BOSSCO GT-1 Operating and maintenance manual

SERVICE NOTES

Issued by RJA

Copyright © 2016 Roland Corporation

All rights reserved. No part of this publication may be reproduced in any form without the written permission

of Roland Corporation.

CC-KWS17057067E0

Sep. 2016 GT-1

Table of Contents

Cautionary Notes ..............................................................2

Specifications .....................................................................3

Location of Controls (Top)...............................................4

Location of Controls Parts List (Top) .............................4

Location of Controls (Rear)..............................................5

Location of Controls Parts List (Rear)............................5

Exploded View ..................................................................6

Exploded View Parts List.................................................7

Exploded View (Fig. A)....................................................8

Exploded View Parts List (Fig. A) ..................................9

Plain View ........................................................................10

Disassembly Procedure..................................................11

Block Diagram/Wiring Diagram..................................12

Parts List ...........................................................................13

Virus Check......................................................................15

Verifying the Version......................................................15

Data Backup and Restore Operations ..........................15

Performing a Factory Reset............................................15

System Update Procedure..............................................16

Test Mode .........................................................................16

Circuit Board (Main, Exp Pedal Board) .......................22

Circuit Diagram (Main Board: 1/3)..............................24

Circuit Diagram (Main Board: 2/3)..............................26

Circuit Diagram (Main, Exp Pedal Board: 3/3) ..........28

Revise Information

Dec. 7, 2016 p. 20 Corrected an error.

Nov. 17, 2016 p. 20 Added a test item.

Mar. 24, 2017 p. 20 Added a caution.

2

Sep. 2016 GT-1

Cautionary Notes

Before beginning the procedure, please read

through this document. The matters described may

differ according to the model.

Back Up User Data!

User data may be lost during the course of the procedure. Refer to Data

Backup and Restore Operations (p. 15) in the Service Notes and save the

data. After completing the procedure, restore the backed-up data to the

product.

Part Replacement

When replacing components near the power-supply circuit or a heat-

generating circuit (such as a circuit provided with a heat sink or including a

cement resistor), carry out the procedure according to the instructions with

respect to the part number, direction, and attachment position (mounting so as

to leave an air gap between the component and the circuit board, etc.).

Parts List

A component whose part code is ******** will not be supplied as a service part

because one of the following reasons applies.

• Because it is supplied as an assembled part (under a different part code).

• Because a number of circuit boards are grouped together and supplied as

a single circuit board (under a different part code).

• Because supply is prohibited due to copyright restrictions.

• Because reissuance is restricted.

• Because the part is made to order (at current market price).

• Because it is carried in electronic data on the Roland web site.

• Because it is a package or an accessory irrelevant to the function

maintenance of the main body.

• Because it can be replaced with an article on the market. (battery or etc.)

Circuit Diagram

In the circuit diagram, “NIU” is an abbreviation for “Not in Use,” and

“UnPop” is an abbreviation for “Unpopulated.” They both mean non-mounted

components. The circuit board and circuit board diagram show silk-screened

indications, but no components are mounted.

Roland Japan Warranty

Please send the problem report with followings when the defect occurred

within one year from production and within one month from the first

customer’s purchase.

• Model name:

• Serial number:

•Version:

• Purchase date by the first customer: yyyy/mm/dd

•Symptom:

• Frequency: always, sometimes or seldom

• Confirmed the symptom at your service dept: Yes/No

3

Sep. 2016 GT-1

Specifications

BOSS GT-1: Guitar Effects Processor

Sampling Frequency

44.1 kHz

AD Conversion

24 bits + AF method

* AF method (Adaptive Focus method) is a proprietary method from Roland &

BOSS that vastly improves the signal-to-noise (SN) ratio of the AD and DA

converters.

DA Conversion

24 bits

Effects

108 types

Patches

99 (User) + 99 (Preset)

Phrase Loop

32 sec.

Nominal Input Level

INPUT: -10 dBu, AUX IN: -20 dBu

Maximum Input Level

INPUT: -7 dBu, AUX IN: 0 dBu

Input Impedance

INPUT: 1 MΩ, AUX IN: 27 kΩ

Nominal Output Level

OUTPUT (L/MONO, R): -10 dBu, PHONES: -10 dBu

Output Impedance

OUTPUT (L/MONO, R): 1 kΩ, PHONES: 44 Ω

Recommended Load Impedance

OUTPUT (L/MONO, R): 10 kΩ or greater, PHONES: 44 Ω or greater

Controls

DOWN switch, UP switch CTL1 switch

EASY SELECT button, EASY EDIT button, FX1/COMP button, OD/DS

button, PREAMP button, FX2/MOD button, DELAY button, REVERB button,

MEMORY EDIT button, EXIT button, ENTER button, MENU button

1 knob, 2 knob, 3 knob

Expression pedal

Display

Graphic LCD (132 x 32 dots, backlit LCD)

Connectors

INPUT jack, OUTPUT (L/MONO, R) jacks: 1/4-inch phone type

CTL2, 3/EXP2 jack: 1/4-inch TRS phone type

AUX IN jack: Stereo miniature phone type

USB COMPUTER port: USB type B

DC IN jack

Power Supply

Alkaline battery (AA, LR6) x 4, AC adaptor (sold separately)

Current Draw

200 mA

Expected battery life under continuous use

Alkaline: Approx. 7 hours

* These figures will vary depending on the actual conditions of use.

Dimensions

305 (W) x 152 (D) x 56 (H) mm

12-1/16 (W) x 6 (D) x 2-1/4 (H) inches

Maximum height:

305 (W) x 152 (D) x 74 (H) mm

12-1/16 (W) x 6 (D) x 2-15/16 (H) inches

Weight (including battery)

1.3 kg

2 lbs 14 oz

Accessories

Owner’s manual (#5100051784)

Leaflet “USING THE UNIT SAFELY”(#********)

Alkaline battery (AA, LR6) (#********) x 4

Options (sold separately)

AC adaptor: PSA series

Footswitch: FS-5U, FS-5L, FS-6, FS-7

Expression Pedal: FV-500L, FV-500H, Roland EV-5

* 0 dBu = 0.775 Vrms

* Printed matters will not be supplied after the end of the production. Then,

download the electronic file from the Roland web site.

