Bluerock Tools SL-1.25 Quick start guide

OPERATIONAL MANUAL

MODEL: SL-1.25 SEAM LOCKER

by BLUEROCK ® Tools

Volume

1.0

MWS-

SL-1.25 SEAM LOCKER

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects. Remove the machine from

the packaging in a safe manner. Check to ensure all accessories are included with the item while unpacking. If any parts are found

to be missing, contact the retailer as soon as possible. Do not throw away the packaging until the item is out of the guarantee

period. Dispose of the packaging in an environmentally responsible manner. Recycle if possible. Keep all plastic bags away from

children due to risk of suffocation.

WEEE - Waste Electrical & Electronic Equipment. Note this machine should be disposed of as electrical & electronic

waste.

ãTHE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2020

1033 Andover Park East, Tukwila WA 98133, USA

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

SL-1.25 SEAM LOCKER

Table of Contents

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 3!

INCLUDED'ACCESSORIES' 3!

ADDITIONAL'AVAILABLE'ACCESSORIES' 3!

ADDITIONAL ACCESSORIES FOR THIS MACHINE MAY BE FOUND IN BLUEROCK ® TOOLS’ ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 3!

OPERATIONS' 4!

PURPOSE! 4!

OPERATIONAL PRINCIPLES! 4!

MACHINE COMPONENTS! 5!

RUNNING THE MACHINE! 7!

TRANSPORTING THE MACHINE!10!

TROUBLESHOOTING'11!

GENERAL'MAINTENANCE'12!

OCCASIONAL'MAINTENANCE'12!

PARTS'LIST'13!

BREAKDOWN'VIEW'15!

SL-1.25 SEAM LOCKER

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE OPERATING INSTRUCTIONS!

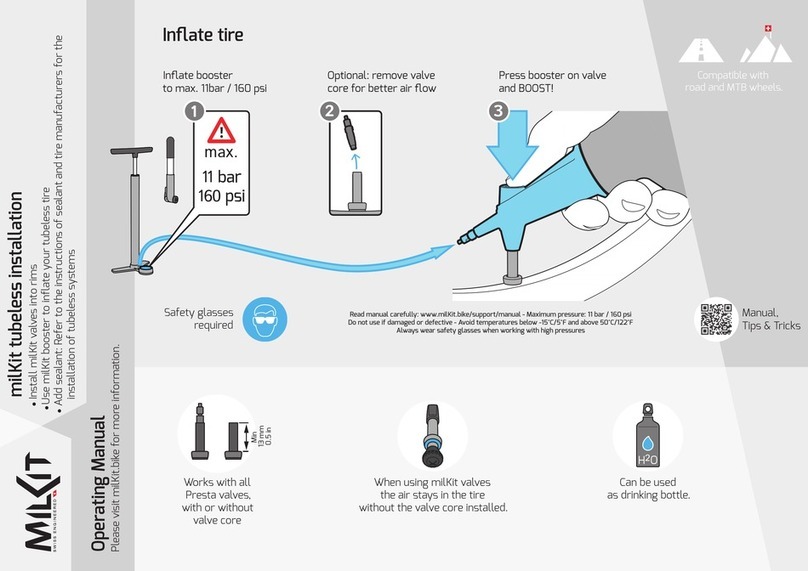

Safety glasses must be worn at all times in

work areas. Use a full face mask whenever

possible.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective clothing

must be worn.

Safety gloves should be worn at all times

and jewelry must not be worn.

Hearing protection should be

worn when using this machine.

Read operational manual prior to use.

PRE-OPERATIONAL SAFETY CHECKS

Ø Examine the power cord and plug for damage.

Ø Examine the body of the machine and inspect for damage or defects.

Ø Examine the Driving Wheels and Support Floor to ensure they are operable.

Ø Make certain the on/off switch is in the off position.

OPERATIONAL SAFETY CHECKS

Ø ONLY to be operated by qualified personal who have read instructions.

o NOTE: Failure to read and follow instructions could result in electrical shock, fire, property damage and/or

serious injury!

Ø DO ensure all non-essential people are clear of the immediate work area.

Ø DO keep body parts, clothing & power cords clear of turning pieces. Stay alert and use common since when using

this tool.

Ø DO use both hands when using this machine.

