Bobe CMP User manual

IMPORTANT SAFETY INFORMATION: READ AND FOLLOW ALL INSTRUCTIONS

Save these instructions. Leave manual with homeowner after installation.

Improper installation, adjustment, alteration, service, or lack of maintenance can cause injury or property damage. Read

the installation, operating, & maintenance instructions thoroughly before installing or servicing this equipment.

FIRE POT / FIRE TABLE

INSTALLATION INSTRUCTIONS - AUTO IGNITION

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

®

Scan with your phone for Step by Step

instructions, or visit www.c-m-p.com/tech

2

Do not store or use gasoline or ammable vapors and liquids in vicinity of this appliance.

Do not install this appliance near any combustibles. A Liquid Propane cylinder not connected for use

shall not be stored in the vicinity of this or any other appliance.

RISK OF SHOCK OR ELECTROCUTION. Hazardous voltage can shock, burn and cause death or serious

property damage.

Installation must be performed by a licensed professional. Improper installation, adjustment, alteration,

service or maintenance can cause injury or property damage. Installer must follow all local codes as well

as National Fuel Gas Code, ANSI Z223.1.

This product must be installed by a licensed or certied electrician or a qualied pool professional in

accordance with the National Electric Code (NEC) or Canadian Electric Code (CEC), CSA C22.1.

Turn o power to controls before installation/service. Failure to comply will either damage or destroy the

product and will void the warranty.

To reduce the risk of injury, do not permit children to use this product.

If you smell gas, shut o the gas to the appliance and extinguish any open ame. If the odor lingers

keep away from appliance and immediately call gas supplier or re department. Do not leave any ame

unsupervised.

Gas pressure should not exceed 1/2 psi.

Carbon Monoxide Hazard: This appliance can produce carbon monoxide which as no odor. Using it in an

enclosed space can cause serious injury or death. Never use this appliance in an enclosed space such as

a camper, tent, car or home.

.

HOT! DO NOT TOUCH. SEVERE BURNS MAY RESULT. CLOTHING IGNITION MAY RESULT.

Glass and other surfaces are hot during operation and cool-down. CAREFULLY SUPERVISE children near

this appliance. Alert children and adults to hazards of high temperatures.

IMPORTANT WARNINGS & SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

DANGER

SAVE THESE INSTRUCTIONS

ADHERE TO ALL LOCAL CODES CONCERNING INSTALLATION AND OPERATION.

• For outdoor use only.

• Product is not intended to be a starter for wood or any other combustibles.

• Test for gas leaks prior to use.

• Verify correct gas fuel type. Never use an alternative fuel, including bio-fuel, ethanol, lighter uid or any other fuel.

• Installation must be performed by licensed gas piping professional.

• When product is not in use for an extended period, turn o gas to prevent unwanted start-up.

• The use of a cover when not in operation is recommended.

• Verify gas shut o is located outside of the product or column. The gas shuto should NOT be used to adjust ame

height.

• An approved gas valve or keyed valve shall be installed upstream of the unit and located in an accessible area that is

within 5ft from the unit.

Do not modify units from factory conguration. Doing so will void the warranty.

Manufacturer is not responsible for damage due to improper installation.

NOTICE

3

B. SYSTEM REQUIREMENTS

Installation must be performed by a licensed contractor. Installer must follow all local codes as well as National Fuel Gas

Code, ANSI Z223.1. We suggest that our products be serviced annually by a professional certied in the US by the National

Fireplace Institute (NFI) as NFI Gas Specialists or in Canada by WETT (Wood Energy Technical Training). Installer must follow all

instructions carefully to ensure proper performance and safety.

NOTICE

This Product is for outdoor use only.

GAS REQUIREMENTS

REQUIRED GAS PRESSURE

DESCRIPTION WATER COLUMN

LIQUID PROPANE 10"WC

NATURAL GAS 3.5"WC

Input pressure should not exceed 1/2 psi

Note: check with your gas supplier to verify

gas ows and pressures available at the

location of your installation. In many cases

utility companies will install larger meters at no

charge to accommodate larger ows.

