30.30.01.03275 Status 11.2022

Index 02

J. Schmalz GmbH

Johannes-Schmalz-Str. 1

72293 Glaen, Germany

Tel. +49 +7443- 2403- 0

Fax +49 +7443 / 2403 - 259

hp://www.schmalz.com

Instruction Manual

Schmalz Blower SB-L-EX

Page 1/2

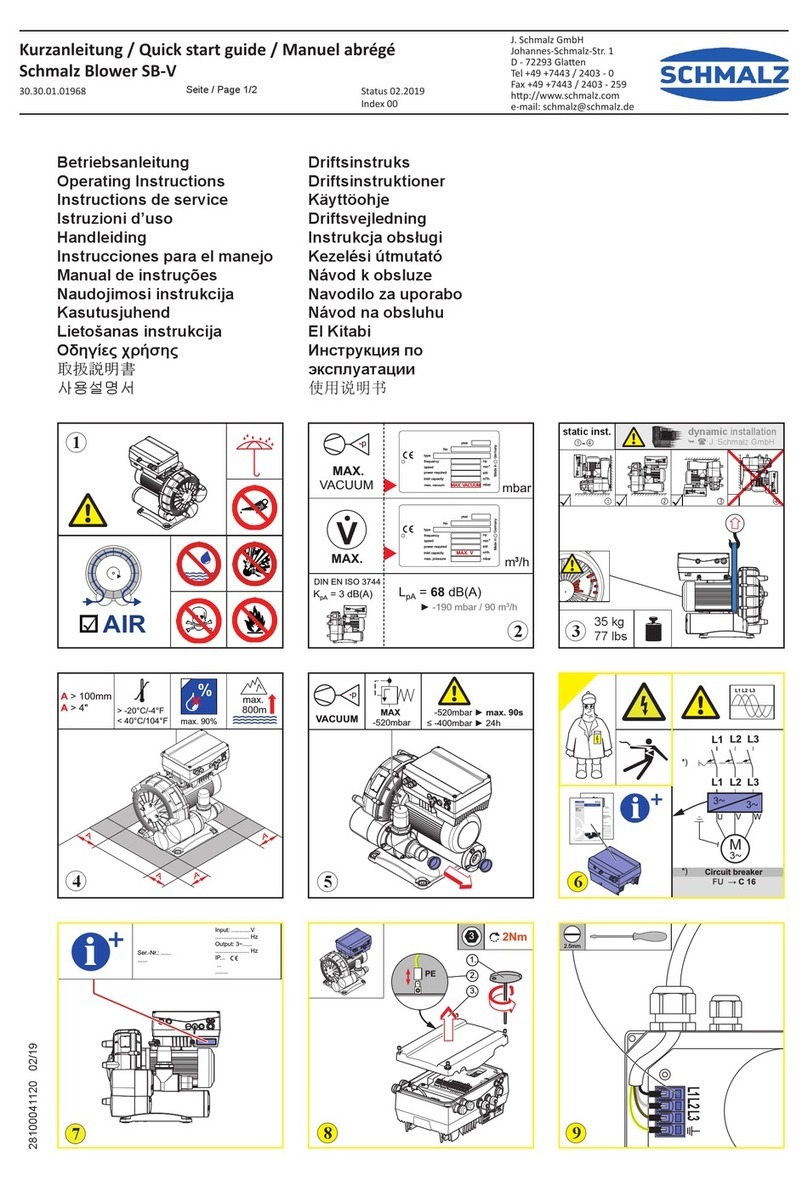

1 Instruction Manual Schmalz Blower SB-L-EX

Scope

These operating instructions apply to the following

side-channel compressors:

Schmalz Blower SB-L-EX

with the following technical data:

* Values in brackets can only be achieved for a short time

in cyclic operation, see conditions of use

Year of manufacture: 2022

Max. surface temperature:

190 °C (50 Hz)

190 °C (60 Hz)

Ambient temperature:

-10 °C < t < 40 °C

Explosion protection labeling:

II 3G/3G Ex h IIB T3 Gc/Gc X

II -/3D Ex h IIIB 190°C -/Dc X

Safety regulations

Please observe the safety standard DIN

EN 1012-2 for vacuum pumps.

