BONHOEFFER BON-P-BLV-26 User manual

INSTRUCTION MANUAL

BLOWER (3 IN 1)

B

ON-P-

BLV

-

26

2

1. COMPONENT LIST

1. Power unit 2. Upper handle 3. Vacuum tube fans 4. Throttle trigger 5. Trigger Lock

6. Screw of the engine air outlet protrusion 7. First blower tube 8. Second blower tube

9. Second vacuum tube 10. First vacuum tube 11. Air-filter cover 12. ON/OFF switch

13.Choke lever 14. Starter 15.Curved tube 16.Bag 17. Fuel tank 18. Air filter knob

19.Fuel oil mixture canister 20. Socket wrench

3

2. DESCRIPTION OF SYMBOLS

1) Warning! Danger. The failure to use this machine correctly can be hazardous for oneself and others.

2) Read the instruction manual before using the machine

3) If you are using the machine every day in normal conditions,you can be exposed to noise level of 85 dB(A)

or higher.Wear earplugs and a protective helmet.

4) Danger of dismemberment! Never use the machine with the grille open.

5) Warning! Keep away from hot surfaces.

6).The exhaust and other parts of the engine will get very hot during use, do not touch.

EXPLANATORY SYMBOLS ON THE MACHINE (If present)

11)Fuel tank

12)Engine stop switch positions

a=stop

b=run

13 Choke

a=CHOKE=cold engine start

b=RUN=normal gear and warm engine start

3. SAFETY INSTRUCTIONS

A) TRAINING

1) Read the instructions carefully: Become acquainted with the controls and the proper use of the

machine. Learn how to stop the engine quickly.

2.) Only use the machine for purpose for which it was designed, namely:

- The movement and accumulation, by blowing, of leaves,grass, debris of various limited weight and

modest dimensions.

-Vacuum collection of the leaves,grass, various debris of limited weight and modest dimensions,

excluding liquids of any kind.

-The machine must be used for accumulation and collection of inflammable or explosive products,

4

hot embers or combustion material without a flame, lit cigarettes, pieces of grass, sharp objects,

metal objects, stones and any other object that could be dangerous to the operator and others.Any other use

may be dangerous and damage the machine.

3) Never allow children or persons unfamiliar with these instructions to use the machine. Local regulations

can restrict the minimum age of the operator.

4) Never use the machine if the user is tired or unwell, or has taken medicine, drugs, alcohol or any

substances which may slow his reflexes and compromise his judgement.

5) If the machine is sold or lent to others, make sure that the operator looks over the user instructions

contained in this manual.

6) Bear in mind that the operator or user is responsible for accidents or hazards occurring to other people or

their property.

B) PRELIMINARY OPERATIONS

1) Always wear adequate clothing which does not hamper movements when using the machine.

–Always wear slim-fitting protective clothes, anti-vibration gloves, protective goggles, half mask respirator,

protective earplugs, anti-shear safety boots with non–slip soles.

–Never wear scarves, shirts, necklaces or any hanging or flapping accessory that could catch in the machine.

–Tie your hair back if it is long.

2) WARNING: DANGER! Petrol is highly flammable.

–Keep the fuel in containers which have been specifically manufactured and homologated for such use.

–Never smoke when handling fuel.

–Slowly open the fuel tank to allow the pressure inside to decrease gradually.

–Top up the tank with fuel in the open air, using a funnel.

–Add fuel before starting the engine. Never remove the fuel tank cap or add fuel while the engine is running

or when the engine is hot.

–If you have spilt some fuel, do not attempt to start the engine but move the machine away from the area of

spillage and avoid creating any source of ignition until the fuel has evaporated and fuel vapours have

dissipated.

–Immediately clean up all traces of fuel spilt on the machine or on the ground;

–Never start the machine in the same place you refilled it with fuel.

–Make sure your clothing does not come into contact with the fuel, on the contrary, change your clothes

before starting the engine.

–Always put the tank and fuel container caps back on and tighten well.

3) Replace faulty or damaged silencers.

4) Before using the machine, carry out an accurate inspection of the machines efficiency and in particular:

–the throttle trigger must move freely, it must not need forcing and should return automatically and rapidly

back to the neutral position;

–the engine stop switch must easily move from one position to the other;

–the electric cables and in particular the spark plug cable must be in perfect condition to avoid the generation

of any sparks, and the cap must be correctly fitted on the spark plug;

–the machine handgrips and protection devices must be clean and dry and well fastened to the machine;

–the guards must never be damaged;

–the rotor must never be damaged;

–the bag must never be damaged.