PERFECT FLAME™FIRE LINE

BURNER SIZE BTUS

IN K’S

FIRE LINE -24” 40

FIRE LINE -29” 50

FIRE LINE -35” 55

FIRE LINE -48” 70

FIRE LINE -61” 80

FIRE LINE -74” 85

FIRE LINE -87” 95

FIRE LINE -100” 105

FIRE LINE -113” 115

FIRE LINE -126” 150

FIRE LINE -134” 175

FIRE LINE -146” 185

PERFECT FLAME™FIRE RING

BURNER SIZE BTUS

IN K’S

FIRE RING - 9” 50

FIRE RING -16” 120

FIRE RING -22” 175

FIRE RING -29” 230

FIRE RING -35” 240

FIRE RING -42” 270

ELECTRICAL REQUIREMENTS

• Auto ignition requires 12 VAC

• The included transformer steps down from 120 VAC to 12VAC

• Installer should check voltage after installation to ensure proper values

• In the United States the National Electrical Code® (NEC®) and in Canada the Canadian Electrical Code (CEC), require that

all metallic components of a pool structure, including reinforcing steel, metal ttings and above ground components be

bonded together (forming an equipotential bonding grid) with a solid copper conductor not smaller than an 8 AWG (6

AWG in Canada).

• To prevent premature failure of the appliance resulting from stray voltages and voltage dierentials, the burner must be

bonded to other equipment which is part of the pool plumbing system with a solid copper wire not smaller in diameter

than 8 AWG (6 AWG in Canada).

• The National Electrical Code® (NEC) allows listed low-voltage gas-red lumiaires, decorative replaces, re pits and

similar equipment using low voltage igniters that do not require grounding, and are supplied by a listed transformer /

power supply with outputs that do not exceed the low-voltage contact limit (15 V RMS ac, 30 V continuous DC) to be

permitted to be located less that 1.5m (5ft) from the inside walls of the pool.

• Metallic equipment, including metallic gas piping, shall be bonded in accordance with the NEC in the US, and Canadian

Electrical Code (CEC) in Canada.

• In the NEC and CEC require that all metallic components of a pool structure, including reinforcing steel, metal ttings and

above ground components be bonded together (forming an equipotential bonding grid) with a solid copper conductor

not smaller than an 8 AWG (6 AWG in Canada)

4

A. FIRE POT/TABLE INSTALLATION

1. LOCATION

DRAINAGE

• Fire pot/tables should have adequate drainage for rainwater. Select a location with adequate drainage. Install above

grade to prevent water retention.

ACCESS

• Leave easy adequate access for installation and maintenance.

• To safely turn o the burner, you must have clear and easy access to the ON / OFF valve AFTER the appliance is

connected to the gas supply.

CLEARANCE

• Recommended Clearances: Sides 4 ft / Top 10 ft: Combustibles/structures not to be closer than 4’ on the horizontal

plane, 10’ overhead. (FIG 1).

• No combustible structure should be above the re feature.

• Do not completely enclose. No more than two side structures should be around the re feature.

• Do not recess the re feature below ground/oor level.

• Natural stone such as granite or marble must be kept away from heat and ame. Contact and close proximity can

result in cracking or explosion.

• Install re features out of the way of pedestrian trac. Provide space to allow a safe distance from the heat and ame.

• Vent collars and drainage should never be obstructed.

10ft

4ft 4ft

OUTDOOR

USE ONLY FLAMMABLE

OR COMBUSTABLE

ITEMS

FIGURE 1: Adequate Clearance

2. SETUP

DRAINAGE

• For natural gas only, a dedicated drain line may be installed under the pot/table.

• Installations using propane should not have drains located below the unit. Drainage should be achieved with vent

holes in the product and/or around the column.

VENTING

• WARNING: All installations must have proper ventilation around and under the unit to allow possible accumulated gas

to escape. Failure to do so may cause a dangerous build-up of gas and can explode.

• Ventilation location must be such that any settled gas can escape.

• Vents are pre-installed in the re pot and table. If installing on an open column or pedestal, ventilation must be added

to prevent dangerous gas build-up.

5

A. FIRE POT/TABLE INSTALLATION

• The top of a column or pedestal on which re feature is installed should be sealed around.

• A minimum of two vents on opposing sides of a column are required. See Table 1 for minimum vent requirements.

Multiple vents evenly spaced totaling minimum requirement or more is also acceptable. Minimum air openings shall

not be less than 3 inches.

• One vent should be within 12 inches of the bottom of the column and another within 12 inches from the top of the

column.

• Vents should not be blocked from air circulation.

