BONHOEFFER BON-P-BC36 User manual

INSTRUCTION MANUAL

BRUSHCUTTER

BON-P-BC36 I BON-P-BC45

2 / 26

DESCRIPTION OF THE SYMBOLS

The use of symbols in this manual is intended to draw your attention to

possible risks. The safety symbols and the explanations that accompany

them must be perfectly understood. The warnings in themselves do not

remove the risks and cannot replace correct actions for preventing

accidents.

Read the instruction handbook and follow all warning and safety instructions

before any use, refer to the corresponding paragraph in the present

manual.

Complies with European regulations applicable to this product.

Remove the ignition cable before all maintenance work, and read the

instructions for use.

Take care of the proportion when handling fuel and lubricants!

Do not expose to rain.

The exhaust and exhaust gases are hot. Do not touch them.

3 / 26

Danger of injury from flying parts! Always maintain a sufficiently safe

distance. Beware of thrown objects. The distance between the machine and

bystanders should be at least 15 meters

Start engine creates sparking.

Sparking can ignite nearby flammable gases.

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

For outdoor use only.

Strictly no naked flames or smoking near the appliance!

Wear ear protection, eye protection and head protection and gloves when

using the product.

Wear slip-resistant footwear when using the device.

Push the bubble 10 times before use to make sure the fuel full of the oil

way.

4 / 26

Choke closed (cold start position).

Choke open (run position)

Beware of blade thrust

Make sure the cutting head isn’t at startup and during work in contact with

foreign objects.

Do not use toothed saw type blade.

Pay more attention to the operator's feet to avoid injured.

Keep bystanders away. Do not touch the nylon line until it stops completely.

Cutting path of trimmer head:450mm

Cutting path of brush cutter:255mm

5 / 26

SAFETY WARNINGS

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

The machine shall always be used in accordance with the manufacturer’s instructions laid

down in the instruction handbook.

The manufacturer will not be liable in cases of inappropriate use or modifications of the

appliance. Also, follow the safety advice, the installation and operation manual and also

to the valid accident prevention regulations.

Appliances with incorrect or missing parts or without a security case are not to be operated.

The service center provides you with information concerning replacement parts.

1). Training

a) Read the instructions carefully. Be familiar with the controls and proper use of the

equipment.

b) Never allow children or people unfamiliar with these instructions to use the machine. Local

regulations can restrict the age of the operator.

c) Never work while people, especially children, or pets are nearby.

d) Keep in mind that the operator or user is responsible for accidents or hazards occurring

to other people or their property.

e) Major repair work shall be carried out only by specifically trained personnel.

f) All persons and animals must be kept at least 15 meters from the machine while it is

working.

2). Preparation

a) WARNING-Petrol is highly flammable:

-store fuel in containers specifically designed for this purpose;

-refuel outdoors only and do not smoke while refueling;

-add fuel before starting the engine. Never remove the cap of fuel tank or add petrol while

the engine is running or when the engine is hot;

-if petrol is spilled, do not attempt to start the engine but move the machine away from the

area of spillage and avoid creating any source of ignition until petrol vapors have

dissipated;

-replace all fuel tank and container caps securely.

b) Replace faulty silencer.

c) Before using, always visually inspect to see that the tools are not worn or damaged.

Replace worn or damaged elements and bolts in sets to preserve balance.

d) Do not smoke near the machine.

e) Do not wear loose clothing, jewellery, or similar items that could be caught in the starter

or other moving parts.

f) Never put any items into the ventilation openings. Non-observance may lead to injury, or

damage to the machine.

g) It is necessary reduction in power due to use in higher temperatures, altitudes and

humidity as below conditions.

6 / 26

-Max Working Temperature: 40°C

-Max altitudes: 1000 m

-Max humidity: 95%

3). Operation

a) Do not operate the engine in a confined space where dangerous carbon monoxide fumes

can collect.

b) Keep the machine free of oil, dirt and other impurities.

c) Please always place the appliance on even and stable surfaces.

d) Never operate the appliance inside buildings or in an environment without proper

ventilation. Pay attention to air flow and temperature.

e) Do not operate or store the appliance in wet or humid surroundings.

f) Ensure the sound absorber and air filter work properly. These parts serve as flame

protection in case of misfire.

g) To avoid possible burn injuries, do not touch the exhaust system or other parts that

become hot during operation. Pay attention to the warnings on the machine.

h) The engine must not be operated with excessive rotary speed. The operation of the engine

with excessive rotary speed raises the risk of injury. Parts which affect the rotary speed

must not be altered or replaced.

i) Regularly check for leakage or traces of abrasion in the fuel system, such as porous pipes,

loose or missing clamps and damage to the tank or tank cap. Before use all defects must

be repaired.

j) Work only in daylight or in good artificial light.

