BLUEROCK STRIPINATOR MWS-83MD Quick start guide

OPERATIONAL MANUAL

MODEL: MWS-83MD STRIPINATOR ® WIRE STRIPPING

MACHINE

US PATENT # US8839695B2

by BLUEROCK ® Tools

Volume

1.1

MWS-MWS-83MD

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects.

Remove the machine from the packaging in a safe manner. Check to ensure all accessories are included with

the item while unpacking. If any parts are found to be missing, contact the retailer as soon as possible. Do

not throw away the packaging until the item is out of the guarantee period. Dispose of the packaging in an

environmentally responsible manner. Recycle if possible. Keep all plastic bags away from children due to

risk of suffocation.

©THE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2016

1100 SW 16th St • Suite D

Renton, WA 98057

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

MWS-83MD

Table&of&Contents&

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 3!

OPERATIONS' 4!

PURPOSE! 4!

INSTALLATION! 4!

OPERATIONAL PRINCIPLES! 4!

MACHINE COMPONENTS! 5!

PROCESSING WIRE! 6!

WIRE TYPE GUIDE! 7!

WIRE GUIDE DIAGRAM! 7!

RUNNING WIRE! 7!

TROUBLESHOOTING' 9!

MAINTENANCE'10!

CHANGING'BLADES'10!

PARTS'LIST'13!

BREAKDOWN'VIEW'14!

MWS-83MD

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE

OPERATING INSTRUCTIONS

Safety glasses must be worn at all times

in work areas.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective clothing

must be worn.

Gloves, rings and jewelry must not be

worn as wire could catch on the item

and bring hands towards the machine.

PRE-OPERATIONAL SAFETY CHECKS

ØEnsure the safety guards are secure and correctly fitted.

ØSecure and support the work piece using clamps, bench vices, bolts, etc.

OPERATIONAL SAFETY CHECKS

ØONLY to be operated by qualified personal who have read instructions.

ØDO ensure all non-essential people are clear of the immediate work area.

ØDO keep fingers and hands & power cords clear of cutting/rolling channels.

ØDO allow machine to reach operating speed before inserting wire.

ØDO NOT make side-bolt centering adjustments while the machine is running.

ØDO NOT wear loose clothing or gloves as death or dismemberment can occur. When feeding

wire/cable, gloves can snag on scrap wire and bring hand towards machine.

ØDO NOT operate machine outside of machine specifications.

ØDO NOT touch moving parts while the machine is turning.

Chapter

1

MWS-83MD

2

ØDO NOT remove machine guards while machine is running. Only to be removed for

maintenance and oiling by qualified personal and put back on the machine after maintenance

is complete.

ØDO NOT allow children or untrained personal near machine.

ØDO NOT put cable/wire longer than 1 meter into machine.

ØDO NOT use this machine in the rain, if peeling wet cable/wire, keep the blades dry, oil the

machine often, test the blades and machine for oxidation.

MWS-83MD

3

Specifications

MECHANICAL DATA

Blades

5 Blades – 5 Channels – 3 Round/2 Square Channels

Cuts Top of Wire

Cutting Assembly

Single Cutting And Roller Channel

Cutting Speed

Human/Chuck Drill Dependent

Wire Cutting Range

16 AWG – 1/2” OD Wire (Certain Square/Round Multicore

Type Wires)

Drive System

Manual Hand Crank System/User Supplied Drill

SHIPPING DATA

Shipping Weight

39 Pounds

Shipping Carton

15” x 12” x 9”

Chapter

2

MWS-83MD

4

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE

OPERATING THIS MACHINE!

PURPOSE

ØThe purpose of the MWS-83MD is to remove outer and inner jackets from wires and

cables in order to separate the inner copper or aluminum. These types of machines

are widely used in the recycling industry to extract copper and aluminum for

recycling.

ØThe wire jackets are also able to be recycled by many recyclers so inquire with your

local scrap buyers.

INSTALLATION

ØInstall the machine in a dry place.