VENTILATION OPENING SIZE

BURNER SIZE BTUS

IN K’S

MINIMUM VENT SIZE

EACH TWO REQUIRED

FIRE RING -9” 50 12.5in2

FIRE RING -16” 120 30in2

FIRE RING -22” 175 43.8in2

FIRE RING -29” 230 57.5in2

FIRE RING -35” 240 60in2

FIRE RING -42” 270 67.5in2

FIRE LINE -24” 40 10in2

FIRE LINE -29” 50 12.5in2

FIRE LINE -35” 55 13.8in2

FIRE LINE -48” 70 17.5in2

FIRE LINE -61” 80 20in2

FIRE LINE -74” 85 21.3in2

FIRE LINE -87” 95 23.8in2

FIRE LINE -100” 105 26.3in2

FIRE LINE -113” 115 28.8in2

FIRE LINE -126” 150 37.5in2

FIRE LINE -134” 175 43.8in2

FIRE LINE -146” 185 46.3in2

AIR MIXER FOR PROPANE UNITS

BURNER SIZE AIR MIXER P/N AIR MIXER BTUS

FIRE RING -9” 8-1392-01 50K

FIRE RING -16” 8-1450-01 120K

FIRE RING -22” 8-1451-01 175K

FIRE RING -29”

8-1453-01 240K

FIRE RING -35”

FIRE RING -42” 8-1454-01 270K

FIRE LINE -24”

8-1392-01 50KFIRE LINE -29”

FIRE LINE -35”

FIRE LINE -48”

8-1459-01 85KFIRE LINE -61”

FIRE LINE -74”

FIRE LINE -87”

8-1450-01 120KFIRE LINE -100”

FIRE LINE -113”

FIRE LINE -126”

8-1459-01 170K ( 2 ×85K)

FIRE LINE -134”

FIRE LINE -146”

TABLE 1: COLUMN VENT REQUIREMENT

3. GAS LINE

• To eliminate unnecessary pressure drop, ensure the pipe length and amount of elbows used is minimized.

• Corrugated ex hoses are known to cause a whistling sound. A whistle-free hose is recommended for gas supply to

the burner.

• You must have clear and easy access to the ON / OFF valve AFTER the appliance is installed and connected to the gas

supply in order to safely turn o the burner.

• Openings from the gas/water line should be sealed, so that gas does not collect in these spaces.

• For gas pressure and BTU requirements see charts on page 3.

6

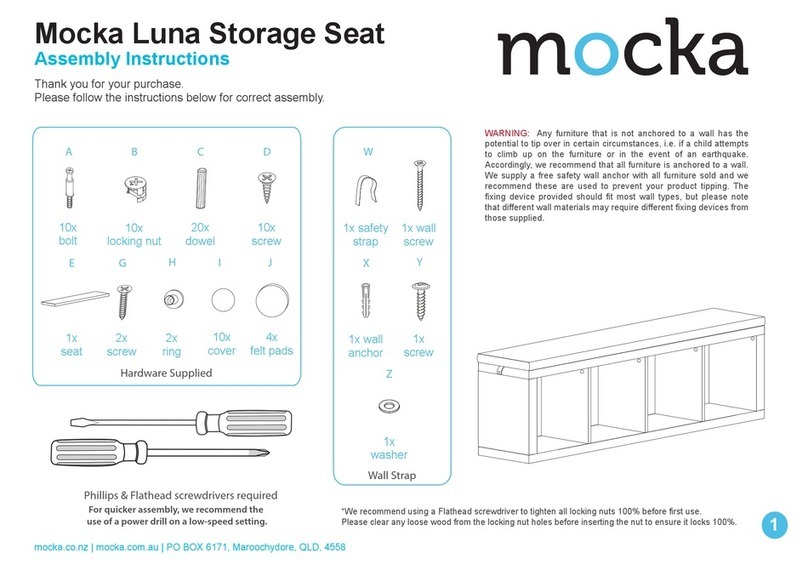

1. AUTO IGNITION COMPONENTS

• All gas and electrical connections are on the box.

• Transformer: 120VAC to 12 VAC transformer is included.

• Pilot Connections: Probes connect to the side of the box to the SS burner and spark electrode. There is a dedicated

gas line pre-installed for the pilot ame.

• Other Items

• Air mixer: Pre-installed with Liquid Propane units

• Flow restricter: Pre-installed with Natural Gas units

• Gas ow regulator: Pre-installed with 18in exible gas line

• Shut-o valve: Not included

Burner

Ceramic

Heat Shield

Spark

Igniter Air Mixer (LP)

Flow Restricter (NG)

Igniter

Power

Pilot Gas

1/2in Gas

Connection

Gas Line

Pressure

Regulator

Shutoff

Valve

Bonding

Lug

12VAC Power

from Transformer

Connection

to 12VAC

FIGURE 1: COMPLETE AUTO IGNITION SYSTEM

2. IMPORTANT INFORMATION FOR PROPANE UNITS

• Air mixers required for Liquid Propane. For propane units, the correct air mixer should come pre-installed.

