Lea LE 25254-D User manual

LE 25254-D3MANUEL

LE 25254-D

24

23

22

22

22

20

17

15

11

9

8

8

3

2

English

1. Introduction

2. Safety rules and precautions

3. Warning symbols

4. Machine symbols

5. Machine description

6. Start up instructions

7. Machine usage

8. Maintenance and service

9. Trouble shooting

10. Transport

11. Storing

12. Recycling or disposal your machine

13. Warranty

CE Declaration of conformity

Thank you for choosing this Garland machine. We

are sure that you will appreciate the quality of the

machine and that the machine will help you to carry

out its required functions for a long period of time.

Remember that this machine comes with a large and

expert after sales network to which you can take your

machine for maintenance, repair or for purchase of

spare parts and accessories.

Attention! Read all the security warnings

and the instruction manual. Non

compliance could result in fire and/or a

serious injury. Before using the machine read the

manual carefully and especially that related to secure

and correct start up.

Use this brushcutter only to cut grass and

small bushes. Any other type of usage is dangerous

and run at your own risk. Do not use the machine

for other jobs. For example, do not use the machine

to cut wood, plastic materials, bricks or construction

material. The use of the machine for other uses could

be dangerous.

Keep all the warning signs and the manual for

future reference. If you sell the machine, remember

to pass on the manual to the new owner.

The expression switch to position “open” means

offline and to position “close” means connected.

Remember user is the responsible of danger and

accidents caused to other people or things. The

manufacturer will not be liable for damages caused by

an inadequate or incorrect use of the machine.

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

1. INTRODUCTION

INDEX

2

English

To avoid incorrect manipulation of this machine,

read the instruction manual before using the machine

for the first time. All information included in this

manual is relevant and important for your security

as well as for the security of other people, animals

and objects surrounding you. Should you have any

doubts with respect to the information contained in

this manual, please ask a specialist or visit your local

dealer where you purchased the machine.”

The next danger and precautions list include the most

probably situations that can be happen while machine

is being using. If you are in a non listed situation

in this manual use your common sense to use the

machine in the most safety way possible or, if you feel

danger, don’t use the machine.

2.1. USERS

This machine has been designed to be used by

people over 18 and who have read and understood

the instruction manual. This machine can not be

used by persons (including children) with reduced

physical, psychological or mental capabilities, or lack

of experience or knowledge.

Attention! Do not allow underage people to use

the machine.

Attention! Do not allow people who have not

understood this manual clearly to use this machine.

Before using this machine, familiarise yourself with all

the controls, security devices and how these are used.

If you are not an expert user, we strongly recommend

that you practice firstly with some simple chores

preferably in the presence of an expert user.

If you are not a professional user, we strongly

recommend that you start by performing some simple

tasks and if possible, in front of a professional user.

The blade of this machine is sharp, operate it wrongly

could be dangerous.

Attention! Only lend this machine to people

familiarised in the use of this type of machine. Always

lend the machine with the instruction manual so

that this new user reads it in detail and understands

it. This machine is dangerous if used by untrained

hands.

This machine is dangerous in hands of untrained

users.

2.2. PERSONAL SECURITY

Be alert and vigilant when using this machine and use

common sense.

Avoid inhaling exhaust fumes. This machine produces

hazardous gases such as carbon monoxide than could

cause dizziness, fainting or death.

Do not use this machine if tired or under the influence

of drugs, alcohol or medicines. One moment of

distraction could cause severe personal injuries.

Never operate the machine with defective guards, or

without safety devices.

Do not modify the machine controls or regulations of

speed motor .

Clear the work place of tools and keys prior to start

up. If the machine comes into contact with a key or

tool in the work place, this could be propelled causing

personal damages.

2. SAFETY RULES AND

PRECAUTIONS

3

English

Do not overstretch. Maintain your feet well placed on

the floor and maintain a good equilibrium at all times.

Always maintain proper foot support and run the

machine only when standing on a fixed surface, safe

and stable. Or unstable sliding surfaces may cause

loss of balance or control of the machine.

Keep all parts of body away from the cutting elements

when the machine is running. Before start up, make

sure that the cutting element is not in contact with any

object. One small lapse in attention can cause your

clothes or any body part to be caught by the cutting

device.

Always use the brushcutter attached to the harness

and grip machine with your right hand on the rear

handle and your left hand on the front handle. Hold

this machine with hands reversed increases the risk of

bodily injury and should not be done.

Be extremely careful when cutting shrubs and young

trees. Thin materials can be projected towards the end

user or could make you lose your equilibrium.

If you are a novice user, we recommend you have a

minimum practice on a flat surface

If the machine vibrates abnormally stop the engine,

inspect the machine looking for the possible cause

and repair. If you don’t find the reason take your

machine at your service.

Do not touch the exhaust of the machine with the

engine running or just after it has been stopped. The

exhaust of this machine reaches high temperatures

during operation of the engine and kept some minutes

after the stop thereof.

Do not leave the machine running unattended. If

you must leave the machine unattended shut off the

engine, wait until the cutting device stops and unplug

the spark plug wire.

When transporting the machine, make sure it is

hooked to the harness and with your hands on the

handles, with the engine stopped, with the blade

protector and at a distance from your body parts.

When transporting or storing the machine, always

cover the blade. An appropriate use of the machine

will greatly reduce the risk of accidental contact with

the cutting elements.

Do not attempt to remove cut material from the work

area or the cutting device when it is in motion. Be sure

the machine is off when you perform cleaning debris.

Do not handle the machine by the cutting device. The

cutting device has sharp edges that can hurt yourself.

Store the machine well away from children

Never use the machine if the protections are defective

or without all security devices in proper working order.

Do not modify the machine controls or the engine

speed.

2.2.1.WORKING CLOTHES AND SECURITY

EQUIPMENT

Dress adequately. Do not wear loose clothing or

jewels. Maintain your hair, clothes and gloves well

away from all moving parts.

When using this tool wear the next safety equipment:

- Security glases or protective mask.

- Ear protection.

- Working gloves.

- Non slippery boots.

- Long trousers.

The use of additional working and security equipment

will reduce the risk of personal injury.

The noise of the machine is uncomfortable. Always

4

English

use ear protection. If you use this machine very often,

visit your doctor regularly to check up on your hearing

capacity.

Attention! As you are working with ear protectors,

you must pay more attention to visual warnings as you

will hear less because of the ear protectors.