* In the interest of product improvement, the specifications and/or appearance of

this unit are subject to change without prior notice.

4

Sep. 2016 GT-1

Location of Controls (Top)

fig.panel-top.eps

Location of Controls Parts List (Top)

321

4

5

No. Part Code Part Name Description Q’ty

1 5100051758 KEY UNIT 1

5100051446 SWITCH EVPAWCD2A 12

2 5100051759 DISPLAY COVER 1

5100053348 LCD QFG13232-30-PTDSOS-R 1

5100051760 DISPLAY CUSHION 1

3 5100051761 R-KNOB 3

******** NUT attached to VR 3

5100053342 ROTARY POTENTIOMETER R1132G6JV1O203FC50F9 3

4 5100051751 SWITCH PEDAL 3

5100051753 SWITCH PEDAL SW SPRING 3

5100051766 SWITCH PEDAL TACT SPRING 3

5100051752 SWITCH PEDAL ESCUTCHEON 3

01780101 TACT SWITCH SKQKABD010 3

5 01016167 11M/M ROTARY POTENTIOMETER RK11K1140AFG 10KX1 1

5

Sep. 2016 GT-1

Location of Controls (Rear)

fig.panel-rear.eps

Location of Controls Parts List (Rear)

1 2 3 5 64

No. Part Code Part Name Description Q’ty

1 02897334 6.5MM JACK HTJ-064-10D 1

2 5100028016 3.5MM JACK HTJ-035-10ABPP1 2

3 02341712 6.5MM JACK HTJ-064-10I(F3449106R0) 2

4 02341645 6.5MM JACK HTJ-064-04A 1

5 5100047083 USB CONNECTOR U7F04D-B1NB 1

6 13449720 DC JACK HEC2305-016250 1

6

Sep. 2016 GT-1

Exploded View

fig.bunkaizu-total.eps

View 2

View 1

1

a

3

4

14

11

6

7

8

9

10

5

13

b

c

a

15

12

16

18

19

17

17

20

22

21

22

Refer to Fig. A

7

Sep. 2016 GT-1

Exploded View Parts List

No. Part Code Part Name Description Q’ty

1 5100051761 R-KNOB 3

3 5100051759 DISPLAY COVER 1

4 5100051748 TOP COVER 1

5 5100051760 DISPLAY CUSHION 1

6 5100051758 KEY UNIT 1

7 5100051751 SWITCH PEDAL 3

8 5100051753 SWITCH PEDAL SW SPRING 3

9 5100051766 SWITCH PEDAL TACT SPRING 3

10 5100051752 SWITCH PEDAL ESCUTCHEON 3

11 5100051756 STAY 1

5100051442 MAIN BOARD ASSY 1

* This unit includes the following parts.

12 ******** MAIN BOARD 1

13 ******** EXP PEDAL BOARD 1

14 5100053348 LCD QFG13232-30-PTDSOS-R 1

15 5100052212 SWITCH PEDAL HOLDER 3

16 5100051749 BOTTOM COVER 1

17 5100047009 BATTERY TERMINAL ± 3

18 5100053384 BATTERY TERMINAL - 1

19 5100053383 BATTERY TERMINAL + 1

20 5100051750 BATTERY COVER 1

21 5100051763 VR PEDAL CUSHION HEEL 2

22 5100051765 RUBBER FOOT 4

a******** NUT attached to VR 4

b******** WASHER attached to VR 1

c 5100046938 PLAIN WASHER 9.1X14X0.5 ZC 1

8

Sep. 2016 GT-1

Exploded View (Fig. A)

fig.bunkaizu-pedal.eps

A1

A2

A3

A4

A5

A7

A8

A6

A7

A9

a

b

c

g

h

h

d

f

e

9

Sep. 2016 GT-1

Exploded View Parts List (Fig. A)

No. Part Code Part Name Description Q’ty

A1 5100053334 BOSS BADGE 1

A2 5100051754 VR PEDAL 1

A3 5100051763 VR PEDAL CUSHION HEEL 1

A4 5100051757 PIN STAY 1

A5 5100051756 STAY 1

5100051442 MAIN BOARD ASSY 1

* This unit includes the following parts.

A6 ******** EXP PEDAL BOARD 1

******** MAIN BOARD Refer to Exploded View (p. 6). 1

A7 5100051764 VR PEDAL BOLT HOLDER 2

A8 5100051755 VR PEDAL HOLDER 1

A9 5100051762 VR PEDAL CUSHION TOE 2

a******** NUT attached to VR 1

b******** WASHER attached to VR 1

c 5100046938 PLAIN WASHER 9.1X14X0.5 ZC 1

d 5100052791 U NUT M6 BZC 1

e 5100052792 PLAIN WASHER 6.5X12.8X1.0 BZC 1

f 5100052795 SCREW M6X50 HEXSOCKET MACHINE BZC 1

g 40127023 PLAIN WASHER 3X8X0.5 ZC 2

h 40011278 SCREW 3X8 BINDING TAPTITE P FE ZC 4

10

Sep. 2016 GT-1

Plain View

fig.heimen.eps

View 1

View 2

View 1

View 2

a

b

c

c

c

No. Part Code Part Name Description Q’ty

a 40011278 SCREW 3X8 BINDING TAPTITE P FE ZC 4

b 40012867 SCREW M3X8 PAN MACHINE W/SW+PW ZC 3

No. Part Code Part Name Description Q’ty

c 40019123 SCREW 3X8 BINDING TAPTITE S BZC 13

11

Sep. 2016 GT-1

Disassembly Procedure

1. Remove the battery cover and take out the battery.

2. Remove the screws (x 4) in the battery case.

3. Detach the pedal.

4. Remove the knobs (x 3) and VR nuts (x 3).

5. Remove all screws (x 9) on the bottom.

6. Lift the bottom cover gently and disconnect the connectors (x 2) on the main board.

7. Detach the bottom case.

8. Disconnect the flat cable (x 1) and wiring (x 1) connecting the main board to the LCD.

9. Remove the screws (x 7) securing the main board.

10. Detach the main board.

* Give attention to ensure that the wirings do not ride up on the rib and are not pinched by the upper and lower cases when assembling.