k) Never pick up or carry a machine while the engine is running

l) Stop the engine:

-whenever you leave the machine

-before refueling

m) Before checking or adjusting the machine, the ignition plug and the ignition wire

respectively must be removed to prevent accidental starting.

n) Do not use of the machine when the operator is tired, ill or under the influence of alcohol

or the drugs.

o) Comply with local regulations to use the brush cutter.

p) Contact your local government offices for information regarding minimum age

requirements for operating the equipment.

q) Wear safety goggles and ear protection. Other safety equipment for the hands, legs and

feet is recommended. Correct safety equipment reduces the risk of injury caused by

catapulted foreign bodies or in the event of accidental contact with the brush cutter.

r) Ensure that you maintain a steady foothold. Only use the brush cutter on flat surfaces

where you have a firm footing.

s) While working, always wear substantial footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals. Always keep proper footing and

operate the brush cutter only when standing on fixed, secure and level surface.

t) Always hold the brush cutter with two hands (right hand hold the right handle to control

the trigger and the left hand hold on handle bar). To put hands in wrong positions increases

the risk of injury and must therefore be avoided. Changing regularly of work position and

taking frequent breaks are needed.

u) Always use the harness when operate the tool, and adjust the length of the harness to

ensure it is suitable for operation.

v) Always use the correct blade and spool recommended by the manufacturer.

w) Take care against injury to feet and hands from the cutting means.

x) Always ensure that the ventilation openings are kept clear of debris

y) Perform daily inspection before use and after any fall or other impact to identify significant

defects.

7 / 26

z) Keep a correct working position, rest frequently and change working positions. Keep

balance position during operation, use the harness.

aa) It has been reported that, for some people, the vibrations produced by the motorized hand

tools can lead to develop a disease called Raynaud's syndrome or white finger. Symptoms

may include tingling, numbness and blanching of the fingers, usually caused by exposure

to cold. Heredity, exposure to cold and dampness, diet, smoking and work habits are all

thought to contribute to the development of these symptoms. There is currently no

evidence that a certain type of vibration or exposure actually contributes to the

development of this assignment. Some measures that can reduce the effects of vibration,

can be taken by the operator:

• Keep your body warm in cold weather. During use, wear gloves to keep your hands and

wrists warm. It has been reported that cold weather is one of the main causes of Raynaud's

Syndrome.

• After each period of operation, exercise to increase circulation.

• Take frequent breaks. Limit the duration of daily exposure.

• Keep the tool well maintained, all fasteners tightened and worn parts replaced.

• In case of occurrence of one or more of the symptoms described above, stop using the

tool and seek medical attention.

4). Maintenance and storage

a) Keep all nuts and screws tight to be sure the equipment is in safe working condition.

b) Never store the equipment with petrol in the tank inside a building where fumes can reach

an open flame or spark.

c) Allow the engine to cool before storing in any enclosure.

d) To reduce the fire hazard, keep the engine, silencer and petrol storage area free of

vegetative material and excessive grease.

e) Replace worn or damaged parts for safety.

f) If the fuel tank has to be drained, this should be done outdoors.

g) Always clean and maintenance before storage.

h) Never disassembly the guards for cutting attachments.

i) Always store the metal blade in cool and dry place, never use rusted blade. It may cause

serous injure during working.

5) TRANSPORTATION AND HANDLING

a) Whenever the machine is to be handled or transported you must:

-turn off the engine, wait for the cutting device to stop and disconnect the spark plug cap;

-fit the cutting device guard;

-use protective gloves when handling the blades.

-Keep the blade protection device on.

-only hold the machine using the handgrips and position the cutting device in the opposite

direction to that used during operation.

b) When using a vehicle to transport the machine, position it so that it can cause no danger

to persons and fasten it firmly in place to avoid it from tipping over, which may cause

damage or fuel spillage.

INTENDED USE

This unit is designed to be used in accordance with the descriptions and safety

instructions indicated in this operating manual

- for private use

- for trimming lawn edges and small inaccessible areas of grass (e.g. under bushes)

8 / 26

- for cutting wild growth, shrubs and undergrowth.

It is not permitted to use this unit for any other purposes.

The user is liable for all injuries to third parties and damage to their property.

Operate the unit only in the technical condition as stipulated and delivered by the

manufacturer.

Arbitrary changes to the unit will exclude the manufacturer from any liability for resulting

injury and/or damage.