You must always carry:

- Tooling

- Signalling tape to limit work area.

- Mobile phone (for use in case of an

emergency)

2.2.2. VIBRATIONS

The prolonged use of the machine, exposes the

client to vibrations that in extreme cases and through

many hours of use of the machine could cause the

¨white finger syndrome¨ also known as Raynaud

phenomenon. This causes a reduction in the tact of

the fingers and their capacity to regulate temperature

generating a lack of sensibility. This sickness could

in extreme cases cause problems with the nerve

endings.

The exposure to the vibrations is the cause of

the white finger syndrome. To minimise this

effect as much as possible, follow the following

recommendations:

- Always use gloves

- Always have your hands warm

- Ensure that the cutting device is always sharp.

- Take frequent breaks

- Always hold the machine tightly by the handles

If you detect any of the symptoms of the white finger

syndrome, consult immediately with your doctor.

2.3. SECURITY IN THE WORKPLACE

Do not work with the machine in areas with an

explosive atmosphere or near inflammable liquids,

gases or dust.

Do not start the machine in a closed area. The exhaust

fumes, the vapours of the petrol and the chain oil,

all contain carbon monoxide and other dangerous

chemical substances. In case of gas concentration

due to insufficient ventilation, eliminate from the

work area everything that impedes the correct flow of

air and do not work in this area again until it is well

ventilated and the gas concentration does not happen

again.

The area included in a 15m radius around the

machine must be considered risk zone and nobody

should be there while the machine is working and,

when necessary, a cord and warning signals must be

used around the working area

Maintain children and passers-by well clear when

working with the machine. Distractions can cause a

lack of control.

When work is to be performed simultaneously by two

or more persons, always check for the presence and

location of others so as maintain a distance between

each person sufficient to ensure safety.

2.4. SECURITY WHEN USING FUEL

IMPORTANT: The fuel used is highly inflammable. If

the fuel or the machine catch fire, fight the flames

with a dry dust fire extinguisher.

Always avoid eye contact with the fuel and the oil. If

petrol or oil were to come into contact with your eyes,

clean these immediately with clean water. If your eyes

are still irritated, visit the doctor immediately.

5

English

Do not refill the machine in a closed area. The petrol

and oil vapours all contain dangerous chemical

substances. In case of gas concentration due to

insufficient ventilation, eliminate from the work area

everything that impedes the correct flow of air and do

not work in this area again until it is well ventilated

and the gas concentration does not happen again.

Gasoline and oil are extremely flammable

and explosive under certain conditions. Do

not smoke while preparing or refueling.

Do not approach any flame or hot element to the fuel.

Do not smoke when handling fuel, when refilling or

when working.

Do not refill fuel in areas where flames,

sparks or hot sources are. Refill only in

ventilated areas with engine off. Do not

overfill the fuel to try to overfill the fuel tank. In case

of fuel leakage, eliminate these before starting the

machine, do not attempt to start the engine but move

the machine away from the area of spillage and avoid

creating any source of ignition until petrol vapours

have dissipated.

Refill fuel before to start the machine. Do not unscrew

the combustible tank cap while the engine is running

or engine is hot.

Make sure the gas cap is properly closed while

operating the machine. Be sure to properly close the

gas cap after refueling.

Store fuel in a bottle or tank homologated and

according to current regulations.

2.5. USE AND CARE OF THE MACHINE

Use this brushcutter only to cut grass and small

bushes. Any other type of usage is dangerous and

run at your own risk. Do not use the machine for

other jobs. For example, do not use the machine to

cut wood, plastic materials, bricks or construction

material. The use of the machine for other uses could

be dangerous.

Use this machine and its accessories

according to the instructions provided and

taking into account working conditions and

work to be done. The use of this machine for jobs

different to those stipulated can cause danger. The

manufacturer will not be responsible for damages

provoked through an inadequate use of the machine.

Check that all security elements are installed and in

good working condition.

Remember that it is the end user operating the

machine who is responsible for any danger or

damages caused to other people or things. The

manufacturer will not in any case be held liable for

damages caused by an incorrect use of this machine.

The sharp cutting tool is very dangerous. If

instructions are not followed it will result in serious

injury.

Keep all parts of your body away from the cutting tool

during operation.

Do not force the machine over its capacity. Use the

machine for the correct job. The use of the machine

for its proper job, will ensure that you work better and

more safely.

Keep the machine with a good maintenance. Ensure

all moving parts are aligned and that no other parts

are damaged or broken. If the machine is damaged,

repair before use. Many breakages occur because

machines are poorly maintained.

6

English

Maintain the cutting elements sharp and clean.Cutting

elements that are clean and well sharpened, are

easier to control and less likely to block.

Maintain the handles of these machines dry and

clean. Oily or greasy handles are slippery and will

cause loss of control of the machine.

Switch off the machine, unplug the spark plug and

make sure the cutting tool is stopped before carrying

out any adjustments to any part of the machine,

refuelling, cleaning , transport or storage the machine.

Such security measures reduce the risk of accidental

start up.

If the machine starts vibrating in a strange way, stop

it and examine it to find out the cause. If the motive

is not clear, take the machine to your nearest service

agent. Vibrations are always an indicator that the

machine has a problem.

Stop the engine whenever you leave the machine.

Reduce the throttle setting during engine shut down

and, if the engine is provided with a shut-off fuel

valve, turn the fuel off when engine is stopped.

2.6. SERVICE

Periodically take your machine for revision by a

qualified after sales service and use only original

spare parts. This will guarantee that the machine is

always in good working condition.

7

English

Warning labels indicate required information for the

use of the machine.

In order to ensure safe operation and maintenance of

the machine are the following symbols in the machine.

Air positions:

Do not let people enter in the work area.

This area will be of a diameter of 15

meters from the point in which you are

working.

Warning and care.

Use protective non skid boots with

protective steel.

Use appropriate security gloves.

It is necessary to use eye and acoustic

protection at any time.

It is necessary to read this manual

carefully before using this machine.

Attention!: Do not touch the cutting blade.

Attention!, Danger!: The cutting tool can

project hard objects.

Caution! Hot Surface.

Do not smoke or bring a flame to the

combustible or the machine.

Fuel tank. Located in the combustible

tank cap. Mix 2 stroke oil and gasoline.

Open = Normal operating position.

Located in the top of the filter.

Open = Normal operating position.

Located in the top of the filter.

Position for starting the machine in cold.

Located on the of air filter cover.

