System Description

3

System Overview with Functional Variants

The SE 220 LSNi SmartKey arming device is a system solution for arming intrusion systems. The

individual components of the system can be put together as required for the intended usage. Op-

eration types with or without the SPE blocking element are possible. Control authorizations for

arming/disarming are defined during control panel programming. The system is programmed us-

ing an appropriate programming program. All the information and explanations you need to pro-

gram the system can be found in the online help, i.e. directly on the screen.

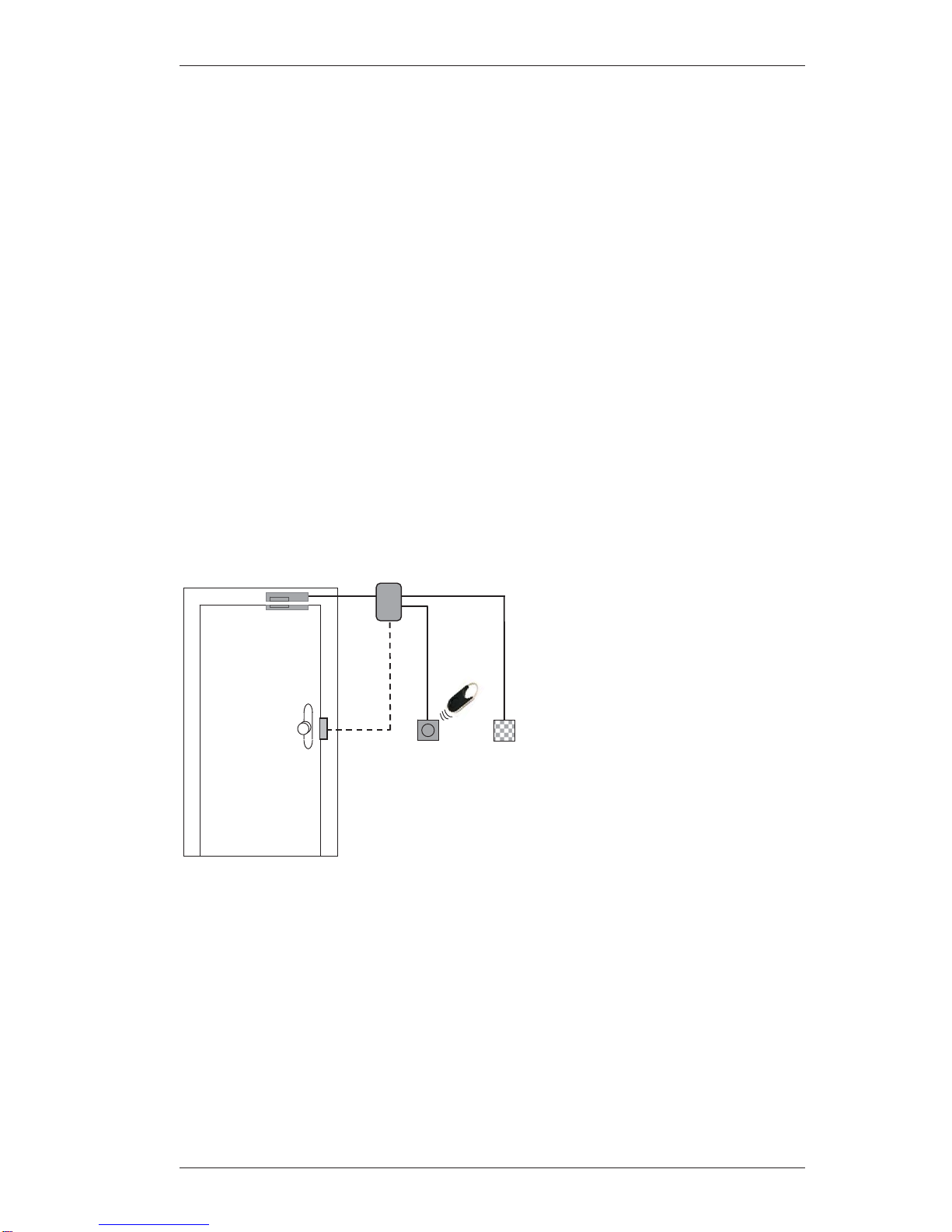

SPE blocking element

The SPE blocking element is an additional

lock for the door and is meant to prevent

unauthorized entry to the armed area. The

SPE blocking element is always installed in

conjunction with a kit in the secure area to

enable it to accommodate different doors.