TECHNICAL SPECIFICATIONS

Model

BON-P-BC36

BON-P-BC45

Equipment mobility

Hand-held

Hand-held

Engine type

2-stroke

2-stroke

Maximum power

1.2 kW/7500min-1

1.6 kW/7500min-1

Fuel ratio

40:1 40:1

Volumes of fuel tank

750cm³

950cm³

Engine displacement

35.5cm3

44.8cm3

Max engine speed for brush

cutter

10000 min-1

10000 min-1

Max engine speed for grass

trimmer

9200 min-1

9500 min-1

Gear ratio

19:14

19:14

Cutting diameter

2T blader:255mm

Nylon head:

450mm

2T blader:305mm

Nylon head:

450mm

Spool for grass trimmer line

Ø2,4mm/4m

Max:6800min-1

Ø2,8mm/4m

Max:7000min-1

Engine idling speed

3000min-1±300

min-1

3000min-1±300

min-1

Clutch engagement speed

4200min-1

4200min-1

Unit mass (empty tanks

without cutting attachment)

7.2kg 8.7kg

Noise Information

Measured sound values determined according to ISO 11806-1

The noise figures quoted are emission levels and are not necessarily safe working levels.

Whilst there is a correlation between the emission and exposure levels, this cannot be

9 / 26

used reliably to determine whether or not further precautions are required. Factors that

influence the actual level of exposure of work-force include the characteristics of the work

room, the other sources of noise, etc. i.e. the number of machines and other adjacent

processes, and the length of time for which an operator is exposed to the noise. Also the

permissible exposure level can vary from country. This information, however, will enable

the user of the machine to make a better evaluation of the hazard and risk.

Wear hearing protection!

Vibration total values (triax vector sum) determined according to ISO 11806-1:

The vibration emission level given in this information sheet has been measured in

accordance with a standardized test given in ISO 11806-1 and may be used to compare

one tool with another.

It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool.

However if the tool is used for different applications, with different accessories or poorly

maintained, thevibration emission may differ.This may significantly increase the exposure

level over the total working period.

An estimation of the level of exposure to vibration should also take into account the

times when the tool is switched off or when it is running but not actually doing the job.

This may significantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the effects of vibration

such as: maintain the tool and the accessories, keep the hands warm, organization of

work patterns.

10 / 26

LIST OF MAIN PART

ASSEMBLY

1Tube

15 Guard fixture

2Throttle trigger

16

Cutting attachment guard

3Engine switch

17 Socket wrench

4Throttle trigger lockout

18 Spanner

5

Suspension

point

19 Allen keys S5

6Cable

20 Allen keys S4

7Muffler cover

21 Trimmer head

8Cylinder cover

22 Harness

9Spark plug cover

23 Fuel mixture container

10 Air filter cover

24 Line Cutter

11 Choke lever

26 Additional guard

12 Fuel tank cap

27 Glass

13 3T

B

lade

28 Gloves

14 Gearbox

11 / 26

WARNING!

Please ensure that the brush cutter is switched off properly and that the engine has

stopped completely before assembly and adjustment.