Position for starting the machine in cold.

Located on the of air filter cover.

Never use only fuel or fuel in a bad

state. Mix unleaded fuel grade 95 and

synthetic oil for 2 stroke engines to

2.5% (40:1).

3. WARNING SYMBOLS

4. MACHINE SYMBOLS

Caution! Maximun speed of gear

XXXX min-1.

Sense of rotation.

Maximum tool rotation

speed.

XXXX min-1.XXXX min-1.

“O” = Off (The machine don´t work).

“I”= On (The machine is ready to work).

Positions start switch:

8

English

5. MACHINE DESCRIPTION

5.1. CONDITIONS OF USAGE

Use this brushcutter only to cut grass and small bushes. Any other type of usage is dangerous and run at

your own risk. Do not use the machine for other jobs. For example, do not use the machine to cut wood, plastic

materials, bricks or construction material. The use of the machine for other uses could be dangerous.

The use of this machine for jobs for which it was not designed will cause dangerous situations.

Use this machine outdoors, in dry atmospheres and in temperatures ranging from 5º C to 45º C.

Remember user is the responsible of danger and accidents caused to other people or things. The manufacturer

will not be liable for damages caused by an inadequate or incorrect use of the machine.

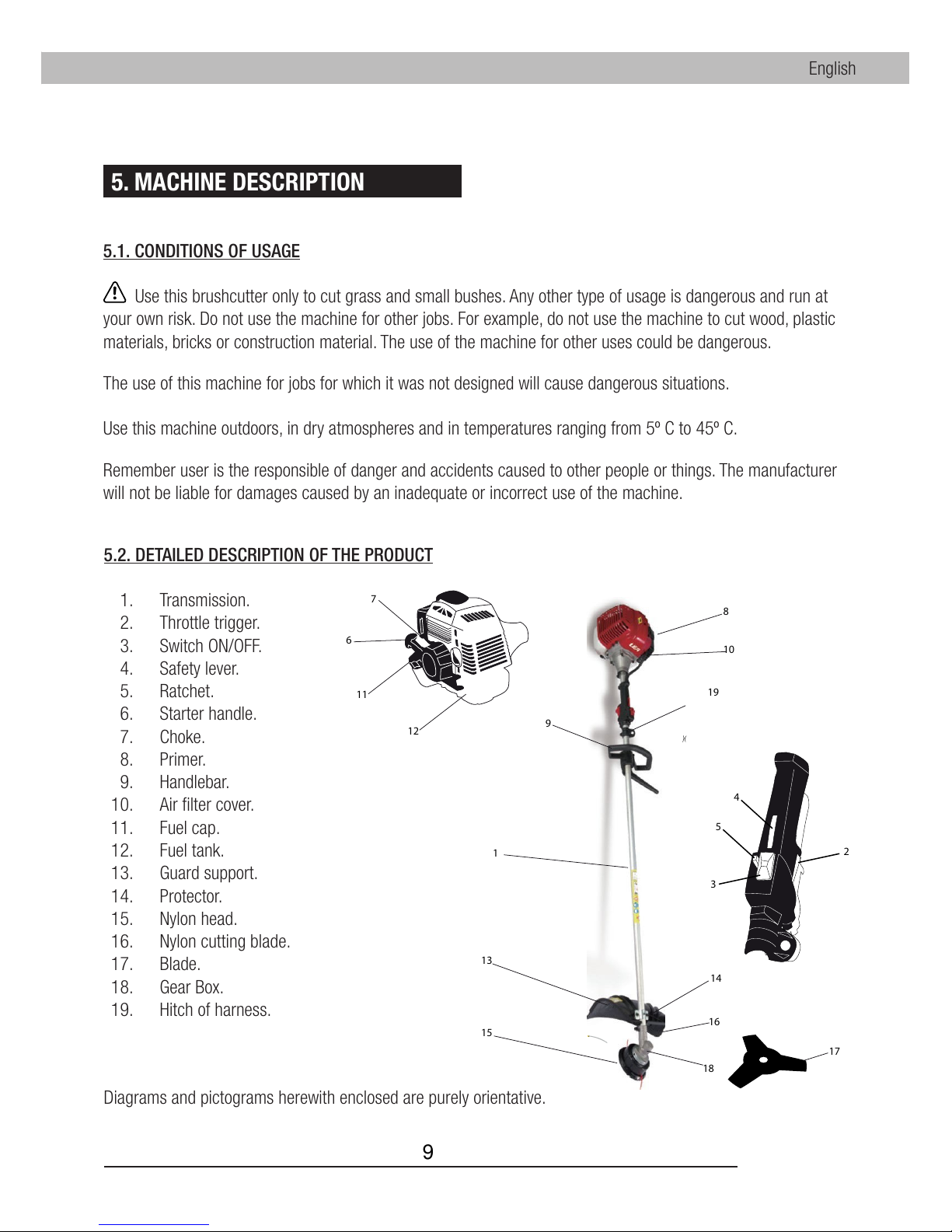

5.2. DETAILED DESCRIPTION OF THE PRODUCT

1. Transmission.

2. Throttle trigger.

3. Switch ON/OFF.

4. Safety lever.

5. Ratchet.

6. Starter handle.

7. Choke.

8. Primer.

9. Handlebar.

10. Air filter cover.

11. Fuel cap.

12. Fuel tank.

13. Guard support.

14. Protector.

15. Nylon head.

16. Nylon cutting blade.

17. Blade.

18. Gear Box.

19. Hitch of harness.

1

9

19

10

8

13

15

18

16

14

2

3

5

4

7

6

11

12

17

Diagrams and pictograms herewith enclosed are purely orientative.

9

5,6

650

0,70

25.4

LE25254-D

English

5.3. TECHNICAL DATA

The technical characteristics can be changed without prior warning.

