safety guards are carried out under the complete

responsibility of the users.

These operations should therefore only be carried out by

specialized and authorized technical personnel.

-Check that none of the accident preventing safety devices

(barriers, guards, casings, microswitches, etc.) have been

tamperedwithandthattheyareallperfectlyfunctionalbefore

operating.Thesedevicesshouldberepairedifthisisnotthe

case.

-Never remove the safety devices.

-To prevent personal risks, only use power tools that are

correctlyconnectedto thegroundingtap andthatconformto

the national safety regulations.

-Neverevertamperwiththeelectricalsystemorwithanyother

mechanism.

-Never ever use the hands or unsuitable instruments to

locateleaksfrompipes.Air,fluidsunderpressureor irritants

couldcauseseriousdamagetobothpersonsand/orproperty.

-Neverusethehandsinsteadofadequatetoolswhenoperating

the machine.

-Never use the hands or other objects to stop moving parts.

-PAY THE UTMOST ATTENTION TO THE DATA PLATES

AFFIXED TO THE MACHINE WHENEVER WORKING ON

THIS OR ON THEIR NEAR VICINITY.

-Theuserisobligedtokeepallthedataplatesandstickersin

a legible condition.

-It is essential for the user to replace all data plates and

stickersasmayhavedeterioratedforanyreasonorasarenot

clearlyvisible,orderingnewonesfromtheSparesServiceof

BLUE SEAL.

-Contact the person in charge of maintenance in the event of

malfunctionsordamagetothemachinecomponentswithout

proceeding with further repairs.

-It is absolutely forbidden for anyone to use the machine for

purposes other than those explicitly established and

documented.Themachinemustalwaysbeusedintheways,

times and places established by common sense, the laws in

forceineachnation,evenwhentherearenospecificprovisions

to govern the sector in the specific country of use.

-BLUE SEAL declines all responsibility for accidents or

damage to either persons or propertry as may arise

followingfailureto complywitheither therelativesafety

provisions or the instructions herein.

-These instructions, together with the provisions

governing machine installation and electrical

connections form an integral part of the Accident

Preventing Industrial regulations in force in each

individual country.

-THESESAFETYPROVISIONSINTEGRATEANDDONOT

SUBSTITUTE THE SAFETY PROVISIONS LOCALLY IN

FORCE.

-NEVERevermakehurriedorinaccuraterepairsascould

jeopardize the correct operation of the machine.

-ALWAYS ASK FOR HELP FROM SPECIALIZED

PERSONNEL IN CASE OF DOUBT.

-ANY TAMPERING BY THE USER RELIEVES THE

MANUFACTURER FROM ALL LIABILITY, THE USER

BEINGINTHISCASESOLELYRESPONSIBLETOWARDS

THE COMPETENT ACCIDENT PREVENTION

AUTHORITIES.

ENGLISH