5) Thoroughly inspect the whole work area and remove anything that could be projected by the machine

5

(when used as a blower) or block the vacuum tube (when used as vacuum collector) or be a hazardous

source (stones, branches, iron wire, bones etc.).

C) OPERATION

1) Do not operate the engine in a confined space where dangerous carbon monoxide fumes can develop.

2) Do not mount equipment or accessories on the machine not foreseen or approved by the manufacturer.

3) Mow only in daylight or good artificial light.

4) Never use the machine:

–without mounting all the accessories foreseen for each use (as blower or vacuum collector);

–when people, especially children or pets are nearby;

–in confined spaces, in the presence of fumes, in an explosive environment or close to inflammable materials

or electrical equipment.

5) Take on a firm and well-balanced position:

–where possible, avoid working on wet, slippery ground or in any case on uneven or steep ground that does

not guarantee stability for the operator;

–never run, but walk carefully paying attention to the lay of the ground and any eventual obstacles;

–assess the potential risks of the ground to be mown and take all necessary precautions to ensure your own

safety, especially on slopes or on bumpy, slippery or unstable ground.

6) Make sure the machine is securely locked when you start the engine:

–start the engine in an area at least 3 meters from where you re-fuelled;

–check that there is nobody within at least 15 meters of the machine's range of action;

–do not direct the silencer and therefore the exhaust fumes towards inflammable materials.

7) Do not change the engine governor settings or overspeed the engine.

8) Do not strain the machine too much and do not use a small machine for heavy-duty works. If you use the

right machine, you will reduce the risk of hazards and improve the quality of your work.

9) Ensure the machine does not come into contact with foreign bodies and possible flying debris and dust

being thrown up by the air; do not direct the air jet in the direction of people or animals.

10) Never insert objects into the vaccum inlet (when being used as vacuum collector) and avoid the intake of

large objects that could damage the rotor.

11) During use keep your hands well away from the intake grille and from the air outlet and do not obstruct the

air vents.

12) Stop the engine:

–when mounting or removing accessories for blowing or collecting:

–whenever you leave the machine unattended;

–before re-refuelling;

–during movements between work areas.

13) Stop the engine and disconnect the spark plug cable:

–before cleaning, checking or working on the machine;

–after the intake of a foreign body. Inspect the machine for any damage and make repairs before restarting it

again;

–if the machine starts to vibrate abnormally;

–when the machine is not in use.

14) To avoid the risk of fire, do not leave the machine with the engine hot on leaves, dry grass or other

inflammable material.

D) MAINTENANCE AND STORAGE

6

1) Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition. Routine

maintenance is essential for safety and for maintaining a high performance level.

2) Do not perform any work on the machine that is not described in this manual unless adequately skilled with

appropriate tools.

3) Do not store the machine with fuel in the tank in an area where the fuel vapours could reach an open flame,

a spark or a strong heat source.

4) Allow the engine to cool down before storing in any enclosure.

5) To reduce fire hazards, keep the engine, exhaust silencer and fuel storage area free from sawdust,

branches, leaves, or excessive grease; never leave containers with the debris inside the storage area.

6) If the fuel tank has to be emptied, this should be done outdoors once the engine has cooled down.

7) Wear work gloves when performing all maintenance.

8) For safety reasons, never use the machine with worn or damaged parts. Damaged parts are to be

replaced and never repaired. Only use original spare parts. Parts that are not of the same quality can

seriously damage the equipment and compromise safety.

9) Before putting the machine away, check you have removed wrenches or tools used for maintenance.

10) Store the machine out of the reach of children.

E) TRANSPORTATION AND HANDLING

1) Whenever the machine is to be handled or transported you must:

–turn off the engine and disconnect the spark plug cap;

–only hold the machine using the hand grips and position the tubes so that they do not obstruct.

2) When using a vehicle to transport the machine, remove the tubes and position it so that it can cause no

danger to persons and fasten it firmly in place to avoid it from tipping over, which may cause damage or fuel

spillage.