• Do not attempt to move, adjust or remove the air mixer for LP units. Failure to do so could result in personal injury

and damage to unit/property.

• Vent collars for an air mixer intake on a propane system should not be obstructed.

• Our units are NOT intended to be used with small portable LP tanks.

B. AUTO IGNITION INSTALLATION

7

B. AUTO IGNITION INSTALLATION

3. GAS CONNECTION

a. Before beginning, ensure the gas line is turned OFF.

b. Run 1/2” gas line to the inlet connection of the pre-installed regulator.

• Each unit ships with a regulator pre-installed. All installations must have gas regulator installed to maintain the

gas pressure to the system.

• The regulator should be installed horizontally. The directional arrow should point away from the gas source and

towards the gas valve.

• Gas regulator should be placed near the bottom of the re feature such that it is not aected by temperature

from the burner.

c. Use pipe dope/joint compound on ALL threaded ttings EXCEPT ared ttings.

d. Verify all gas connections are tightened securely. ALWAYS perform leak tests and make repairs as needed.

e. DO NOT daisy chain the gas lines. (See Section D)

f. A shut-o valve must be installed at each re feature or valve. The primary gas valve must be located where they can

be easily accessible so that the gas can be shut o quickly in case of an emergency.

g. Keep pipe length and elbows to a minimum to eliminate unnecessary pressure drops.

h. The use of a corrugated gas line can cause unwanted noise.

4. ELECTRICAL CONNECTION

a. Power Requirements

1. Auto ignition requires minimum 12 VAC

2. The included transformer steps down from 120 VAC to 12VAC.

3. Installer should check voltage after installation to ensure proper values.

4. Max length of wire from the transformer to system is up to 75ft with 16 Gauge wire.

5. For distances over 75ft - 150ft use 14 Gauge wire.

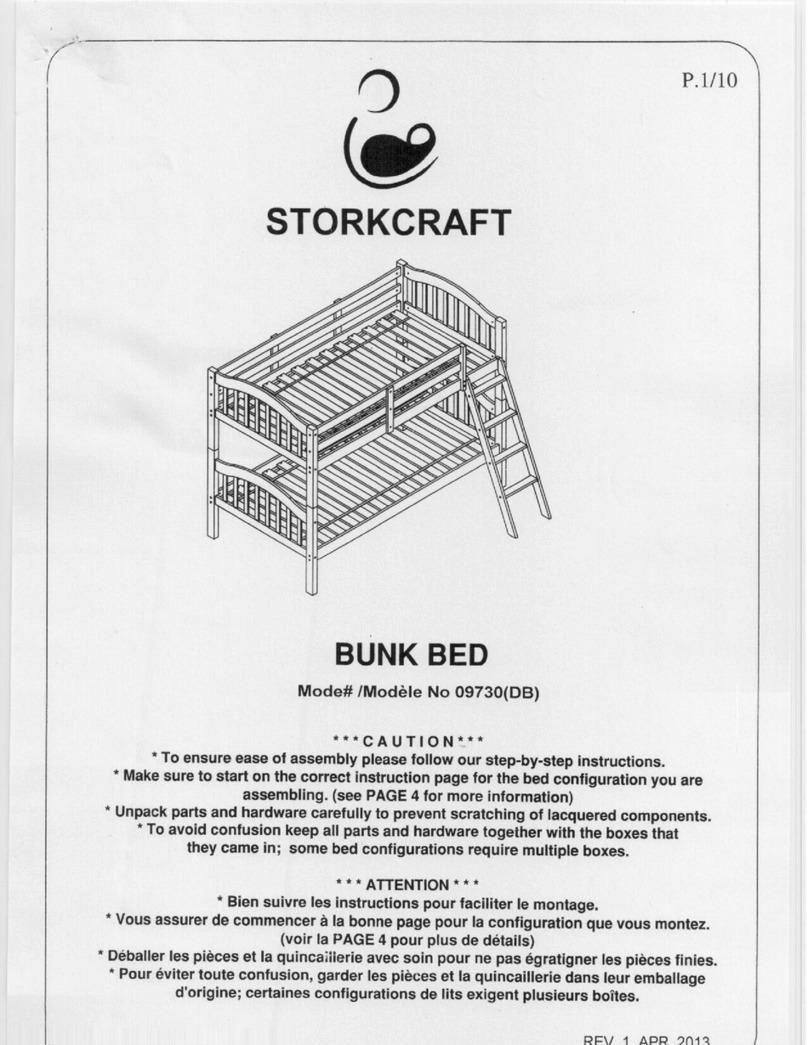

b. Connections (Fig 2)

1. Run electrical cable through an approved conduit. Conduit should be sealed to prevent gas settling or intrusion.

2. Connect 120V to the included or approved Pool & Spa Rated Class 2 transformer (T).

3. There are three wire connections on the side of the auto igniter. Connect 12V power from the transformer using

wire nuts (3).