Modications or changes to the side-chan-

nel compressor can only be made with the

approval of the factory.

Air compression produces high tempera-

tures >60 °C. Position the compressor so

that hot surfaces are out of reach, cordon

o the trac area or provide warning signs.

Intended use

This side-channel compressor is authorized for use in

areas where explosive atmospheres are present only

rarely and for a short period of time (category 3).

The motor corresponds to Directive 2014/34/EU.

The side-channel compressor is used to generate a

vacuum.

The key data on the type plate applies up to an altitude

of 800 m above sea level. For installation outside of

this range, the manufacturer must be consulted and the

application must be examined on a case-by-case basis.

The device is suitable for sucking in mixtures which are

not liable to explode. It must be ensured that an explosive

atmosphere does not form inside the device for extended

periods of time. The device is not suitable for conveying or

compressing toxic or ammable media. Matter must never

be allowed to accumulate inside the device, as this could

result in a possible imbalance. Operate the side-channel

compressor in such a way that only normal atmospheric

air can be sucked in.

If media containing dust is conveyed, use suction lters

and carry out maintenance regularly. Pyrophoric dusts/

dusts with pyrophoric properties are never to be conveyed.

The operating conditions specied in the technical data

must be complied with at all times.

The ambient temperature must not exceed 40 °C and must

not fall below -10 °C. This also applies to the medium to

be conveyed.

