Bole Laser Craft Grange Farm Tipper Wagon User manual

Other Bole Laser Craft Toy manuals

Popular Toy manuals by other brands

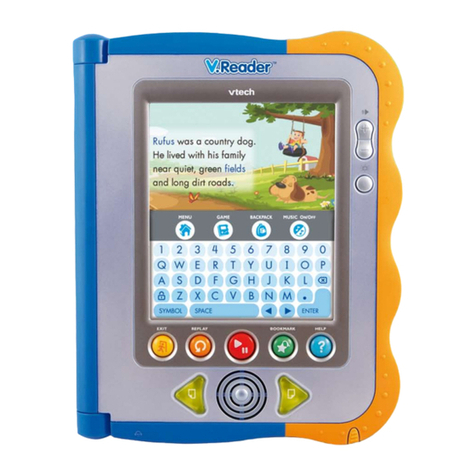

V-tech

V-tech V.Reader Interactive E-Reading System user manual

V-tech

V-tech Magical Lights Unicorn Parents' guide

Micron Wings

Micron Wings Student Flyer instructions

Step 2

Step 2 Lifestyle Custom Kitchen 8569 manual

Pro Boat

Pro Boat Blackjack 55 owner's manual

V-tech

V-tech Toot-Toot Animals Farm user manual

KNEX

KNEX 4 Wheel Drive Truck Building Set Building Basics

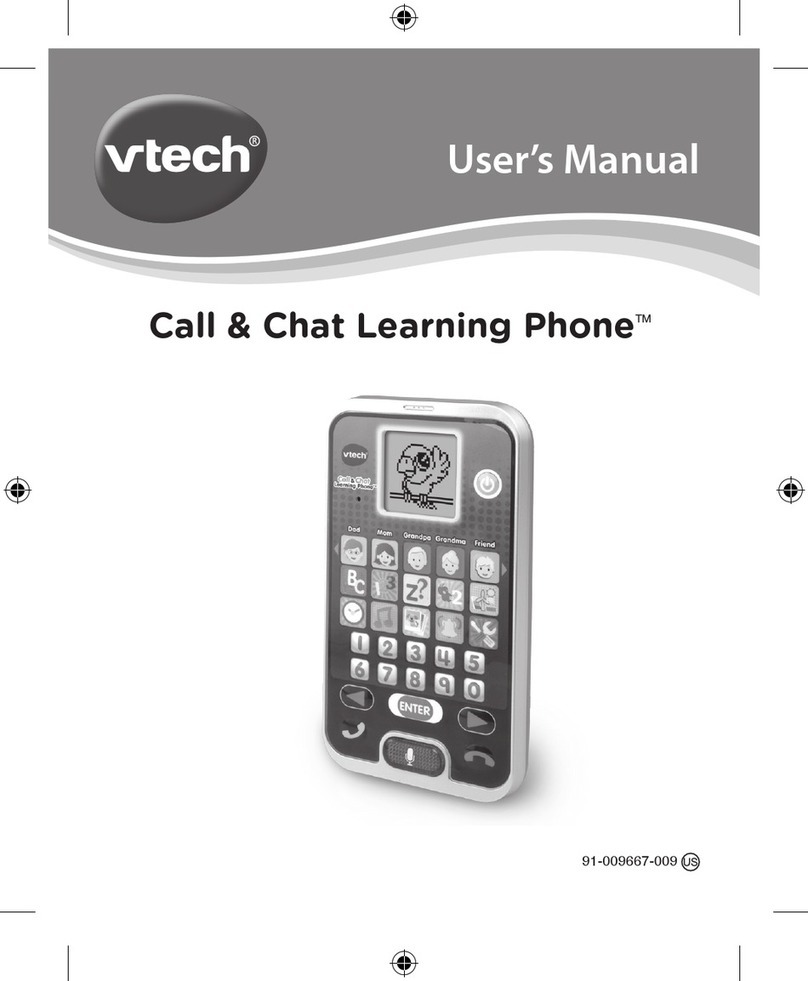

V-tech

V-tech Call & Chat Learning Phone user manual