F) ENVIRONMENTAL PROTECTION

1) Dispose of the packaging and waste materials in accordance with the local laws in force.

2) Never pollute the environment with used oil, fuel or other pollutants.

3) At the time of decommissioning, do not pollute the environment with the machine, hand it over to a disposal

center, in accordance with the local laws in force.

G) HOW TO READ THE MANUAL

Certain paragraphs in the manual contain particularly significant information and are marked with various

levels of highlighting with the following meaning:

Or

These give details or further information on what has already been said, and aim to prevent

damage to the machine.

Non-observance will result in the risk of injury to oneself or others.

Non-observance will result in the risk of serious injury or death to oneself or others.

NOTE

IMPORTANT

WARNING

DANGER

7

4. PREPARE THE MACHINE

The machine can be used as both a blower and a vacuum collector; for both of these uses it is necessary to

correctly arrange the appropriate accessories included with the equipment.

Unpacking and completing the assembly should be done on a flat and stable surface,

with enough space for moving the machine and its packaging, always making use of suitable

equipment.

Disposal of the packaging should be done in accordance with the local regulations in force.

1. USE AS A BLOWER (Fig. 1,2,3,4)

Fit the first blower tube with engine:

–Remove the screw of protrusion of the air outlet align the first blower tube hang hole with the protrusion of

the air outlet, and insert the first blower tube. See Fig.1,

–Then tighten the two screws in Fig.2

Fit the first blower tube with second tube

–Align the second blower tube compartment with the protrusion of the first tube, push the tube and turn it 90°

clockwise, in order to fix it in place, and tighten the screw. Then the blower tube assembled.See Fig.3.

Note: The blower function incl. two tube, first tube and second tube. In this machine, for second tube,

it incl. two kinds, one is round and another is flat, function and assembly steps are the same.

The machine is correctly assembled when the second tube of the blower chute is pointed

towards the ground.

WARNING

NOTE

NOTE

8

The engine can not start if you don’t assemble the blower tube when using as blower.

2. USE AS A VACUUM COLLECTOR (Fig. 2)

Fig. 5+6+7+8

Fit the first vacuum tube with engine:

–Press the pin of the vacuum tube cover and pull up the cover in Fig.5.

–There are 4 grooves in the end of the first vacuum tube, align the grooves with the pin of the engine housing,

push the tube and turn it 90° anticlockwise, in order to fix it in place, see Fig.6

Fit the first vacuum tube with second tube

–Align the second vacuum tube compartment with the protrusion of the first tube, push the tube and turn it

90° clockwise, in order to fix it in place, and tighten the screw. Then the blower tube assembled.See Fig.7

Fit the first leaf collecting tube and bag

–Remove the screw of protrusion of the air outlet align the leaf collecting tube hang hole with the protrusion of

the air outlet, and insert the first blower tube. See Fig.8.1

9

–Then tighten the two screws in Fig.8.1

–Insert the tube fitting end chute in the specific bag and close the opening with the supplied strap.See Fig.8.2

Fit the single harness

–Hang the belt over your shoulder and adjust height using the strap like Fig.9

The machine is correctly assembled when the tube’s terminal chute is pointed downwards

and to the left of the operator.

The machine is correctly assembled when the rounded part of the chute is pointed towards

the ground.

The engine can not start if you don’t assemble the vacuum tube when using as

vacuum.

5. PREPARING TO WORK

CHECKING THE MACHINE

Before starting work please:

–check that all the screws on the machine are tightly fastened;

–when used as a vacuum collector, make sure the bag is integral, well-closed and that the zipper works

correctly;

–check that the air filter is clean;

–check that the handgrips are well fastened;

–prepare accessories according to the type of work (as blower or vacuum collector) and make sure they are

correctly mounted;

–fill will fuel as indicated below.

PREPARING THE FUEL

This machine is fitted with a two-stroke engine which requires a mixture of petrol and lubricating oil.

This is two stroke engine, never use 4-stroke oil or water.

Using petrol alone will damage the engine and invalidate the warranty.

Only use quality fuels and oils to maintain high performance and guarantee the

duration of the mechanical parts over time.

• Petrol characteristics

Only use unleaded petrol with a fuel grade of at least 90 ON.

Unleaded petrol tends to create deposits in the container if preserved for more than 1

months. Always use fresh petrol!