Description Brushcutter

Brand

Model

Engine 2 stroke

Cylinder capacity (cm3)

Maximum power (kW) (ISO 8893)

Engine speed at idle speed (min-1)3.000

Maximum engine speed (min-1)9.000

Maximum rotation of the head tool (min-1)6.700

Petrol consumption at maximum power (ISO8893) (kg/h) 0,5

Capacity of deposit (cm3)

Cutting tool

Cutting diameter (mm) Blade 255

Nylon head 420

Thickness of cutting tool

(mm)

Blade 1,6 (tapering tip blade)

Nylon head Ø 2,5

Number of cutting edges Blade 3 teeth blade (metal blade)

Nylon head 2 flexible line (nylon cutting head)

Interior diameter of blade (mm) 25,4

Maximum permitted speed

(min-1)

Blade 10.000

Nylon head 10.000

Vibration level (ISO 22867) (m/s2)7,5

Sound pressure level (ISO 22868) (dB(A)) 96

Guaranteed sound power level (ISO 22868) (dB(A)) 114

Weight (kg) (without petrol, cutting tools and protector)

LEA

10

English

6.1.LIST OF MATERIALS

This machine includes the following elements that you

will find inside the box:

•Machine.•Protector.•Handlebar.•Tools.•Cuttingaccessories.•Harness.•Instructionmanual.Ensure that all elements listed above are included with

the machine. Thanks to the quality control checks at

the factory it is highly unlikely that any elements will

be missing. If you were to find any element missing,

do not use the machine until the defect has been

repaired or the machine is complete.

Using the machine with defective parts or without all

the elements can cause severe personal damages.

6.2. MOUNTING THE MACHINE

6.2.1.INSTALLATION OF THE HANDLEBAR

Install the handle on the top transmission bar as

shown in the figure placing it at a distance from the

accelerator that is comfortable for you as end user.

Tighten the screw to avoid that the handle moves.

6.2.2 GUARD SUPPORT ASSEMBLY

The skirt of the protector must not be worn when

working with the cutting disk.

The transmission can be locked by inserting a tool or

screwdriver through the transmission hole and the

notch on the plate (3).

6. START UP INSTRUCTIONS

Protector

Guard support

Protector

Protector flap

11

English

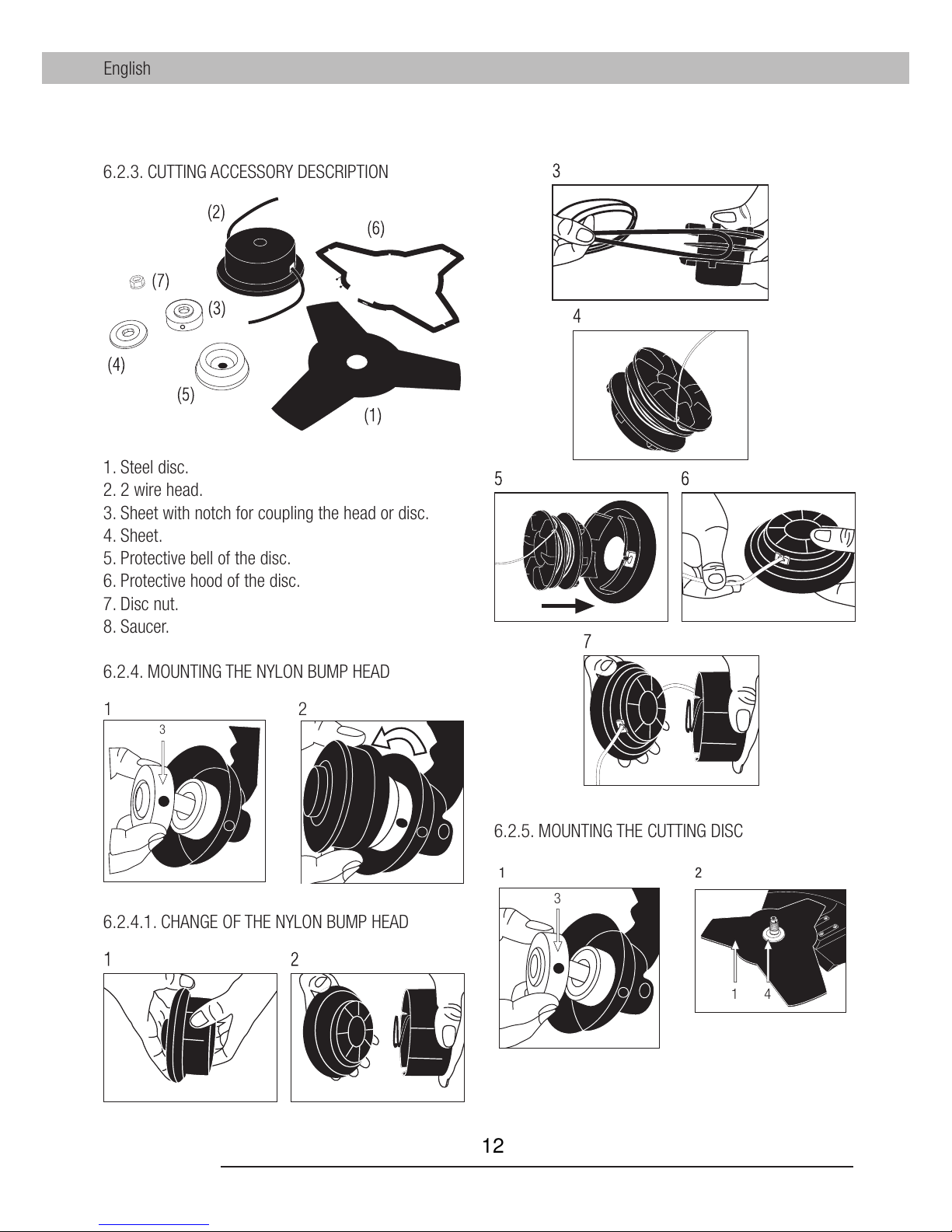

6.2.3. CUTTING ACCESSORY DESCRIPTION

1. Steel disc.

2. 2 wire head.

3. Sheet with notch for coupling the head or disc.

4. Sheet.

5. Protective bell of the disc.

6. Protective hood of the disc.

7. Disc nut.

8. Saucer.

6.2.4. MOUNTING THE NYLON BUMP HEAD

6.2.4.1. CHANGE OF THE NYLON BUMP HEAD

6.2.5. MOUNTING THE CUTTING DISC

21

3

41

21

3

12

English

6.2.6. HARNESS INSTALLATION

6.3. FUEL

IMPORTANT: The fuel used is highly

inflammable. If the fuel or the machine

catch fire, fight the flames with a dry dust

fire extinguisher.

Do not smoke while preparing or refueling.

Do not approach any flame or hot element

to the fuel.

Use unleaded fuel of 95° and synthetic oil for 2 stroke

engines.

Motor Fuel: Mixture (Gasoline 40: Oil 1)

2.5%.