4. Wrap wire nuts with electrical tape or use waterproof wire nuts to prevent moisture from getting in. Make sure

wire nuts are positioned away from the bottom of the burner assembly.

5. Connect ground from incoming power. (If required by local codes)

6. Do not “daisy chain” electrical lines. (See Section D). Each transformer can supply up to four auto ignitor

connections.

7. The igniter contains a bonding lug on the bottom. To install, loosen the set screw, insert the bond wire into the

hole and tighten the setscrew until the bond wire is secured into place.

8

B. AUTO IGNITION INSTALLATION

BURNER

X1 BLACK

X2 ORANGE

X1 BLACK

120V BLACK

X2 ORANGE

GREEN / GROUND

TRANSFORMER

120V WHITE

GREEN

FIGURE 2: WIRING DIAGRAM

4. CHECK SYSTEM

a. Perform all above listed safety checks before start up. Before operating smell all around the appliance area for gas

odors and next to the oor because some gases are heavier than air and will settle on the oor.

b. Ensure any person standing close to the re feature is aware you will be turning the re feature on prior to actually

turning it on.

c. Do not add glass or rock media to the pan until a system test is complete.

d. At each burner assembly, check that the spark electrode is arcing from the pilot to the button. You should be able to

hear and see the electrode spark. If there is no spark, make sure that the burner assembly is receiving 12VAC from the

control panel.

e. Allow the unit to run for approximately ve minutes then turn o.

f. After all units have been lit, they can be adjusted for ame size.

g. Turn on system and check for re-ignition.

9

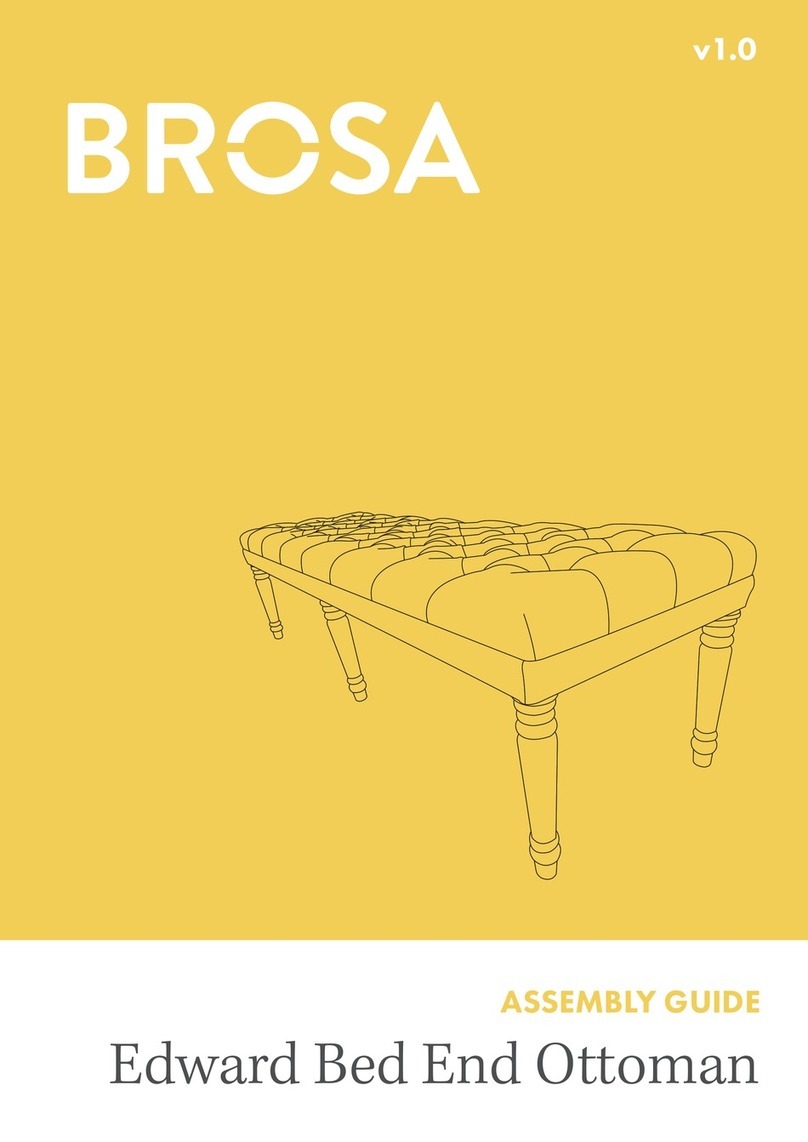

C. OPERATION & MAINTENANCE

1. GLASS OR ROCK FILL MEDIA

• Use only approved re glass or rock media on burners. Incorrect media can melt or explode leading to bodily injury

or product damage.