• Oil characteristics

NOTE

NOTE

IMPORTANT

IMPORTANT

IMPORTANT

NOTE

IMPORTANT

10

Only use top quality synthetic oil specifically for two-stroke engines.

Your dealer can provide you with oils which have been specifically developed for this type of engine, and

which are capable of guaranteeing a high level of protection.

The use of these oils makes it possible to prepare a 4% mixture, consisting in 1 part oil to 40 parts petrol.

• Preparation and preservation of the fuel mixture

Petrol and the fuel mixture are highly inflammable!

–Keep the petrol and fuel mixture in homologated fuel containers, in safe place, away from any

flames or heat sources.

–Never leave the containers within the reach Of children.

–Never smoke whilst preparing the mixture and avoid inhaling the petrol fumes. The chart indicates the

amount of petrol and oil to use to prepare the fuel mixture according to the type of oil used.

Petrol

2–stroke synthetic oil

litres

litres

cm3

1

0.04

40

2

0.08

80

3

0.12

120

5

0.2

200

10

0.4

400

To prepare the fuel mixture:

–Place about half the amount of petrol in a homologated tank.

–Add all the oil, according to the chart.

–Add the rest of the petrol.

–Close the cap and shake well.

The fuel mixture tends to age. Do not prepare excessive amounts of the fuel mixture to

avoid the formation of deposits.

Keep the petrol and fuel mixture containers separate and easily identifiable to avoid the

mistake of using one in place of the other.

Periodically clean the petrol and fuel mixture containers to remove any eventual deposits.

REFUELLING

Never smoke whilst refuelling and avoid inhaling the petrol fumes.

Carefully open the tank top as pressure could have formed inside.

DANGER

IMPORTANT

IMPORTANT

IMPORTANT

DANGER

DANGER

11

Before refuelling:

–Place the machine on a flat stable surface, with the fuel tank cap facing upwards.

–Clean the fuel tank cap and the surrounding area to avoid any dirt from entering the tank During refilling.

–Carefully open the fuel tank cap to allow the pressure inside to decrease gradually.

To fuel:

–Shake the tank with the fuel mixture well.

–Using a funnel, pour an amount of fuel mixture suited to the work to be performed in the supplied graduated

bottle.

–Close the graduated bottle cap and refuel using the nozzle without filling the tank to the rim (Fig. 10)

Fig. 10

The machine tank is best filled with about half graduated bottle capacity.

Always close the fuel tank cap firmly.

Immediately clean all traces of fuel which may have dripped on the machine or the

ground and do not start the engine until the petrol fumes have dissipated.

6. HOW TO START - USE - STOP THE ENGINE

STARTING THE ENGINE

The engine must be started in an area at least 3 meters from where you refilled the fuel

tank.

Before starting the engine, place the machine on stable ground and make sure blowing or vacuum tubes are

not crushed.

• Cold starting

A “cold” start of the engine means starting it after at least 5 minutes from when it was

switched off or after refuelling.

To start the engine (Fig. 11+Fig.12+Fig.13+Fig.14+Fig.15+Fig.16):

IMPORTANT

WARNING

WARNING

WARNING

NOTE

12

1. Set the switch to position «I». Fig.11

2. Operate the starter, moving lever to <CHOKE> Fig.12

3. Press the primer device button 7 times to prime the carburettor Fig.13

4. Hold the machine firmly with one hand on the handgrip, in order not to lose control of the

machine during starting.

5. Pull the starter rope slowly for 6 - 15 cm until you feel some resistance, then tug it hard a few times until you

hear the engine pop voice Fig.14

To avoid breaking the starter rope, do not pull the whole length of it or let it slide along the

edge of the cable guide hole. Release the starter gradually, to avoid letting it fly back uncontrollably.

6. When the engine is pop/ready to start, disconnect the starter by turning the lever to <ON> Fig.15

7. Pull the starter rope again, fully turning the throttle (4) until the engine starts as normal.

8. Let the engine run idle for at least 1-2 minutes to warm up before using the machine.

If the starter rope is pulled repeatedly with the choke on, it may flood the engine and make

starting difficult.

If you have flooded the engine, remove the spark plug and gently pull the handle on the starter rope to

eliminate any excess fuel; then dry the spark plug electrodes and replace it on the engine

• Hot starting

IMPORTANT

IMPORTANT

13

When hot starting (immediately after stopping the engine), follow the procedure indicated above in points 11 -

13 - 15 - 16.

