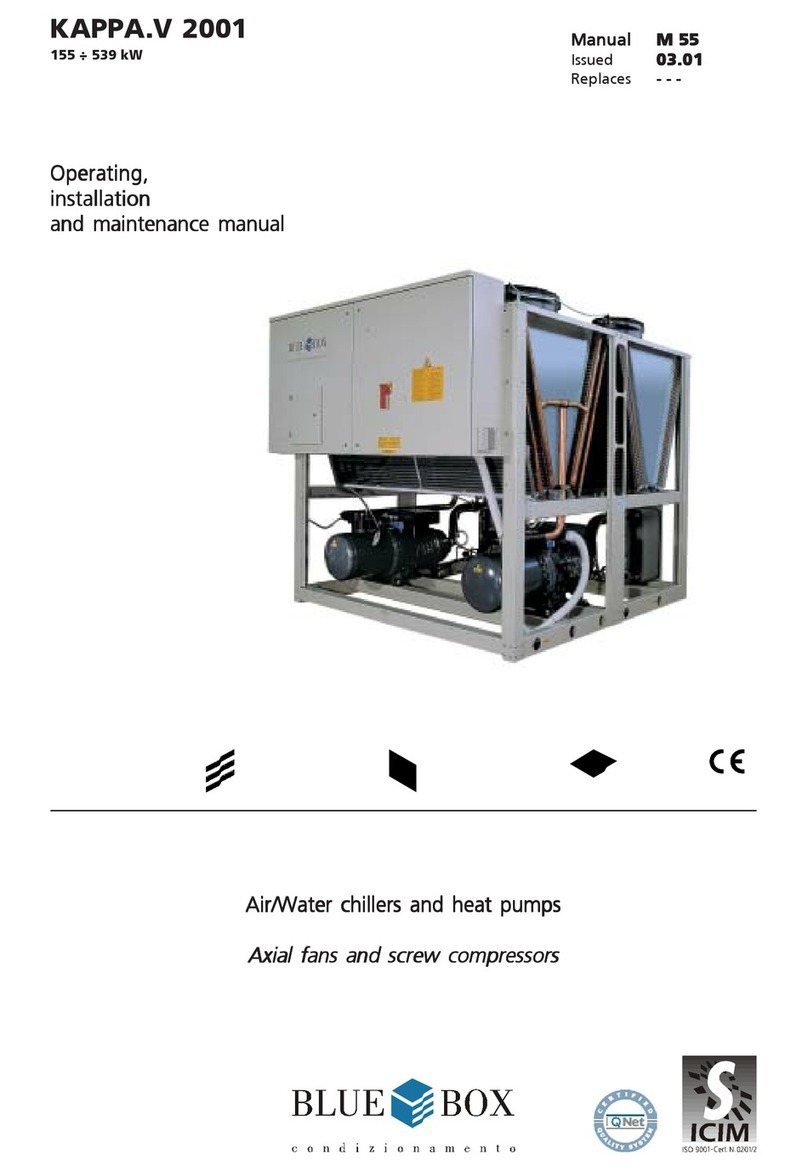

BlueBox SIGMA 2002 User manual

Table of contents

Other BlueBox Chiller manuals

Popular Chiller manuals by other brands

Samsung

Samsung AG042KSVANH installation manual

KKT chillers

KKT chillers KSC Series Opearting instructions

Trane

Trane AquaStream 2 CGWN Series Installation operation & maintenance

Bromic Heating

Bromic Heating Medifridge MED0140GD instruction manual

MP Systems

MP Systems V Series Installation operation & maintenance

McQuay

McQuay PM AGZ-2 product manual

IV Produkt

IV Produkt Envicooler Operation and maintenance instructions

Everpure

Everpure Commercial Grade Water Chiller CGCL1 Installation and operating guide

Electrolux