• Glass media max level: ll up to 1/4in above the burner height.

• For glass or rock ll media, leave an airow gap around the ventilation slots for the pilot light box.

Max Glass Media

Airflow GapPilot

FIGURE 3: MEDIA PLACEMENT

2. BURNER SETUP

• Prior to turning appliance on visually inspect re feature to ensure debris such as leaves or other combustible

material has not collected inside the feature. This could burn and emit embers once the re feature is turned on.

• Each burner should have a ame height of approximately 12” – 15” from the top of the pan.

• Each burner should be adjusted as required so that the ame size at each burner is similar in appearance to each

other.

• Install decorative rock or glass on top of the “burner support” and burner assembly. Do not completely cover/

obstruct the burner.

3. START UP

a. WARNING: Perform all above listed safety checks before start up.

b. Before operating, smell around the appliance area for gas odors and next to the oor because some gases are

heavier then air and will settle on the oor.

c. Ensure any person standing close to the re feature is aware you will be turning the re feature on prior to actually

turning it on.

d. Turn System on.

e. If the system locks, reset by turning power OFF and then back ON.

f. The pilot ame will ignite. The main gas valve will open after the pilot ame is lit. If main re does not ignite, the

system will cycle and attempt to light again.

g. If the pilot ame is extinguished at any time, the system will shut down. It will automatically attempt to restart again

with the ignition sequence.

h. Once installed, the gas control valve should not be used to adjust the ame.