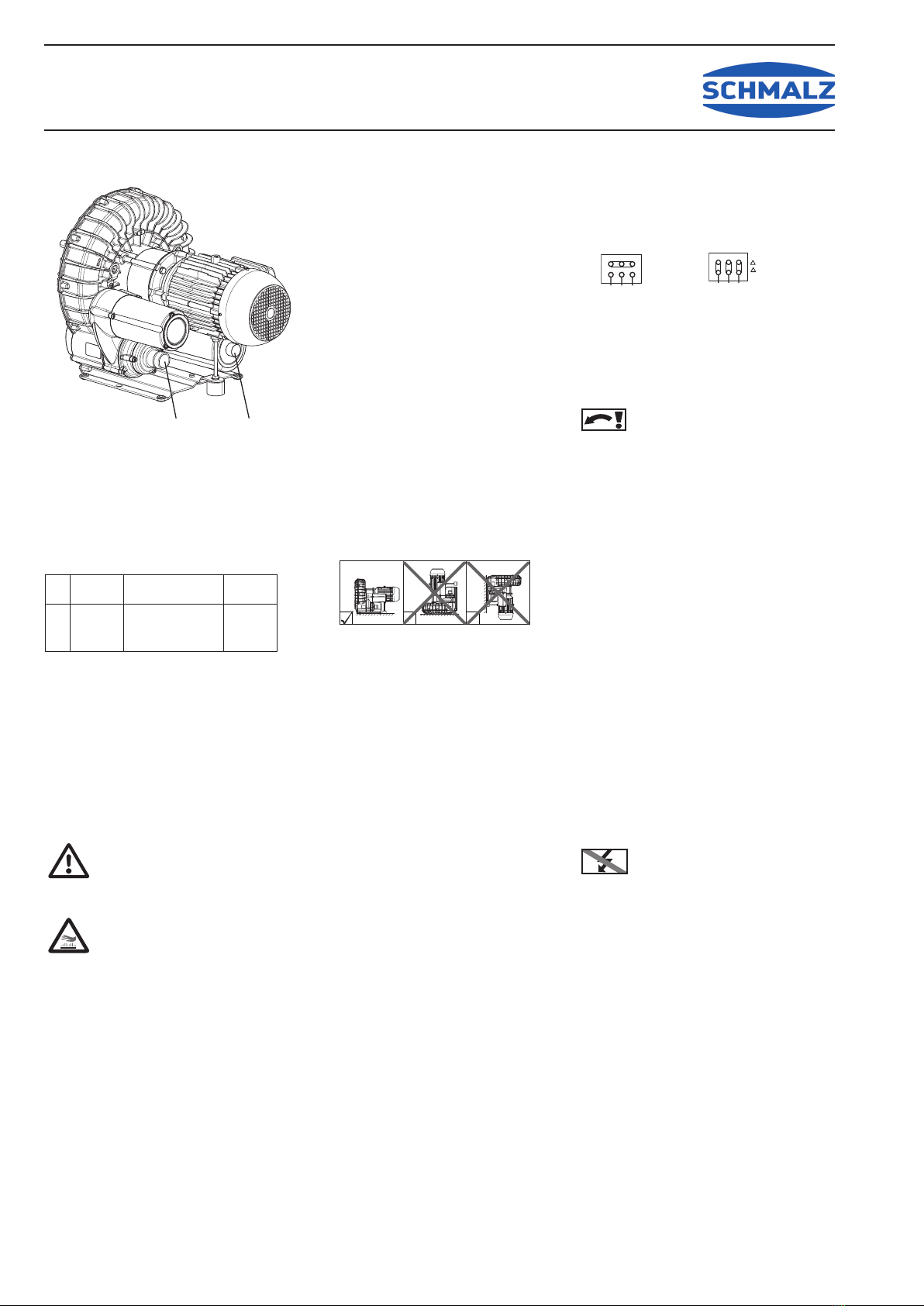

Foreseeable misuse

Use is not permitted for:

- Ambient conditions in which explosive atmospheres of

gases, vapors or mist occur frequently or occasionally

(category 1 or 2).

- Ambient conditions in which explosive dusts occur con-

tinuously, frequently or occasionally (category 1 or 2).

- Suction of gases or dusts in which an explosive state is

continuously, frequently or occasionally formed.

- Operation outside the operating conditions specied in

the technical data.

Exceeding the exhaust air temperature of 190 °C must be

avoided. If necessary, this must be ensured by monitoring.

Transportation and storage

Store the side-channel compressor in a dry place and

protect from water splashes.

Lift and transport with suitable transport belts.