Ø DO guard against electric shock by preventing body contact with grounded surfaces such as pipes, radiators, ranges,

refrigerators, etc.

Chapter

1

SL-1.25 SEAM LOCKER

2

Ø DO be mindful that power tools can expose an operator to vibrations transmitted trough contact with the machine.

Prolonged exposure can lead to medical issues which should be discussed with a medical professional.

Ø DO use a dust extraction system for working materials that create or contain dust. The operator should also wear a

protective respiratory device.

Ø DO NOT place your hand/hands into the processing line.

Ø DO NOT make adjustments to machine while the machine is running.

Ø DO NOT use this machine with water or any type of liquids.

Ø DO NOT leave the machine running when not in use.

Ø DO NOT hold the work piece by hand or using body. Always mechanically clamp or secure work piece to create a

safe distance between the user and workpiece.

Ø DO NOT allow liquids or dust to enter the machine’s ventilation system.

Ø DO NOT operate machine outside of machine specifications.

Ø DO NOT touch moving parts while the machine is running as death or dismemberment could occur.

Ø DO NOT remove machine components while machine is connected to a power source. Only to be removed for

service by qualified personal and put back on the machine after service is complete.

Ø DO NOT allow children or untrained personal to operate machine.

Ø DO NOT use this machine in the rain or a wet environment. If using outdoors, make sure the surface is clean and dry.

Ø DO NOT operate in the presence of explosive materials as power tools create sparks which may ignite dust or fumes.

Ø DO NOT use on a work area that may contain a live electrical wire/circuit.

Ø DO NOT use the machine overhead.

Ø DO NOT operate this machine on the same work surface where welding is being performed. This could result in

severe damage to the machine or personal injury to the user.

Ø DO NOT operate this machine on a lower voltage as this could limit the motor life and work efficiency.

o NOTE: Use of long small gauge power extension cords can result in decreased voltage. As local voltages

can vary, it may be a good idea to test the voltage at the end of the extension cord to ensure proper voltage

requirements are met. You might also consult an electrician to make sure the length of cord matches up

with the proper wire gauge for this size motor. Make sure to use outdoor cords when operating outdoors.

Use a GFCI circuit if using in wet locations.

SL-1.25 SEAM LOCKER

3

Specifications

ELECTRICAL DATA

Voltage

120V, 60Hz

Current

11.6 Amps

Motor Size

1400W

Power Connection

US Standard Type Plug

Protective Insulation

Class II

MECHANICAL DATA

Lock Capacity

0.8mm – 1.25mm

Material Tensile Strength 400N/mm2

0.03-0.04inch

22-18 Gauge

Inner Radiuses

Min 5.9”

Outer Radiuses

Min 11.8”

Machine Speed

150 RPM Single Speed Gearbox

Working Speed

13-23 ft/min

Nominal Power Consumption

500W

Noise*

Typically 81dB (A) to 85dB (A)

Vibration*

Typically less than or equal to 2.5 m/s2

* The measured values specified above may be

exceeded while working.

SHIPPING DATA

Machine Weight

11.5lbs

Shipping Weight

19lbs

Shipping Carton

19” x 12” x 9”

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

Primary Handle (Lever)

1

Edge Preparation Tool

1

Allen Head Wrench

1

Additional Available Accessories

Additional accessories for this machine may be found in BLUEROCK ® Tools’ online shop at

www.bluerocktools.com or from your local retailer.

Chapter

2

SL-1.25 SEAM LOCKER

4

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE OPERATING THIS MACHINE!

PURPOSE

Ø The purpose of the SL-1.25 Seam Locker is to close Pittsburgh lock joints on correspondingly pre-

machines workpieces, e.g. ventilation ducts, housings, containers, etc.

OPERATIONAL PRINCIPLES

Ø The lock seam can be closed on straight or slightly curved contours

Ø The machine adjusts itself automatically to the sheet thickness to be processed.

Ø The model SL-1.25 is for locking seams 0.8mm-1.25mm ONLY.

Range of Sheet Thickness

Height of flange

(B) [mm]

Picture

[mm]

[Gauge]

0.75mm-1mm

22-21 guage

0.03-0.04 in

9-11

B Height flange

>1mm-1.25mm

21-18 guage

0.04-0.05 in

11-13

Ø The quality of the locking seam depends on the height of flange B. If B is too large or too small, the lock

seam cannot close properly.

