BOPIXEL OPR407 Series User manual

OPR407 Series DLP projector operating manual

Catalogue

一、 Precautions ......................................................................................................... 1

二、 Module Specifications ........................................................................................2

三、 Interfaces Introduction ......................................................................................5

3.1 Connectors Positions Introduction ....................................................................5

3.2 Interfaces Description ....................................................................................... 6

3.2.1 J1 Extended video interface ....................................................................6

3.2.2 J2 I2C Interface .......................................................................................7

3.2.3 J3 External I2C Enable Jumper .............................................................. 7

3.2.4 J4 Trigger Interface .................................................................................7

3.2.5 J10 12V Power Connector ...................................................................... 8

3.2.6 J11 Fan Connector .................................................................................. 8

3.2.7 J14 External Power Supply Connector ................................................... 8

3.2.8 J12 USB internal connector .................................................................... 8

四、 Instruction .......................................................................................................... 9

4.1 Product Description .......................................................................................... 9

4.2 Software and Documents .................................................................................. 9

4.2.1 Software .................................................................................................. 9

4.2.2 Reference Documents ............................................................................. 9

4.3 Software Installation ....................................................................................... 10

4.3.1 GUI software .........................................................................................10

4.3.2 Others ....................................................................................................11

4.4 Hardware connection ...................................................................................... 11

4.4.1 Driver Installation ................................................................................. 11

4.5 GUI Instruction ............................................................................................... 12

4.5.1 Connect module to computer ................................................................12

4.5.2 "Display" mode to test patterns and images ......................................... 13

4.5.3 "light control" mode to customize stripe patterns .................................17

4.5.4 Firmware programming ........................................................................ 24

4.5.5 Debug instructions ................................................................................ 25

4.6 DLP advanced control mode ...........................................................................26

4.6.1 Precise brightness control ..................................................................... 28

4.6.2 Build-in stripe patterns ..........................................................................31

4.7 Make a Batch file ............................................................................................ 33

4.8 Make Firmware ...............................................................................................38

五、Appendix .............................................................................................................43

5.1 DLP4710EVM-LC Firmware Release Notes ................................................. 43

5.2 "Internal Patterns" mode operation steps ........................................................44

5.3 How to Modify the Specifications of Test Patterns? ...................................... 51

六、FAQ ..................................................................................................................... 53

6.1 How to Program the DLPC3479? ................................................................... 53

6.2 What is a 1D pattern? ......................................................................................53

6.3 Why would you want to use a 1D pattern? ..................................................... 53

6.4 What is a pattern set? ...................................................................................... 54

6.5 How many patterns can be stored in each pattern set? ................................... 54

6.6 How to change frame rate of internal pattern?............................................... 54

6.7 Why is there a minimum pre-exposure dark time and post-exposure dark time

limit? ..................................................................................................................... 55

6.8 What actually happens in pre-exposure dark time and post-exposure dark time?

.............................................................................................................................. 55

6.9 What timings are supported by Internal pattern streaming mode? ................. 56

6.10 Do these minimum darkfield times have to be calculated? .......................... 56

七、Guarantee ........................................................................................................... 57

1

一、 Precautions

Please read all instruments before use, otherwise the product

may be damaged.

1) The optical module is in the device and the circuit board is exposed, so do not

drop it from a height.

2) This device contains high-precision optical components, so please do not

disassemble without authorization.

3) The module is powered by 12V power supply. A 12V, 10A or higher current

adapter is suitable. Otherwise, it may cause the adapter to overcurrent and power off

when the brightness is increased.

4) DMD flat cable connector has a limited service life, so it is not allowed to unplug

the cable without authorization.

5) It is strictly forbidden to Unplugging the DMD flat cable when the module is

power on condition. This will damage the DMD.

6) Please pay attention to anti-static measures before use. Static electricity will

cause damage to the main chips or DMD.

7) This module is turned on when it is powered on. If it does not work properly,

please contact us.

8) Note: The GUI software version is 2.2.0.6 in this document, and the

operating system is Win10 x64.

2

二、 Module Specifications

1) Module projection resolution: 1920 x 1080

2) Max frame speed of image input: 60Hz (2D and 3D) for 1080p

3) Internal storage frame rate: 1440Hz (1 bit) , 180Hz (8bit)

4) Integrated internal storage can store more than 1000 graphics.

5) Maximum Power: 100W

6) Support USB connection to official GUI control software, and external I2C and

SPI connection to control module and firmware programming

7) Support trigger input and output. 3.3V or 5V (default) power output is optional.