ØBolt down or secure in some manner so as to be able to have access to both the front

wire inlets and the back wire outputs.

ØMake certain the machine is firmly secure so it will not tip or fall.

OPERATIONAL PRINCIPLES

ØThis machine pulls wire into the machine across an assembly of a single cutting

channel and a single rolling channel.

ØThe main cutting blade shaft and main rolling shaft run inversely to create a

mechanism that pulls the wire into front of the machine.

Chapter

3

MWS-83MD

5

MACHINE COMPONENTS

ØThe main components of the MWS-83MD are the central cutting (top) and rolling

assemblies (bottom) which has the drill shaft. These are driven by human power

using a hand-wheel and hand-crank or by a user supplied chuck type drill. The safety

guards are situated on top of the assemblies as well as in front where the wire guide

is situated.

oThe safety components must be not be removed except by a qualified

technician.

ØNOTE: The drill shaft is most suitable for continuous smaller/medium size wires. It's

not made for continuous large wire operations. It can put excess stress on the shaft

over time making it vulnerable to breakage.

ØThis machine has one primary adjusting point. The main way is though the two T-

bolts. These are the black bolts on the top of the machine that have a locking wing

nut. These T-bolts are used to tighten or loosen the springs that control the upper

cutting assembly. Essentially these are used to cut deeper or shallower into wire

jackets. If you are not able to put a piece of wire in a channel (and have already tried

to run it through larger channels), it may be necessary to loosen the T-bolt

oIt is not uncommon for users to over-tighten these T-bolts thinking they need

more spring tension, when in reality they just needed to strip down a cutting

channel.

oGenerally if you’re cutting in the right channel a full turn of the T-bolt (either

tighter or looser) is all that is needed.