Mix gasoline and oil in a bottle homologated for this

use. If you will mix more combustible just prepare

the amount you will use the short term. Do not use

fuel that has been stored over two months. The

fuel stored for long periods lose its characteristics

making it harder to start the engine and giving poorer

performance.

FILLING THE FUEL TANK

1. Choose an open are ato perform this situation

2. Stay away from the area where you have made the

preparation of the mixture.

3. Remove the combustible tank cap and fill with fuel.

4. Close tighly the fuel cap and remove all traces of

fuel that have been spilled with a rag.

WARNINGS:

- Always switch off the engine before refueling.

- Do not start the machine in a closed area. The

exhaust fumes, the vapours of the petrol and the

chain oil, all contain carbon monoxide and other

dangerous chemical substances. In case of gas

concentration due to insufficient ventilation,

eliminate from the work area everything that

impedes the correct flow of air and do not work in

this area again until it is well ventilated and the gas

concentration does not happen again.

- Do not refill fuel in areas where flames, sparks or

hot sources are. Refill only in ventilated areas with

engine off. Do not overfill the fuel to try to overfill

the fuel tank. In case of fuel leakage, eliminate

these before starting the machine, do not attempt

to start the engine but move the machine away

from the area of spillage and avoid creating any

source of ignition until petrol vapours have

dissipated.

- Stay away at least 3 meters from the zone where

you have refueled before started the machine.

- Refill fuel before to start the machine. Do not

unscrew the combustible tank cap while the engine

is running or engine is hot.

- Do not use fuel with ethanol or methanol because

will damage the engine.

4

7

5

3

13

English

6.4. START UP

6.4.1. CHECK POINTS BEFORE STARTING

Do not use this machine if it becomes damaged

or wrongly regulated.

Use this machine for the purpose for which it was

designed. Any other use may be dangerous for the

user to the machine and for people, animals and

things you may have around.

Verify that :

- The machine completely and look for loose parts

(screws, nuts, etc.) and damages.

- The protector is properly attached to the machine.

- There are not fuel leaks.

- Verify that the disk or head is not damaged.

- Check the air filter is clean. Clean the filter if

necessary.

Press, repair or replace everything you need before

using the machine.

Do not use attachments on this machine out of our

recommendations because their use may cause

serious injury to the user, the machine and the people,

animals and things close to the machine.

Before starting the machine, remove the guard

protecting the cutting unit.

Before starting the machine make sure that all moving

parts of the machine are not in contact with any object.

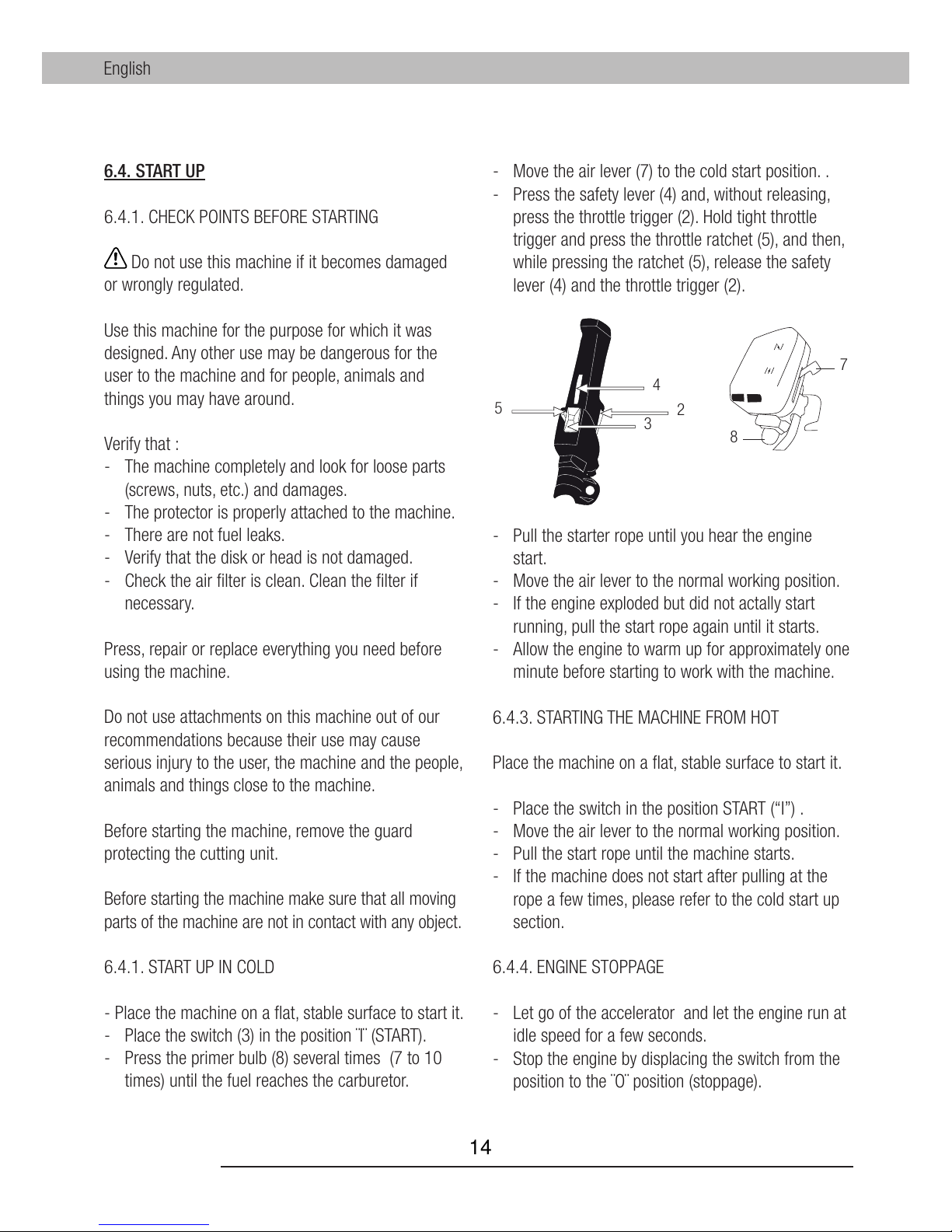

6.4.1. START UP IN COLD

- Place the machine on a flat, stable surface to start it.

- Place the switch (3) in the position ¨I¨ (START).

- Press the primer bulb (8) several times (7 to 10

times) until the fuel reaches the carburetor.

- Move the air lever (7) to the cold start position. .