USE OF THE ENGINE

Motor rpm must be proportionate to the type of work and is regulated by the throttle (4) on the upper hand grip.

The throttle trigger can be kept in place using the lock lever (5).

Avoid using the engine at full power for the first 6–8 working hours.

STOPPING THE ENGINE (Fig. 17)

To stop the engine:

–Return the release lever up (5).

–Release the throttle control (4).

–Set the switch to position «O».

7. USING THE MACHINE

To respect people and the environment:

–Try not to cause any disturbance.

–Scrupulously comply with local regulations and provisions for the disposal of waste materials after

work.

–Scrupulously comply with local regulations and provisions for the disposal of oils, petrol, damaged

parts or any elements which have a strong impact on the environment.

Prolonged exposure to vibrations can cause injuries and neurovascular disorders

(also called “Raynaud’s syndrome” or “white hand”), especially to people suffering from circulation

disorders. The symptoms can regard the hands, wrists and fingers and are shown through loss of

sensitivity, torpor, itching, pain and discolouring of or structural changes to the skin. These effects

can be worsened by low ambient temperatures and/or by gripping the handgrips excessively tightly. If

the symptoms occur, the length of time the machine is used must be reduced and a doctor consulted.

Always wear suitable clothing when using the machine. Your dealer

can provide you with all the information on the most suitable accident-prevention devices to

guarantee your safety.

WARNING

IMPORTANT

IMPORTANT

WARNING

14

The machine is with auto-choke function, when you press the throttle trigger to speed

up, the choke lever would return to . <ON>, it is no machine problem.

1. USE AS A BLOWER (Fig. 18)

Fig.18

The machine must always be firmly gripped with your right hand on the upper handgrip

during work.

Engine speed should be adjusted to the type of material to be removed:

–use the engine at low speed for lightweight material and small bushes on the lawn;

–use the engine at average speed to move grass and lightweight leaves on pavement or solid ground;

–use the engine at high speed for heavier materials like fresh snow or voluminous dirt.

Always pay the utmost attention to prevent removed material or dust from injuring

people or animals or damaging property. Always assess wind direction and never work against the

wind.

2. USE AS A VACUUM COLLECTOR (Fig. 19)

Fig. 19

The machine must always be firmly held with both hands during work. Place your

left hand on the upper hand grip and your right hand on the lower hand grip so that the bag is on the

right-hand side of the operator.

When used as a vacuum collector, it is best to use the engine at average/high speed. During collection, keep

the rounded end of the tube a few centimeters off the ground.

WARNING

WARNING

WARNING

15

The bag also works as a filter similar to a common home vacuum. For this reason it is best that:

–it is always free to expand and the support strap not tangled;

–it is not fully filled;

–collected objects that could jeopardise integrity are promptly removed.

To empty the bag:

–switch the engine off;

–open the zipper and empty the bag without disconnecting it from the fitting tube.

When used as a vacuum collector not collect damp grass or leaves to avoid clogging the

rotor and coil.

A too full bag reduces machine efficiency and could cause the engine to overheat.

3. END OF OPERATIONS

When you have finished your work:

–Switch off the engine as indicated above (Fig.17).

–Disconnect the spark plug cap.

–Empty the bag if used as a vacuum collector.

–If the blower tubes are removed, replace the fastening screw and relevant washers (Fig. 1 and 2).

–If the vacuum tubes are removed, close the grille by catching it to the detent (Fig. 5).

8. MAINTENANCE AND STORAGE

Correct maintenance is essential to maintain the original efficiency and safety of the machine over time.

During maintenance operations:

–Remove the spark plug cap.

–Wait until the engine is sufficiently cold.

–Do not work on the machine if not in possession of the necessary skills and tools.

–Never dispose of oils, fuel or other polluting materials in unauthorized places.

CYLINDER AND SILENCER

To reduce fire risks, periodically clean the cylinder fins with compressed air and clear the silencer area from

dust, leaves or other debris.

STARTING SYSTEM

To avoid overheating and damage to the engine, always keep the cooling air vents clean and free of sawdust

and debris. The starter rope must be replaced as soon as it shows signs of wear.

