Bopp & Reuther Vortex VTX3 K i Ex Wiring diagram

VTX3

VTX3VTX3

VTX3 Supplementary Instructions

Supplementary InstructionsSupplementary Instructions

Supplementary Instructions

Vortex flowmeter

Equipment category II 2 G, EPL Gb

in protection type intrinsic safety "i"

© Bopp & Reuther Messtechnik GmbH 12/2018 - Z-EN-09001-id-A Exi-Gb

CONTENTS

2

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

VTX3

1 Safety instructions 3

1.1 General notes ................................................................................................................... 3

1.2 EU conformity ................................................................................................................... 3

1.3 Safety instructions............................................................................................................ 3

2 Device description 4

2.1 Device description ............................................................................................................ 4

2.2 Type code .......................................................................................................................... 4

2.3 Marking............................................................................................................................. 5

2.4 Flammable products ........................................................................................................ 7

2.5 Equipment category .........................................................................................................7

2.6 Types of protection ........................................................................................................... 8

2.7 Ambient temperature / temperature classes.................................................................. 8

2.8 Electrical data................................................................................................................. 16

3 Installation 17

3.1 Mounting ......................................................................................................................... 17

3.2 Special conditions........................................................................................................... 18

4 Electrical connections 19

4.1 General notes ................................................................................................................. 19

4.2 Power supply .................................................................................................................. 19

4.3 Inputs / Outputs .............................................................................................................. 20

4.4 Grounding and equipotential bonding............................................................................ 20

4.5 Flow sensor circuits (remote version only) ................................................................... 22

5 Operation 23

5.1 Start-up........................................................................................................................... 23

5.2 Operation ........................................................................................................................ 23

5.3 Electrostatic charge .......................................................................................................23

6 Service 24

6.1 Maintenance ................................................................................................................... 24

6.2 Dismantling .................................................................................................................... 24

7 Notes 26

SAFETY INSTRUCTIONS

1

3

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

1.1 General notes

This additional instruction applies to explosion-protected versions of vortex flowmeters with

protection type intrinsic safety "i", equipment category II 2 G and EPL Gb.

It completes the standard manual for the non-explosion protected versions.

The information given in this instruction contains only the data relevant to explosion protection.

The technical details given in the manual for the non-explosion protected versions remain

unchanged unless they will be excluded or replaced by this instruction.

1.2 EU conformity

The manufacturer declares with the EU declaration of conformity on his own responsibility

conformity with the protection goals of directive 2014/34/EU for use in hazardous areas with gas.

The EU declaration of conformity for the equipment category II 2 G is based on the EU type

examination certificate of the KIWA ExVision:

The "X" after the certificate number refers to special conditions for safe use of the device, which

have been listed in these instructions.

1.3 Safety instructions

If these instructions are not followed, there is a risk of explosion.

Assembly, installation, start-up and maintenance may only be performed by personnel trained in

explosion protection!

KIWA 18 ATEX 0041X

KIWA 18 ATEX 0041XKIWA 18 ATEX 0041X

KIWA 18 ATEX 0041X

CAUTION!

The operator or his agent is responsible for observing any additional standards, directives or

laws if required due to operating conditions or place of installation.

This applies in particular to the use of easily detachable process connections when measuring

flammable media.