-Press the safety lever (4) and, without releasing,

press the throttle trigger (2). Hold tight throttle

trigger and press the throttle ratchet (5), and then,

while pressing the ratchet (5), release the safety

lever (4) and the throttle trigger (2).

- Pull the starter rope until you hear the engine

start.

- Move the air lever to the normal working position.

- If the engine exploded but did not actally start

running, pull the start rope again until it starts.

- Allow the engine to warm up for approximately one

minute before starting to work with the machine.

6.4.3. STARTING THE MACHINE FROM HOT

Place the machine on a flat, stable surface to start it.

- Place the switch in the position START (“I”) .

- Move the air lever to the normal working position.

- Pull the start rope until the machine starts.

- If the machine does not start after pulling at the

rope a few times, please refer to the cold start up

section.

6.4.4. ENGINE STOPPAGE

- Let go of the accelerator and let the engine run at

idle speed for a few seconds.

- Stop the engine by displacing the switch from the

position to the ¨O¨ position (stoppage).

3

52

4

8

7

14

English

6.4.5. POINTS TO BE VERIFIED AFTER MACHINE

STARTS

It is neccesary to pay attention to posible loosening

or overheating of parts of the machine. If you detect

any anomalies stop inmediatly the machine and check

it carefully. In case of failure take the machine to

the repair service. In any case you should continue

working if you feel that the performance is not correct.

Do not use the machine if it is damaged or

incorrectly regulated.

6.4.5.1. CHECKING THE CLUTCH

After starting up and the engine is hot, the cutting

tool must not be moved if the engine is idle. If the

cutting tool turns with the engine running and without

accelerating, it will be necessary to regulate the idling

regime of the engine. To do this, turn the carburetor

nut “T” until the engine stops.

If you are unable to regulate the idling regime to stop

the cutting tool, because the engine stalls, please

contact the customer service for help.

The regulation of the screws (H) and (L) must only be

carried out by an official technical servicer.

7. MACHINE USAGE

Only use this machine for those jobs for which it

has been designed. The use of this machine for other

uses is dangerous and could cause damages to the

user and/or the machine.

Do not start the machine in a closed area.

The exhaust fumes, the vapours of the

petrol and the chain oil, all contain carbon

monoxide and other dangerous chemical substances.

In case of gas concentration due to insufficient

ventilation, eliminate from the work area everything

that impedes the correct flow of air and do not work

in this area again until it is well ventilated and the gas

concentration does not happen again.

Mow only at daylight or in good artificial light. Do not

use this machine at night, with fog and with reduced

visibility. Always make sure that you can clearly see all

the working area.

Avoid operating the equipment in wet grass, where

feasible. Take special care when using this machine

in the rain or after rain because the ground is slippery

and you can slip.

If you slip or fall stop accelerating and move the

switch to “O” (Off).

Do not bring any cutting elements near when the

machine is in use and the engine running.

Do not rely solely on the warning signs on the

machine. Be always alert.

It is neccesary to pay attention to posible loosening

or overheating of parts of the machine. If you detect

any anomalies stop inmediatly the machine and check

it carefully. In case of failure take the machine to

the repair service. In any case you should continue

working if you feel that the performance is not correct.

Remember to always use the machine with clean

hands and without petrol and oil.

Clean the work area and eliminate any obstacles that

could cause accidents. Check the working area and

remove any objects that could cause the cutting tool of

the machine to get tangled on. Also remove any parts

that the cutting tool could violently hit causing these to

15

English

move in the direction of the user or other people and/

or animals.

Do not allow any other person into the work area.

All other people must be at least at a distance of 15

metres as it is a dangerous area. Never leave this

machine unattended.

It is imperative that the engine is turned off when

carrying the machine from one working area to

another.

Never touch elements that can be hot during

the start up or operating the machine, for

example, the escape, sparks or high voltage

cables.

Do not use accessories except those recommended

by our company as otherwise the use of other non

original accessories could cause severe damages to

the end user, to passers-by and to the machine.

Always follow the safety rules stated in this manual.

7.1. FIXING THE MACHINE AND GUIDANCE

Hold the machine with the harness,

hands on the handles and with

the right hand in such a position

that you can action the controls

(accelerator and security switch).

Attention! So as to reduce the risk of loss of

control and possible damages (that could even be

fatal) to the end user and/or those surrounding him,

never use this machine single handedly.

7.1.1. CUT WITH THE NYLON HEAD

WARNING: Wear eye and audible protection at all

times. Do not look directly to the cutting line because

can cause serious damage to the head and the eyes.

Use the head line in difficult areas.

If the header hits a rock or other object stop the

machine and check its status. Do not use damaged or

poorly balanced heads.

Hold the brush cutter in the way

that the head do not touch the

ground and with an inclination of

20º in the sense you are cutting.

Make cuts from the left to the

right to prevent that the grass

fall into the cutting area. Be

careful to not hit the head

with rocks or the ground. The

beatings against objects or

the ground will reduce the

life of the head, may spoil

creating a dangerous environment for you and the

people close to you.

The nylon threads are shortened with the use, when

they are too short accelerate the engine and press the

head against the ground. Then leave wire from the

head. If you leave too much wire the blade will cut in

excess.

Remember that the end of the nylon threat is the one

that makes the cut. Get a better result if you do not

introduce the entire head in the cutting area. Enter

the head slowly and let the nylon tips cut the grass at

their own pace.

WARNING DANGER: Do not operate the brush

cutter in areas with metallic materials.

16

English

Always use the proper protective equipment. Don’t

use this machine in areas where you can’t see properly.

7.1.2. CUT WITH THE DISC

Check the disc holder and make sure it is tight and

there are no signs of damage or abrasion.

Make sure the disc and disc holder are firmly installed

in accordance with the instructions and that the disc

spins freely without producing abnormal sounds.

CUTTING METHOD:

- Cut with the left front of the disc.

- Always cut to the left keeping the disc slightly

inclined to the left.

IMPORTANT:

- Only use this machine to cut grass. Do not let

the disc touch materials that can not cut as stones,

metals, hard wood, wire mesh, etc.

- Keep the blade sharp. A bad sharpened disc cause

a higher cutting force on the machine as well as

increased risk of rebound or projection materials.

- Keep the area to be cut clean with no traces of

chopped vegetables or other materials.

8. MAINTENANCE AND SERVICE

Make periodic inspections of the machine to ensure

that the machine is correct. For a thorough inspection

take the machine to your dealer.