fig.wiring.eps

12

Sep. 2016 GT-1

Block Diagram/Wiring Diagram

fig.block.eps

JK1

INPUT

Q3

BUFF

IC5

ADDA

IC6B

AF-A/D

IC6A

BUFF

Pre-Emphassis

+23.52dB

LIN

RIN

LOUT

ROUT

SD

+3.3dB

IC7B

BUFF

IC7A

BUFF

De-Emphassis

-8.16dB +5dB

IC7B

BUFF

IC7A

BUFF

Q22

MUTE-

Tr

Q23

MUTE-

Tr

JK5

PHONE

S

Q20

MUTE-

Tr

Q21

MUTE-

Tr

JK3

OUTPU

T

JK4

OUTPU

T

JK6

AUX

Q8.9.10

MUTE-

CTL

+9dB

Power ON : GND

JK2

DC IN

FOR PSA-**S

(9.65-8.55V)

F1

FUSE

CN8

AA x 4

(6.4-3.6V)

IC4

DCDC

OUT1

OUT2

OUT3

OUT5

D+1.2

D+3.3

FBD+3.6

FBAVCC

IC13

Reg

A+3.3

Q19

Ripple

FIR

AVCC

Q1,Q2

Protection

IC21

ESC2

CKCPU

X1

16.9344 CKUDL

IC12

Buffer

IC10

48MHz

AIN

XMUTE-OUTPUT

SD

JK8

USB UDDP/UDDM

IC11

RESET RESET

IC9

S/F SFI

JK7

CTL/EX

P

IC3

SDRAM

(ERAM)

64Mbit

ED

IC14

LATCH

IC2

SDRAM

(WORK)

128Mbit

MD

MA

EA

CN5

IC15

INV

LCD-E

D+3.3

LCD-BACKLIGHT

IC16

VR1

VR2

VR3

SW14

SW15

MPX-A,B

SW4

:

SW13

SW1

SW2

SW3

GPIO

R122

R124

C100

BAT-MONITOR PVCC

AD-MPX

LED*

GPIO

CN7

CN6

VR4 AIN

EXP PDL BOARD

MAIN BOARD

LCD

LCD

UI

2

1

No. Part Code Part Name Description Q’ty

1 5100052119 WIRING W1 (BATTERY) 1

2 5100052120 WIRING W2 1007#26 3X230 1

13

Sep. 2016 GT-1

Parts List

fig.-part1-e.eps

Note: The parts marked # are new. (initial parts) The description “Q’ty” means a necessary number of the parts per one product.

Due to one or more of the following reasons, parts with parts code ******** cannot be supplied

as service parts.

• Supply is prohibited due to copyright restrictions.

• It is carried in electronic data on the Roland website.

• The part is made to order (at current market price).

• It can be replaced with an article on the market. (battery or etc.)

• It is a package or an accessory irrelevant to the function maintenance of the main body.

• A number of circuit boards are grouped together and supplied as a single circuit board (under a different part code).

• Reissuance is restricted.

• It is supplied as an assembled part

(under a different part code).

Safety Precautions:

The parts marked have

safety-related characteristics. Use

only listed parts for replacement.

CASING

# 5100051748 TOP COVER 1

# 5100051754 VR PEDAL 1

# 5100051751 SWITCH PEDAL 3

# 5100051752 SWITCH PEDAL ESCUTCHEON 3

# 5100051750 BATTERY COVER 1

# 5100051749 BOTTOM COVER 1

CHASSIS

# 5100051767 JACK HOLDER 1

# 5100052212 SWITCH PEDAL HOLDER 3

# 5100051764 VR PEDAL BOLT HOLDER 2

# 5100051755 VR PEDAL HOLDER 1

# 5100051757 PIN STAY 1

# 5100051756 STAY 1

KNOB, BUTTON

# 5100051758 KEY UNIT 1

# 5100051761 R-KNOB 3

SWITCH

# 5100051446 SWITCH EVPAWCD2A 12

01780101 TACT SWITCH SKQKABD010 3

JACK, EXT TERMINAL

5100028016 3.5MM JACK HTJ-035-10ABPP1 2

02341712 6.5MM JACK HTJ-064-10I(F3449106R0) 2

02897334 6.5MM JACK HTJ-064-10D 1

02341645 6.5MM JACK HTJ-064-04A 1

13449720 DC JACK HEC2305-016250 1

5100047083 USB CONNECTOR U7F04D-B1NB 1

DISPLAY UNIT

# 5100053348 LCD QFG13232-30-PTDSOS-R 1

PWB ASSY

# 5100051442 MAIN BOARD ASSY 1

* This unit includes the following parts.

******** MAIN BOARD 1

******** EXP PEDAL BOARD 1

POTENTIOMETER

01016167 11M/M ROTARY POTENTIOMETER RK11K1140AFG 10KX1 1

# 5100053342 ROTARY POTENTIOMETER R1132G6JV1O203FC50F9 3

WIRING, CABLE

# 5100052119 WIRING W1 (BATTERY) 1

# 5100052120 WIRING W2 1007#26 3X230 1

SCREWS

40012867 SCREW M3X8 PAN MACHINE W/SW+PW ZC 3

# 5100052795 SCREW M6X50 HEXSOCKET MACHINE BZC 1

40019123 SCREW 3X8 BINDING TAPTITE S BZC 13

40011278 SCREW 3X8 BINDING TAPTITE P FE ZC 8

# 5100052791 U NUT M6 BZC 1

40127023 PLAIN WASHER 3X8X0.5 ZC 2

# 5100052792 PLAIN WASHER 6.5X12.8X1.0 BZC 1

5100046938 PLAIN WASHER 9.1X14X0.5 ZC 1

14

Sep. 2016 GT-1

MISCELLANEOUS

# 5100053383 BATTERY TERMINAL + 1

# 5100053384 BATTERY TERMINAL - 1

5100047009 BATTERY TERMINAL ± 3

# 5100053334 BOSS BADGE 1

# 5100051759 DISPLAY COVER 1

# 5100051765 RUBBER FOOT 4

# 5100053354 SHIELD COVER 1

5100018712 JACK SHIELD 1

# 5100051760 DISPLAY CUSHION 1

# 5100051762 VR PEDAL CUSHION TOE 2

# 5100051763 VR PEDAL CUSHION HEEL 3

# 5100051753 SWITCH PEDAL SW SPRING 3

# 5100051766 SWITCH PEDAL TACT SPRING 3

5100027814 LOCKING CABLE TIE CV-100V0K 1

ACCESSORIES (Standard)