MWS-83MD

6

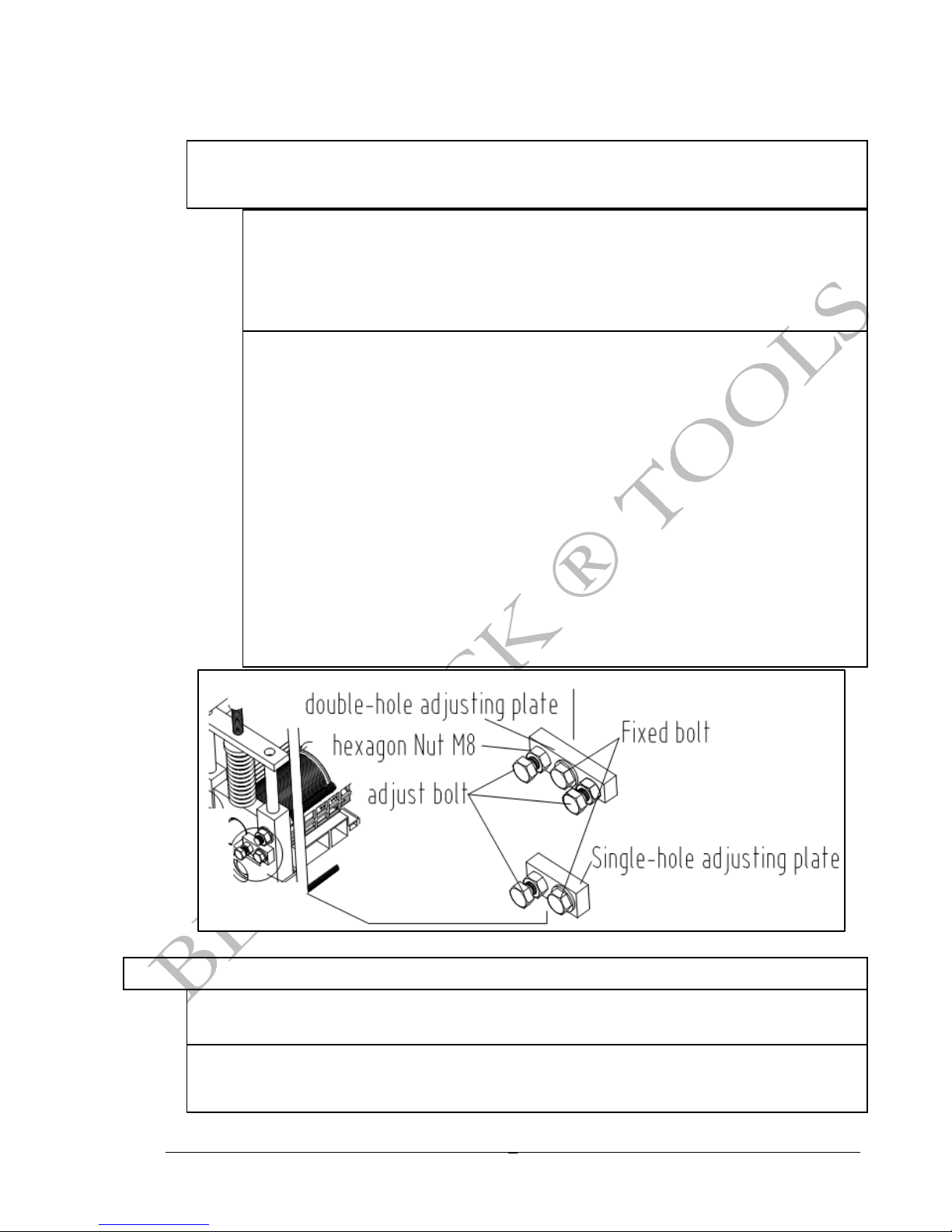

ØThe secondary adjusting point on this machine are the side centering bolts. These

are the bolts with lock nuts on them located on the side of both bearing housings that

adjust the top cutting assembly from right to left.

oIt is generally not recommended to adjust these bolts unless the smallest

channel cutting blades are not centered in the cutting channel. To access

this, the user will look down the smallest left channels and visually gauge if

the blades are centered. If these centering bolts have too much play in them,

the entire cutting channel can move too much from right to left during running

wire.

oIf the blades are not centered or have too much play, they can be adjusted.

You really only need the entire cutter assembly (from bearing housing on

right to bearing housing on left) to have about 1/16” of play. Essentially, you

just need enough room for the centering bolts to allow the entire assembly to

raise when a piece of wire goes through the channel and pushes up the entire

cutter assembly. It is generally recommended to set the centering bolts by

unscrewing the centering bolts on both sides of the assembly a few

turns. Then looking down the left (small wire) cutting channels, tap the

housing right or left to get the blades in the center of the channel. Screw the

bolts in evenly from both sides (right and left bolts). Be careful here not to

move the entire assembly. When they are tight against the housings, take

another look down the left channel guides making sure the cutters are still in

the center of the channel groove. If they are not, readjust. Next loosen the

centering bolts by about ½a turn on both the right and left side. This leaves

just enough of an air gap to allow the cutting assembly to raise, but not travel

too much from right to left. Next tighten the lock nuts. Make sure not to

tighten or loosen the centering bolt on this step by using another wrench to

ensure it doesn’t spin.

PROCESSING WIRE

ØThere is a wire guide in front of the main shaft and blade shaft where the cables will

be manually inserted. See wire input guide diagram below for a general

understanding of what wires can go in certain cutting channels.

ØThe wire input guide will be used as a general starting point for processing wire.

Before processing, it is recommended to collect similar wire types to assist in wire

processing efficiency.

MWS-83MD

7

ØSelecting the correct input to run the wire through can take some time and

experience. The general rule is to start in a much larger wire guide than the wire in

question, run the wire, check the wire. If not cut, step down to a smaller input guide

and try it again. It is a general misconception that the user should put a wire in the

hole that is the exact same size of the wire. This is rarely the case. After a while the

user will know from experience which guide is right for certain wire types.