2

DEVICE DESCRIPTION

4

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

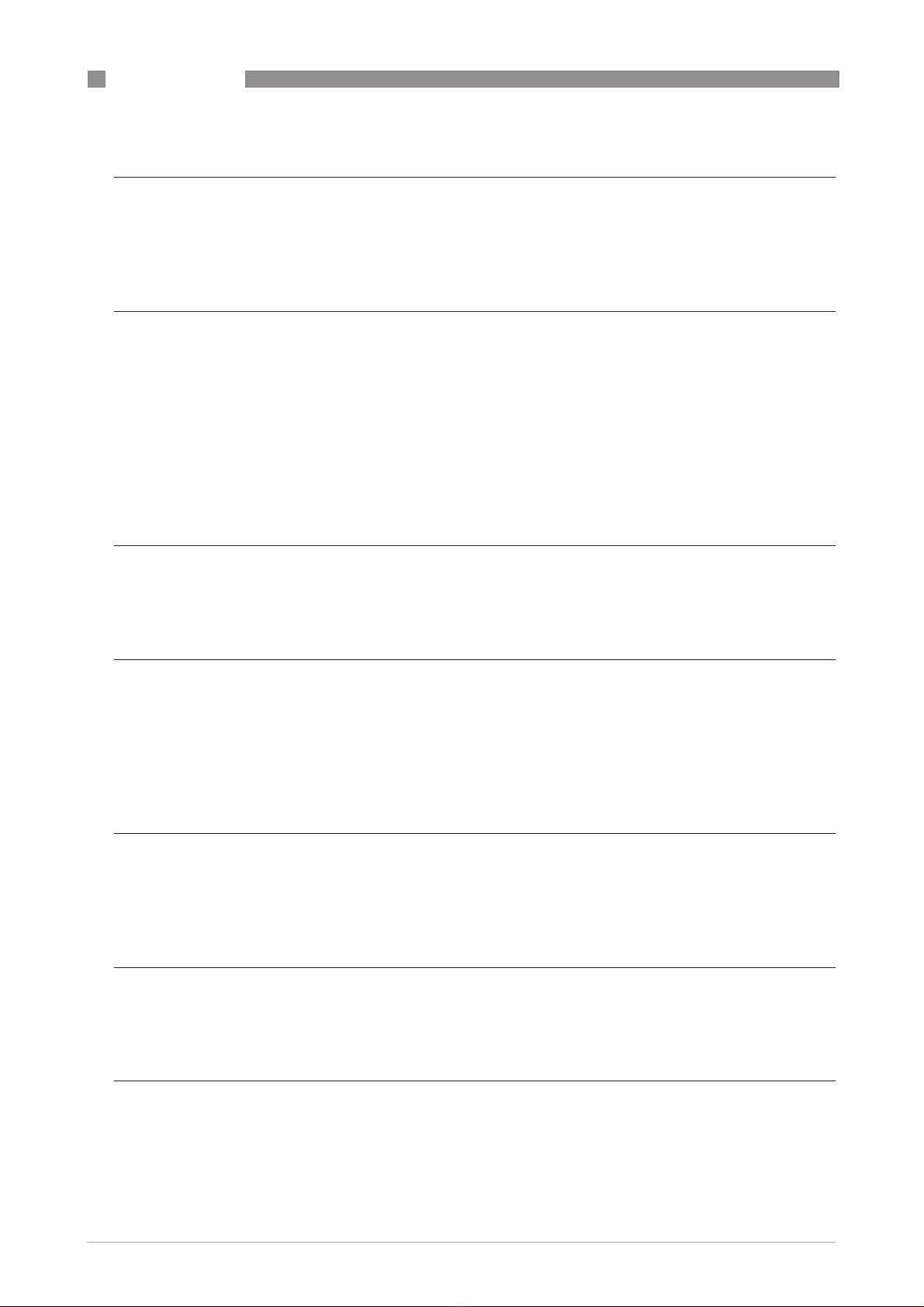

2.1 Device description

Vortex flowmeters measure and display the flow of flammable and non-flammable gases and

liquids. The signal converter includes either a 4...20 mA signal output with optional HART

®

communication or a bus connection. There are bus connections available according to the FISCO

model for connecting to the Foundation Fieldbus or Profibus PA. Signal converters with signal

output have a separate binary output and a separate current input.

The VTX3 W remote version consists of the SV18 flow sensor and the KV18 ..i-Ex signal converter.

2.2 Type code

The safety description code consists of the following elements*:

The remote version consisting of the flow sensor SV 18 and the signal converter KV 18 020 is

called the VTX3 W.

Figure 2-1: Safety description code for the compact version

1 Product designation

2 Type series

3 Compact version

4 Electrical signal output

free - current output 4...20 mA with optional HART

®

communication

FF - Foundation Fieldbus bus connection

PA - Profibus PA bus connection

5 Intrinsically safe supply

6 Ex - explosion-protected version

Figure 2-2: Safety description code for the signal converter of the remote version

1 Product designation

2 Type series

3 Remote version

4 Electrical signal output

free - current output 4...20 mA with optional HART

®

communication

FF - Foundation Fieldbus bus connection

PA - Profibus PA bus connection

5 Intrinsically safe supply

6 Sensor electronics VFC 020

7 Ex - explosion-protected version

Figure 2-3: Safety description code for the flow sensor of the remote version

1 Product designation

2 Type series of flow sensor

DEVICE DESCRIPTION

2

5

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

2.3 Marking

The marking of the devices in accordance with the description code is shown on the nameplates

below. On both the compact devices and the remote versions, the main plate is located on the

signal converter housing. On the remote versions there is an additional marking on the flow

sensor.

Compact versions with two signal converters for dual measurement (dual version) are each

marked with a nameplate, which is attached to each of the signal converter housings.

The details relevant to explosion protection are identical on both nameplates.

Figure 2-4: Example of a nameplate for the compact version

1 Device version VT3X K

2 Production order number

3 Serial number

4 Year of manufacture

5 Ex data according to KIWA 18 ATEX 0041X

6 Permissible ambient temperature range

7 Maximum values intrinsically safe circuits

8 Safety instructions, disposal and data matrix

9 Internet address of the manufacturer

2

DEVICE DESCRIPTION

6

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

Figure 2-5: Example of the nameplates for the remote version

1 Device version VT3X W

2 Production order number

3 Serial number

4 Year of manufacture

5 Ex data according to KIWA 18 ATEX 0041X

6 Permissible ambient temperature range

7 Maximum values intrinsically safe circuits

8 Safety instructions, disposal and data matrix

9 Internet address of the manufacturer

DEVICE DESCRIPTION

2

7

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

2.4 Flammable products

Atmospheric conditions:

Atmospheric conditions:Atmospheric conditions:

Atmospheric conditions:

The standard atmospheric conditions under which it may be assumed that Ex equipment can be

operated are:

•Temperature: -20...+60°C / -4...+140°F

•Pressure: 80...110 kPa (0.8...1.1 bar) / 11.6...15.9 psi

•Air with normal oxygen content, typically 21%v/v

Ex equipment operating outside the standard temperature range must be tested and certified

(e.g. for ambient temperature range -40...+65°C / -40...+149°F).

Ex equipment operating outside the standard atmospheric pressure range and standard oxygen

content is not permitted.

Operating conditions:

Operating conditions:Operating conditions:

Operating conditions:

Vortex flowmeters operate outside the standard atmospheric pressure range, which means that

explosion protection, regardless of the zone assignment, is fundamentally not applicable for the

measuring unit (piping).

2.5 Equipment category

Vortex flowmeters are designed in category II 2 G and EPL Gb according to EN 60079-0 and

EN 60079-11 for use in zone 1. The inside of the measuring unit is also approved for zone 1.

CAUTION!

Operation with flammable products is only permitted as long as no explosive fuel/air mixture

builds up inside of the piping at the same time the atmospheric conditions are exceeded.

The operator is responsible to ensure that the flowmeter is operated safely in terms of the

temperature and pressure of the products used. In case of operation with flammable products

the measuring units must be included in the periodic pressure tests of the piping.

Definition of zone 1 according to EN 1127-1, Appendix B:

An area in which an explosive atmosphere, as a result of the mixture of flammable substances in

the form of gas, steam or mist with air, under normal operation may occasionally occur.

