Borg & Overstrom T1 User manual

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children shall not

play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

The unit should be isolated from the electricity supply before removal of any covers. Great care must be

employed when working with high pressure carbon dioxide, and in no cases should the maximum

operating pressure of 0.4MPa (4 bar) be exceeded.

The appliance is not suitable for installation in an area where a water jet could be used.

The appliance has to be placed in a horizontal position

WARNING: Keep ventilation openings in the appliance enclosure or in the built-in structure clear of

obstruction.

WARNING: When positioning the appliance, ensure the supply cord is not trapped or damaged.

WARNING: Do not locate multiple portable socket-outlets or portable power supplies at the rear of the

appliance.

This appliance is intended to be used in household and similar applications such as:-

Staff kitchen areas in shops, offices and other working environments

Farm houses and by clients in hotels, motels and other residential type environments

Bed and breakfast type environments

Catering and similar non-retail applications

A-weighted emission sound pressure level is below 70 dB(A)

Release date 04.02.2022

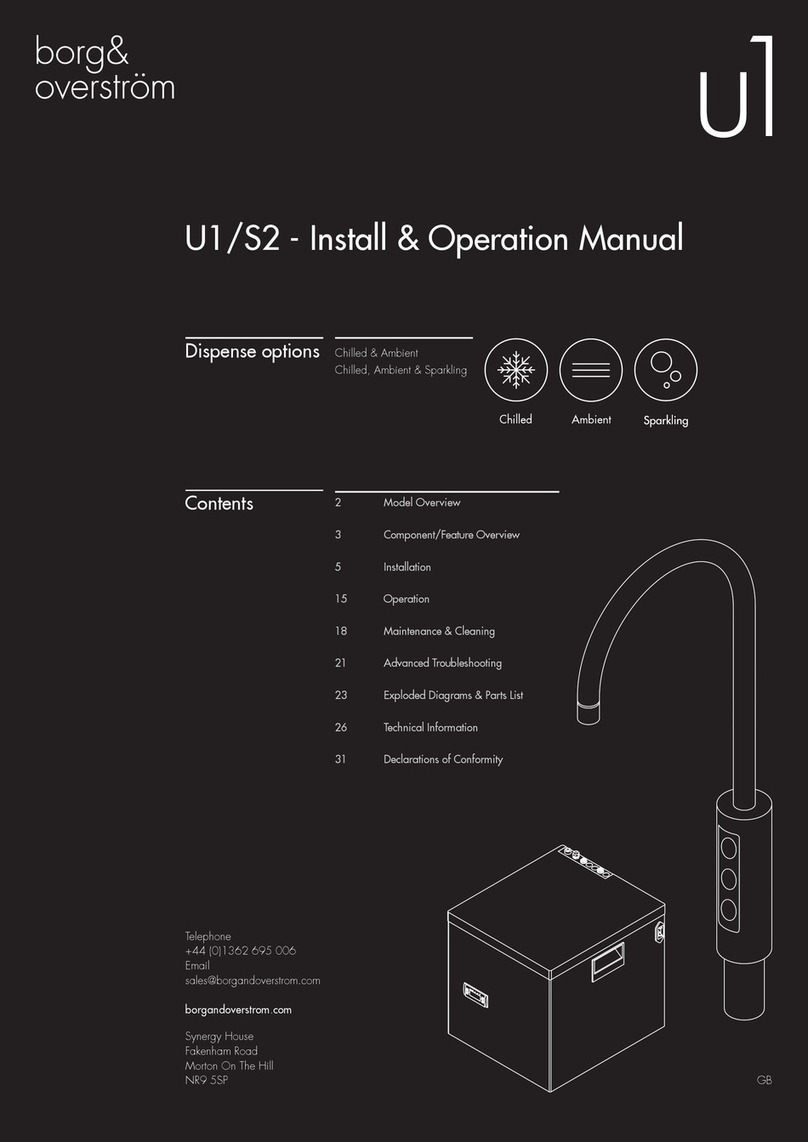

T1 Install & Operation

Manual

Safety

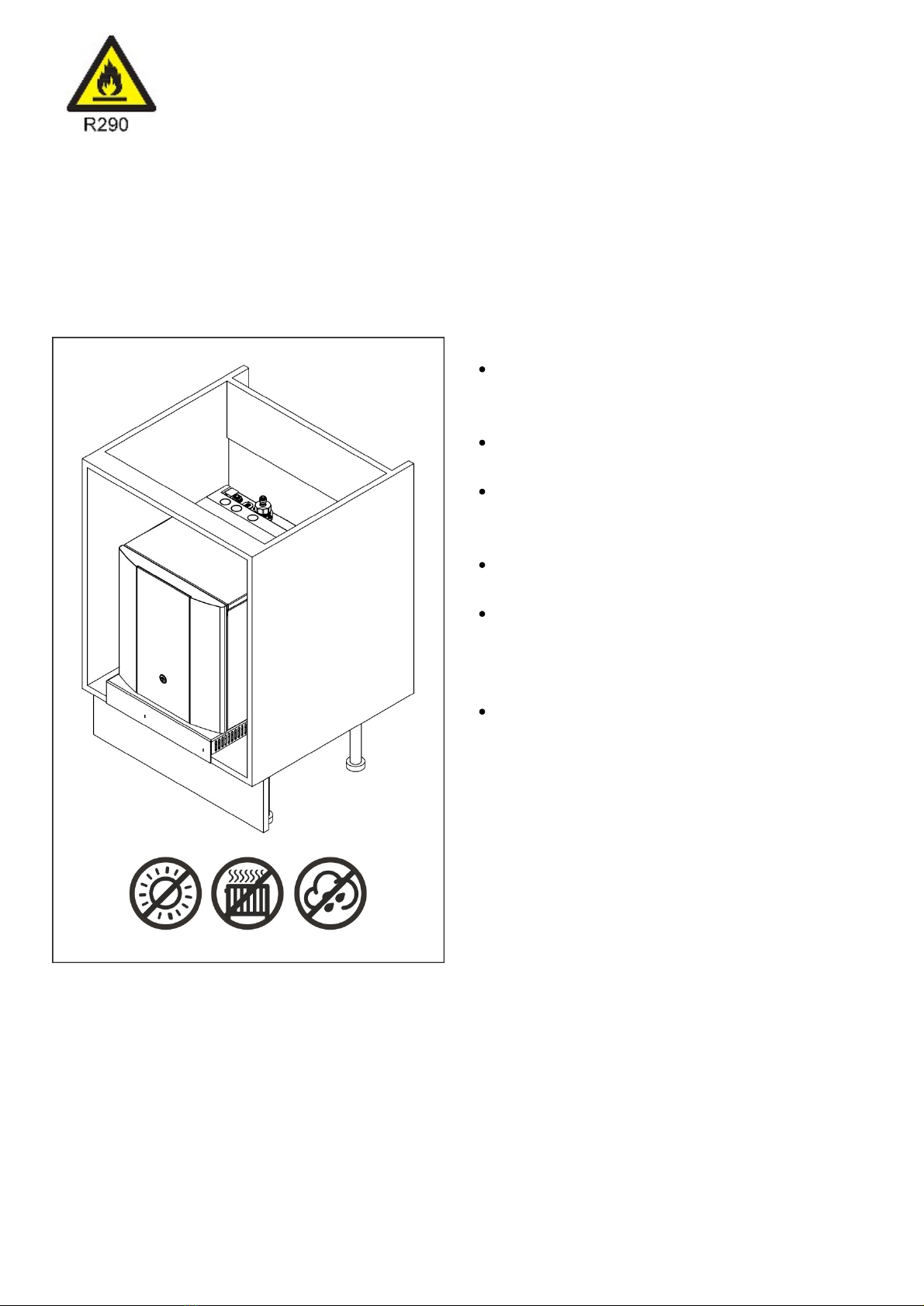

R290 is a refrigerant-grade propane used on a wide range of commercial

refrigeration and air conditioning units. A highly pure propane, it has a low

environmental impact and nominal global warming potential (GWP), meaning it

possesses no qualities that can destroy the ozone layer. R290 also is the preferred

hydrocarbon alternative of the Environmental Protection Agency (EPA), substituting

more harmful fluorocarbon refrigerants like R22, R134a, R404a and R502.

Units with R290 can only be maintained and repaired by authorized technicians who

are

properly trained and certified.

Always place the dispenser in its vertical

position, on a surface which can capably

support its weight.

