4

•Avoid creating a source of ignition for spilled fuel. Do not

startthe engine until fuel vapors dissipate.

•Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not smoke.

Keep sparks and open flames away from the area while

addingfuel or operating the unit.

WHILE OPERATING

•Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can be fatal. Operate this unit

onlyin a well-ventilated outdoor area.

•Wear safety glasses or goggles that meet ANSI Z87.1 stan-

dards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face or dust mask if the

operationis dusty.

•Wear heavy long pants, boots, gloves and a long sleeve

shirt. Do not wear loose clothing, jewelry, short pants, san-

dalsor go barefoot. Secure hair above shoulder level.

•The cutting attachment shield must always be in place while

operating the unit. Do not operate unit without both trim-

ming lines extended, and the proper line installed. Do not

extendthe trimming line beyond the length of the shield.

•This unit has a clutch. The cutting attachment remains sta-

tionary when the engine is idling. If it does not, have the

unitadjusted by an authorized service technician.

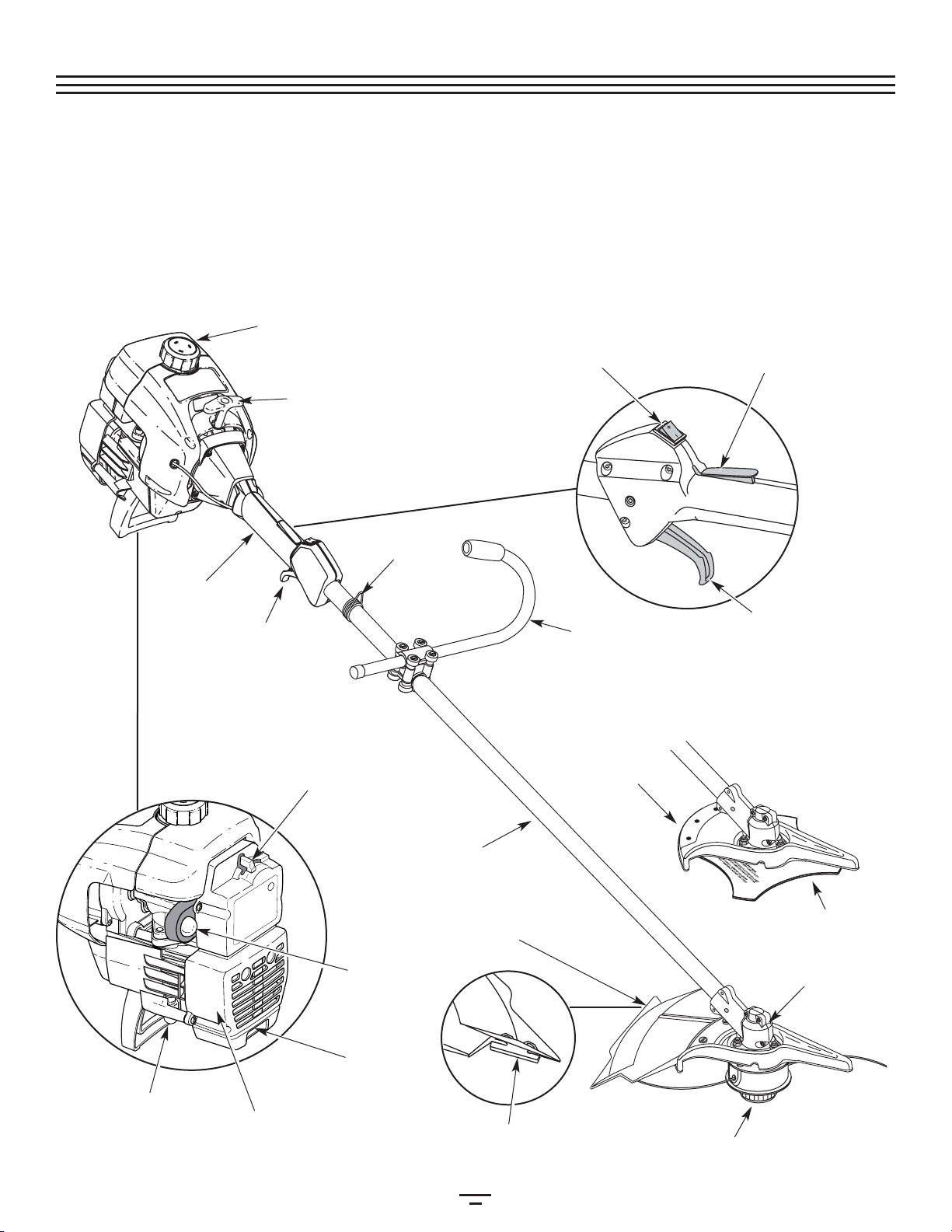

•Adjust the J-handle to your size in order to provide the best

grip.