2

DEVICE DESCRIPTION

8

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

2.6 Types of protection

2.7 Ambient temperature / temperature classes

Because of the influence of the temperature of the product, no fixed temperature class is

assigned to vortex flowmeters. The temperature class of these devices is rather a function of the

product temperature and ambient temperature that is present and the specific device version.

The classification is outlined in the following tables.

The tables take into account the following parameters:

•Ambient temperature T

amb

•Product temperature T

m

•Nominal size DN

•Heat resistance of the connecting cable

The marking is:

ATEX II 2 G Ex ia IIC T6...T2 Gb

II 2 G Ex ia IIC T6...T2 GbII 2 G Ex ia IIC T6...T2 Gb

II 2 G Ex ia IIC T6...T2 Gb

(compact version, flow sensor in remote version)

or

II 2 G Ex ia IIC T6 Gb

II 2 G Ex ia IIC T6 GbII 2 G Ex ia IIC T6 Gb

II 2 G Ex ia IIC T6 Gb

(signal converter in remote version)

The marking contains the following information:

The marking contains the following information:The marking contains the following information:

The marking contains the following information:

II

IIII

II Explosion protection, group II

2

22

2Equipment category 2

G

GG

GGas explosion protection

Ex ia

Ex iaEx ia

Ex ia Intrinsically safe, level of protection "ia"

IIC

IICIIC

IIC Gas group, suitable for gas groups IIC, IIB and IIA

T6...T2

T6...T2T6...T2

T6...T2 Temperature class range

(compact version, flow sensor in remote version)

T6

T6T6

T6 Temperature class

(signal converter in remote version)

Gb

GbGb

Gb EPL, suitable for zone 1

In principle, operation is possible in all ranges of the temperature classes T1...T6.

DEVICE DESCRIPTION

2

9

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

The permitted ambient temperature range is indicated on the nameplate; depending on the

device version it is T

amb

= -40...+65°C / -40...+149°F.

The minimum product temperature is -40°C/-40°F.

The maximum permissible product temperatures listed in the tables are valid under

the following conditions:

•

The measuring device is installed and operated in accordance with the manufacturer's

installation instructions.

•

It must be ensured that the flowmeter is not heated by the effects of additional heat radiation

(sunshine, neighbouring system components) and thus operated above the permissible

ambient temperature range.

•

Insulation must be limited to the piping. Unobstructed ventilation of the signal converter

must be ensured.