WIRE TYPE GUIDE

ØSheathed flat cable: ≤0.55” (14mm) x 0.31” (8mm) WxH

ØTwisted flat cable: ≤0.31” (8mm) x 0.23” (6mm) WxH

ØSingle-core cable: Dia. Φ0.07” (2mm) ~ Φ1” (25mm)

Round cable Sheathed flat cable Twisted flat cable Single-core cable

WIRE GUIDE DIAGRAM

RUNNING WIRE

ØDo all pre-operational and operational safety checks from Chapter 1.

ØSecuring the machine and installing the hand-wheel and hand-crank or using a user

supplied chuck type drill to the 12mm drill shaft.

ØHave your wires ready to process, by separating them by type and cutting them into

3-4’ lengths.

ØSelect a wire to strip.

ØDecide on which guide is the correct guide input.

MWS-83MD

8

ØIf using the hand crank- run the wire through while turning the hand-crank until the

wire is all the way through. You can also partially run the wire through with the hand-

crank and go to the output of the machine and pull the wire through the remainder of

the way.

ØIf using a drill and the drill shaft, slowly turn the drill forward causing the drill to turn

the lower roller shaft. After a comfortable speed is reached (slowly enough to have

power over the drill and control inputting wire safely) put a piece of wire in the

machine. Be cautious in the beginning to only use your drill as slowly as possible to

get a feel for how quickly the drill pulls the wire in. When in doubt, take your finger

off the power of your drill and regroup.

oIf the wire did not cut through the complete jacket, run it through again

through a smaller channel.

oIf there are no smaller channels, tighten the T-bolt half/full turn closest to the

channel you’re attempting to use.

ØSeparate the wire from the jacket

oOn smaller wire this will be done by pulling the wire out of the jacket.

oFor larger wires with thicker jackets, if you are not able to pull the wire out of

the jacket, you may need to run the wire through again cutting into the

opposite side of the wire jacket.

MWS-83MD

9

Troubleshooting

Problem

Solution

Wires get jammed in the

machine

There are a few possible fixes for this:

1: Loosen the top hand cranks to take pressure off springs to allow more room for

the springs to depress.

2: Check to make sure you are running the wire through the right channel. This

takes some time to figure out. Be patient when clearing the machine. Try the step

down method. Start in a larger hole than you think. Work your way down to a

smaller hole until ideal cut is made.

3: Only use the 1st two channels for running Romex®. They have the Rectangular

Guides.

4: The jacket on the wire you are trying to run is too thick. This machine will not

strip some wires where the jacket is too thick or the materials are too dense, such

as some underground plastics.

For smaller wire, the cut

in the wire jacket is not

in the center of the wire

The side adjustments could be out of alignment on the cutter rollers. The cutter

rollers on the top of the cutting assembly can adjust right to left. The cutting blades

should be centered in the middle of every roller. You can look down the middle of

every roller from front and back of the machine to see if the cutters are in the center.

If they are not, you can adjust the top cutter and rollers by adjusting the side bolts

(with the lock nut) to slightly shift the cutter/roller. Make sure you do not tighten the

bolts too much so the top cutter/roller assembly cannot raise and lower as wire

passes through. Think of these bolts as side stops only, just to keep the assembly

inline, so leave about 1mm gap in-between bolt and cutter/rollers.

The machine is

excessively loud and

makes grinding noise

These machines are generally on the noisier side as they use a gear drive system.

Firstly make sure the gears are greased. This can help with the noise. You can also

check the side adjustments as they could be out of alignment on the cutter rollers.

The cutter rollers on the top of the cutting assembly can adjust right to left/right.

The cutting blades should be centered in the middle of every roller especially those

on the left. You can look down the middle of every roller from front and back of the

machine to see if the cutters are in the center. If they are not, you can adjust the top

cutter and rollers by adjusting the side bolts (with the lock nut) to slightly shift the

cutter/roller. Make sure you do not tighten the bolts too much so the top

cutter/roller assembly cannot raise and lower as wire passes through. Think of

these bolts as side stops only, just to keep the assembly inline, so leave about 1mm

gap in between bolt and cutter/rollers.