Ø The seam locker uses 3 stages to lock a seam as it rolls over material. Those stages are outlined below.

Chapter

3

SL-1.25 SEAM LOCKER

5

1

First Stage

2

Second Stage

3

Third Stage

Ø The components within the rolling assembly are outlined below with specific attention to the stages shown

above.

12

Support Roller

21

Guide Rail

13 & 17

1st Stage 30 Deg

Rollers

25

3rd Stage Horizontal

Roller

14 & 18

2nd Stage 75 Deg

Roller

MACHINE COMPONENTS

Ø The main components of the SL-1.25 are the head assembly, gearbox, motor, housing and main handle.

The head assembly is driven by the gearbox and the motor.

o These components must be not be removed except by a qualified technician. Power must be

disconnected prior to any service.

Ø The machine has a single speed switch located on the main handle (the machine body).

SL-1.25 SEAM LOCKER

6

1

Adjustment Lever

6

Guide Rail

2

On/Off Switch

7

30 Deg. Drive Roller

3

Gearbox

8

75 Deg. Drive Roller

5

Support Roller

9

Roller

Ø The clearance between the rollers and the guide rail can be locked into place using the adjustment lever.

This is used to place the machine into position prior to use (at the beginning of the channel) and take the

machine away from the workpiece after use (at the end of the channel).

Ø This machine has two positions within the adjustment lever.

o Tool Open: Position 1. This is a disengaged position. This points away from the direction of

travel.

§

o Tool Working: Position 2. This is the engaged position. This position should point in the

direction the machine will be going.

SL-1.25 SEAM LOCKER

7

§

• NOTE: No adjustments are used for sheet thickness. The machine will

automatically adjust itself depending on the sheet thickness as long as it’s

within machine’s specifications.

Ø Machining Inner Radiuses:

o If using the machine to lock seals in an inner radius capacity, the supporting rollers must be

removed prior to use. This is part 1 in the figure below. If using it for outer radiuses, the support

rollers can stay in place.

§

RUNNING THE MACHINE

Ø Do all pre-operational and operational safety checks from Chapter 1.

Ø Consider your security and stability as well as the orientation of the machine in the work area.

o Consider the work surface material, condition, strength, density and rigidity. These factors

directly affect the tools operation and user safety.

o Ensure the work surface is free of debris, oil, etc.

§ CAUTION: Always guide the electric cord away from the back of the machine and

ensure it does not pull across sharp surfaces!

o NOTE: For better results, lightly oil the rollers on the machine prior to using.

Ø Plug the machine into power source.

o Start the machine by sliding switch 1 in picture below forward. Stop the machine by sliding the

switch backwards and release.

SL-1.25 SEAM LOCKER

8

o

o CAUTION: Only lay the machine down on surface once the turning parts have come to a complete

stop.

Ø Depending on the construction of the channel to be locked, the seam locker can be used in 2 different

ways: “Open Channel” and “Beginning Flange.” These 2 methods are outlined below:

o Open Channel:

§ In open channel operation you essentially have no constraints at the front and back of

the channel

• 1) Bevel the web at the beginning of the channel to approximately 30 degrees

with a length of 5mm. See below:

•

• 2) Move lever in direction of the feed (tool in working position towards the end

of the end of the channel).

SL-1.25 SEAM LOCKER

9

•

• 3) Switch machine on and place at the begging of the channel. The curved

guide rail on the machine ensures an easy placement of the machine at the

beginning of the channel.

• 4) The machine is drawn through the channel as the driving rollers feed the

machine over the material while locking the seam.

• 5) Lock seam on channel.

• 6) Move lever into open position.

• 7) Switch machine off and remove from material.

o Beginning Flange:

§ In beginning flange operation you essentially have constraints at some points in the

channel.

• 1) Prepare the channel so that the machine can be brought into position. See

preparation detail below:

•

SL-1.25 SEAM LOCKER

10

• 2) Move lever into position against the channel with the lever in the open

position (away from the direction of feed)

• 3) Set the machine up against the prepared material on the channel.

• 4) Move lever in direction of the feed (tool in working position towards the end

of the end of the channel).

• 5) Switch machine on.