During use this machine must remain in its

upright position.

Adequate ventilation must be allowed for –

we recommend using the supplied ventilation

ducting kit.

Keep the machine away from sunlight, heat

and moisture.

Power and water supply points must be

available near the dispenser, and must meet

the criteria specified in the ‘Specification’

section of this manual.

The environment where this machine is

installed must be free of dust and

corrosive/explosive gases.

Waste Electrical Products:

The WEEE symbol indicates that this item contains electronic

components which must be collected and disposed of separately.

Never dispose of electrical waste in general municipal waste. Collect

and dispose of such waste separately.

Make use of the return and collection systems available to you, or

your local recycling programme. Contact your local authority or place

of purchase to find out what schemes are available.

Electrical and electronic equipment contains hazardous substances

which, when disposed of incorrectly, may leak into the ground. This

can contribute to soil and water pollution which is hazardous to

human health; and endangers wildlife.

It is essential that consumers look to re-use or recycle electrical or

electronic waste

to avoid it going to landfill sites or incineration without treatment.

COOLING SYSTEM Stainless steel direct chill coil encased in a solid-block system for

instant response cool down action. Ultra efficiency compression

system with capillary control.

Environmentally friendly R290 refrigerant.

COLD TEMPERATURE 2°C - 11°C.

OUTPUT PER HOUR (ProCore) 50 litres Chilled

50 litres Sparkling

DISPENSE Quadra Neck Faucet with ergonomically designed and situated

light touch sensitive controls.

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED, &

SPARKLING

ProCore 0.20kW - 230V

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED &

AMBIENT

ProCore 0.14kW - 230V

QUANTITY OF

REFRIGERATION GAS

R290a 33g

POWER SUPPLY 220V - 240V AC (50 Hz)

WATER CONNECTION Mains in - 3/4” BSP

C02 CONNECTION 1/4” Push Fit.