# 5100051784 OWNER’S MANUAL MULTILANGUAGE 1

15

Sep. 2016 GT-1

Virus Check

Before repair or inspection, carry out a virus check on the GT-1. Follow

steps 1and 2of System Update Procedure (p. 16) and start up, and

then make a USB connection to the computer by the appropriate method

of the virus check.

If it has been infected by a virus, format it after obtaining permission

from the end user. For the formatting procedure, refer to Performing a

Factory Reset (p. 15).

Verifying the Version

1. Hold down ENTER and connect a plug into the INPUT jack.

2. When the BOSS logo on the display, release your fingers.

The version information is displayed.

3. Disconnect the plug.

The power is switched off.

Data Backup and Restore

Operations

Items Required

•Computer

•USBcable

• MIDI sequence program (Cakewalk Sonar LE or etc.)

* Install this to the computer above.

•GT-1driver

* Obtain this from the following web pages, and install it on the computer just

described.

http://www.roland.co.jp/

http://www.roland.com/

Data Backup Operations

1. Connect the computer to the USB COMPUTER connector.

2. Start the MIDI sequence program on the computer and set the MIDI input

device to the GT-1.

3. Create two MIDI tracks (track 1 and track 2) and input the following two

kinds of SysEx data into the track 1.

F0 41 7F 00 00 00 30 11 00 00 00 00 00 02 00 00 7E F7

F0 41 7F 00 00 00 30 11 10 00 00 00 00 63 00 00 0D F7

4. Set the track 2 in standby for recording and start recording and playback.

The SysEx data on step 3is sent to the GT-1, and then the GT-1 which

received this data sends the system setting and all patch data (U01 to

U99) to the MIDI sequence program.

When the recording and playback starts, BULK DATA SENDING...

appears on the screen of the GT-1 and the display returns to the initial

screen in about 1 second, but the data is sending from the GT-1

continuously. After the sending is completed, stop the sequence

program. It takes about 40 to 50 seconds to complete the sending.

5. Delete the track 1 in the MIDI sequence program and let the track 2

standby for playback, then save it.

This completes the backup procedure.

6. Disconnect the USB cable.

Data Restore Operations

1. Connect the computer to the USB COMPUTER connector.

2. Start the MIDI sequence program on the computer and set the MIDI

output device to the GT-1.

3. Load the SysEx data which has been backed up to the track and send it to

the GT-1.

BULK DATA RECEIVING... is displayed on the screen of the GT-1 while

sending is in progress and the display returns to the initial screen when

the sending is completed.

This completes the restore procedure.

4. Disconnect the USB cable.

Performing a Factory Reset

1. Press MENU.

The MENU screen appears.

2. Turn the knob (1, 2or 3; whatever possible) to highlight F.RESET and

press ENTER.

The FACTORY RESET screen appears.

3. Turn the knob 1counterclockwise to set FROM to SYSTEM and turn the

knob 3clockwise to set TO to U99.

Now, the unit was set as the system parameter and all user patches (U01

to U99) are reset.

4. To execute the factory reset, press ENTER. To cancel it, press EXIT.

Pressing ENTER displays a confirmation screen.

5. To execute the factory reset, turn the knob (1, 2or 3; whatever possible) to

highlight OK and press ENTER. To cancel it, highlight CANCEL and

press ENTER, or press EXIT.

EXECUTING... is displayed while the factory reset is in progress.

When the procedure is finished, the initial screen returns.

16

Sep. 2016 GT-1

System Update Procedure

Items Required

•Computer

•USBcable

• Dummy plug

• Update program (obtained via Service Net)

* The update program is made up of the following two files.

GT-1ROM.BIN

ROMINFO.TXT

Procedure

1. Prepare the update program to any folder on the computer.

2. Hold down EXIT and connect a dummy plug to the INPUT jack.

3. When GT-1 Updater appears on the screen of the GT-1, release your

fingers.

4. Connect the computer to the USB COMPUTER connector.

USB Connected. appears on the screen of the GT-1 and the BOSS_GT-1

drive appears on the screen of the computer.

5. Copy the update programs (two files) to the BOSS_GT-1 drive.

6. End the USB connection and detach the USB cable.

Push [ENTER] to start. is displayed on the screen of the GT-1.

7. Press ENTER.

The update starts.

When Completed. is displayed, the update has finished.

8. Disconnect the dummy plug from the INPUT jack.

The power is switched off.