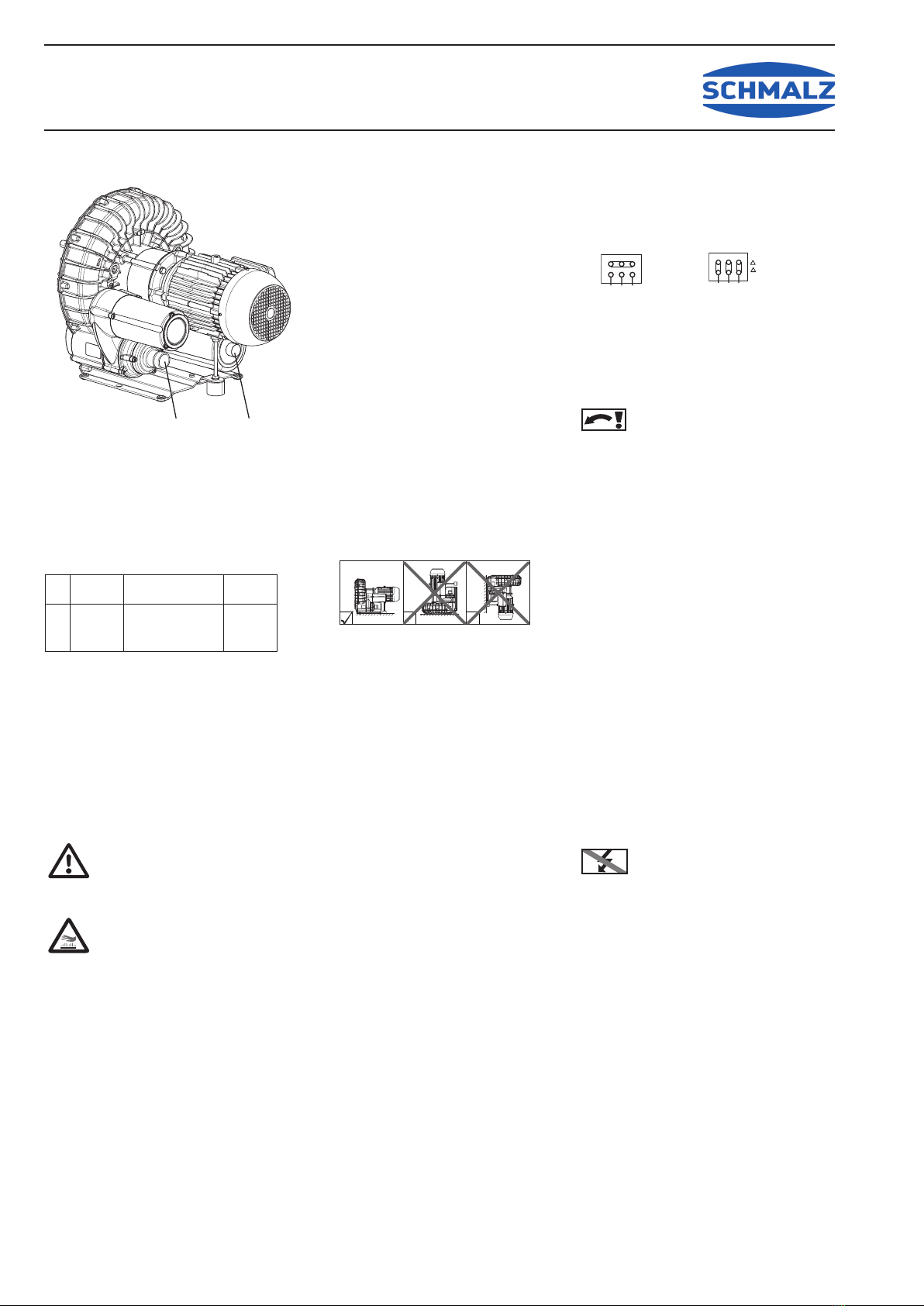

Setup

We recommend that you install the compressor in such

a way that maintenance work can be carried out easily.

optimal unacceptable unacceptable

There must be at least 10 cm of free space between the

device and adjacent walls, so that the air ow for cooling

is not obstructed.

The blower must not be installed in silencer box covers.

Protect against dust deposits.

The side-channel compressor may only be mounted

horizontally with a base. The base has vibration-reduc-

ing elements (item 511) in the mounting holes. When

tightening the fastening screws, ensure that the base

does not come into direct contact with the ground (gap

≥ 0.5 mm). The contact surface must be level to ensure

that the base stands securely. Direct exposure to the sun

should be avoided.

Operating conditions

Surface temperatures above 190 °C must be avoided.

The device must be operated within the pressure ranges

indicated on the type plate and within the permissible

ambient temperature range.

The Blower SB-L-EX is also suitable for cyclic operation.

It must be ensured that a load time (= lifting the load) of

max. 60 seconds is followed by a rest phase (in which the

device is operated without load) of at least 30 seconds.

Mounting

Ensure correct dimensioning and clean pipelines. Prevent

foreign objects from entering the compressor.

The diameter of the pipes must correspond to the con-

nection threads as a minimum requirement. Use the next

largest diameter for pipes longer than 2 m.

Keep connections free of oil, grease, water or other

contaminants.

Protective caps should only be removed shortly before

mounting for DA and SA devices. Do not connect to the

pipe network yet.