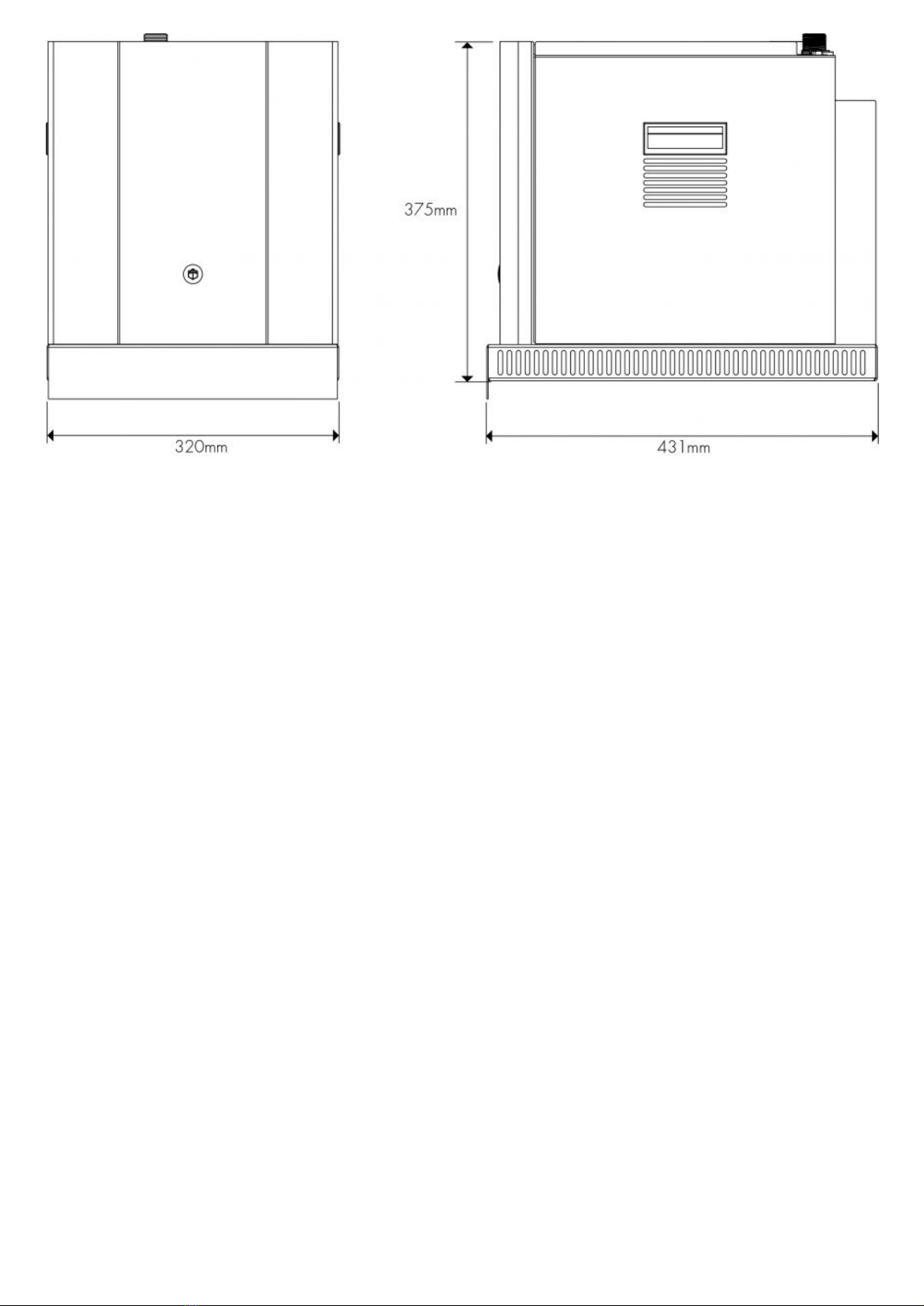

DIMENSIONS (w x d x h) 320 x 370 x 340mm.

WEIGHT 24Kg

RATED CURRENT - CHILLED &

AMBIENT

ProCore 1A

RATED CURRENT - CHILLED,

AMBIENT & SPARKLING

ProCore 1.2A

FUSE RATING 5A

MINIMUM TO MAXIMUM

INLET WATER

PRESSURE

0.05MPa (0.5 bar) - 1.0 MPa (10 bar)

Internally regulated to 0.3 MPa (3 bar)

CO2 PRESSURE 0.4MPa (4 Bar) Maximum

MINIMUM TO MAXIMUM

AMBIENT ROOM OPERATING

TEMPERATURE

5°C - 35°C

CLIMATIC CLASS N

Introduction

The T1 epitomises cutting-edge design and innovation with its contoured tap and compact ProCore unit. This

is

our most discreet range and will fit into any environment seamlessly.

The ProCore dispenser is a cooler designed to provide chilled and carbonated water. All the materials and

components

are tested during the entire production process in order to satisfy all expectations.