V-tech

V-tech Go! Go! Cory Carson The Carson Playhouse Parents' guide

J. Perkins

J. Perkins TWISTER BELL 47 manual

V-tech

V-tech 2-in-1 Learn & Zoom Motorbike user manual

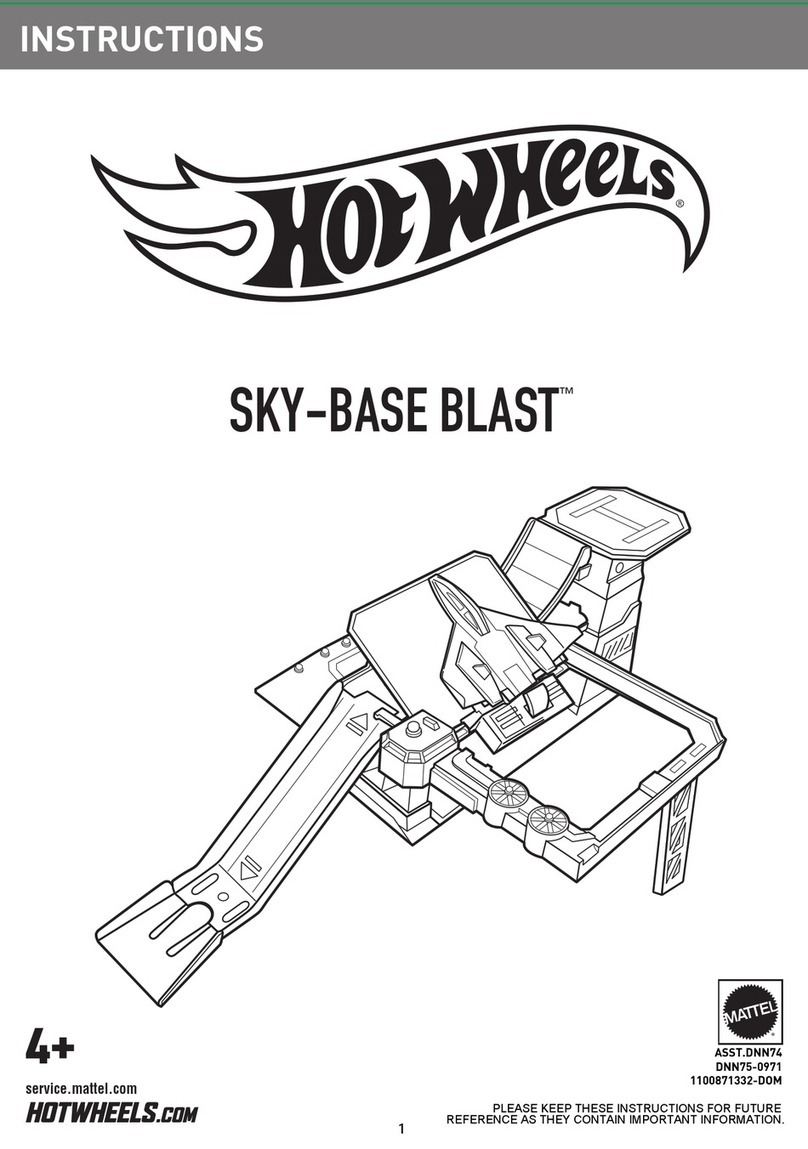

Hot Wheels

Hot Wheels SKY-BASE BLAST instructions

V-tech

V-tech Power Zone 2000 user manual

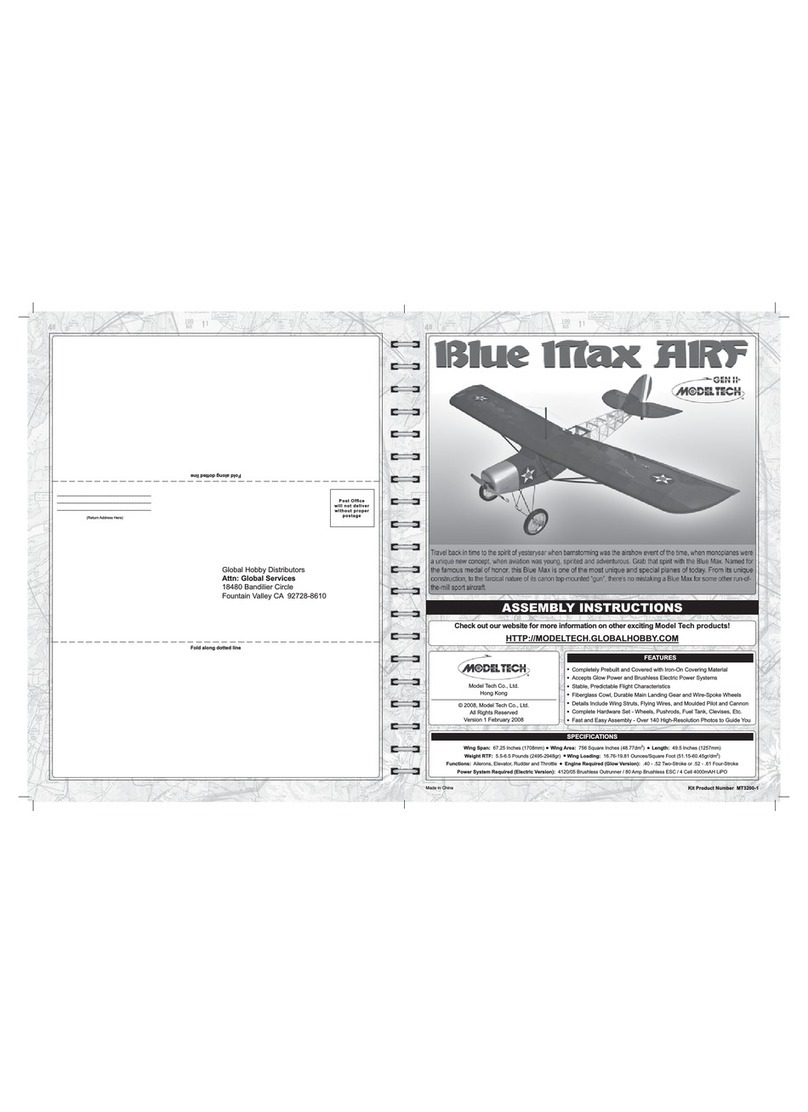

Modeltech

Modeltech Blue Max Assembly instructions

V-tech

V-tech V.Flash: Spiderman Countdown to Doom user manual

Hobby King

Hobby King Mellizo-50e manual

KNEX

KNEX SUPER MARIO TANOOKI MARIO 38461 Assembly instructions

V-tech

V-tech Peppa Pig Learning Watch Parents' guide