2

DEVICE DESCRIPTION

10

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

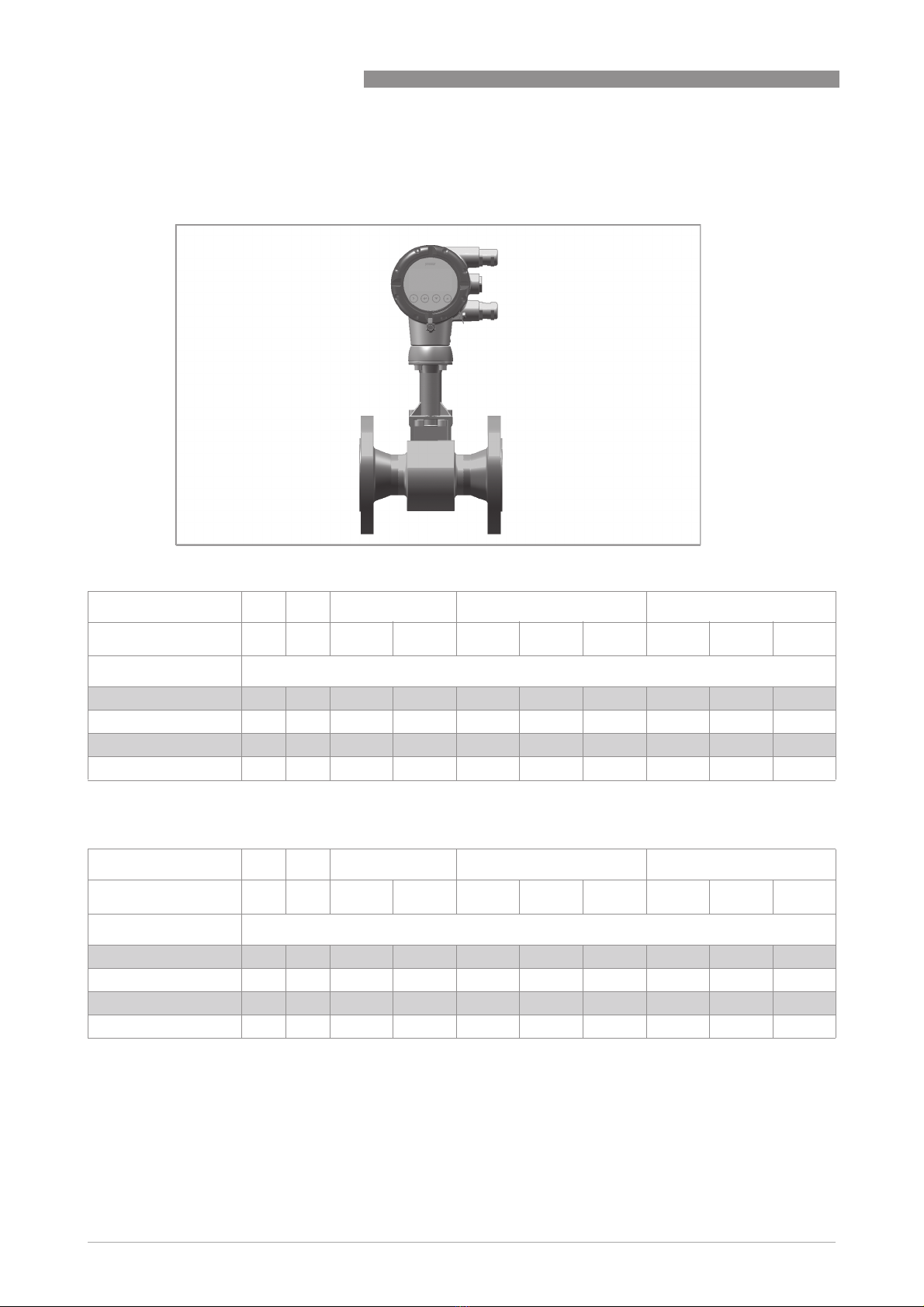

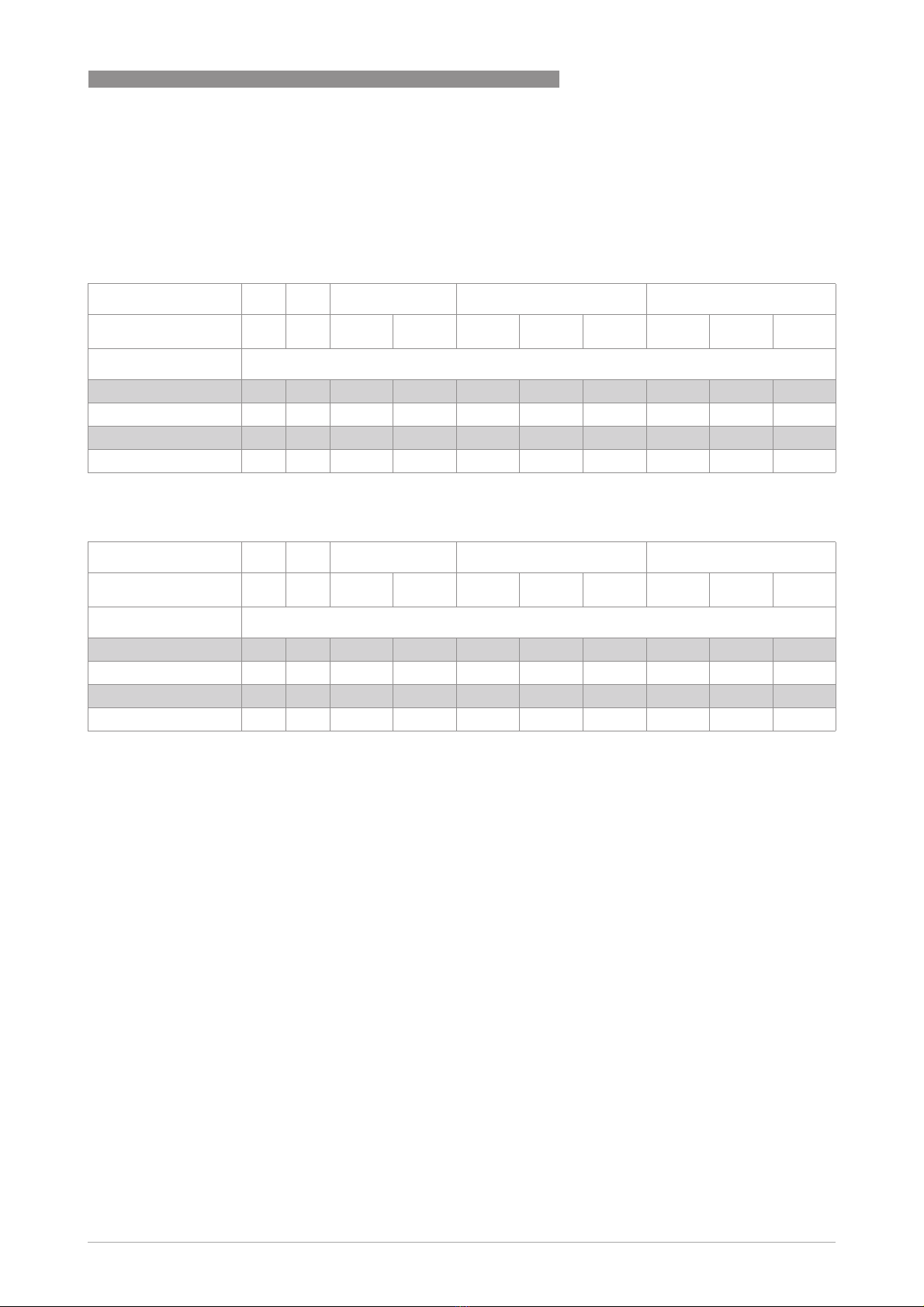

Max. permissible product and ambient temperatures with signal converter or

connection box mounted above the flow sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 85 65 135 135 1 200 200 1 185 1 240 210 1 185 1

DN40…50 75 65 135 135 1 200 195 1 165 1 240 195 1 165 1

DN80…100 70 65 135 1 135 1 200 165 1 145 1 240 1 165 1 145 1

DN150...300 80 65 135 135 1 200 200 1 170 1 240 200 1 170 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 185 149 275 275 1 392 392 1 365 1 464 410 1 365 1

DN40…50 167 149 275 275 1 392 383 1 329 1 464 383 1 329 1

DN80…100 158 149 275 1 275 1 392 329 1 293 1 464 1 329 1 293 1

DN150...300 176 149 275 275 1 392 392 1 338 1 464 392 1 338 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