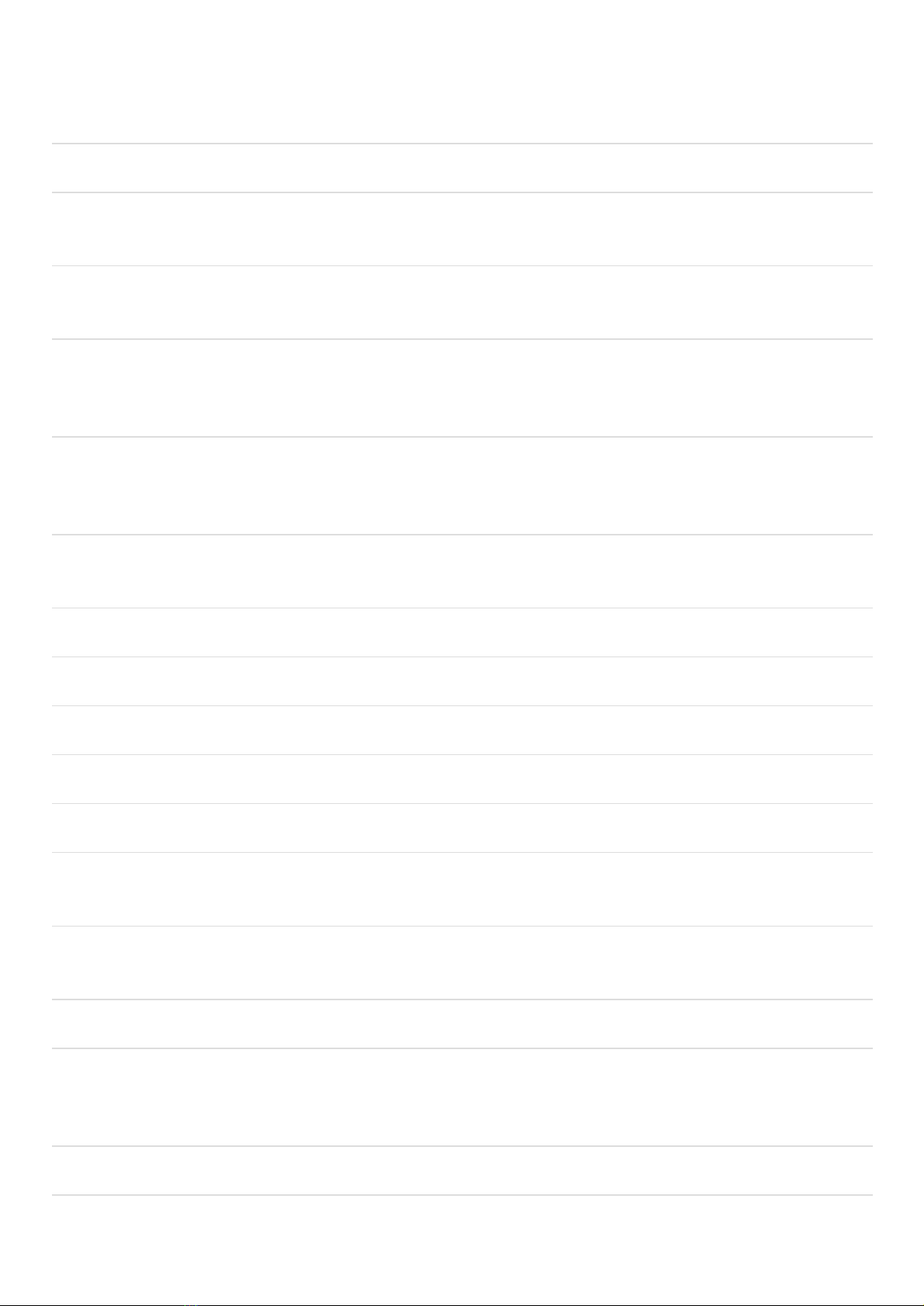

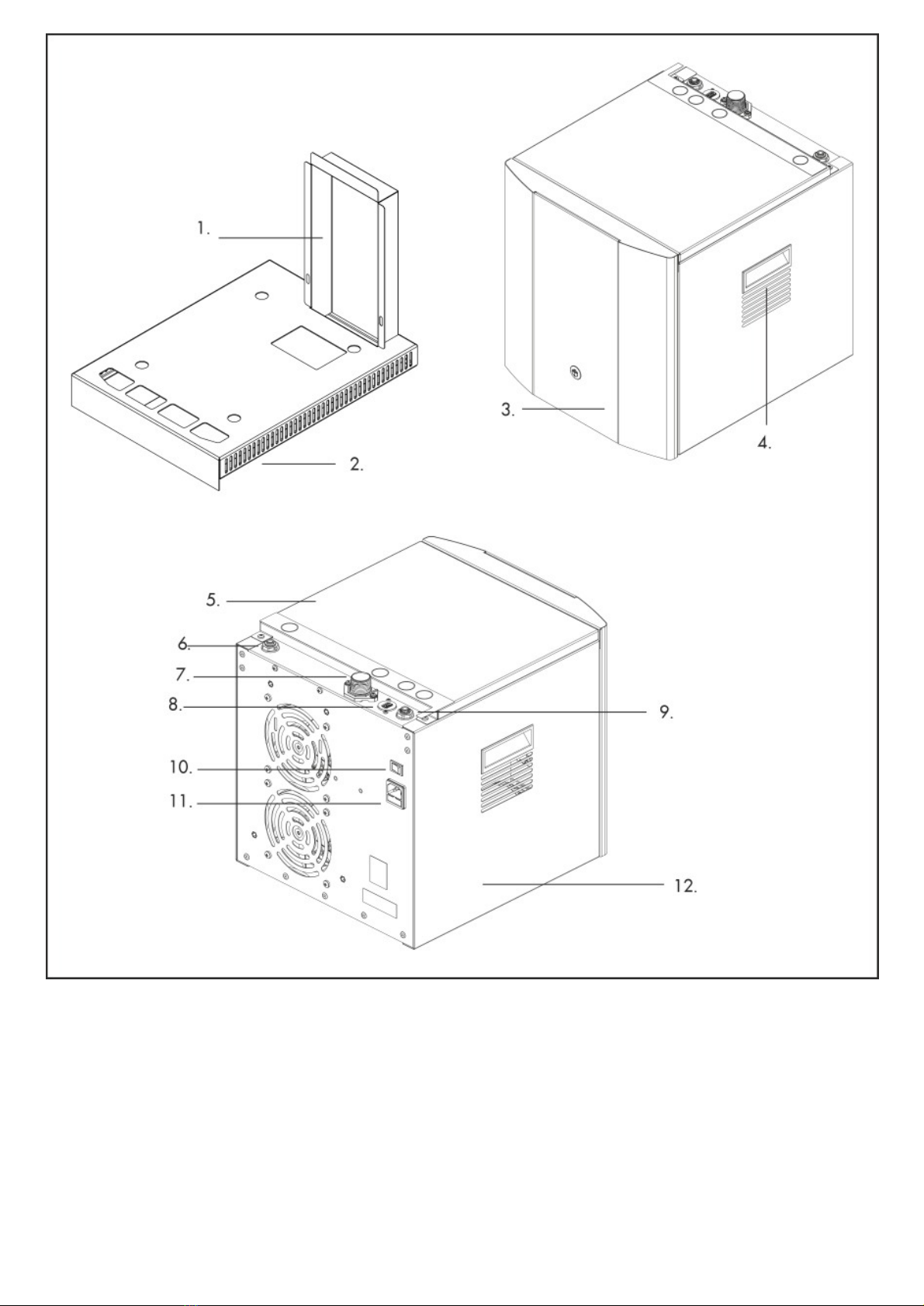

Model Overview

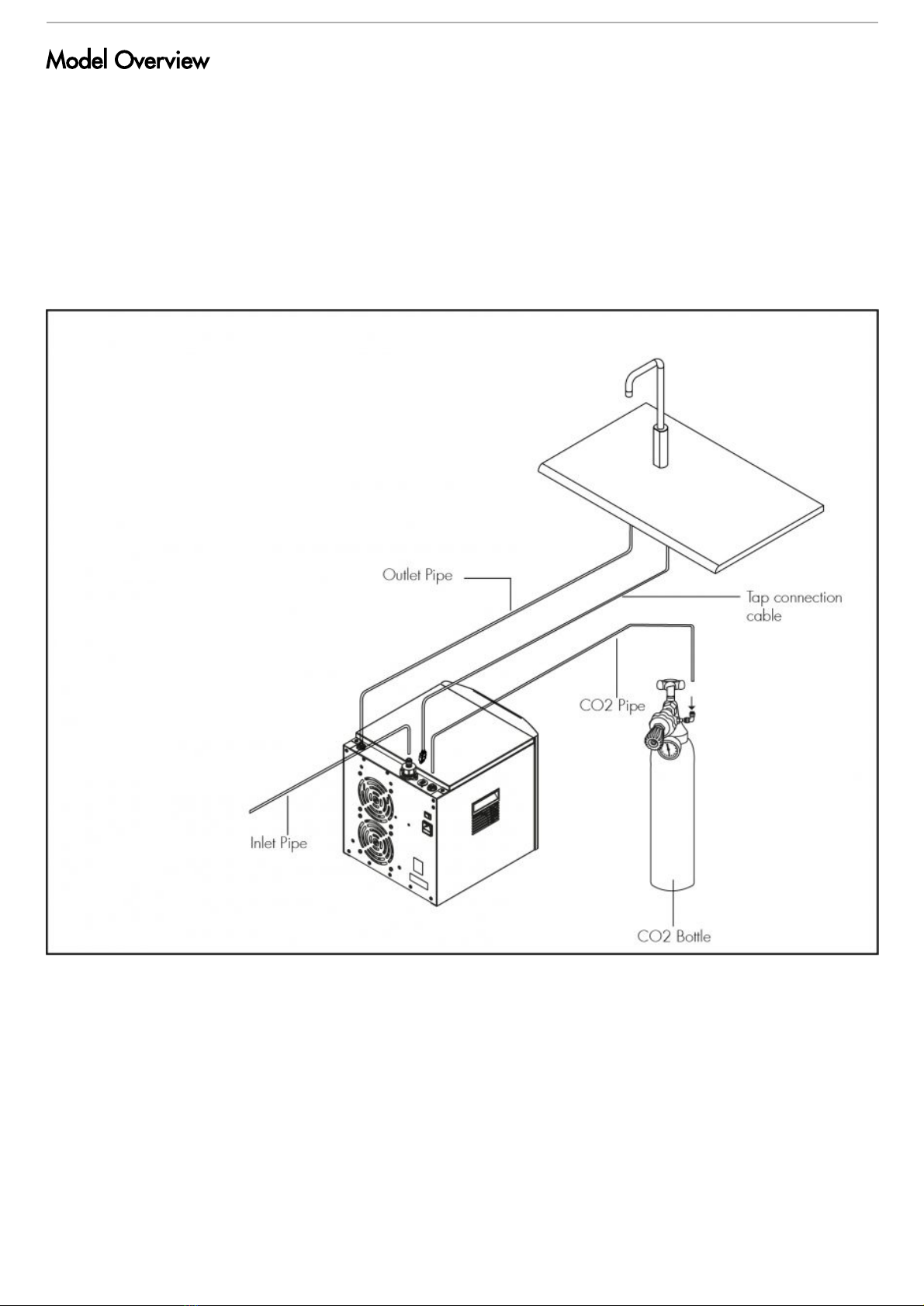

1. Faucet, 2. Capacitive touch display, 3. Fixing Threads and Bracket, 4. Water Outlet Pipe, 5. Connector

Cable

ProCore Electronic - Major Components

Contents:

1 no Undercounter Unit

1 no 2.0m Power Cord Set

1 no Co2 Regulator with Gauge & Connection

tube*

1 no ProCore Simple-fit Ventilation Kit

1. ProCore Simple-fit Chimney, 2. ProCore Simple-fit Base, 3. Front Panel, 4. Carry Handle, 5. Top Panel,