•Be sure the cutting attachment is not in contact with any-

thingbefore starting the unit.

•Usethe unit only in daylight or good artificial light.

•Avoid accidental starting. Be in the starting position when-

ever pulling the starter rope. Both the operator and unit

must be in a stable position while starting. Refer to the

Starting/StoppingInstructions.

•Usethe right tool. Only use this tool for its intended purpose.

•Donot overreach. Always keep proper footing and balance.

•Always hold the unit with both hands when operating.

Keepa firm grip on both handles or grips.

•Keep hands, face, and feet at a distance from all moving

parts. Do not touch or try to stop the cutting attachment

whenit rotates.

•Do not touch the engine, gear housing or muffler. These

parts get extremely hot from operation, even after the unit

isturned off.

•Do not operate the engine faster than the speed needed to

cut, trim or edge. Do not run the engine at high speed

whennot cutting.

•Always stop the engine when cutting is delayed or when

walkingfrom one cutting location to another.

•If you strike or become entangled with a foreign object,

stop the engine immediately and check for damage. Do

not operate before repairing damage. Do not operate the

unitwith loose or damaged parts.

•Stop the unit, switch the engine to off, and disconnect the

sparkplug for maintenance or repair.

•Use only original equipment manufacturer replacement

parts and accessories for this unit. These are available from

your authorized service dealer. Use of any non-original fac-

tory parts or accessories could lead to serious injury to the

user,or damage to the unit, and void your warranty.

•Keep unit clean of vegetation and other materials. They may

becomelodged between the cutting attachment and shield

.

•To reduce fire hazard, replace a faulty muffler and spark

arrestor. Keep the engine and muffler free from grass,

leaves,excessive grease or carbon build up.

WHILE OPERATINGWITH CUTTING BLADE

•Read and understand all safety warnings before operating

thisunit.