Test Mode

Items Required

• AC adaptor (PSA-series device)

•Computer

• Amp-equipped monitor speakers

• Signal generator

• Oscilloscope

•Noisemeter

•Tester

• Expression pedal (EV-5)

•USBcable

•Dummyplug

• 1/4-inch mono phone plug with 47-kΩ load resister

• 1/4-inch stereo phone plug

• Miniature stereo phone plug

• Current-consumption measurement tool

fig.check-cable.eps

• Foot switch (FS-5U x 2 or FS-6 x 1)

* Set the POLARITY switch and the MODE switch on the foot switch as shown

below.

fig.FS-5U.eps

fig.FS-6.eps

• Y cable (having one 1/4-inch stereo phone plug and two 1/4-inch

monaural phone plugs) or 1/4-inch stereo phone cable

•GT-1driver

* Obtain this from the following web pages, and install it on the computer just

described.

http://www.roland.co.jp/

http://www.roland.com/

FS-5U

FS-6

17

Sep. 2016 GT-1

Test Items

1. VERSION (p. 17)

2. DEVICE (p. 17)

3. CURRENT (p. 17)

4. JACK SW (p. 18)

5. SW/LED (p. 18)

6. LCD/ENCODER (DEV) (p. 18)

7. LCD/ENCODER (p. 18)

8. INTERNAL EXP1 (CALIBRATION) (p. 19)

9. CTL (p. 19)

10. EXT EXP2 (p. 19)

11. AUDIO SELF (p. 19)

12. NOISE (p. 19)

13. AUDIO OUTPUT (p. 19)

14. AUDIO INPUT (p. 19)

15. FACTORY RESET (p. 20)

16. AD NOISE (p. 20)

* Test items 6, 11, 13, 15, and 16 are not required at the service.

Entering the Test Mode

1. Connect the AC adaptor and hold down PREAMP, REVERB and

MEMORY EDIT and connect a 1/4-inch mono phone plug into the INPUT

jack.

* To execute 3. CURRENT (p. 17), connect the AC adaptor using the current-

consumption measurement tool.

* To execute 12. NOISE (p. 19), connect a 1/4-inch mono phone plug with 47 kΩ

load resistor to the INPUT jack. Other test items can be carried out by the

dummy plug.

2. When the BOSS logo appears on the display, release your fingers.

Entering the Test Mode displays the TEST MENU.

fig.test-0.eps

Selecting Test Items

In the TEST MENU, turn the knob (1, 2or 3; whatever possible) to select

a test item and press ENTER.

To return to the TEST MENU, press EXIT.

* It is impossible to return from 5. SW/LED to the TEST MENU until all

buttons have been pressed.

Quitting the Test Mode

Disconnect the plug from the INPUT jack to switch off the power.

1. VERSION

This verifies the version.

1. In the TEST MENU, select 1. VERSION and press ENTER.

Version information is displayed under the VER text at the top left of the

screen.

* Ignore other displays.

2. Press EXIT to return to the TEST MENU.

2. DEVICE

This verifies the operation of each device.

1. Connect the computer to the USB COMPUTER connector.

2. In the TEST MENU, select 2. DEVICE and press ENTER.

Each device is checked automatically, and if no problems are found, Pull

out the USB cable. appears.

fig.test-2.eps

3. Disconnect the USB cable.

4. Press EXIT to return to the TEST MENU.

3. CURRENT

This measures the current consumption.

1. Use the current-consumption measurement tool to connect the AC

adaptor.

2. Enter the Test Mode, select 3. CURRENT in the TEST MENU and press

ENTER.

3. Verify that the current-consumption is from 165 to 195 mA.

4. Press EXIT to return to the TEST MENU.

18

Sep. 2016 GT-1

4. JACK SW

This verifies the sensing operation of jacks.

1. Connect the 1/4-inch stereo phone plug to the CTL2,3/EXP2 jack and the

miniature stereo phone plug to the PHONES jack.

2. In the TEST MENU, select 4. JACK SW and press ENTER.

A screen like the one shown below is displayed.

[CTL] EJECT

[PHONES] EJECT

3. Disconnect the plug from the CTL2,3/EXP2 jack.

A screen like the one shown below is displayed.

[CTL] INSERT

[PHONES] EJECT

4. Connect the plug to the CTL2,3/EXP2 jack again.

A screen like the one shown below is displayed.

[CTL] OK

[PHONES] EJECT

5. Disconnect the plug from the PHONES jack.

A screen like the one shown below is displayed.

[CTL] OK

[PHONES] INSERT

6. Connect the plug to the PHONES jack again.

A screen like the one shown below is displayed.

[CTL] OK

[PHONES] OK

7. Detach the both plugs.

8. Press EXIT to return to the TEST MENU.

5. SW/LED

This verifies the switch operation.

1. In the TEST MENU, select 5. SW/LED and press ENTER.

LEDs of , , CTL1 and from FX1/COMP to REVERB light up red.

A screen like the one shown below is displayed.

fig.test-5.eps

2. Press .

The LED lights up blue.

3. Press .

The LED goes off.

4. In the same way, press respectively and CTL1 twice.

5. Press the button displayed on the screen in sequence.

6. After pressing buttons until MENU, press EXIT to return to the TEST

MENU.

6. LCD/ENCODER (DEV)

This item is not required at the service.

7. LCD/ENCODER

This verifies the display of the LCD screen.

1. In the TEST MENU, select 7. LCD/ENCODER and press ENTER.

fig.test-7-1.eps

2. Slowly turn the knob 1clockwise.

The value displayed on the screen increases by one unit at a time and the

contrast grows darker.

* If the knob is turned in the opposite direction or the wrong knob is turned, a

black band appears at the bottom area of the screen. In this case, turn the knob 1

clockwise and continue to the test.

3. When the value displayed on the screen reaches 24, turn the knob

counterclockwise slowly.

The value displayed on the screen decreases by one unit at a time and the

contrast grows fainter.

When the value displayed on the screen reaches 1, and the knob is turned

counterclockwise further, a screen like the one shown below is displayed.

fig.test-7-2.eps

4. Slowly turn the knob 2 clockwise.

The value displayed on the screen increases by one unit at a time and the

display of the bar advances to the right.

5. When the value displayed on the screen reaches 24, turn the knob

counterclockwise slowly.

The value displayed on the screen decreases by one unit at a time and the

display of the bar advances to the right further.

When the value displayed on the screen reaches 1, and the knob is turned

counterclockwise further, a screen like the one shown below is displayed.

fig.test-7-3.eps

6. Test the knob 3in the same way.

When the value displayed on the screen reaches 1, and the knob is turned

counterclockwise further, a screen like the one shown below is displayed.

fig.test-7-4.eps

7. Verify that the black frame around the screen have no missing dots, then

press ENTER.