6. Water Outlet, 7. Water Inlet, 8. Tap Connection, 9. CO2 Inlet*, 10. On/Off Switch, 11. Power

Connection, 12. Side Panel

Please Note:

Mains Installation Kit & Filters are supplied as extra items

according to individual ordering requirement.

*Sparkling versions only

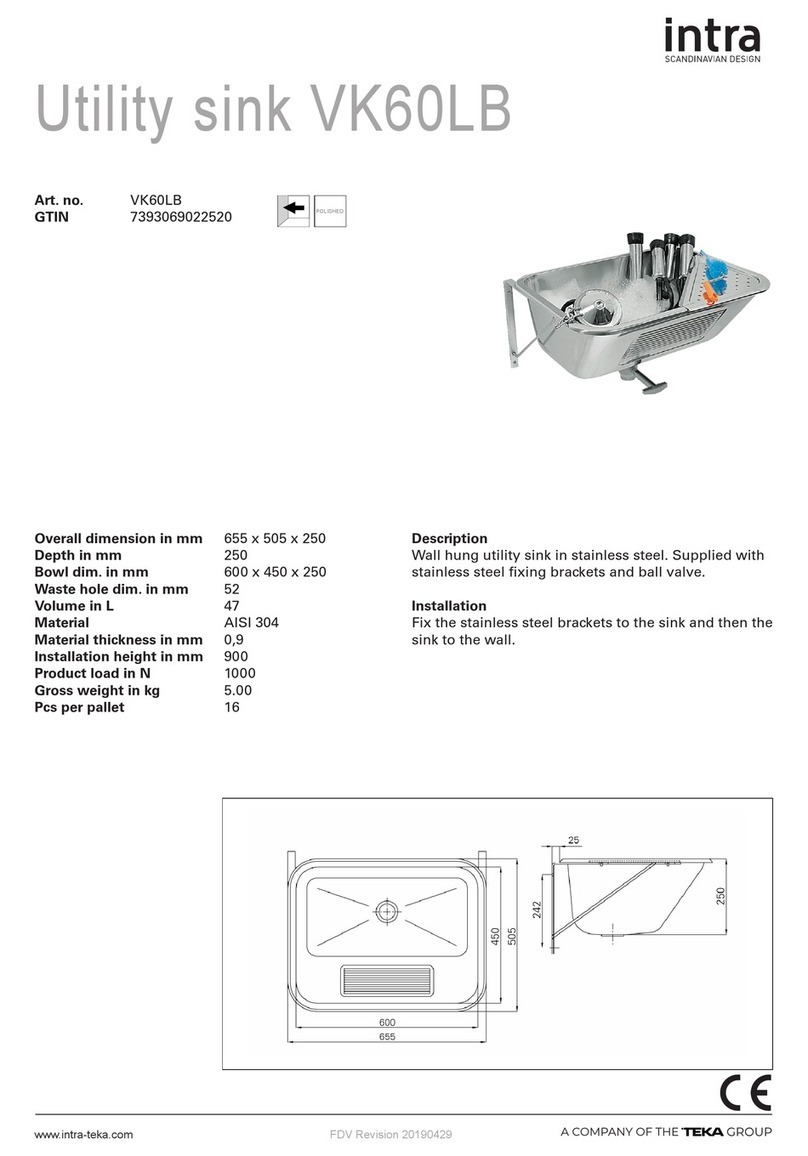

Dimensions

Identify a suitable location for the ProCore unit. It should be positioned within 1.0m of the faucet, and within

2.0m of suitable services connections. Allow enough space to fit the ventilation ducting system.