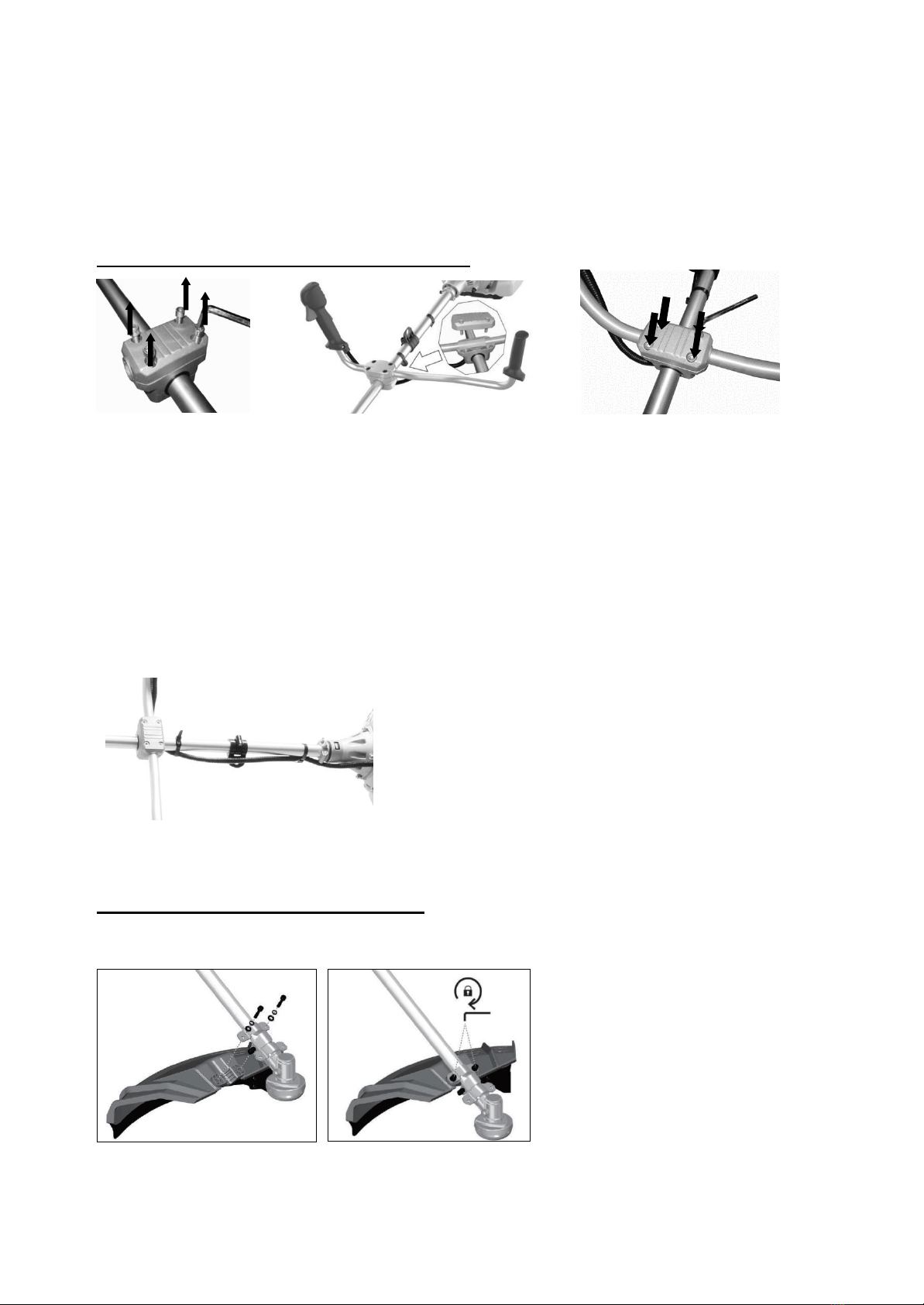

Assembly of the handle (Fig.1-1,1-2,1-3)

Fig.1-1 Fig.1-2 Fig.1-3

1) Remove the screws infixing device and remove the upper cover.(fig.1-1)

2) Place the handle in position and assemble the upper cover.(fig.1-2)

3) Assemble and tighten the screw.(fig.1-3)

CAUTION!

Do not tighten the screws until you have set the handle in optimal working position. Please

always adjust the handle position with full assembled accessories.

The black cable tie can be used to fix the throttle cable to the metal tube. (Fig.2)

Fig.2

Assembly the guard (Fig.3-1, Fig.3-2)

1) Place the guard on the fixture.(fig3-1)

2) Assemble and tighten the screws.(fig.3-2)

Fig.3-1 Fig.3-2

12 / 26

WARNING!

1. When using the cutting line head, the additional guard, with line cutting knife, must

always be fitted. (Fig.3-3,Fig.3-4)

Secure the additional guard (26) using the screw (B). (Fig.3-3)

Fig.3-3

2. Take off the additional guard .

Screw off the screw (B); (Fig. 3-3)

Push the clip(C), and pull out the additional guard. (Fig.3-4)

Fig.3-4

WARNING!

Please check the blade and output shaft after each adjustment or assembly, it must be

correctly assembled and running smoothly.

Wear protective gloves when handling the guard.

Fitting the 2T blade

Take the outer flange off after release the nut, then put the blade, outer flange, shield and

nut according to priority as below picture. Note the blade rotation direction needs be same

as below picture. Use screw driver to hold flange and tighten nut counter-clockwise,

ensure the nut is tightened enough.

.

Fig.4.1

Release blade (Fig.5)

C

16

13 / 26

Use screw driver to hold flange and release nut, the blade can be took off.

Fig.5-1 Fig.5-2

WARNING!

Please make sure the cutting head has been assembled correctly before use!