The image shows a door-mounted installa-

tion; for other variants, please see installing

the SPE blocking element. A conventional

magnetic contact can be used with the

door-mounted installation kit. Operation ty-

pes with and without blocking elements are

possible.

SE 220 LSNi control unit

The control unit processes the status reports of

all components in the system, communicates

these reports to the intrusion alarm system and

controls the SPE blocking element. The control

unit is installed in the secure area.

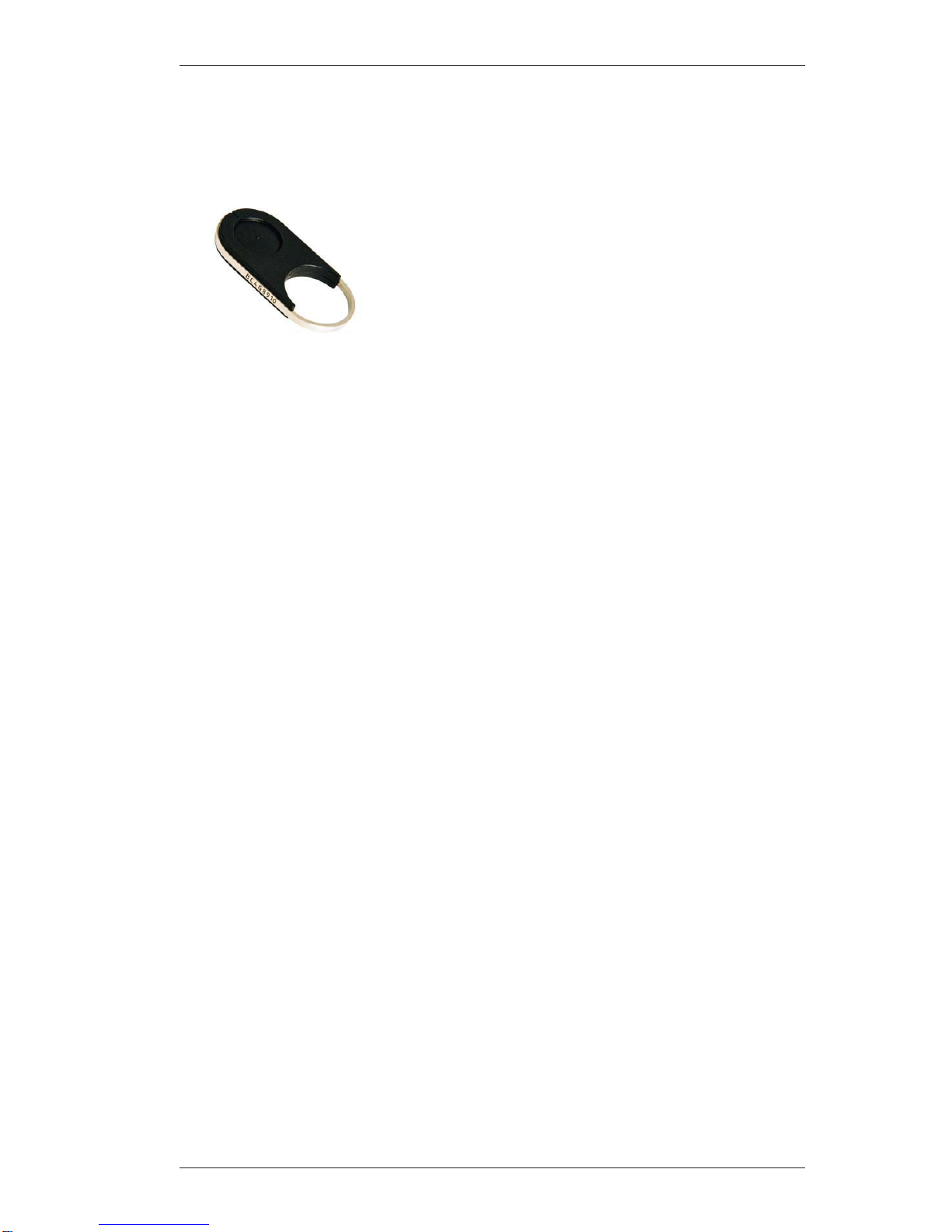

Reader

The system is armed and disarmed

by holding an electronic key up to

the reader. The LED and buzzer

provide information about the status

of the system as well as operation.