8) Support parallel or BT656 video input.

OPR407 series (DLP4710)

Type OPR407185 OPR407700 OPR407100 OPR407185S

Working

distance

mm

MI

N

TY

P

MA

X

MI

N

TY

P

MA

X

MI

N

TY

P

MA

X

MI

N

TY

P

MA

X

10

0185 450 300 700 1200 300 100

02000 100 185 450

Screen size

(TYP)

mm

140*79 604*340 1054*593 158*128*92

Depth of

focus

(TYP)

mm

-55~+100 -200~+300 -500~+500 -30~+40

Throw

Ratio 1.32 1.16 0.94 1.32

Precision

um 73 315 549 73

Mode Orthographic projector Scheimpflug/Tilt

structure

Dimension

mm 127*73*47 132*73*47 127*73*47 130*78*55

Distortion <0.5%

Resolution 1920*1080

Uniformity

JBMA >90%

Contrast 500:1

Light

source RGB LED

3

OPR407185 Dimension OPR407185 Dimension

OPR40718S schematic diagram

4

OPR407185S Screen size

5

三、 Interfaces Introduction

The connector location and pin 1 location are marked in the image above. Pin 1

is marked with a triangle on the circuit board, please pay attention to the comparison.

3.1 Connectors Positions Introduction

Connector Matching plug type Description

J1 AXT650124 Extended video interface

J2 51021-0600 I2C interface

J3 2.0mm Jumper I2C enable

J4 51021-0800 Trigger interface

J5 AXT680124 DMD flat cable

J6 87439-1000 Red LED output

J7 87439-1000 Green LED output

J8 87439-1000 Blue LED output

6

J10 43645-0200 12V Power supply

J11 51021-0400 12V Power for fan

J14 51021-0400 12V, 5V, 3.3V power supply

J12 51021-0400 USB interface internal connector

J11 USB type C USB interface

3.2 Interfaces Description

3.2.1 J1 Extended video interface

Pin Definition Description Pin Definition Description

1 PDATA21 Video Signal

Input

50 PDATA22 Video Signal Input

2 PDATA20 49 PDATA23

3 PDATA19 48 GND

4 PDATA18 47 PCLK Video Signal

control

5 PDATA17 46 DATEN_CM

D

6 PDATA16 45 VSYNC_WE

7 GND 44 HSYNC_CS

8 PDATA15 Video Signal

Input

43 PDM_CVS_T

E

9 PDATA14 42 3DR_D

10 PDATA13 41 E_SCL External I2C

interface

11 PDATA12 40 E_SDA

12 PDATA11 39 EX_I2C_OE pull up 3.3V to

enable external I2C

13 PDATA10 38 EXT_CLK External SPI

interface

14 PDATA9 37 EXT_MOSI

15 PDATA8 36 EXT_MISO

16 GND 35 EXT_CSZ

17 PDATA7 Video Signal

Input

34 EXT_PROJ_O

N

pull up 3.3V to

power on the DLP

18 PDATA6 33 MCU_ACK I2C reply sent by

MCU

19 PDATA5 32 MCU_REQ I2C request sent by

GUI

20 PDATA4 31 GND

21 PDATA3 30 S_HOST_IRQ Slave reports error

22 PDATA2 29 M_HOST_IR

Q

Master reports error

23 PDATA1 28 SPI_BUS_SE External SPI

7

L channel switching

24 PDATA0 Video Signal

Input

27 EXT_SPI_EN External SPI

Enable

25 GND 26 GND

3.2.2 J2 I2C Interface

It has the same function as the J1 flat cable, and use a general connector, which

is convenient for customers to use.

Pin Definition Description

1 E_SCL External I2C bus clock

2 E_SDA External I2C bus data

3 EX_I2C_OE External I2C bus is enabled. After the voltage is pulled up to

3.3V, the external I2C is enable, and the USB to I2C channel is

closed.

4 NC

5 EXT_PROJ_ON The voltage is pulled up to 3.3V to turn on, and the 0V voltage is

used to turn off.

6 GND Signal Ground

3.2.3 J3 External I2C Enable Jumper

It is used to force enable the external I2C interface. Connecting the jumper can

enable external I2C interface, and then connection with GUI software using USB will

be disabled.