Electrolux EAT1AX operating instructions

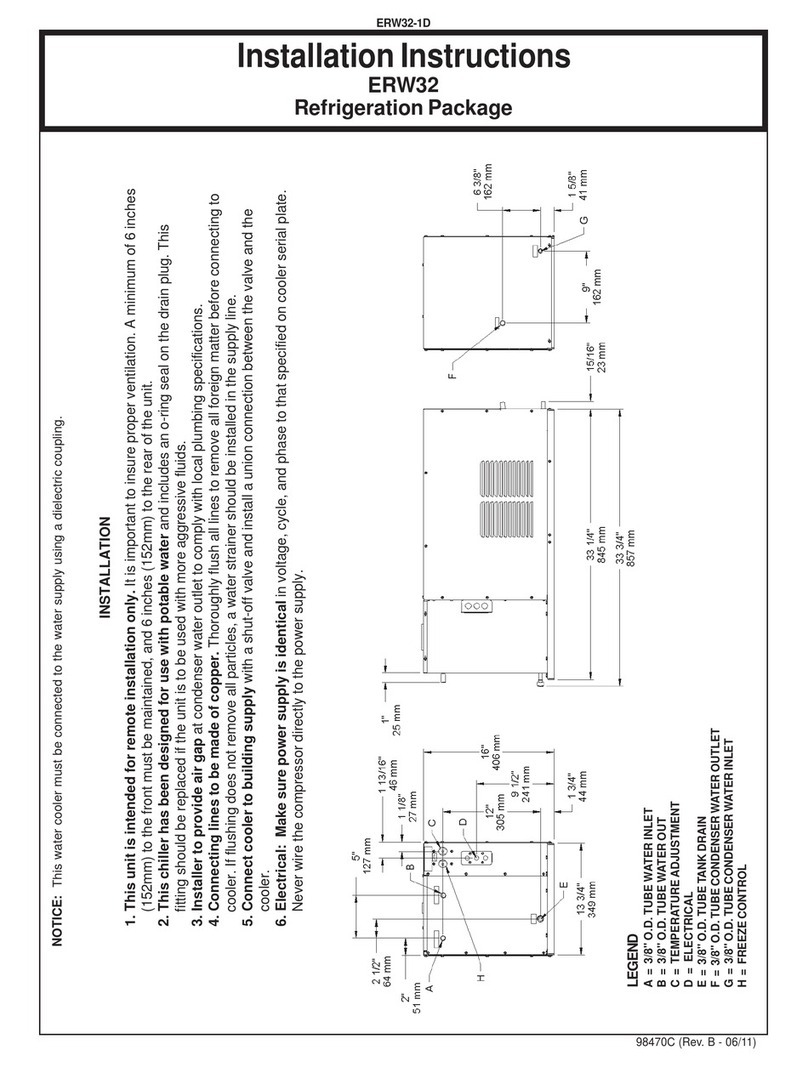

Elkay

Elkay ERW32 installation instructions

United Technologies

United Technologies Carrier Touchpilot 30XW-V Installation, operation and maintenance instructions

omi

omi CHW Series Operating and maintenance manual

Daikin

Daikin Exigo E1500 Operation manual

Carrier

Carrier 30HR Series installation instructions

Polar Refrigeration

Polar Refrigeration CB929 instruction manual

Daikin

Daikin EWWD120J-SS Installation, operation and maintenance manual

AIREDALE

AIREDALE SmartCool SN Series Technical manual

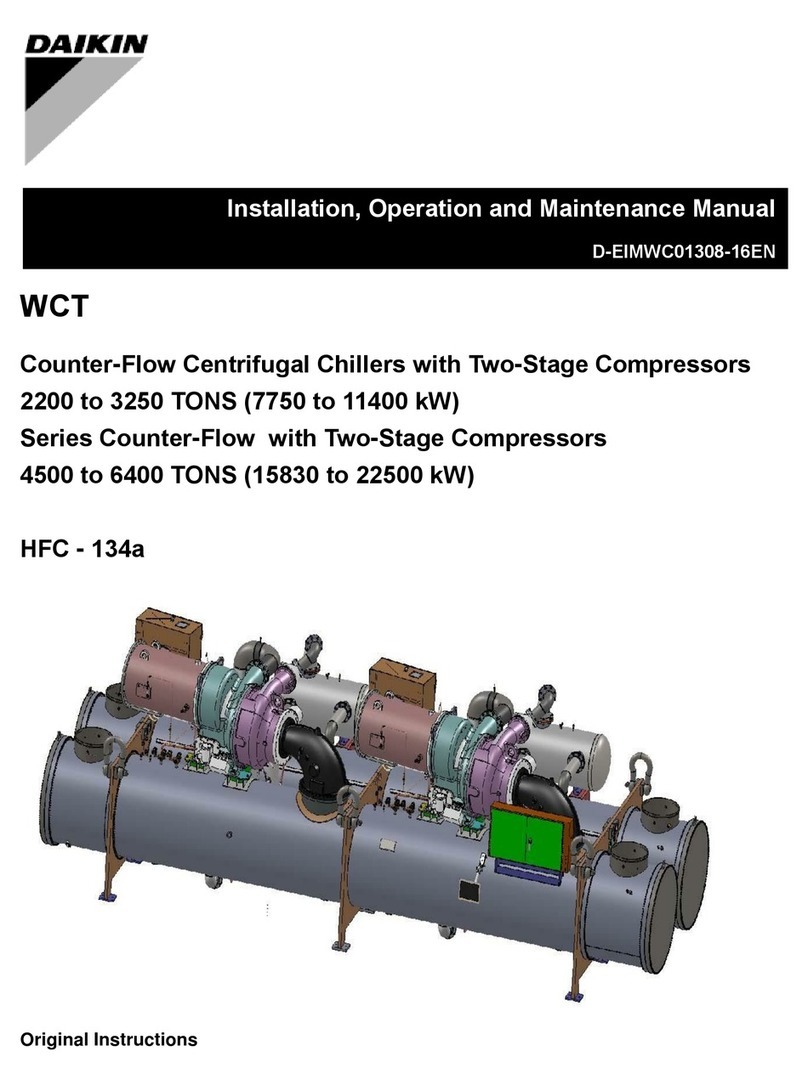

Daikin

Daikin WCT Installation, operation and maintenance manual