Nylon head

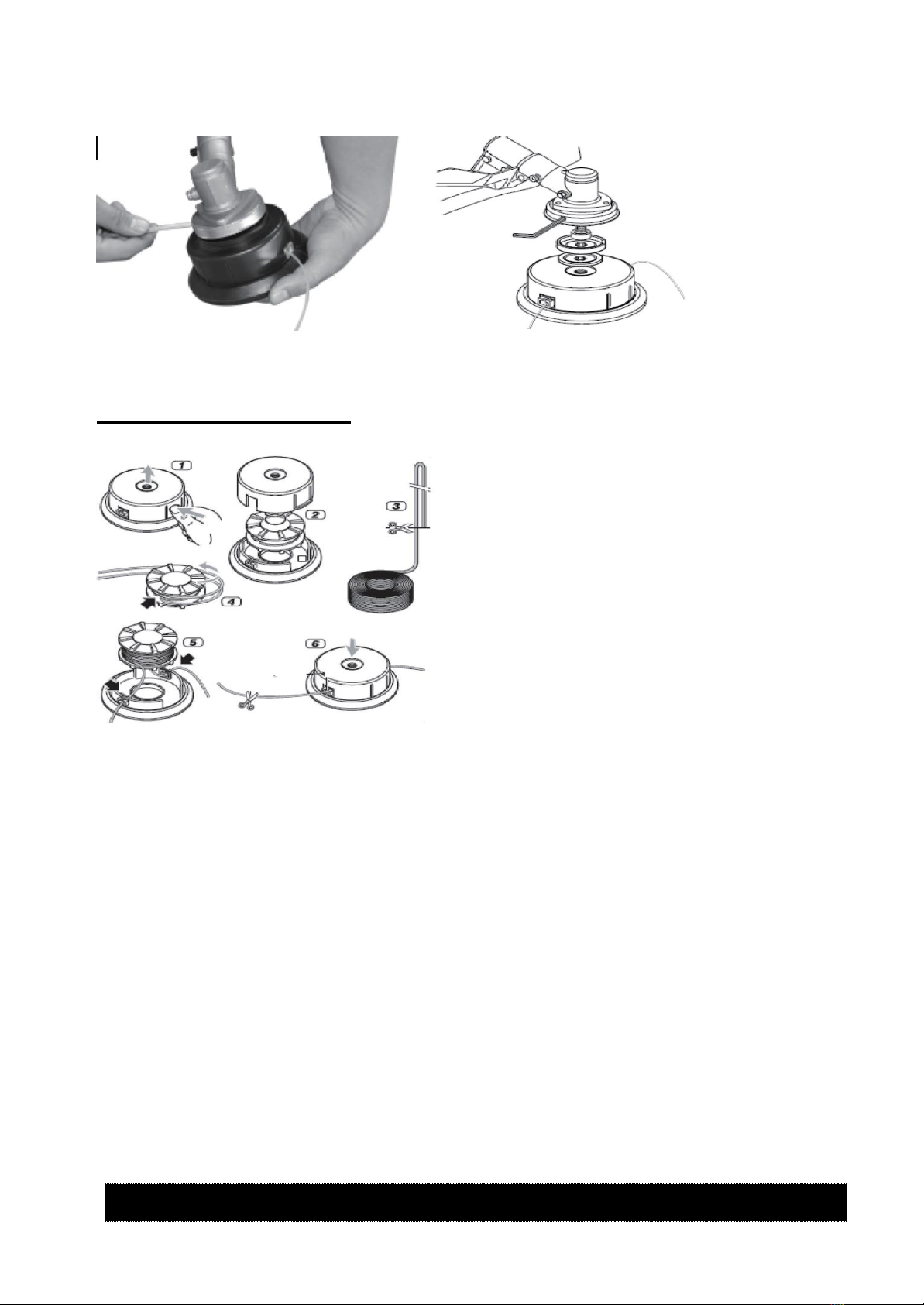

Release the nut(Fig.6)

Line up the two holes of flange and shield, use one screw driver to hold the flange as

below and turn the socket wrench clockwise, the nut will be released.

Fig.6

Fit the Nylon cutting head.(Fig.7)

Remove another shield after release the nut. Still hold the flange, take the Nylon cutting

head on the shaft and rotate counter-clockwise, the Nylon cutting head is fitted.

Fig.7

Release the Nylon cutting head.(Fig.8)

14 / 26

Use screw driver to hold flange and then rotate the Nylon cutting head clockwise till it is

well fixed, it will be replaced.

Fig.8

Replacing cutting line.(Fig.9)

Stop the engine, follow the sequence below.

Fig.9

WARNING!

Never use non-recommended cutting attachments and appropriate guards and their

location. The non approved cutting attachments may cause serous injure during working.

OPERATION

Before use

Please always read the instruction manual carefully and check the machine before

operating.

WARNING!

The brush cutter is fitted with a two-stroke engine, so no need fill oil separately. Fill

the oil mixed with fuel, please consult below section .

Check the cutting attachment, never use blades that are dull, cracked or damaged.

Make sure the handle and safety features are in good working order. Never use a machine

that lacks a part or has been modified outside its specifications.

The enclosures must be correctly fitted and undamaged before you start the machine.

WARNING!

Please always use quality gloves, foot, ear and eye protector. They should be with CE

mark and tested according to PPE (Person Protective Equipment) directive.

The poor equipments may reduce the protection and result in personal injury during

working.

Engine fuel

WARNING!

The brush cutter is fitted with a two-stroke engine; use fuel mixed with oil only.

Onlyfuel the machine in well-lit areas. Avoid fuel spillage. Never refuel the machine during

operation. Let the engine cool down for about two minutes before refueling.

Refueling must not be carried out near naked flames, control lamps or spark producing

electrical equipment such as electric tools, welders or sanders.