NUTS AND SCREWS

Periodically check that all the nuts and screws are securely tightened and the hand grips are tightly fastened.

IMPORTANT

IMPORTANT

WARNING

16

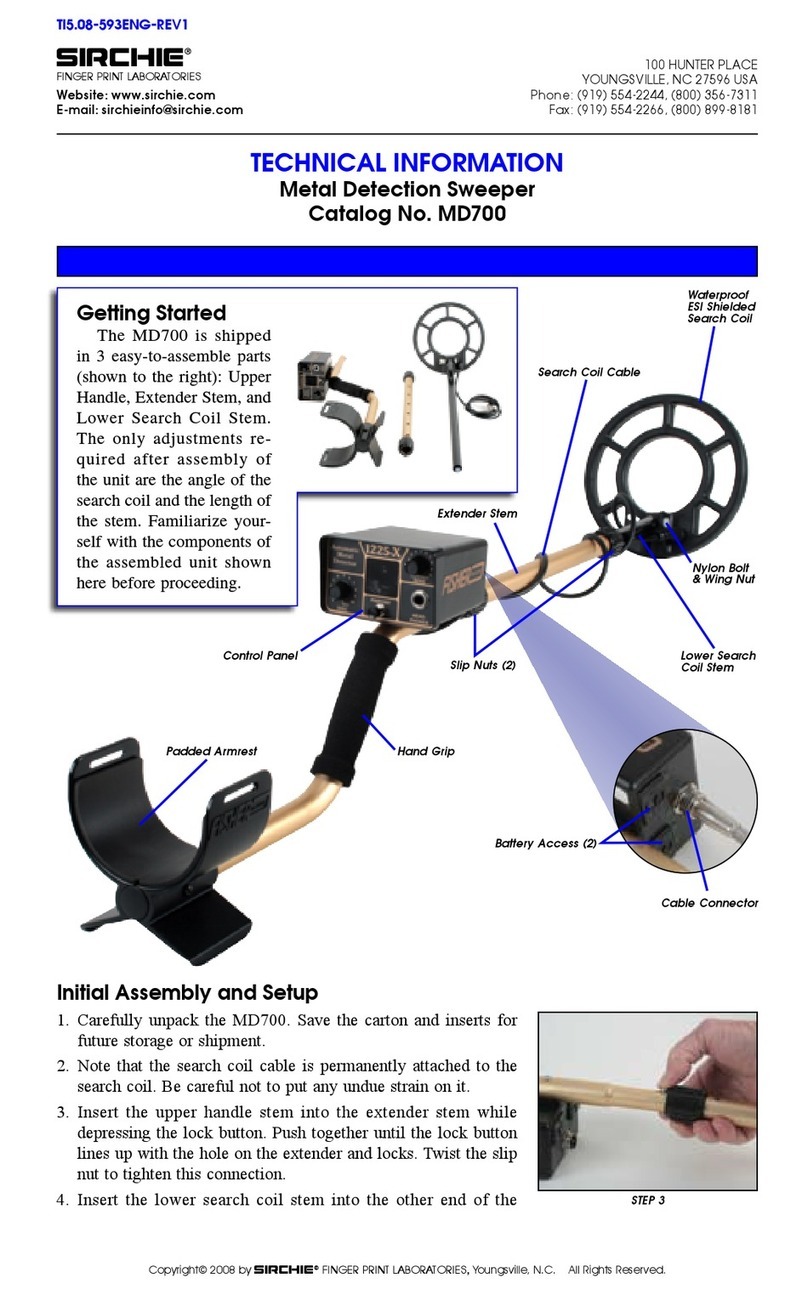

CLEANING THE AIR FILTER (Fig. 20)

Fig.20

Cleaning the air filter is essential to guarantee the efficiency and duration of the machine.

Do not work with a damaged filter or without a filter, as this could permanently damage the engine.

It must be cleaned after every 8-10 working hours. Clean the filter as follows:

–Loosen the knob (1), remove the cover (2) and the filter element (3).

–Wash the filter element (3) with soap and water. Do not use petrol or other solvents.

–Leave the filter to dry in the open air.

–Replace the filter element (3) and the cover (2) and tighten the knob (1).

FUEL FILTER

Inside the fuel tank there is a filter which prevents impurities from entering the engine. The filter should be

replaced once a year by your Retailer.