Install the suction lter with the lter cartridge in a hori-

zontal position or facing downward so that no dirt enters

the compressor during maintenance work. Suction lters

must be provided for the explosion protection area (see

instructions for the explosion protection dust lter).

Connecting the motor

Integrate the compressor into the power supply in such a

way that all relevant regulations are observed, in particular

DIN EN IEC 60079-14 and DIN EN IEC 60079-17.

The motor must only be connected by a qualied electrician

in accordance with the circuit diagram (in the terminal box)

or using ready-to-use connector models.

Pay attention to the supply voltage and frequency.

Check whether the local voltage requires a star or delta

connection. The bridges in the terminal box must be

implemented in accordance with the information sheet

displayed.

Prerequisite: house connection with clockwise rotary

eld

Provide a motor-protection switch (+ type C circuit-breaker)

and adjust to the rated current of the motor (data is shown

on the motor type plate).

If there are motor protection switches and/or other electrical

components in the hazardous area, these components

must also be approved for this purpose.

Let the motor start up briey and check

the direction of rotation (arrow on the

housing). Switch phases if the direction of

rotation is incorrect.

Operation of the side-channel compressor with frequency

inverters is prohibited.

Avoid more than 10 switching operations per hour.

All metal parts of the device must be grounded at the

installation site, especially when using rubber buers.

Appropriate grounding straps or cables must be connected

by a qualied electrician.

Start of operations

Ensure the connection of the pressure line for the DA or

the suction line for the SA is durable and secure.

Only use hoses approved for the explosion protection area.

Avoid mechanical stresses caused by pipe connections or

housing attachments using elastic connections.

Expansion joints and lines must be inspected regularly

for damaged areas and replaced if necessary.

If explosive media can be expected to penetrate the

compression chamber during the equipment shutdown,

devices must be provided by the customer to eectively

prevent this.

Inadmissibly high operating temperatures result from

dirty suction lters (in this case carry out maintenance)

or excessive pressure dierence.

Maintenance

Maintenance and servicing of the vacuum pump may

only be carried out by specially trained, instructed and

authorized personnel. Only original spare parts from the

manufacturer may be used. Regular maintenance of the

compressor will provide the best results. The intervals

depend on the application and the ambient conditions.

Prior to the start of the maintenance

work, switch the motor o and prevent

an unintentional restart.

Wait for at least 60 minutes before opening the lines or

housing to prevent hot surfaces from being exposed.

Clean the fan hood and the surfaces of the compressor

and motor regularly to prevent overheating due to dust

accumulations.

Replace the roller bearings in the motor at the latest after

4 years or 20,000 operating hours. Maintenance is carried

out on the bearings every 2 years. Shaft sealing rings

are replaced every 6000 hours and at the same time as

the bearing is changed. After changing, the shaft sealing

rings must be run in for 1 hour in a test run. No explosive

atmosphere may be present during the run-in phase.

If lters are used, the lter cartridges should be cleaned

depending on the amount of dust (daily to weekly).

Cleaning must not be carried out while the device is hot.

Let the device cool down. Blow through the lter from the

inside to the outside with compressed air. Wipe or suction

the inside of the lter housing. Always replace damaged,

blocked, oily and greasy cartridges. The cartridges should

be replaced on a monthly or annual basis.

Inlet and outlet lines on the suction and pressure side

must be checked for damage and leaks and replaced

if necessary.

Servicing

In accordance with the German Ordinance on Industrial

Safety and Health (2009/104/EC), If a device in a system

on which explosion protection is dependent is repaired and

has not been checked by the manufacturer after the repair,

it may only be put back into operation after an approved

/

8 9 :

/ /

: 8 9

<9+]

<9+]

/

8 9 :

/ /

: 8 9

9+]

9+]

Frequency

Type Vacuum*Drive

power

50 Hz

60 Hz

50 Hz

5,5 kW

5,5 kW

4,6 kW

1

2

4

-360 (-475) mbar

-340 (-465) mbar

-360 (-475) mbar

SA DA