The reader can be surface mounted

or recessed mounted (outside the

secure area).

Code keypad

There are two types of code keypads

xSmartKey code keypad

xLockable code keypad

The code keypad, used in conjunc-

tion with the reader, allows arming

and disarming of the intrusion alarm

system only after the correct combi-

nation of numbers has been entered

on the code keypad.

If someone is forced to disarm the in-

trusion alarm system under duress,

a silent alarm (hold-up alarm)

can be set off remotely via the code

keypad.

The code keypad can be surface

mounted or recessed mounted (out-

side the secure area).

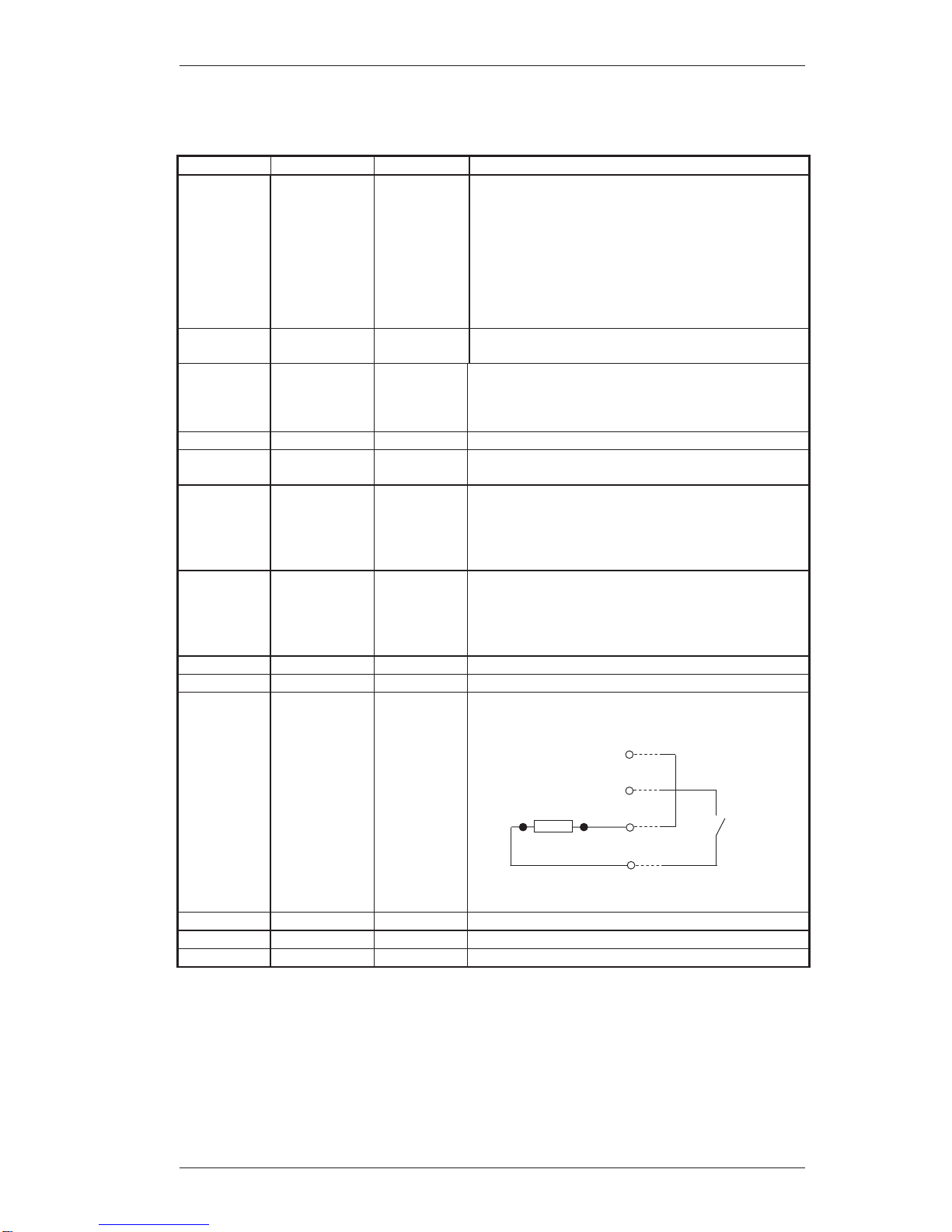

Bolt contact