10

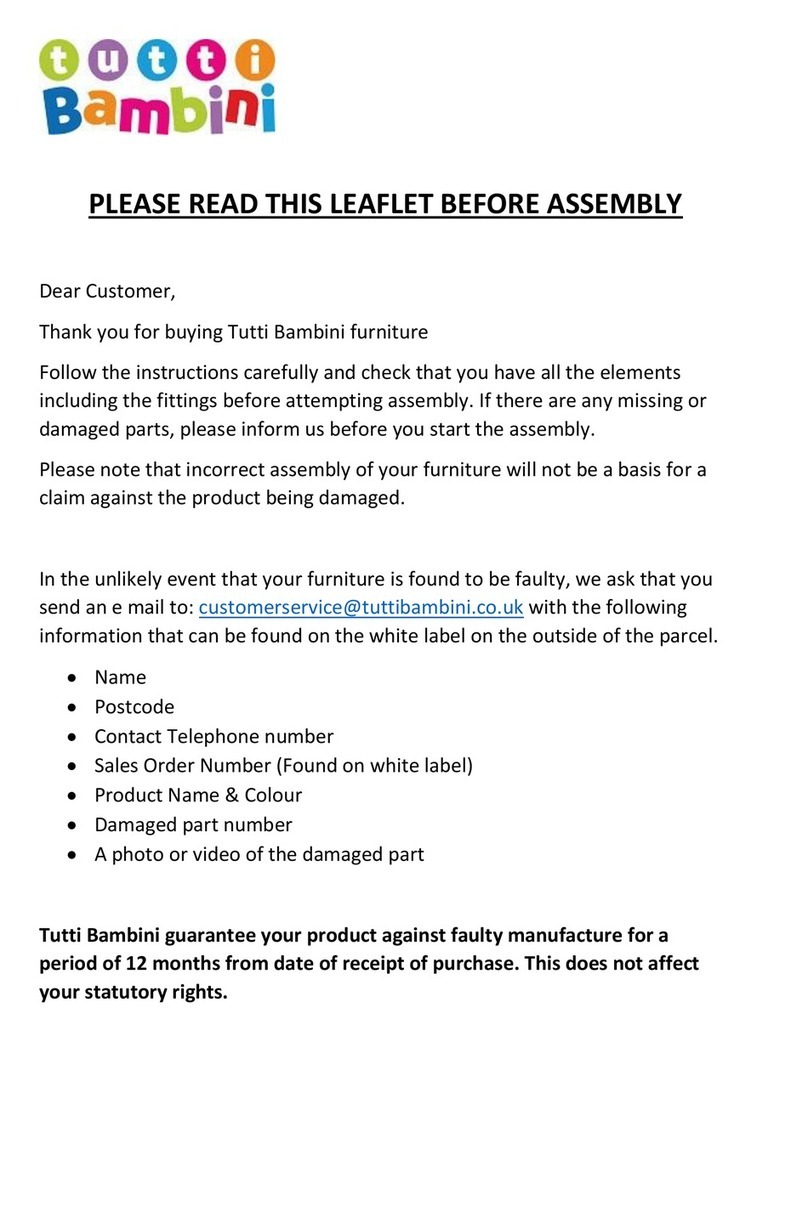

C. OPERATION & MAINTENANCE

SYSTEM START UP

SYSTEM SHUT DOWN

ACTIVE FLAME Flame

Extinguished

ELECTRODE

ACTIVATES

PILOT GAS

VALVE OPEN

IGNITER ATTEMPTS

TO LIGHT

System Light

System Does

Not Light

Re-attempt

15 Times

Cycle

On & O

FIGURE 4: START-UP SEQUENCE

4. MAINTENANCE & CARE

• If any repairs are required, contact a licensed professional.

• Burner

• Inspect the burner before each use of the appliance. If there is any evidence that the burner is damaged, it must

replaced before operating.

• Periodically clean the burner assembly with a wet cloth or cleaning solution to remove carbon build-up. Frequency

of the cleaning will depend on usage. Clean burners as necessary using compressed air.

• Periodically inspect the underside of the burner assembly for any signs of excessive temperatures.

• Check that all gas connections are tight.

• The burner assembly should be covered and protected from snow and ice. The burner should not be operated in

high wind conditions.

• Visually inspect burner holes for debris/insect infestation.

• Pilot assembly requires at least yearly maintenance. Clean the carbon build up on the spark electrode and pilot using

compressed air

• Inspect the gas line regularly. If the line shows evidence of excessive abrasion or wear or if the line is damaged, it must

be replaced before use.

• USE THE SYSTEM! If the feature has been inactive for an extended period, turn re feature on to ensure proper

operation.

11

C. OPERATION & MAINTENANCE

5. MATERIAL CARE

COPPER

PATINA: Dark brown to green to blue. All copper products will patina. Patina is a natural process of oxidation where copper

reacts to the elements and produces a series of colors that build up in order to protect the copper. The nal color can vary

widely depending on location, environment and other factors.

WHAT COLOR WILL MY PRODUCT BE?

All products ship in their natural copper state. Depending on where they are stored or transported, patina may begin to

develop. It is very likely the color may change between manufacture and delivery and will continue to patina after installation.

Copper can be cleaned after installation to reset the patina process.

CLEANING

• Patina color may vary from piece to piece, even when delivered on the same day. If you prefer to restore the material after

installation, a cleaning solution such as TarnX® may be used.

• Hand Prints/Water Spots: Products develop hand prints from handling or water stains from water testing. The natural patina

process will cover up the markings as the whole piece begins to darken.

STAINLESS STEEL

PATINA

Stainless steel does not develop a patina.

CLEANING

• Stainless steel is steel that is “stain-less” however, this DOES NOT MEAN THAT STAINLESS STEEL WILL NEVER RUST OR

CORRODE. Stainless steel can show water spots and deposits of minerals or other natural substances that appear orange,

white and/or brown. We suggest regular cleaning, at least once a month.

• Use distilled, soft or puried water (preferably warm) while cleaning and as a last rinse. Dry with a soft cloth.

• General maintenance can be done with a soft cloth. Windex works well if you want to remove water spots. Otherwise a mild

soap or vinegar (1 part vinegar to 3 parts water) will remove light buildup.

• Try to go in the direction of the natural polishing grains

• Heavier build-up can be cleaned using very ne red Scotch-Brite™cleaning pads.

• In many cases, cleaning over time will greatly reduce reappearance of build-up.

SALTWATER

Stainless steel is not warranted for use in or around salt water. Our products are made of 316 marine grade Stainless Steel.

Stainless steel can get water spots and stainless steel can get deposits of minerals or other natural substances that appeared,

white and/or brown. If this happens you’ll need to clean the areas each time the build up occurs and after 3-6 cleanings the

problem areas should be free of any build up returning.

12

D. TROUBLESHOOTING

SITUATION POSSIBLE CAUSE CORRECTIVE ACTION

Pilot will not light

Air in gas line On a new install, it may take multiple attempts

to completely purge air. On an existing install,

check for leaks.

Debris in gas line Conrm gas line is clear (insulation, dirt, plastic,

excessive pipe sealer etc..)

Igniter element is damaged Replace igniter element

High winds Wait for wind to subside or rotate pan so wind

does not blow across pilot.