DEVICE DESCRIPTION

2

11

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

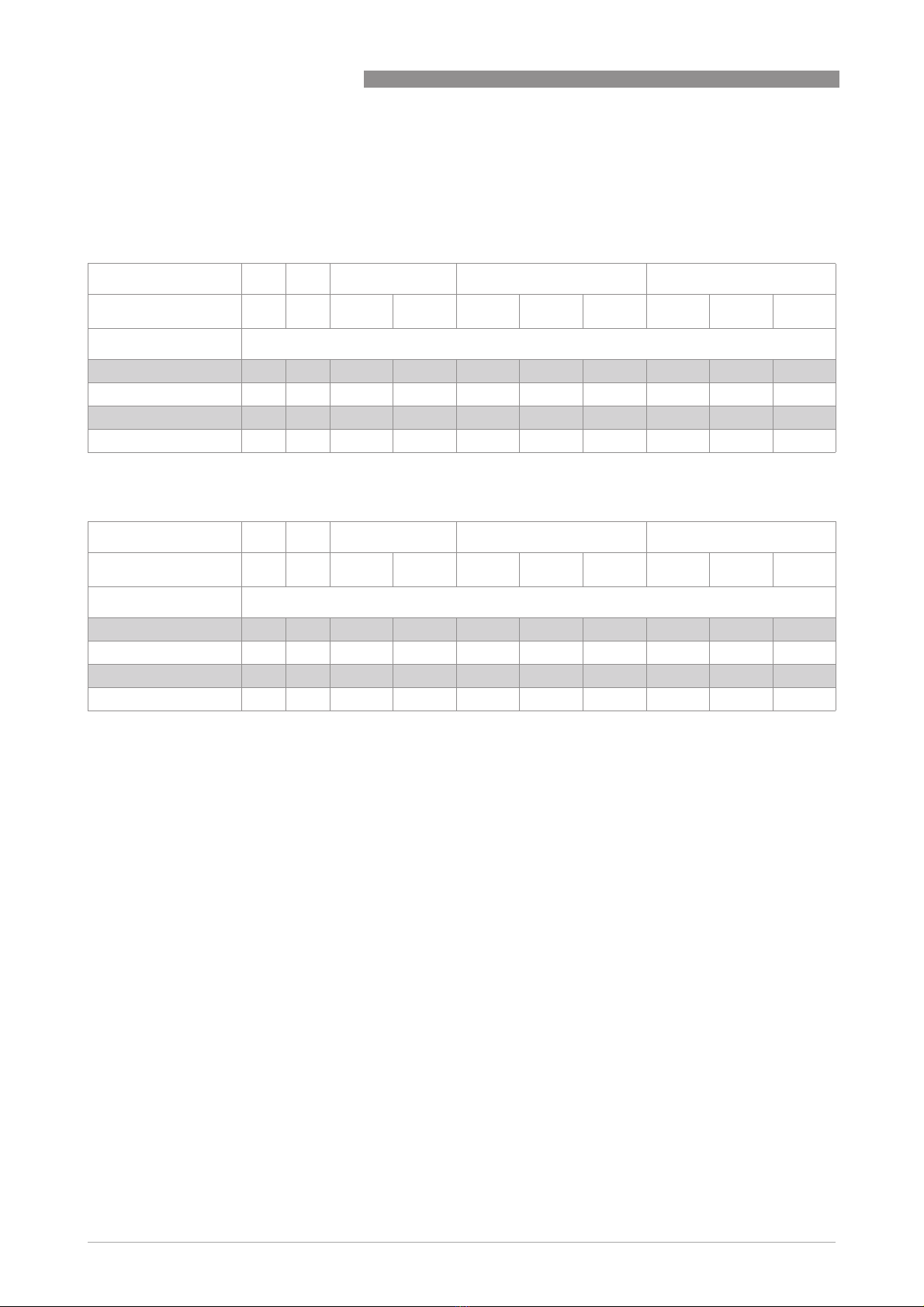

Max. permissible product and ambient temperatures with signal converter or

connection box mounted at side or underneath the flow sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 85 90 135 135 200 200 200 1 240 240 240 1

DN40…50 85 80 135 135 200 200 200 1 240 240 240 1

DN80…100 85 75 135 135 1 200 200 1 200 1 240 240 1 240 1

DN150...300 85 80 135 135 200 200 200 1 240 240 240 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 185 194 275 275 392 392 392 1 464 464 464 1

DN40…50 185 176 275 275 392 392 392 1 464 464 464 1

DN80…100 185 167 275 275 1 392 392 1 392 1 464 464 1 464 1

DN150...300 185 176 275 275 392 392 392 1 464 464 464 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

2

DEVICE DESCRIPTION

12

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

Max. permissible product and ambient temperatures for devices with painted flow

sensors / signal converters or connection box mounted above the flow sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 60 60 120 1 120 1 120 120 1 120 1 120 120 1 120 1

DN40…50 55 60 120 1 115 1 120 120 1 115 1 120 120 1 115 1

DN80…100 55 60 110 1 105 1 120 110 1 105 1 120 110 1 105 1

DN150...300 60 60 120 1 115 1 120 120 1 115 1 120 120 1 115 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 140 140 248 1 248 1 248 248 1 248 1 248 248 1 248 1

DN40…50 131 140 248 1 239 1 248 248 1 239 1 248 248 1 239 1

DN80…100 131 140 230 1 221 1 248 230 1 221 1 248 230 1 221 1

DN150...300 140 140 248 1 239 1 248 248 1 239 1 248 248 1 239 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