3.2.4 J4 Trigger Interface

Pin Definition Description

1 GND Signal Ground

2 PWR_SEL Trigger signal level power supply. 3.3V or 5V can be

available (using different resistors)

3 PATTERN_R

DY

Pattern_ready signal defined by GUI

4 TRIG_OUT2 Trigger output 2 defined by GUI, open-drain output,

pulled up to 5V with a 1k resistor

5 TRIG_IN Trigger input defined by GUI, with optocoupler

isolation, 3.3V~24V compatible

6 EXT_T5

8

7 TRIG_OUT1 Trigger output 1 defined by GUI,open-drain output,

pulled up to 5V with a 1k resistor

8 NC

3.2.5 J10 12V Power Connector

Pin Definition Description

1 12V Power 12V Power Input. Voltage reaching 15V will trigger

overvoltage protection

2 GND Signal Ground

3.2.6 J11 Fan Connector

Pin Definition Description

1 GND Signal ground

2 12V 12V power supply for fan

3 NC

4 NC

3.2.7 J14 External Power Supply Connector

Pin Definition Description

1 GND Signal ground

2 12V 12V power supply for fan

3 5V 5V power supply

4 3.3V 3.3V power supply

3.2.8 J12 USB internal connector

Pin Definition Description

1 GND Ground

2 DP Signal positive

3 DN Signal negative

4 VBUS USB power input

9

四、 Instruction

4.1 Product Description

This module is mainly for structured light application. It can project 2D

chessboard patterns and 1D 1bit and 8bit structured light patterns. The functions of

ordinary projectors have been simplified and cannot be used.

Please note: Since this module functions have been cut down compared to the TI

official module, not all of the functions of the official GUI can be realized. In addition,

the TI official firmware is not suitable for this module, so please use our firmware.

Specific instructions can refer to the TI official document “DLP Display and

Light Control EVM GUI Tool User Guide (Rev. A)”. Other differences from TI

official DLP3010EVM are explained below.

4.2 Software and Documents

4.2.1 Software

Control software GUI: https://www.ti.com/tool/cn/DLPDLC-GUI

Firmware: The firmware of OPR407 series DLP4710LC module is not

compatible with the TI official one. Please use our company firmware and the

compression package will be send to customers after purchasing our products.

API: DLPC34XX-API

4.2.2 Reference Documents

DLP4710LC Series module instructions (this document)

DLP4710LC DMD data sheet

11

The DMD used by OPR407 series DLP module is DLP4710LC, so please select

the DLP4710LC version software.

4.3.2 Others

Please install other softwares as needed. This document does not describe in

detail.

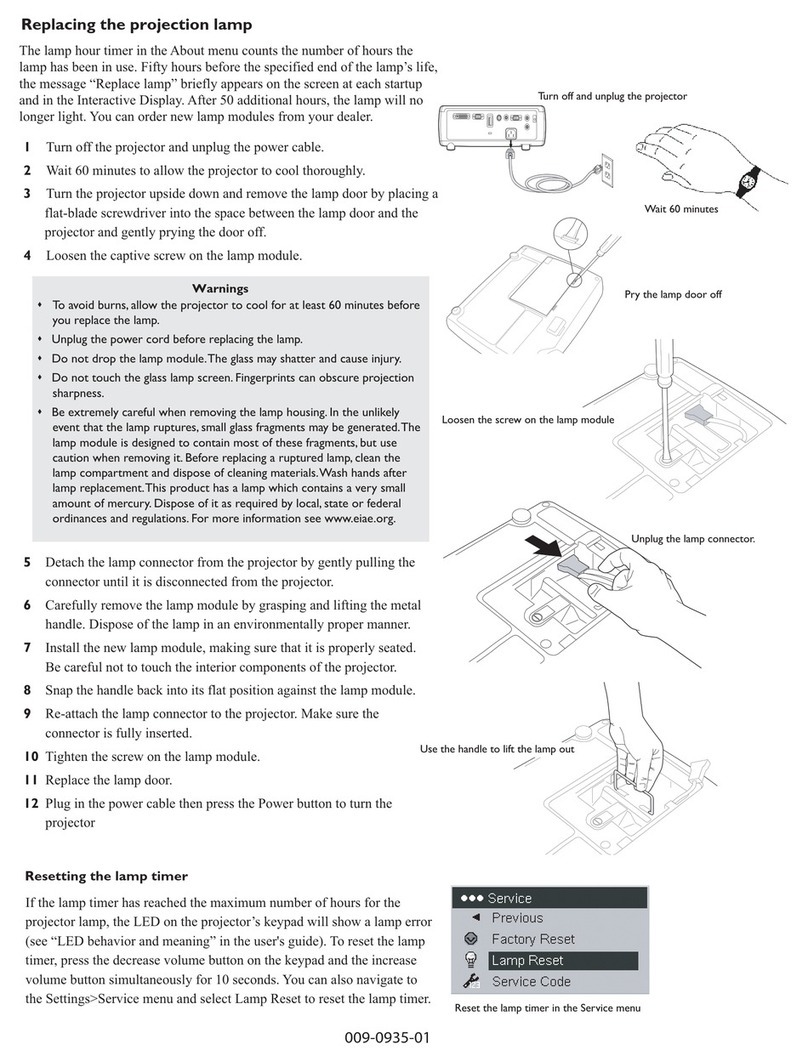

4.4 Hardware connection

4.4.1 Driver Installation

When connecting for the first time, the driver will be automatically installed on