It is necessary to stop the engine and to check

that the cutting tool is stopped before cleaning or

transporting the machine.

Before performing any maintenance or repair

the machine make sure the engine is off and

remove the spark plug cap. Perform all maintenance

of the machine when is set on a flat and clear surface.

Never try adjustments in the machine if it is running

and / or attache to the user by the harness. Perform

all maintenance of the machine when is set on a flat

and clear surface.

Warning! Do not modify the machine or change

the cutting elements. An inadequate use of these

elements can cause serious personal damages and

can even be fatal.

Use only suitable spares to get a proper performance

for this machine. This replacement can be found on

the official distributor of the machine. Using other

sparks may causes risks, damage to the user or

people around the machine.

Carburetor adjustment is complicated and should

be done only by the service.Carburetor regulation

is complicated and should only be carried out by a

service agent. An incorrect regulation of the carburetor

can cause damages to the engine and is sufficient

motive to cancel the warranty.

The removal of security devices, an improper

maintenance, the substitution of elements with non

original elements can cause corporal damages.

8.1. CARE AND MAINTENANCE AFTER USE

Carry out the following operations when you have

finished the work to ensure that the machine is kept in

a perfect condition.

8.1.1. GENERAL MAINTENANCE

Keep clean the machine, especially the fuel tank area

and areas near the air filter.

17

English

Maintain your machine clean and in good conditions.

Clean the covers with a humid towel. Never use petrol

or other flammable products to clean the machine.

8.1.2. BLADE SHARPENING

Blade sharpening should be done in an authorized

after sales. Do not sharpen the blade by yourself. The

blade must be sharpened guaranteeing the correct

angle and equilibrium of the blade. Sharpening if not

an expert can cause excessive vibrations that could

cause damages to the machine and will make the use

of the machine very uncomfortable to the end user.

Be careful when checking the state of the blade,

remember that although the engine has stopped the

blades can be moved manually.

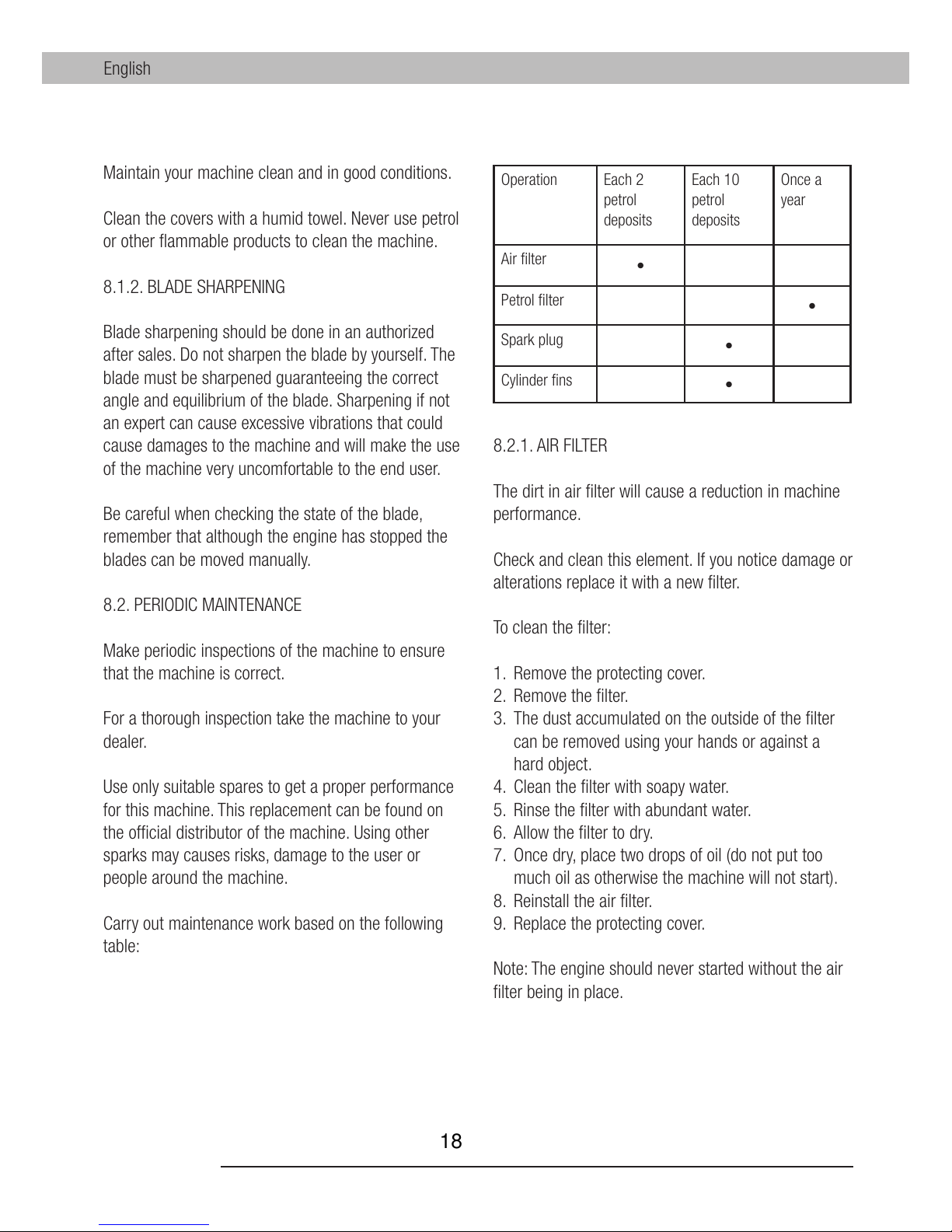

8.2. PERIODIC MAINTENANCE

Make periodic inspections of the machine to ensure

that the machine is correct.

For a thorough inspection take the machine to your

dealer.

Use only suitable spares to get a proper performance

for this machine. This replacement can be found on

the official distributor of the machine. Using other

sparks may causes risks, damage to the user or

people around the machine.

Carry out maintenance work based on the following

table:

8.2.1. AIR FILTER

The dirt in air filter will cause a reduction in machine

performance.

Check and clean this element. If you notice damage or

alterations replace it with a new filter.

To clean the filter:

1. Remove the protecting cover.

2. Remove the filter.

3. The dust accumulated on the outside of the filter

can be removed using your hands or against a

hard object.