CHECKING THE SPARK PLUG (Fig. 21)

Fig. 21

Periodically remove and clean the spark plug using a metal brush to get rid of any deposits.

Check and reset the correct distance between the electrodes.

Replace the spark plug and fasten it firmly using the supplied wrench.

The spark plug must be replaced with one with the same characteristics whenever the electrodes have burnt

or the insulation has worn, and in any case every 50 working hours.

TUNING IDLE SPEED (Fig. 9)

IMPORTANT

17

Fig. 9

Idling must be adjusted when the engine tends to turn off or no significant speed

differences are noted when using the throttle.

Adjustment is performed after starting the engine and letting it run idle for several minutes, using the screw

(1):

–turn clockwise to increase engine rpm;

–turn counter-clockwise to decrease engine rpm.

After adjusting, the engine should idle without irregularities or pauses.

EXTRAORDINARY MAINTENANCE

All maintenance operations not foreseen in this manual must be performed exclusively by your dealer.

All and any operations performed in unauthorized centers or by unqualified persons will totally invalidate the

warranty.

STORAGE

After every working session, clean the machine thoroughly to remove all dust and debris, and repair or

replace any faulty parts. The machine must be stored in a dry place away from the elements.

LONG PERIODS OF DISUSE

If the machine will not be used for a period of more than 2-3 months it is recommended to follow some advice

to avoid difficulty when you wish to use the machine and to prevent permanent damage to the engine.

• Storage

Before putting the machine away:

–Empty the fuel tank.

–Start the engine and run it idle until it comes to a halt, so that it uses up all the fuel that is left in the

carburetor.

–Wait for the engine to cool down and remove the spark plug.

–Pour a teaspoon of fresh oil into the spark plug hole.

–Pull the starter rope several times to deliver oil to the cylinder.

–Replace the spark plug with the piston in the dead end upper position (visible from the spark plug slot when

the piston is at maximum stroke).

IMPORTANT

18

• Restarting work

When you wish to start using the machine again:

–Remove the spark plug.

–Pull the starter rope a few times to eliminate excess oil.

–Check the spark plug as described in chapter “Checking the spark plug”.

9. TROUBLESHOOTING

PROBLEM

LIKELY CAUSE

SOLUTION

1) The engine will

not start or will not

keep running

–Incorrect starting procedure

–Follow the instructions

(see chapter 6)

-Dirty spark plug or incorrect

distance between the electrodes

–Check the spark plug

(see chapter 8)

–Air filter clogged

–Clean and/or replace the filter

(see chapter 8)

–Carburetion problems

–Contact your dealer

–Intake grille open without having

mounted the first vacuum tube.

–Close the grille or mount the first

vacuum tube (see chapter 4)

2) The engine starts

but is lacking in

power

–Air filter clogged

–Clean and/or replace the filter

(see chapter 8)

–Carburetion problems

–Contact your dealer

3) The engine runs

irregularly and lacks

in power when

revved

–Dirty spark plug or incorrect

distance

between the electrodes

–Check the spark plug

(see chapter 8)

–Carburetion problems

–Contact your dealer

–Bag full or clogged

–Empty the bag (see chapter 7)

4) The engine gives

off an excessive

amount of smoke

–Incorrect composition of the fuel

mixture

–Prepare the fuel mixture

according

to the instructions (see chap. 5)

–Carburetion problems

–Contact your dealer

10 TECHNICAL SPECIFICATION

19

Model

BON-P-BLV-26

Product Name

Vacuum & blower (3 in 1)

Piston displacement cm³

25.4

Power KW

0.9

Fuel tank volume ml

400

Maximum air speed km/h

260

Petrol/oil ratio

40:1

Suction capacity (for vacuum) m³/h

810

Mulching ratio (for vacuum)

10:1

Dust bag (for vacuum) L

50

Noise dB(A)

110

N.W.

kgs

5.8

BONHOEFFER

SCAN

TO

VISIT

WEBSITE

Bonhoeffer Machines Bonhoeffer _Machines Bonhoeffer Machines

CORPORATE OFFICE:

PLOT NO. 756, UDYOG VIHAR PHASE-5,

GURUGRAM, HARYANA -122016, INDIA

sa I es@bon hoeerm ac hi n es.com

Table of contents