The machine is not

cutting through the

entire jacket

Increase the tension on the top hand cranks. It is also possible that either you are

cutting wire that has too thick of a wire jacket or too dense a jacket. These jackets

may not be able to cut with this machine

Chapter

4

MWS-83MD

10

Maintenance

ØKeep machine clean and free of debris.

ØGrease internal gears with red grease or Molybdenum grease as needed.

ØSpray antirust oil on blades and blade shaft as needed.

ØInspect blades occasionally to ensure they are sharp for optimal cutting.

Changing Blades

1. Remove upper cutter/roller tensioners and the springs below them.

2. Use 11/16” socket to remove top bolts, and the spacers below them.

3. Take the top guard off.

4. Take the cutter assembly out.

5. Use adjustable large puller to pull bearing housing off the cutter assembly.

6. Use puller to pull bearing from cutter assembly. Make sure to mark the bearings position on

the steel rod to assure the correct position upon reassembly.

Chapter

5

MWS-83MD

11

7. Unscrew spanner nut clockwise. If you do not have a spanner nut wrench, it is possible to

use a pair of vice grips.

8. MAKE SURE YOU MARK THE SPACERS 1 THROUGH 5 (OR 1 THROUGH 4 FOR THE TOP

ASSEMBLY), SO THAT THEY GO BACK ON IN THE SAME ORDER THAT YOU TOOK THEM

OFF.

9. Blades are ready to come off and be replaced.

MWS-83MD

12

10. When re-assembling put the bearing back into the bearing housing before attaching the

housing to the cutter/roller.

11. Follow all other steps in reverse order to reassemble.

MWS-83MD

13

Parts List

Number&

Code&Number&

QTY&

Material&

Name&

1&&

MWS-83MD-0001&

2""

HT200&

Siding&board&

2&&

MWS-83MD-0002&

2""

45#&

Gear&

3&&

MWS-83MD-0003&

1&&

45#&

Main&shaft&

4&&

MWS-83MD-0004&

1&&

Spacer&

5&&

MWS-83MD-0005&

9&&

65Mn&

Blade&

6&&

GB/T5780-2000&

4"

A3&

Hex&nut&M10x90&

7&&

MWS-83MD-0006&

2""

&&

T&shape&handle&

8&&

GB/T62-1988&

2""

ZL102&

Wing&nut&

9&&

GB/T95-1985&

16&&

&&

Washer&Φ10&

10&&

MWS-83MD-0007&

1&&

Top&shield&

11&&

MWS-83MD-0008&

2""

A3&

Iron&plate&

12&&

MWS-83MD-0009&

2""

HT200&

Pressure&cap&

13&&

MWS-83MD-0010&

2""

65Mn&

Big&spring&

14&&

MWS-83MD-0011&

2""

65Mn&

Small&spring&

15&&

MWS-83MD-0012&

4"

Support&tube&

16&&

MWS-83MD-0013&

1&&

Shovel&

17&&

MWS-83MD-001/f&

1&&

45#&

Blade&shaft&

19&&

GB/T5781-2000&

4"

A3&

Hex&bolt&M8x30&

19&&

MWS-83MD-0015&

4"

A3&

Stopper&plate&-2&holes&

20&&

GB/T5781-2000&

6&&

A3&

Hex&bolt&M8x30&

21&&

GB/T95-1985&

6&&

A3&

Washer&Φ8&

22&&

GB/T41-2000&

6&&

A3&

Hex&nuts&M8&

23&&

GB/T41-2000&

12&&

A3&

Hex&nuts&M10&

24&&

GB/T93-1987&

6&&

A3&

Spring&washer&Φ10&

25&&

GB/T95-1985&

12"

A3&

Washer&Φ10&

26&&

MWS-83MD-0016&

2""

30x30

Angle&iron&base&

27&&

MWS-83MD-0017&

3&&

A3&

Tie&rod&m10&

28&&

MWS-83MD-0018&

1"

Feed&inlet&

29&

MWS-83MD-0019&

2"

A3&

Fasten&bar&

Chapter

6

MWS-83MD

14

Breakdown View

Table of contents