A screen like the one shown below is displayed.

fig.test-7-5.eps

8. Press EXIT to return to the TEST MENU.

19

Sep. 2016 GT-1

8. INTERNAL EXP1 (CALIBRATION)

This performs calibration for the pedal of the unit.

1. In the TEST MENU, select 8. INTERNAL EXP1 and press ENTER.

2. Depress the heel side of the pedal all the way and press MENU.

The minimum value offset is saved to the unit.

3. Depress the toe side of the pedal all the way and press MENU.

The maximum value offset is saved to the unit.

4. Forcefully depress the toe.

The PEDAL FX LED next to the pedal lights up.

5. Forcefully depress the toe again.

The LED goes dark.

6. Press EXIT to return to the TEST MENU.

9. CTL

This verifies the operation of the CTL2,3/EXP2 jack.

1. Connect the foot switch (FS-5U x 2, or FS-6 x 1) to the CTL2,3/EXP2 jack.

2. In the TEST MENU, select 9. CTL and press ENTER.

3. While depressing the foot switch connected to the tip side, verify that

[CTL1] on the screen is displayed as ON.

4. While depressing the foot switch connected to the ring side, verify that

[CTL2] on the screen is displayed as ON.

5. Detach the foot switch.

6. Press EXIT to return to the TEST MENU.

10. EXT EXP2

This verifies the operation for the expression of the CTL2,3/EXP2 jack.

1. Connect the expression pedal (EV-5) to the CTL2,3/EXP2 jack (TRS).

2. In the TEST MENU, select 10. EXT EXP2 and press ENTER.

3. Depress the heel side of the expression pedal all the way and verify that

the value of [EXP] displayed on the screen is 4or less.

4. In the same way, depress the toe side of the expression pedal all the way

and verify that the value displayed on the screen is 630 or higher.

5. Detach the expression pedal.

6. Press EXIT to return to the TEST MENU.

* Ignore the display of AD SW.

11. AUDIO SELF

This item is not required at the service.

12. NOISE

This measures residual noise.

1. Connect the 1/4-inch mono phone plug with 47 kΩ load resistor to the

INPUT jack and enter the Test Mode.

2. In the TEST MENU, select 12. NOISE and press ENTER.

3. Connect the amp-equipped monitor speakers to the OUTPUT L/MONO

and Rjacks.

4. Drop the unit from a height of about 5 centimeters and verify that no

abnormal noise is produced.

5. Disconnect the amp-equipped monitor speakers and connect the noise

meter to the OUTPUT L/MONO and Rjacks.

6. Verify that the residual noises are as the following values.

OUTPUT L: -60 dBm or less (DIN-Audio)

OUTPUT R: -60 dBm or less (DIN-Audio)

7. Detach the noise meter.

8. Connect the amp-equipped monitor speakers to the PHONES jack (L, R).

9. Drop the unit from a height of about 5 centimeters and verify that no

abnormal noise is produced.

10. Disconnect the amp-equipped monitor speakers and connect the noise

meter to the OUTPUT L/MONO and Rjacks.

11. Verify that the residual noises are as the following values.

OUTPUT L: -60 dBm or less (DIN-Audio)

OUTPUT R: -60 dBm or less (DIN-Audio)

12. Detach the noise meter.

13. Press EXIT to return to the TEST MENU.

13. AUDIO OUTPUT

This item is not required at the service.

14. AUDIO INPUT

This verifies the input and output of the audio signal.

Input Test

1. Connect the signal generator to the INPUT jack and the unit enters the

Test Mode.

2. In the TEST MENU, select 14. AUDIO INPUT and press ENTER.

3. Connect the oscilloscope to the OUTPUT L/MONO and Rjacks.

4. Input a signal like the following to the INPUT jack.

INPUT: 200-Hz sine wave at 5.0 Vpp

5. Turn the knob 1to set the value shown in the figure below to 0AE.

fig.test-14-1.eps

6. Verify that signals like the following are output from the OUTPUT L/

MONO and Rjacks

OUTPUT L: 200-Hz sine wave at 4.8 to 5.4 Vpp

OUTPUT R: 200-Hz sine wave at 4.8 to 5.4 Vpp

7. Change the connection of the oscilloscope to the PHONES jack and verify

that signals like the following are output.

PHONES L: 200-Hz sine wave at 4.8 to 5.4 Vpp

PHONES R: 200-Hz sine wave at 4.8 to 5.4 Vpp

20

Sep. 2016 GT-1

Input Test (AFAD)

8. Input a signal like the following to the INPUT jack.

INPUT: 200-Hz sine wave at 0.218 Vpp (-20 dBm)

9. Turn the knob 1to set the value shown in the figure below to 0aE.

fig.test-14-2.eps

10. Verify that signals like the following are output from the PHONES jack.

PHONES L: 200-Hz sine wave at 200 to 300 mVpp

PHONES R: 200-Hz sine wave at 3.4 to 3.8 Vpp

11. Connect the oscilloscope to the OUTPUT L/MONO and Rjacks and verify

that signals like the following are output.

OUTPUT L: 200-Hz sine wave at 200 to 300 mVpp

OUTPUT R: 200-Hz sine wave at 3.4 to 3.8 Vpp

* If you verify the each level of L and R channels one by one, measure it with a

plug being connected to another jack.

12. Detach the signal generator and the oscilloscope.

Residual Noise Test

13. Connect the 1/4-inch mono phone plug with 47 kΩ load resistor to the

INPUT jack and enter the Test Mode.

14. In the TEST MENU, select 14. AUDIO INPUT and press ENTER.

15. Connect the noise meters to the OUTPUT L/MONO and Rjacks.

16. Turn the knob 1to set the value shown in the figure below to 0AE. Also

press PREAMP to set muteL to oand press FX2/MOD to set muteR to o.

fig.test-14-3.eps

17. Verify that the residual noises are as the following values.

OUTPUT L: -93 dBm or lower (DIN-Audio)

OUTPUT R: -93 dBm or lower (DIN-Audio)

18. Change the connection of the noise meter to the PHONES jack.

19. Verify that the residual noises are as the following values.

PHONES L: -93 dBm or lower (DIN-Audio)

PHONES R: -93 dBm or lower (DIN-Audio)

20. Detach the noise meter.

AUX Test

21. Connect the oscilloscope to the OUTPUT L/MONO and Rjacks.

22. Connect the signal generator to the AUX IN jack (L, R) and input signals

like the following.