the Internet. The completion of the installation is prompted as following.

Fig.8

12

4.5 GUI Instruction

4.5.1 Connect module to computer

Connect the power plug to the power connector J10, and the plug model is

43645-0200. The load current of the power supply wire should be more than 10A, and

18AWG or higher wire is recommended. The supply voltage is 12V, and supply

current is 10A. The maximum power of the high-power version of DLP4710LC is

100W. If the power supply is insufficient, the module will shut down automatically.

Use USB Type-C cable to connect computer and DLP4710LC module.

Please use our GUI installation package, or download the latest vision from TI

website. Download address: https://www.ti.com.cn/tool/cn/DLP4710EVM-LC. Note:

The GUI downloaded from the official website may be incompatible with our module

and causes problems.

After connecting the module to the computer and the power supply, open the

GUI software.

Check if the connection button at the bottom left has a green symbol. If not, click

the text in the red box in the above figure, and it will become the green checkmark,

13

which means connection is normal.

Click the "Get" button to check the drivers and firmware information. It is

recommended to click this button after module is power on.

4.5.2 "Display" mode to test patterns and images

The "patterns and images" tab in "Display" mode is projection control for the

14

build-in test images.

"Test patterns" is about the build-in test patterns for DLPC chips, which do not

change with firmware changes. The options under "pattern" can control the projection

patterns, and "foreground" and "background" can set the foreground and background

colors. After the settings are completed, click the "Set" button to project.

The "splash image" is about the images to be projected. They vary with different

firmwares. Customers can change them according to their needs. For the modification

method, please refer to the "Make Firmware" section. Select the image needed and

click "Set" button to project.

15

Under the "Video and color" tap, "Video information" is for the external input

signal projection. This function need customers to develop video signal decoder to

realize.

"Color temperature" is to adjust color temperature. Not recommended for

customers.

"Display settings" tap is for the image transformation and distortion correction.

Not recommended for customers.

16

The options under the "IntelliBright" tap are for intelligent brightness

optimization. Not recommended for customers.

The parameters under the "LED current" tap are to adjust the light brightness

manually. Selecting the different colors’ enable boxes can turn on the related LED

light. Click "set" button to confirm. However this function will reset when the

projection pattern option is set, and doesn’t work at the "internal patterns" mode.

Dragging the pointer on the bar under different colors and clicking "Set" button

can change the brightness. The relation between the current and the pointer position

on the bar varies at different module because of different light sources. So please note

that the values displayed in the boxes are not the real values. One module values

cannot be used as the references for another modules. To acquire the available values,

the advanced control mode is needed, which will be introduced in the later section.

17

4.5.3 "light control" mode to customize stripe patterns

In "Light control" mode, the functions under "external patterns" label need

external video signal decoder to realize. This part need to be developed by customers.

Our product does not support following function.

"Internal patterns" tap is the setting of the customized structured light projection.

18

GUI supports 1 bitmap and 8 bitmap. Please pay attention to matching of image

bits and vertical/ horizontal direction when adding patterns. If the added stripes do not

match the options, the projected stripes will be wrong. Stripe image formats are

available in BMP or PNG.

To add horizontal stripes to the projected image, you need to select a single

vertical stripe, that is, a 1x1080 resolution image.

Similarly, to add vertical stripes to the projection image, you need to select a

single horizontal stripe image, that is, a 1920x1 resolution image.

This manual suits for next models

4

Table of contents

Other BOPIXEL Projector manuals

Popular Projector manuals by other brands

Sanyo

Sanyo PLC-XP57L owner's manual

NEC

NEC MultiSync LT280 Specifications

Kodak

Kodak EKTAPRO 9020 CINE Service manual

Digital Projection International

Digital Projection International TITAN Reference 1080p-330-L Technical specifications

Sanyo

Sanyo PLC-XM150L Specifications

Optoma

Optoma EX521 Specifications