1. Make sure the machine is turned off, by turn the engine switch to the “off” position.

2. Check the fuel by a visual check, remove the fuel cap and reviewing the fuel level.

3. Fill unleaded fuel mixed with oil from an approved fuel container into the fuel tank,

because of fuel expands, please fill the tank to the neck of tank only.

4. Turn the fuel cap clockwise to assemble it in position.

WARNING

Do not refill fuel while engine is running or hot.

Make sure fuel is not leaking.

Use quality two-stroke engine oil and make a mixture of 40 parts petrol to one part oil

only (4% oil mixed in fuel).

Never use two-stroke oil intended for water-cooled engines.

Never use oil intended for four-stroke engines.

A poor oil quality and/or too high oil/fuel ratio may jeopardize function and decrease the

life time of catalytic converters.

Use at least 90 octane fuel. We recommend unleaded petrol as it leaves fewer residues

inside the motor and on the ignition plug, and prolongs thelife cycle of the exhaust system.

Never use old or dirty petrol or oil/petrol mixtures. Avoid contamination with dirt or water

15 / 26

16 / 26

in the tank. Occasionally ignition knocking or clanging can be heard with high loads. This

is normal and no cause for alarm. If ignition knocking or clanging occurs during normal

loads and with constant motor speed you should change the petrol quality. If this does not

solve the problem contact an authorized specialist dealer.

When working at continuous high revs a higher octane rating is recommended.

Check the air filter

Check the air filter to be sure it is clean and in good condition.

Loosen the air filter cover screw, and remove the air filter cover, then check the air filter.

Clean or replace the air filter if necessary.

Starting the engine

WARNING!

The cutting attachment may start to move when the engine is started. Make sure the

attachment can not come into contact with any object.

Make sure that no unauthorized persons are in the working area, otherwise there is a

risk of serious personal injury.

1) Press the fuel pump several times until it fills with fuel. (fig.12)

Fig.12

2) Turn the engine switch to the ”I “position.(Fig.13)

Fig.13

Press the throttle trigger, throttle trigger lockout and lock pin together to lock the trigger .

Attention:the switch is auto-returned switch, it would always stays in “I” position,

press it to “O” manually if needed.

3) Move the choke lever to position. (fig.14)

17 / 26

Fig.14

Close the choke: Start position

4) Slowly pull the recoil starter until it pops. (fig.15)

Fig.15

Attention: Check and make sure cutting attachment always stops when the engine

is idling.

Note: when the engine is started for the first time. It will require a number of

attempts

to

start until the fuel travelled from the tank to the

motor

.

5) Turn the choke lever to the run position.(Fig.16)

Fig.16

6) Pull the starter quickly until the engine starts.

7) After starting the engine, let the engine run for 2 to 3 minutes so that it warms up

before subjecting it to any load.

8) Hot start: When the machine is hot, stays the choke level in “Start position”, the user

can start the machine by repeating steps of 1,2,5,6.

Under the following conditions the machine must be stopped:

18 / 26

1. When the motor rotary speed changes

2. When sparks occur

3. When blade are damaged

4. In case of misfire

5. In case of high vibration

6. When flames or smoke appear

7. In rain or stormy weather

WARNING!

Check the cutting attachment always stops when the engine is idling.

