BlueBox ZETA 2002 3,2 Installation guide

This manual suits for next models

14

Table of contents

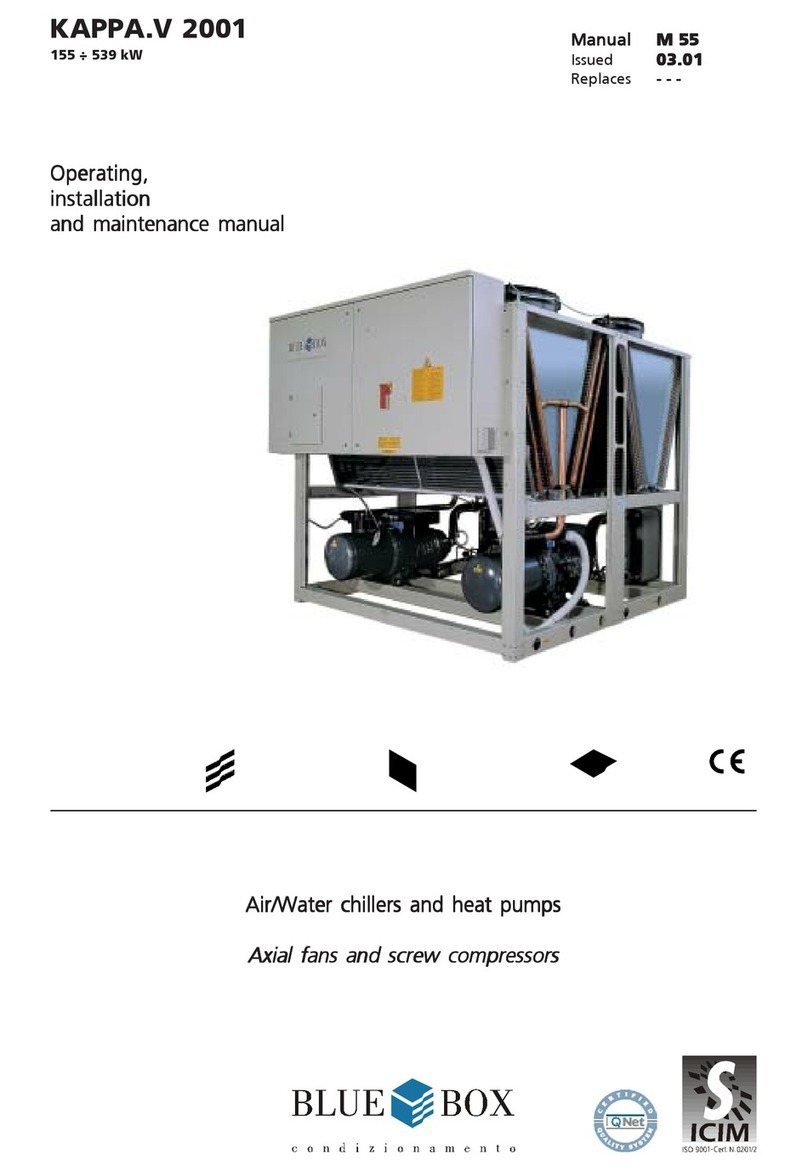

Other BlueBox Chiller manuals

Popular Chiller manuals by other brands

Solid State Cooling Systems

Solid State Cooling Systems ThermoCube product manual

Johnson Controls

Johnson Controls York YCAL0041-0071 quick start guide

RHOSS

RHOSS TCCEY 114 Instructions for use

York

York MILLENNIUM YCAS 250 manual

lancer

lancer SERIES 1500 POSTMIX Operation manual

Conair

Conair EP2 series Original instructions

Envicool

Envicool EMW90HDNC1U user manual

BrewBuilt

BrewBuilt ICEMASTER 100 Assembly instructions

Carrier

Carrier Touch Pilot Control Series Control manual

AERMEC

AERMEC NRL FC 2000 installation manual

McQuay

McQuay Seasonpak PAB Series Installation and maintenance data

Carrier

Carrier 16LJ-F Series installation manual

American Panel

American Panel Blast Chiller AP40BC250-12 Installation and maintenance manual

Diamond

Diamond GTP-10/LD INSTALLATION, USAGE AND MAINTENANCE MANUAL

Hydrofarm

Hydrofarm ACTIVE AQUA AACH100 instruction manual

SMC Networks

SMC Networks HECR Series Installation and maintenance manual

IV Produkt

IV Produkt Envicooler Operation and maintenance instructions

Johnson Controls

Johnson Controls York YD manual