DEVICE DESCRIPTION

2

13

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

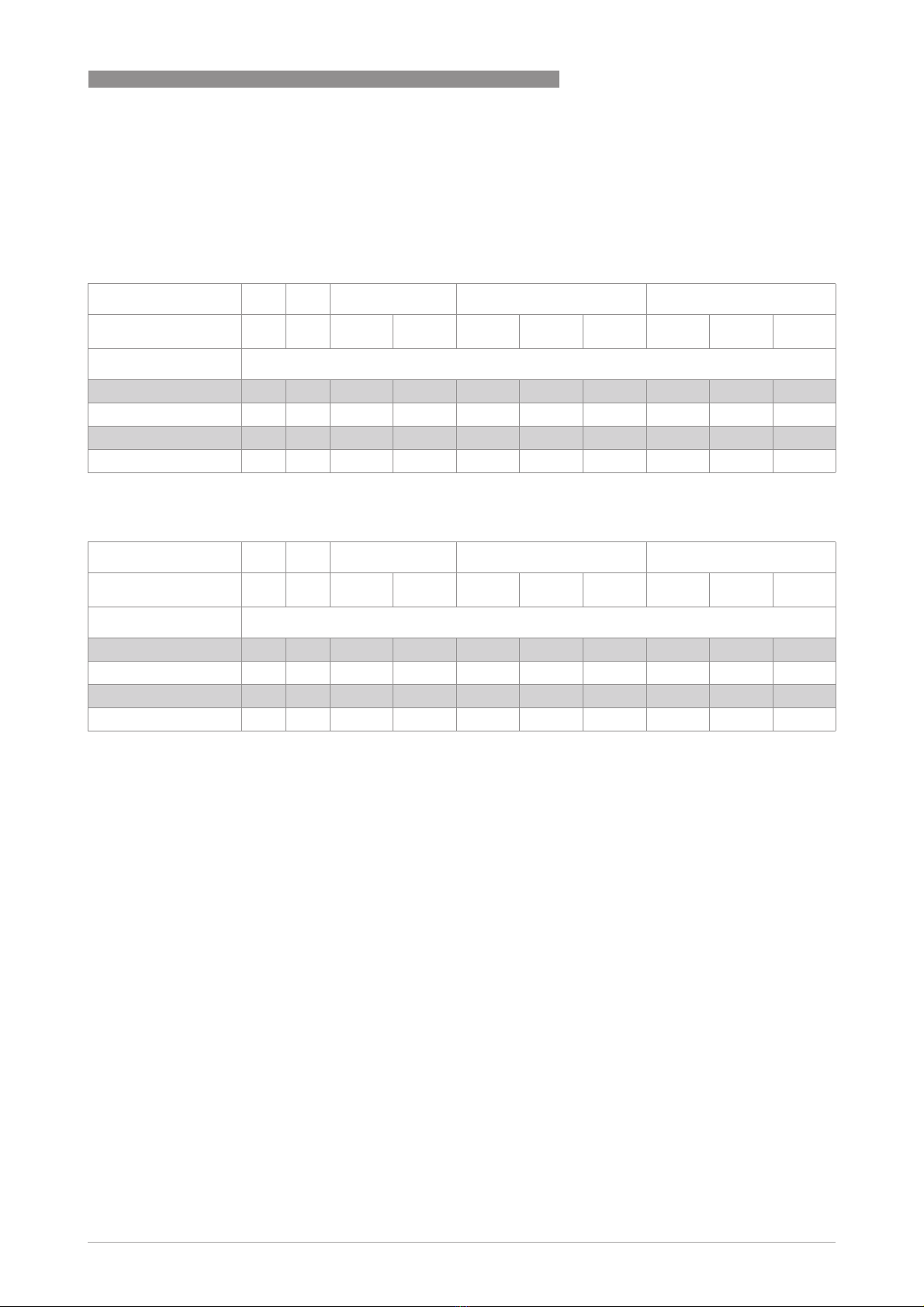

Max. permissible product and ambient temperatures for devices with painted flow

sensors / signal converters or connection box mounted at side or underneath the flow

sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 85 65 120 120 1 120 120 120 1 120 120 120 1

DN40…50 70 65 120 1 120 1 120 120 1 120 1 120 120 1 120 1

DN80…100 70 65 120 1 120 1 120 120 1 120 1 120 120 1 120 1

DN150...300 75 65 120 120 1 120 120 120 1 120 120 120 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 185 149 248 248 1 248 248 248 1 248 248 248 1

DN40…50 158 149 248 1 248 1 248 248 1 248 1 248 248 1 248 1

DN80…100 158 149 248 1 248 1 248 248 1 248 1 248 248 1 248 1

DN150...300 167 149 248 248 1 248 248 248 1 248 248 248 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

2

DEVICE DESCRIPTION

14

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

Max. permissible product and ambient temperatures with signal converter in stainless

steel (bright) or connection box in stainless steel (bright) mounted above the flow

sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 70 60 135 135 1 200 180 1 155 1 225 180 1 155 1

DN40…50 65 60 135 1 135 1 200 160 1 140 1 235 160 1 140 1

DN80…100 60 60 135 1 125 1 200 1 140 1 125 1 200 1 140 1 125 1

DN150...300 65 60 135 1 135 1 200 165 1 145 1 220 165 1 145 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 158 140 275 275 1 392 356 1 311 1 437 356 1 311 1

DN40…50 149 140 275 1 275 1 392 320 1 284 1 455 320 1 284 1

DN80…100 140 140 275 1 257 1 392 284 1 257 1 392 1 284 1 257 1

DN150...300 149 140 275 1 275 1 392 329 1 293 1 428 329 1 293 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

DEVICE DESCRIPTION

2

15

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

Max. permissible product and ambient temperatures with signal converter in stainless

steel (bright) or connection box in stainless steel (bright) mounted at side or

underneath the flow sensor

Temperature class in °C

Temperature class in °F

Temperature class T6 T5 T4 T3 T2

T

amb

in °C40 60 60 65 40 60 65 40 60 65

Nominal size

DN15…25 85 60 135 135 200 200 200 1 240 240 240 1

DN40…50 85 60 135 135 1 200 200 200 1 240 240 1 225 1

DN80…100 85 60 135 135 1 200 200 1 200 1 240 240 1 225 1

DN150...300 85 60 135 135 200 200 200 1 240 240 240 1

1Permanent service temperature of connecting cable and cable entry min. 80°C

Temperature class T6 T5 T4 T3 T2

T

amb

in °F104 140 140 149 104 140 149 104 140 149

Nominal size

DN15…25 185 140 275 275 392 392 392 1 464 464 464 1

DN40…50 185 140 275 275 1 392 392 392 1 464 464 1 437 1

DN80…100 185 140 275 275 1 392 392 1 392 1 464 464 1 437 1

DN150...300 185 140 275 275 392 392 392 1 464 464 464 1

1Permanent service temperature of connecting cable and cable entry min. 176°F

2

DEVICE DESCRIPTION

16

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

2.8 Electrical data

Signal circuits

Signal circuitsSignal circuits

Signal circuits

The vortex flowmeter signal circuits may only be connected to separate, certified, intrinsically

safe isolating amplifiers or zener barriers connected to separate, intrinsically safe circuits with

the following maximum values per circuit:

Flow sensor circuits

Flow sensor circuitsFlow sensor circuits

Flow sensor circuits

For the compact versions, the intrinsically safe flow sensor circuits are designed as internal

circuits.