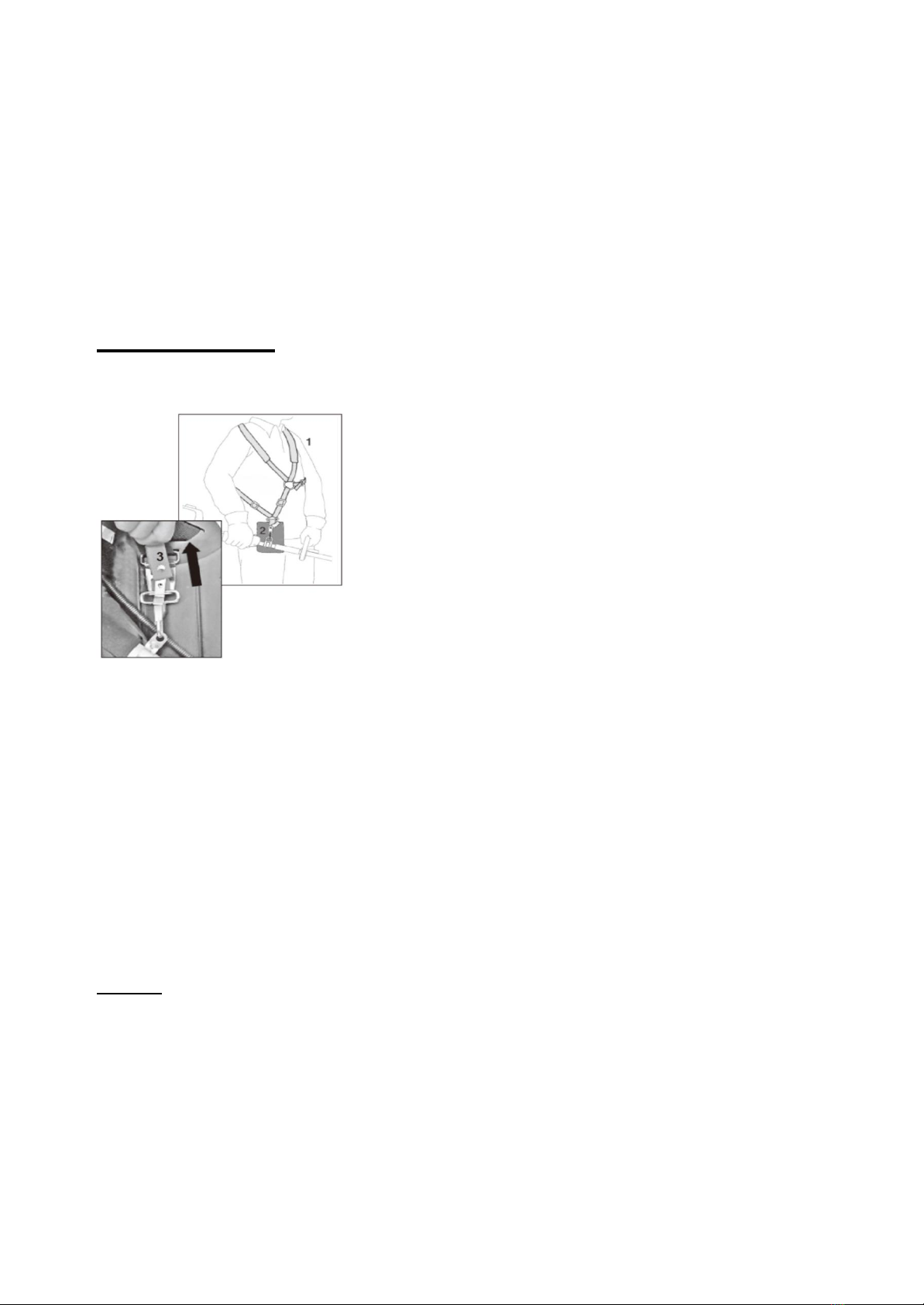

Fit the bet. (Fig.17)

According to picture showing, fit the belt well. Stretch the belt and as below pic, and then

fit the belt on shoulder,

Fig.17-1

The design and type of carry strap may vary..

•Put on the shoulder strap (1).

•Adjust the length of the belt so that the spring hook (2)

is roughly a hand’s width below your right hip.

PLEASE NOTE: This carry strap has a safety device

allowing you to immediately disconnect the strap from

the machine in an emergency. To do so, pull forcefully

on the red pull tab (3) on the strap. This disconnects

the strap from the holding fixture immediately.

NOTE: Never start the motor with the carry strap attached to the machine!

Cutting

During cutting, please don’t keep the running speed just above clutch engagement speed.

Any prolonged use at low speed is likely to cause premature wear of the clutch.

On the other hand, the user should not keep the engine speed in max speed after cutting.

Any prolonged use at the highest speed is likely to reduce lifetime of engine.

Cut the grass from right to left. (fig.18)

CAUTION!

19 / 26

In an emergency, stop the engine by moving the engine switch to the stop position.

If the cutting attachment strikes stone or other debris, stop the engine and check whether

something has been damaged and the cutting attachment is still secure.

If wet grass or branches are remain in the cutting attachment, stop the engine and remove

them.