AUX IN L: 200-Hz sine wave at 2.0 Vp-p

AUX IN R: 200-Hz sine wave at 2.0 Vp-p

23. Press PREAMP to set muteL to xand press FX2/MOD to set muteR to x.

24. Verify that signals like the following are output from the OUTPUT L/

MONO and Rjacks.

OUTPUT L: 200-Hz sine wave at 4.7 to 5.3 Vpp

OUTPUT R: 200-Hz sine wave at 4.7 to 5.3 Vpp

25. Change the connection of the oscilloscope to the PHONES jack and verify

that signals like the following are output.

PHONES L: 200-Hz sine wave at 4.7 to 5.3 Vpp

PHONES R: 200-Hz sine wave at 4.7 to 5.3 Vpp

26. Detach the oscilloscope.

27. Press EXIT to return to the TEST MENU.

15. FACTORY RESET

This item is not required at the service. Do not execute this item. Follow

the procedure in Performing a Factory Reset (p. 15) to execute a factory

reset.

16. AD NOISE

This item is not required at the service.

17. ENCODER DEVICE

This item is not required at the service.

* This item is added from ver. 1.06.

Other manuals for GT-1

2

Table of contents

Popular Accessories For Musical Instruments manuals by other brands

Schatten Design

Schatten Design HFN-C Active installation instructions

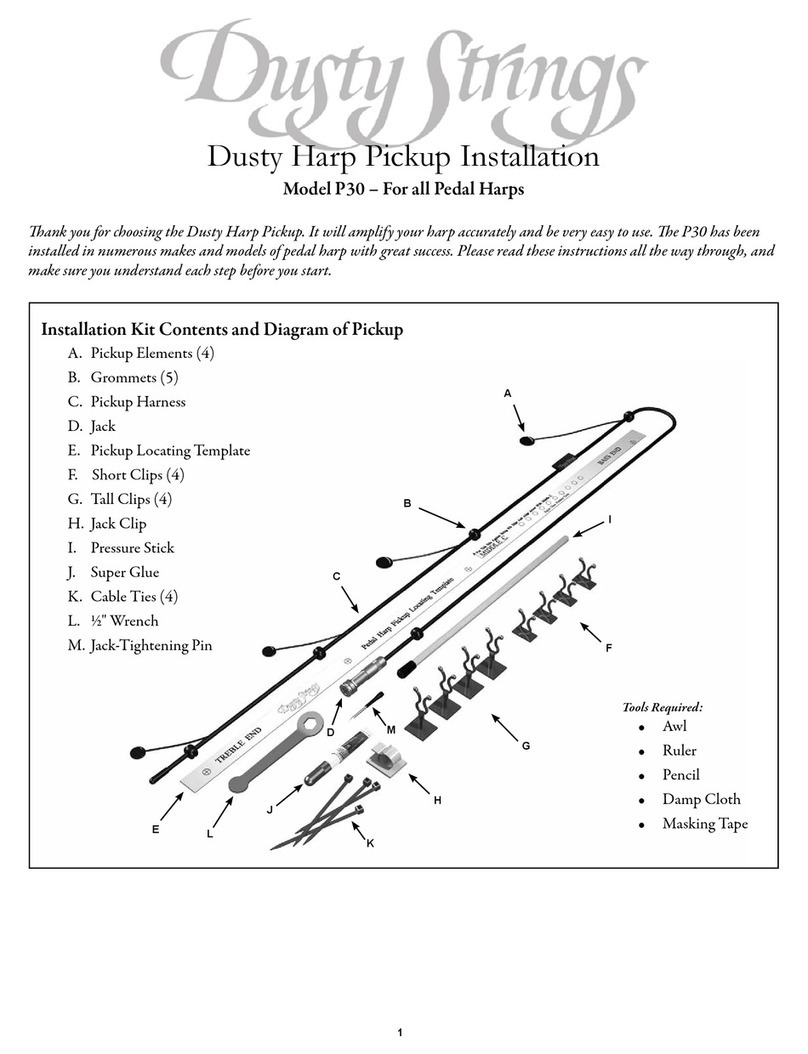

Dusty Strings

Dusty Strings P30 Installation

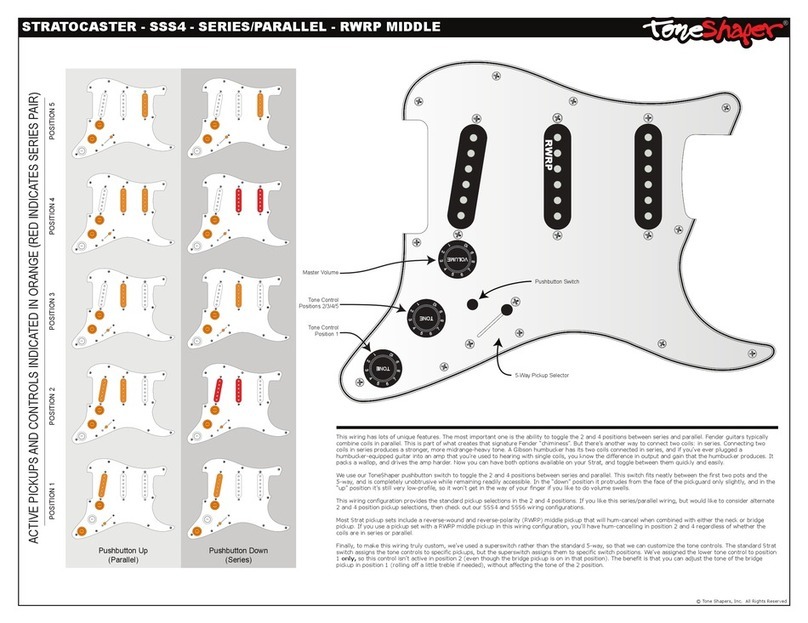

ToneShapers

ToneShapers STRATOCASTER SSS4 Series quick start guide

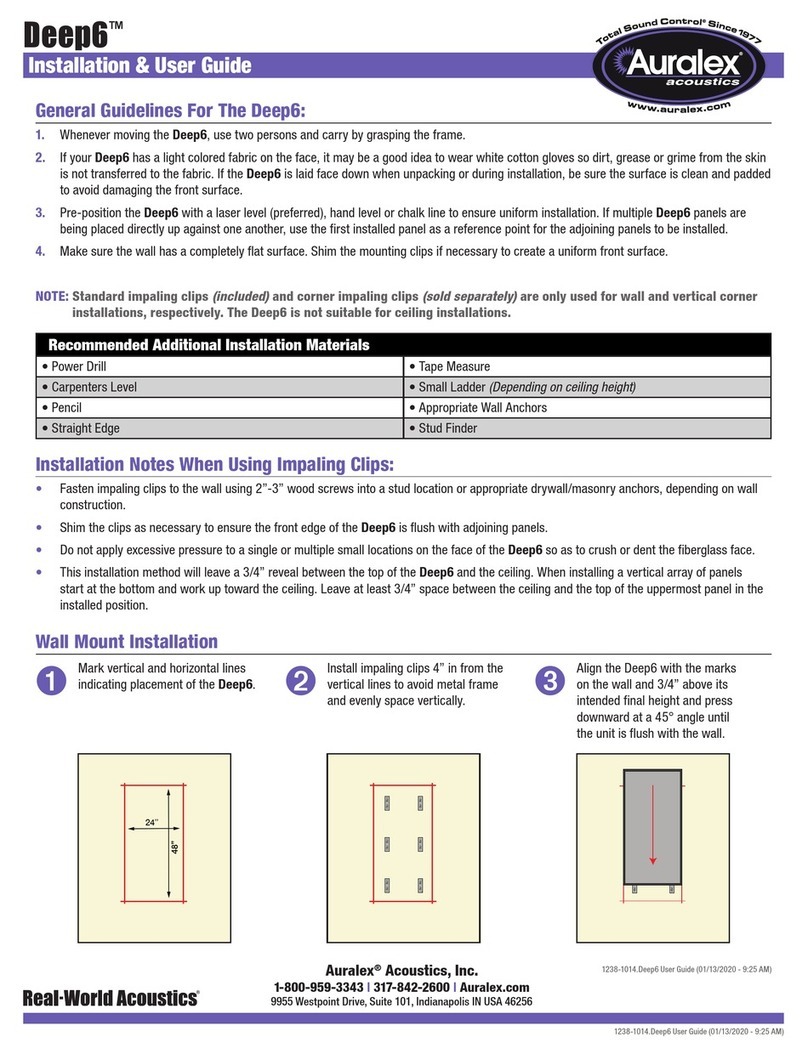

Auralex Acoustics

Auralex Acoustics Deep6 Installation & user guide

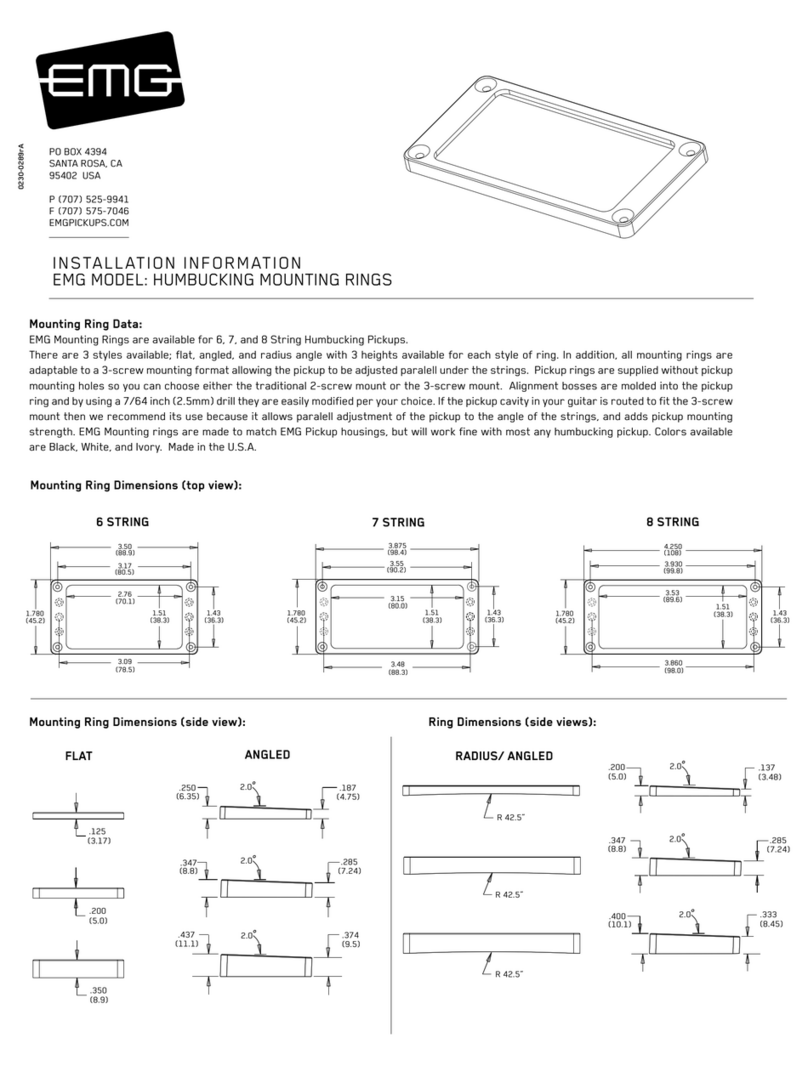

EMG

EMG FLAT 6 MEDIUM Installation information

Konig & Meyer

Konig & Meyer Spider Pro 18876 manual