For the remote versions, the intrinsically safe flow sensor circuits are led through.

The maximum permissible safety values of the flow sensor circuits are listed below:

Remote signal converter, flow sensor circuit (terminal 1 to 7, colour-coded)

Remote signal converter, flow sensor circuit (terminal 1 to 7, colour-coded)Remote signal converter, flow sensor circuit (terminal 1 to 7, colour-coded)

Remote signal converter, flow sensor circuit (terminal 1 to 7, colour-coded)

U

o

=6.65V;I

o

= 1107 mA; P

o

= 650 mW; C

o

=1.5µF; L

o

=73µH

Remote flow sensor (terminal 1 to 7, colour-coded)

Remote flow sensor (terminal 1 to 7, colour-coded)Remote flow sensor (terminal 1 to 7, colour-coded)

Remote flow sensor (terminal 1 to 7, colour-coded)

U

i

=7V;I

i

= 1107 mA; P

i

= 650 mW; C

i

=0;L

i

=0

Device version Circuit

Terminals

Maximum values

U

i

[V] I

i

[mA] P

i

[W] C

i

[nF] L

i

[μH]

VTX3 K i Ex

VTX3 W i Ex

Current output 4...20 mA

C1, C2 30 130 110 ~ 0

Binary output

M1, M2, M3, M4 30 100 110 ~ 0

Current input

I1, I2 30 130 115 ~ 0

VTX3 K FF i Ex

VTX3 W FF i Ex FF / Entity Model I.S.

A1, A2

B1, B2

24 250 1.2 ~ 0 ~ 0

FF / FISCO

A1, A2

B1, B2

17.5 380 5.32 ~ 0 ~ 0

FISCO FIELD DEVICE

VTX3 K PA i Ex

VTX3 W PA i Ex FISCO

A1, A2

B1, B2

24 380 5.32 ~ 0 ~ 0

FISCO FIELD DEVICE

The verification of intrinsic safety for the interconnection between the flow sensor an the signal

converter is not necessary, if the cable length does not exceed 50 m / 164 ft and the supplied

cable is used.

INSTALLATION

3

17

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

3.1 Mounting

Mounting and setup must be carried out according to the applicable installation standards

(e.g. EN 60079-14) by qualified personnel trained in explosion protection.

The information given in the manual and these instructions must always be observed.

Vortex flowmeters must be installed in such a way that

•no external forces are affecting the indication unit.

•the device is accessible for any necessary visual inspections and can be viewed from all sides.

•the nameplate is clearly visible.

•it can be operated from a location with secure footing.