Fig.18

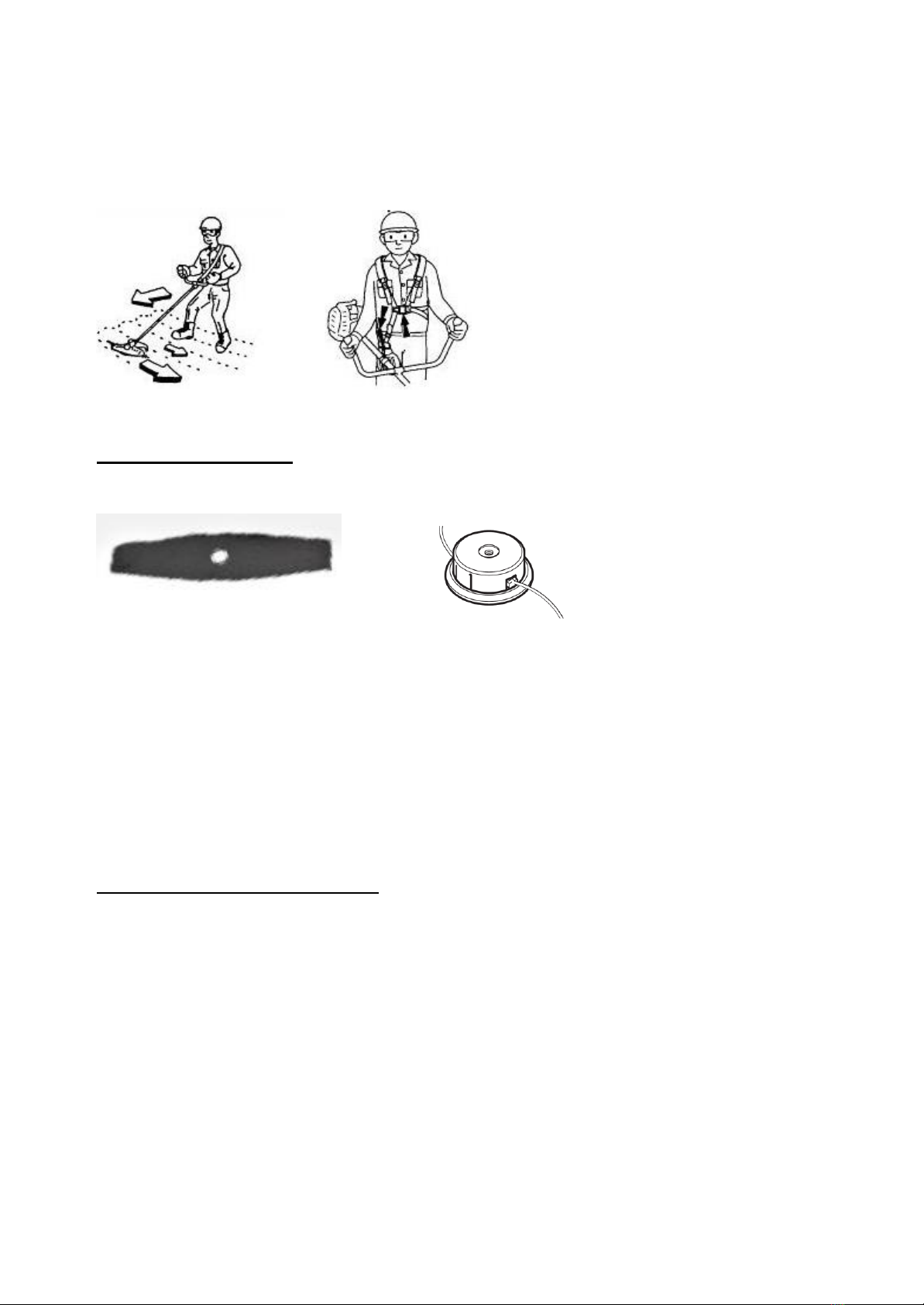

Cutting attachements:

Attention! Use only original cutting devices from the Manufacturer.

Fig.19

WARNING!

In consideration that the selection, application and usage of the accessory to be

fitted in the variety of possible usage are actions made solely by the user, the

latter assumes responsibility for damages of any kind due to such actions. When

in doubt or if lacking knowledge of the specificity of each accessory, contact

specialised gardening centre.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating blade. Pinching or

snagging causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation

at the point of the binding.

For example, if a blade is snagged or pinched by the stone, the edge of the blade that is

entering into the pinch point can dig into the surface of the material causing the blade to

climb out or kick out. The blade may either jump toward or away from the operator,

depending on direction of the blade’s movement at the point of pinching.

Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

20 / 26

a) Maintain a firm grip on the tool and position your body and arm to allow you to

resist kick back forces.

b) Never place your hand near the rotating accessory. Accessory may kick back over

your hand.

c) Use special care when working corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag

the rotating accessory and cause loss of control or kickback.

Extending the cutting line

WARNING: Do not use any kind of metal wire or metal wire encased in plastic in the

cutting head. This may cause serious injuries to the user.

To extend the cutting line run the motor at full speed and tap the cutting head on the

ground. This will automatically extend the line. The cord cutter under the outer guard will

cut the line to the appropriate length. (fig.20)

Fig.20

Stopping the engine

1. Release the throttle trigger and let it run idling for a few minutes.

2. Switch off the engine by moving the engine switch to the stop position.

The cutting attachment may cause an accident if it continues to turn after the engine has

stopped or after the engine switch has been released. When the unit has stopped, check

carefully that the cutting attachment has stopped turning before putting the unit down.

MAINTENANCE

Good maintenance is essential for safe, economical and trouble-free operation. It will also

help reduce air pollution.

The purpose of the maintenance and adjustment schedule is to keep the machine in

the best operating condition.

Turn off the engine before performing any maintenance. If the engine must be run, make

sure the area is well ventilated. The exhaust contains poisonous carbon monoxide gas.

This manual suits for next models

1

Table of contents