The ProCore unit must be installed in accordance with the relevant requirements of:

The appropriate building regulations by application of either The Building Regulations (England and Wales),

The Building Regulations (Scotland) or The Building Regulations (Northern Ireland). In territories other than

those listed the local regulations in force must be complied with.

The Water Supply (Water Fittings) Regulations (England, Wales and Northern Ireland) or The Water

Byelaws in Scotland.

The unit must not be installed where it is liable to freeze. If the unit is thought to be frozen it must not be

switched on. It should be allowed to thaw and must then be thoroughly inspected to ensure it is

undamaged.

Service Requirements

Water: Mains potable water – internally regulated to 0.3MPa (3 bar)

CO2: Food Grade CO2 to be supplied

Min mains pressure 0.05MPa (0.5 bar)

Electricity: 13A supply – Earth Leakage Protected

Waste Drain Connection

Using the M5 allthreads

as provided locate them

into the base of the tap

and tighten till secure. Fit

the gasket on the base

of the tap.

When planning and

providing for the

connection to the

services, always allow

for easily accessible

service isolator fittings

and for the position of

an external water filter.

Identify a suitable

position for the faucet.

Refer to the cut out

guide template.

Ensure worktop is level

to allow system to drain.

Allow for the space

needed for forming the

required cut out. Relate

the selected position to

the underneath of the

counter and check for

any obstructions.

Also allow for the height

of the swan neck under

any overhanging

cupboard/shelf.

Carefully form the

needed hole, using the

correct type of cutter for

the work surface

material.

Observe all local

occupational health and

safety requirements.

Allow sufficient space

for fitting the worktop

fixing bracket.

Tighten the 2 fixing

flange nuts so that the

worktop bracket is fixed

up against the underside

of the worktop.

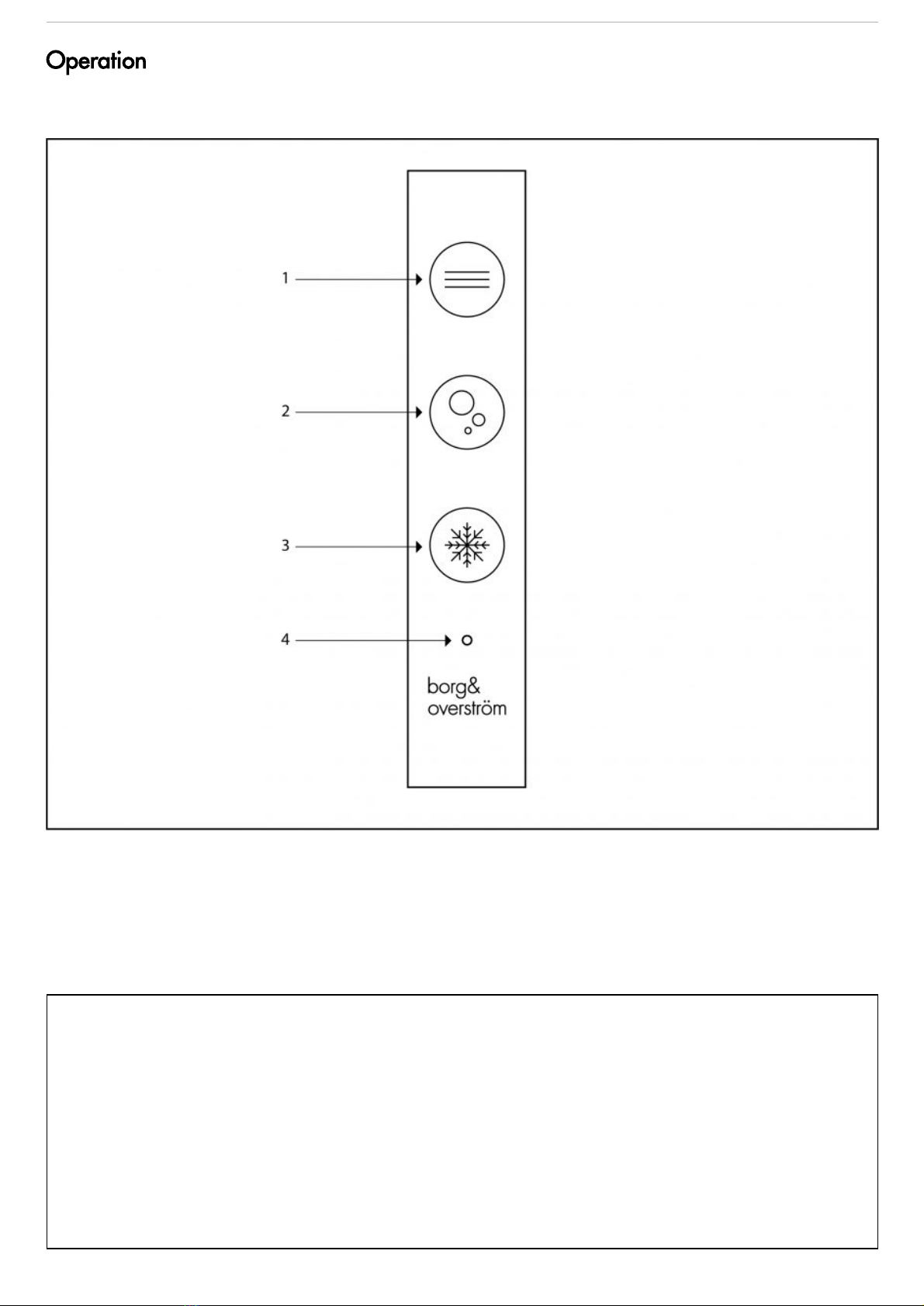

Tap Control Panel

1. Ambient Dispense, 2. Sparkling Dispense, 3. Chilled Dispense,

4. Warning Symbol

Basic Functions

Dispensing from unit:

Press and hold dispense icon and release to finish dispense

Warning Symbol

‘Warning’ symbol will illuminate and flash upon a fault.