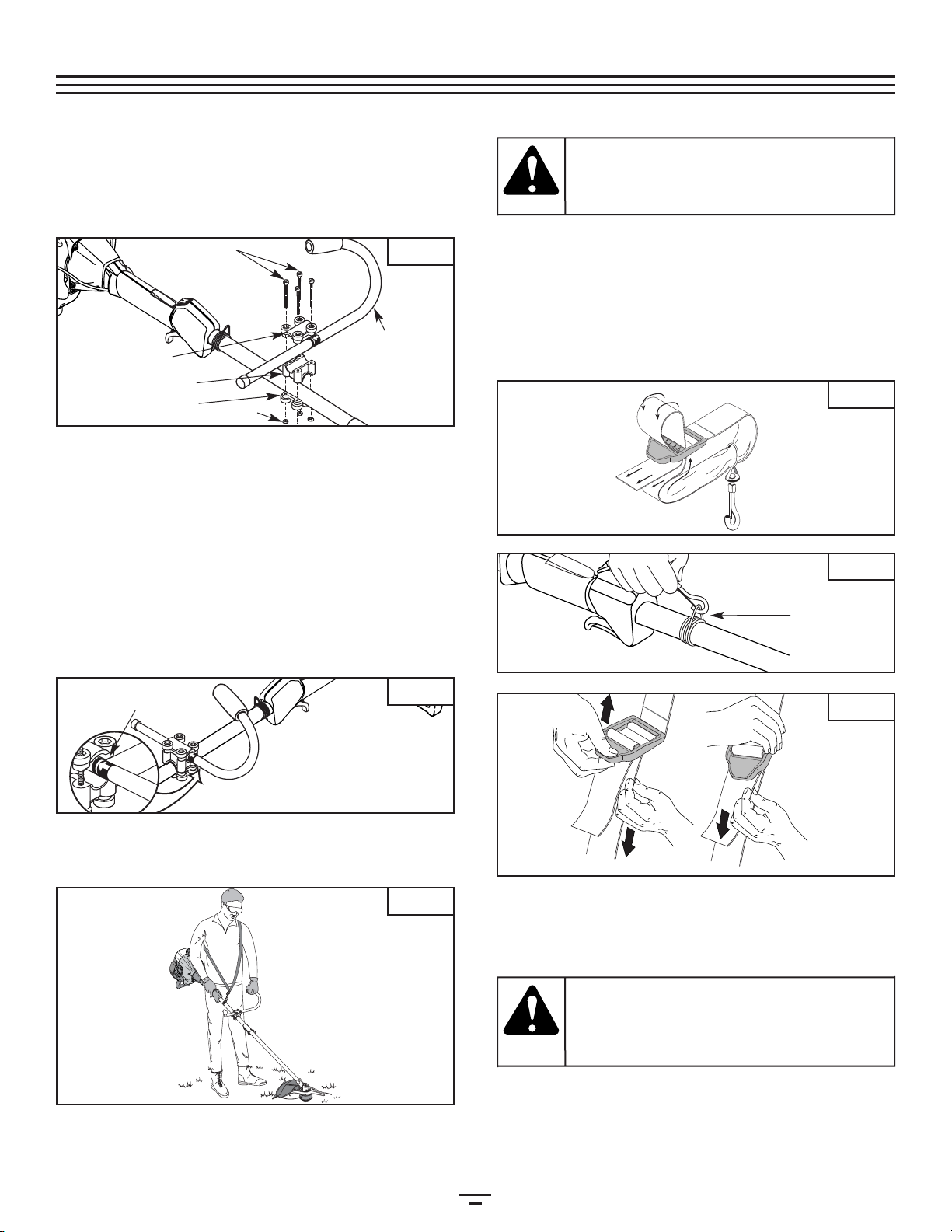

•Always use the shoulder harness when using the brush

bladeaccessory.

•Keep the J-handle between the operator and cutting

attachmentor blade at all times.

•NEVER cut when the cutting blade is 30 inches (76 cm) or

moreabove the ground level.

•Blade thrust may occur when the spinning blade contacts

an object that it does not immediately cut. Blade thrust can

be violent enough to propel the unit and/or operator in

any direction, possibly causing a loss of control. Blade

thrust can occur without warning if the blade snags, stalls

or binds. This is more likely to occur in areas where it is dif-

ficultto see the material being cut.

•For operation with the brush blade, do not cut anything

thickerthan 1/2 inch or a violent kickback could occur.

•Donot attempt to touch or stop the blade when it is rotating.

•Acoasting blade can cause injury while it continues to spin

after the engine is stopped or the throttle trigger is

released. Maintain proper control until the blade has com-

pletelystopped rotating.

•Donot run the unit at high speed when not cutting.

•If you strike or become entangled with a foreign object, stop

the engine immediately and check for damage. Have any

damage repaired before attempting further operations. Do

not operate unit with a bent, cracked or dull blade. Discard

bladesthat are bent, warped, cracked or broken.

•Do not sharpen the cutting blade. Sharpening the blade

can cause the blade tip to break off while in use. This can

resultin severe personal injury. Replace the blade.

•Do not use the cutting blade for edging or as an edger; severe

personal injury to yourself or others may incur. Use the cutting

bladeonly for the purpose as described in this manual.

•Stop the engine IMMEDIATELY if you feel excessive vibra-

tion. Vibration is a sign of trouble. Inspect thoroughly for

loose nuts, bolts or damage before continuing. Repair or

replaceaffected parts as necessary.

After Use

•Clean cutting blades with a household cleaner to remove any

gumbuildup. Oil the blade with machine oil to prevent rust.

•Lock up and store the cutting blade in an appropriate area

toprotect the blade from unauthorized use or damage.

OTHER SAFETYWARNINGS

•Never store a fueled unit inside a building where fumes

mayreach an open flame or spark.

•Allow the engine to cool before storing or transporting. Be

sureto secure the unit while transporting.

•Store the unit in a dry area, locked up or up high to prevent

unauthorizeduse or damage, out of the reach of children.

•Never douse or squirt the unit with water or any other liq-

uid. Keep handles dry, clean and free from debris. Clean

after each use, see CleaningandStorage instructions.

•Keep these instructions. Refer to them often and use them

to instruct other users. If you loan someone this unit, also

loanthem these instructions.

SAVETHESE

INSTRUCTIONS

RULESFORSAFEOPERATION