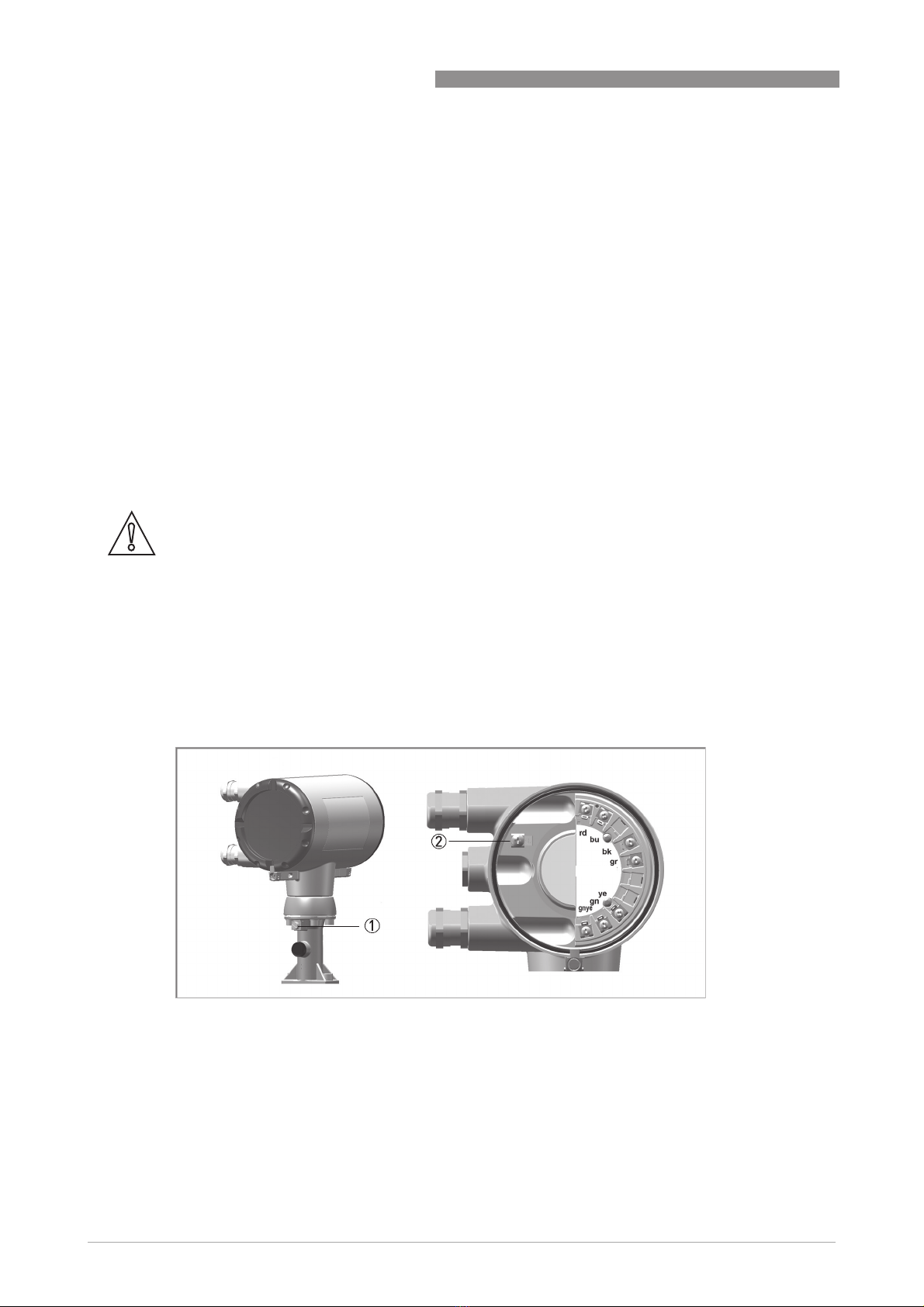

Aligning the signal converter

The signal converter and the connection box for the remote versions may be aligned on the base

or the wall bracket up to a maximum of ±180 . For this reason, the M4 hexagon socket screw

connecting the base and the signal converter or the connection box must be loosened. Once the

signal converter or the connection box has been turned, it must be screwed back on to the base

again (tightening torque 2 Nm).

• De-energise the signal converter.

• Loosen the hexagon socket screw 1.

• Turn the signal converter or the connection box.

• Screw signal converter or connection box back to the base again.

CAUTION!

The manufacturer is not liable for any damage resulting from improper use or use other than the

intended purpose. This applies in particular to hazards due to insufficient corrosion resistance

and suitability of the materials in contact with product.

Figure 3-1: Aligning the signal converter

1 M4 hexagon socket screw on connection housing

3

INSTALLATION

18

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

3.2 Special conditions

Electrostatics

If the installation takes place in hazardous areas of group IIC, the instructions for electrostatics

must be observed. For further information refer to

Electrostatic charge

on page 23.

Thermal and electrical data

Observe the maximum ambient and product temperatures and electrical data. For further

information refer to

Ambient temperature / temperature classes

on page 8 and refer to

Electrical data

on page 16.

ELECTRICAL CONNECTIONS

4

19

VTX3

www.bopp-reuther.de12/2018 - Z-EN-09001-id-A Exi-Gb

4.1 General notes

The separate intrinsically safe signal circuits are electrically connected in the terminal

compartment of the signal converter. The circuits are designed in protection type "intrinsically

safe" and galvanically isolated from ground (test voltage ≥500 V

eff

).

The intrinsically safe flow sensor circuits are connected in the connection boxes on the wall

bracket and on the flow sensor.

The connecting cables should be selected according to the applicable installation standards

(e.g. EN 60079-14) and the maximum operating temperature.

The connecting cable between the flow sensor and the wall bracket for remote versions is part of

the supply.

•The connecting cables must be fixed and laid so they are sufficiently protected against

damage.

•All cores that are not used must be securely connected to the ground potential of the

hazardous area or carefully insulated against each other and against ground (test voltage

≥500 V

eff

).

•Lay cables so as to ensure that there is sufficient distance between surfaces of the flow

sensor and the connecting cable.

•Supplied blind plugs / cable entries guarantee protection against foreign objects and water

(protection category) IP66/67 according to EN 60529.

•Before connecting or loosening the equipotential bonding cable, ensure there are no

differences in potential.

•Any existing cable shields should be connected to ground according to applicable installation

regulations (EN 60079-14). A terminal in the terminal compartment permits a short way

grounding of the cable shields.

•The outer diameter of the connecting cable must be within the sealing range of the cable

entry (6...12 mm / 0.24...0.47").

•Unused cable entries are to be closed.

Ensure that the gaskets and incised gasket ring are tight.

4.2 Power supply

Vortex flowmeters do not require a separate power supply.

The required supply for the built-in electronics is provided via the 4...20 mA current output or the

bus connection.

4

ELECTRICAL CONNECTIONS

20

VTX3

www.bopp-reuther.de 12/2018 - Z-EN-09001-id-A Exi-Gb

4.3 Inputs / Outputs

The terminal assignment is described in the manual. The signal circuits of the vortex flowmeters

may only be connected to certified intrinsically safe slave units or circuits.

For more information refer to chapter "Electrical data".

The current output, the current input and the binary output are designed for connection to a

certified, intrinsically safe circuit in protection type "intrinsic safety Ex ia IIC or Ex ib IIC".

The bus connections are designed for connection to a certified, intrinsically safe circuit in

protection type "intrinsic safety Ex ia IIC or Ex ib IIC" according to the FISCO model or according

to the entity concept.

The current output, the current input and the binary output are reliably separated up to a peak

voltage of 60 V. All signal circuits are electrically isolated from the ground.

4.4 Grounding and equipotential bonding

For compact versions and measuring devices with flange connections, the flow sensor is

conductively connected to the pipeline.

For compact versions and measuring device of the type "sandwich", a separate conductor

connected either to the internal or external PA terminal must be provided to connect to the

equipotential bonding.

CAUTION!

Equipotential bonding

Equipotential bondingEquipotential bonding

Equipotential bonding

Vortex signal converters and flow sensors must be included in the on-site equipotential bonding

system according to EN 60079-14! They are connected to the PA terminals.

Figure 4-1: Ground connection of the compact version

1 Electrical grounding connection on connection piece between the flow sensor and the signal converter

2 Electrical grounding terminal in the housing

This manual suits for next models

5

Table of contents

Other Bopp & Reuther Measuring Instrument manuals