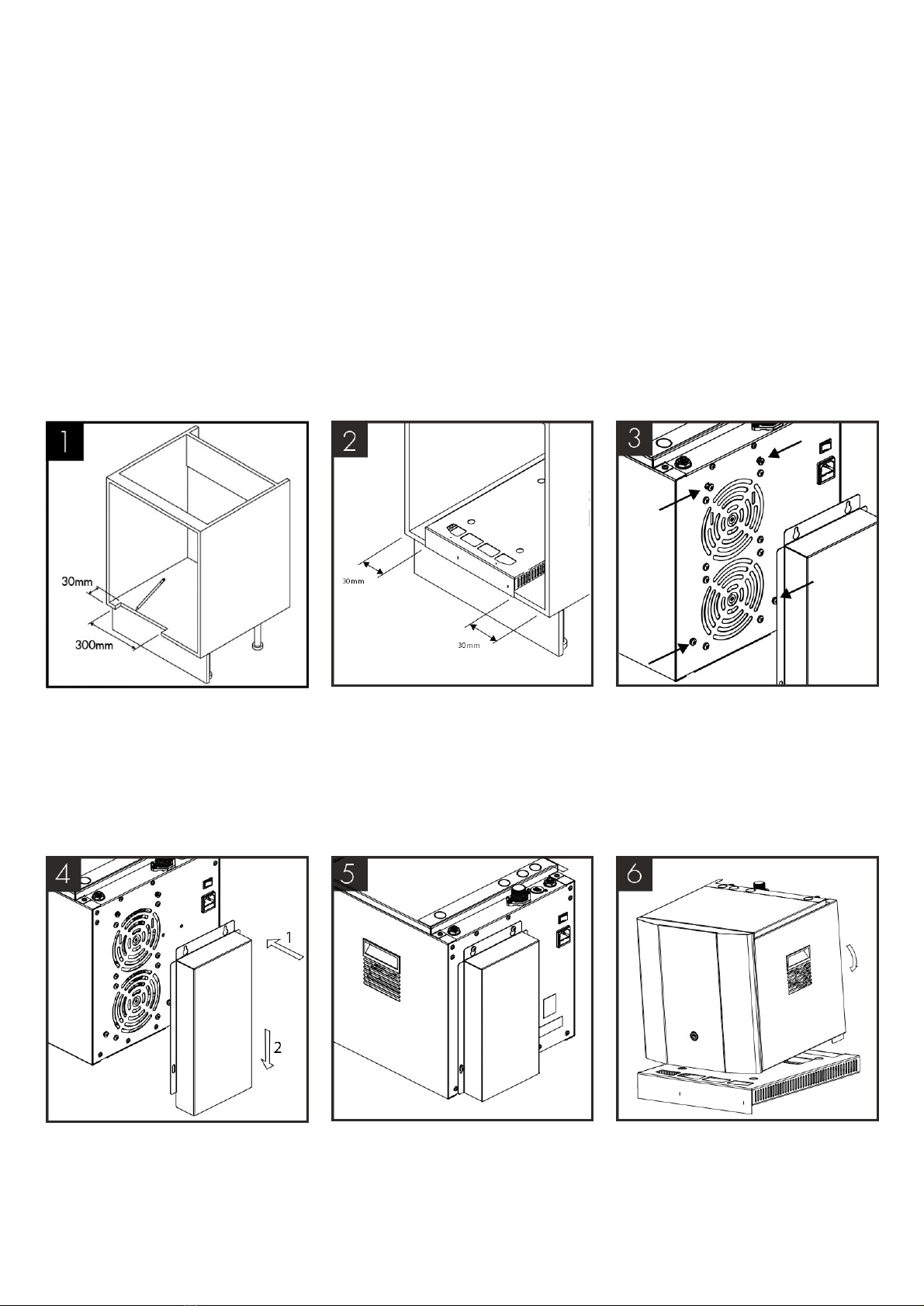

Ventilation System Installation

Operation

When Borg & Overström undercounter units are

installed inside a cabinet or housing, adequate

ventilation is recommended to ensure that they

operate satisfactorily. During a cooling cycle it is

normal for the unit to produce heat, and the

purpose of ventilation is to provide a supply of air

that can absorb the generated heat which would

otherwise accumulate inside the cabinet or

housing, and reduce the cooling performance of

the unit. The amount

of heat generated by the cooling cycle depends

directly upon the amount of usage – the higher the

usage, the more heat produced. To provide

adequate ventilation we recommend that air

grilles/vents are fitted as supplied (or vent

apertures formed) in the cabinet to allow an

airflow as shown below. Normally this should be

enough for all situations.

Important: Before making any cuts into the cupboard or kick board, ensure the area to be cut is free from

water pipes or electrical cables. There is a risk of serious injury or death if electrical cables are cut, and

significant damage to property if a water pipe is cut.

Using the template provided,

carefully mark and cut the

aperture to the edge of the

cabinet.

Situate the ProCore Simple-fit

ventilation base in place centrally

over the aperture. Ensuring that

there is a minimum of 30mm air

gap to each side.

Insert 4 screws into the holes

located. Do not overtighten at this

stage.

Place the rear vent chimney over

the 4 screws and slide

downwards into place.

Tighten all 4 fixing screws. Lift and tilt the unit into position

ready to lower.