4. Clean the filter with soapy water.

5. Rinse the filter with abundant water.

6. Allow the filter to dry.

7. Once dry, place two drops of oil (do not put too

much oil as otherwise the machine will not start).

8. Reinstall the air filter.

9. Replace the protecting cover.

Note: The engine should never started without the air

filter being in place.

Operation Each 2

petrol

deposits

Each 10

petrol

deposits

Once a

year

Air filter •Petrol filter •Spark plug •Cylinder fins •18

English

8.2.2. FUEL FILTER

The fuel tank is equipped with a filter. It is at the end

of the suction pipe and can be removed with the help

of a hook of wire.

Check the fuel filter regularly. Do not allow dirty in the

fuel tank to prevent the filter is dirty. A dirty filter will

make it more difficult to start the engine and cause

malfunctions or stop it.

Check fuel. If you see dirty replace.

If the inside of the fuel tank is dirty you can clean it

with gasoline.

8.2.3. CHECK THE SPARK

The most common problems when starting a machine

are produced by a dirty spark plug or bad. Clean spark

plug and check it regularly. Check the electrode gap is

correct (0,6 - 0,7 mm).

8.2.4. CLEANING THE CYLINDER FINS

The fins of the cylinder are in charge of refrigerating

the engine thanks to these being in contact with the

air. These fins should always be clean and without any

material that prevents the air flow. If the fins are not

clean and blocked with dirt, the engine will overheat

and could even break. Check these fins on a regular

basis.

8.2.4.1. VENTILATION OF AIR INTAKE TO ENGINE

Eliminate any dirt from the ventilation fins so that the

engine is not damaged and to avoid a possible fire.

19

English

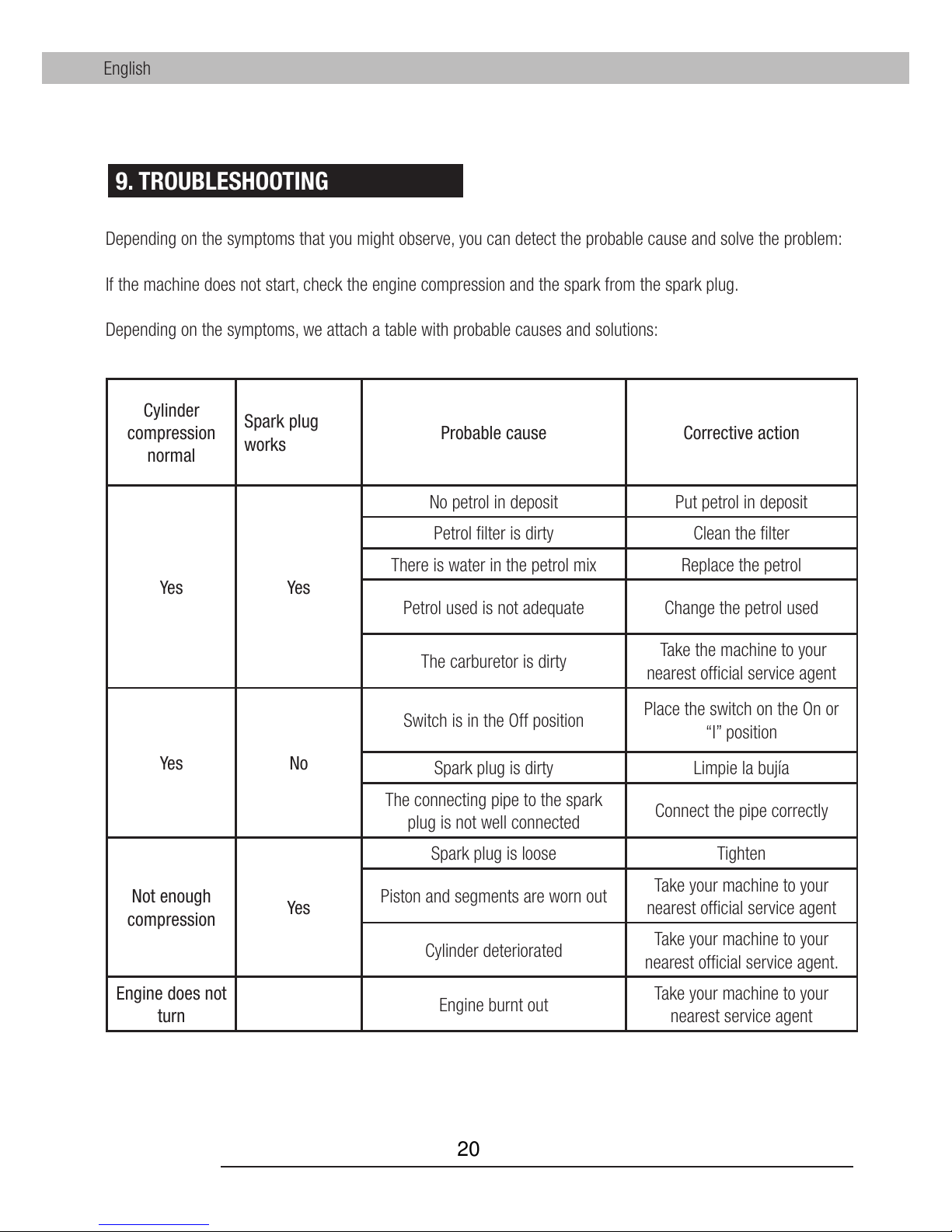

Depending on the symptoms that you might observe, you can detect the probable cause and solve the problem:

If the machine does not start, check the engine compression and the spark from the spark plug.

Depending on the symptoms, we attach a table with probable causes and solutions:

9. TROUBLESHOOTING

Cylinder

compression

normal

Spark plug

works Probable cause Corrective action

Yes Yes

No petrol in deposit Put petrol in deposit

Petrol filter is dirty Clean the filter

There is water in the petrol mix Replace the petrol

Petrol used is not adequate Change the petrol used

The carburetor is dirty Take the machine to your

nearest official service agent

Yes No

Switch is in the Off position Place the switch on the On or

“I” position

Spark plug is dirty Limpie la bujía

The connecting pipe to the spark

plug is not well connected Connect the pipe correctly

Not enough

compression Yes

Spark plug is loose Tighten

Piston and segments are worn out Take your machine to your

nearest official service agent

Cylinder deteriorated Take your machine to your

nearest official service agent.

Engine does not

turn Engine burnt out Take your machine to your

nearest service agent

20

Table of contents

Other Lea Brush Cutter manuals