Pilot will not spark Check voltage to burner. If no voltage, replace

transformer. If correct voltage detected, replace

ignition module.

No pilot gas Turn gas o and conrm pilot solenoid is

energizing. If not energizing replace ignition

module. If energizing but not opening, replace

gas manifold.

Incorrect gas pressure Conrm proper gas pressures. Check for leaks.

A regulator must be installed at each burner.

System will not light / will not

stay lit but the pilot ame is lit

Incorrect gas pressure Conrm proper gas pressures. Check for leaks.

Improperly applied media Remove excess media on burner and remove

the excess media near the pilot housing

Pilot is lit but main burner will

not light

Solenoid failure Check for signs of overheating. If valve is

buzzing or will not energize, replace ignition

module.

System with lava rock has a

small ame

Wet/damp lava rock Lava rock is porous and will hold moisture.

As the heat dries the lava rock out the ame

should grow larger.

Burner or pilot will not shut o Valve is stuck or dirty Replace the gas manifold

13

D. TROUBLESHOOTING

SITUATION POSSIBLE CAUSE CORRECTIVE ACTION

System shutdown due to

high temperature

Temperature exceeding the limit Adequate ventilation should be provided

per instructions

Whistling sound Corrugated gas line used for installation Use whistle free hose - Adjust hose to

create the path of least resistance for gas.

System with propane does

not burn correctly / is very

black / produces a lot of

soot.

Lack of ventilation will cause improper

burning or failure

Conrm air mixer is installed correctly.

Check for proper ventilation do not block

an ventilation paths in the system.

Propane source may be introducing

impurities into the system

Check with your propane provider

COMMON ISSUES/MISTAKES

• Check line connections - do not daisy chain gas or electrical connections. (see Section C)

• Check gas pressure for natural gas and propane. (see Section B)

• If using with propane gas - ONLY use with air mixer correctly installed. (See Fig 2) The ½ “ air mixer for propane

includes stamped marking for gas ow direction. Air mixer is not required with natural gas.

• Check electrical voltage and connections.

• Check ground connections. (if required)

• Upon completing the gas line connection, a small amount of air will be in the lines. When rst lighting the burner, it

will take a few minutes for the lines to purge themselves of this air. Subsequent lighting of the appliance should not

require such purging.

DO NOT DAISY CHAIN

DO RUN INDIVIDUAL LINES

FIGURE 6: DAISY CHAIN GUIDE

14

D. TROUBLESHOOTING

HOW TO PERFORM A LEAK TEST

a. Prepare a leak testing solution of soapy water by mixing in a spray bottle one part liquid soap to one part water.

b. Make sure all the control knobs are in the OFF position.

c. Turn on the gas.

d. Apply the leak-testing solution by spraying it on joints of the gas delivery system. Blowing bubbles in the soap

solution indicates that a leak is present.

e. Stop a leak by tightening the loose joint or by replacing the faulty part with a replacement part recommended by the

manufacturer.

f. Turn the control knob back to the full OFF position.

g. If you are unable to stop a leak: Please consult a gas specialist. Shut o the gas supply to the feature and release

pressure in the hose and manifold. Call/consult an authorized gas appliance service technician or a liquid propane

gas dealer. DO NOT use the appliance until the leak is corrected.

Perform a leak test at least once a year whether the gas supply has been disconnected or not. Whenever any part of the gas

system is disconnected or replaced, perform a leak test. As a safety precaution, remember to always leak test outdoors in a

well-ventilated area. Never smoke or permit sources of ignition in the area while doing a leak test. Do not use a ame, such as

a lighted match to test for leaks.

SAVE THESE INSTRUCTIONS

INSTALLER -LEAVE THIS INSTRUCTIONS WITH HOMEOWNER

Record Information on this System Below & Keep for Your Records

Installer _______________________________________________________________

System Purchased From ______________________________________________

Installation Date _____________________________

Serial Number _______________________________

CMP, LLC

36 HERRING ROAD, NEWNAN, GA 30265

WWW.C-M-P.COM/Bobe

0621sb REV E

®

Other manuals for CMP

1

Table of contents

Popular Indoor Furnishing manuals by other brands

BROSA

BROSA Edward Bed End Ottoman Assembly guide

Tutti Bambini

Tutti Bambini TB10 ToyBox 211707 Assembly instruction

Piranha

Piranha PC28 Assembly instructions

modway

modway Ripple EEI-1532 manual

Ballard Designs

Ballard Designs CASA Florentina Tarvine Double Pedestal Dining Table... Assembly instructions

Decocasa

Decocasa 224700 Assembly instructions