Other manuals for T1

1

This manual suits for next models

1

Table of contents

Other Borg & Overstrom Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Spectrum Brands

Spectrum Brands Pfister Park Avenue LG40-FE0 Quick installation guide

American Standard

American Standard Heritage Bidet 5034 installation instructions

SUMERAIN

SUMERAIN S1364CW installation guide

THE SHOWER LAB

THE SHOWER LAB VIEW 07 manual

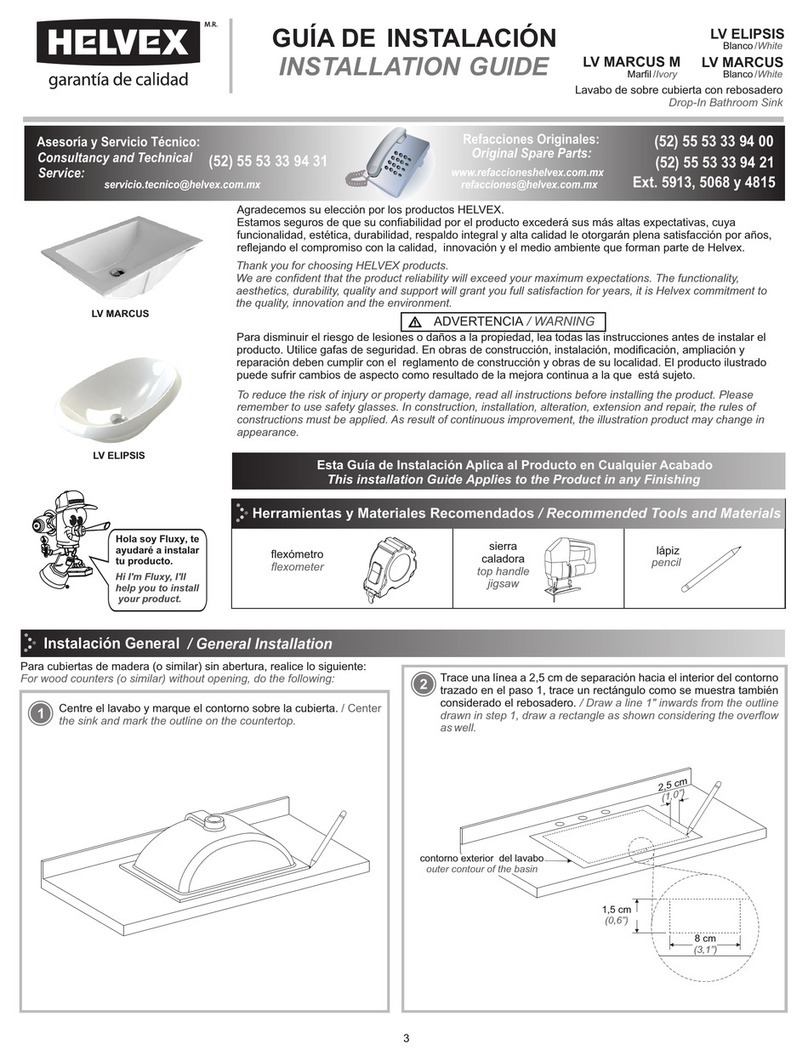

Helvex

Helvex LV ELIPSIS installation guide

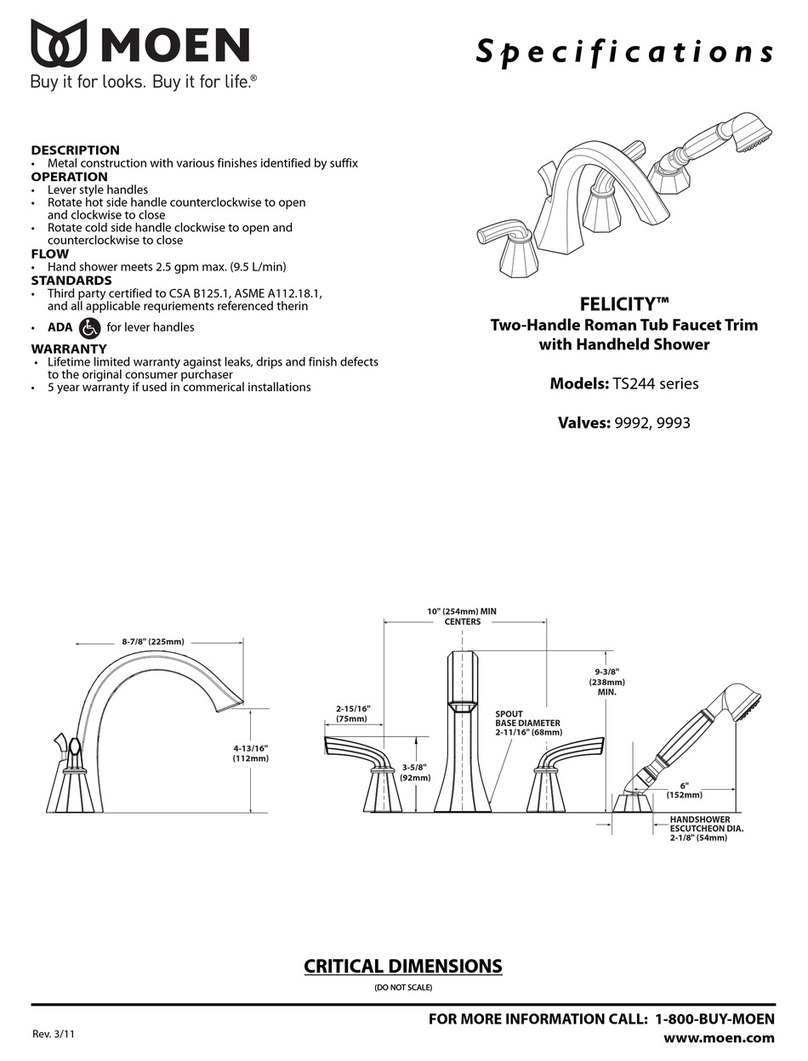

Moen

Moen FELICITY TS244 series Specifications