• 6) The machine is drawn through the channel as the driving rollers feed the

machine over the material while locking the seam.

• 7) Lock seam on channel.

• 8) Move lever into open position (away from feed direction)

• 9) Switch machine off and remove from material.

o NOTE: Some amount of refinishing must be carried our manually at the end of the channel. This

is usually 130mm of manual work.

TRANSPORTING THE MACHINE

Ø When transporting the machine, always carry by the machine main handle.

Ø If transporting inside a vehicle, it is recommended to transport it on its side so as to avoid the item falling

over.

Ø DO NOT carry the machine by the cord.

Ø DO NOT allow the cord or plug to drag along the floor when transporting.

SL-1.25 SEAM LOCKER

11

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

PROBLEM

SOLUTION

Motor does not turn on.

1) Check external power source (extension cord, breaker, etc).

2) Loose internal wire. Check and secure if necessary.

3) Motor brushes defective or worn. Replace if necessary.

4) Check to ensure the motor on/off switch is operable. Replace if necessary.

Excessive sparking when

motor is running.

1) This may indicate the presence of debris in the motor or worn out carbon

brushes. Check the brushes for unusual wear and replace if necessary. Clean

out the internal motor armature if necessary.

2) Armature has a rough edge. Inspect and replace if necessary.

Machine is not locking seems

fully.

1) Wear parts such as Driving Wheels and Pressing Wheels are worn. Replace

worn parts.

2) Work area material is not appropriate for this machine.

Chapter

4

SL-1.25 SEAM LOCKER

12

General Maintenance

Ø Inspect electrical cords and electrical connections.

Ø Keep machine clean and free of debris. Clean motor ventilation slots as necessary.

Ø Check for misalignment, binding and breakage of all moving parts. If damaged, repair tool before use.

Ø Guide Rails of Machine:

o Clean and oil guide rails on the machine after every 10hrs of use. Cleaning the guide rails

can be done with a steel brush. Oil to be used can be Universal Lubricating oil. Check for

misalignment, binding and breakage of all moving parts. If damaged, repair tool before use.

Ø Gearbox Service:

o After 300hrs of use, gearbox grease should be replaced. G1 lubricating grease is

recommended.

Occasional Maintenance

Ø Have the power tool serviced by a qualified service technician using identical replacement parts.

o Change motor brushes:

1) Disconnect machine from power.

2) Take off motor handle housing.

3) Unscrew left and right side brush holder caps.

4) Take out old brushes.

5) Replace with new brushes.

6) Screw in brush holder caps tightly.

o Changing out rollers. If any rollers are disassembled, reassemble using 24Nm or toque and use Loctite

262. If the slotted nut is disassembled, reassemble to 16Nm of torque and use Loctite 262.

Chapter

5

SL-1.25 SEAM LOCKER

13

Parts List

1

Support floor

25

Key

49

Adjusting nut

2

screw

26

Gear

50

screw

3

30°Left Driving wheel

27

Bearing

51

Bearing

4

75°Left Driving wheel

28

Gear

52

Bearing

5

Side wheel

29

Bearing

53

screw

6

screw

30

Gear

54

Gear box cap

7

30°Right Driven wheel

31

Key

55

Bearing

8

75°Right Driven wheel

32

Gear box

56

Clamp

9

Pressing wheel

33

Bearing

57

Wind catcher

10

Pin

34

Gear

58

Motor

11

screw

35

Gear

59

Brush

12

Right machine body

36

Catch spring

60

Brush Holder

13

Pin

37

Gear

61

Field core

14

Left machine body

38

Handlebar

(optional)

62

screw

15

screw

39

screw

63

Case

16

Connection block

40

Turning handle

64

Controller (Only

on 230V

Versions)

17

Bearing

41

Plastic cover

65

Switch push

block

18

Pin

42

Pin

66

Switch lever

19

Screw plate

43

Rotor

67

Switch

20

Screw plate

44

Disc spring

68

Cable fixer

21

Gear

45

Disc spring

69

Motor holder cap

22

screw

46

Central shaft

70

Cable protector

23

Gear

47

Pin

71

Flexible cable

24

Gear

48

Spring

Chapter

6

SL-1.25 SEAM LOCKER

14

SL-1.25 SEAM LOCKER

15

Breakdown View

Table of contents