BOSSCO SMARTHITCH2 RT3 POWER-V User manual

DRIVEN TO BE THE BEST

MSC04082-9

RT3 POWER-V BLADE

WITH SMARTHITCH2

TM

INSTALLATION MANUAL

TABLE OF CONTENTS

WARNINGS................................................................................................................................... 2

SNOWPLOW MOUNTING & REMOVAL PROCEDURE.............................................................. 3

SNOWPLOW ASSEMBLY PROCEDURE .................................................................................... 4

ELECTRICAL SYSTEM WIRING PROCEDURE.......................................................................... 9

HEADLIGHT ADAPTER INSTALLATION PROCEDURE............................................................. 14

ELECTRICAL SYSTEM WIRING SCHEMATIC PLOW SIDE) .................................................... 15

ELECTRICAL SYSTEM WIRING SCHEMATIC TRUCK SIDE) .................................................. 16

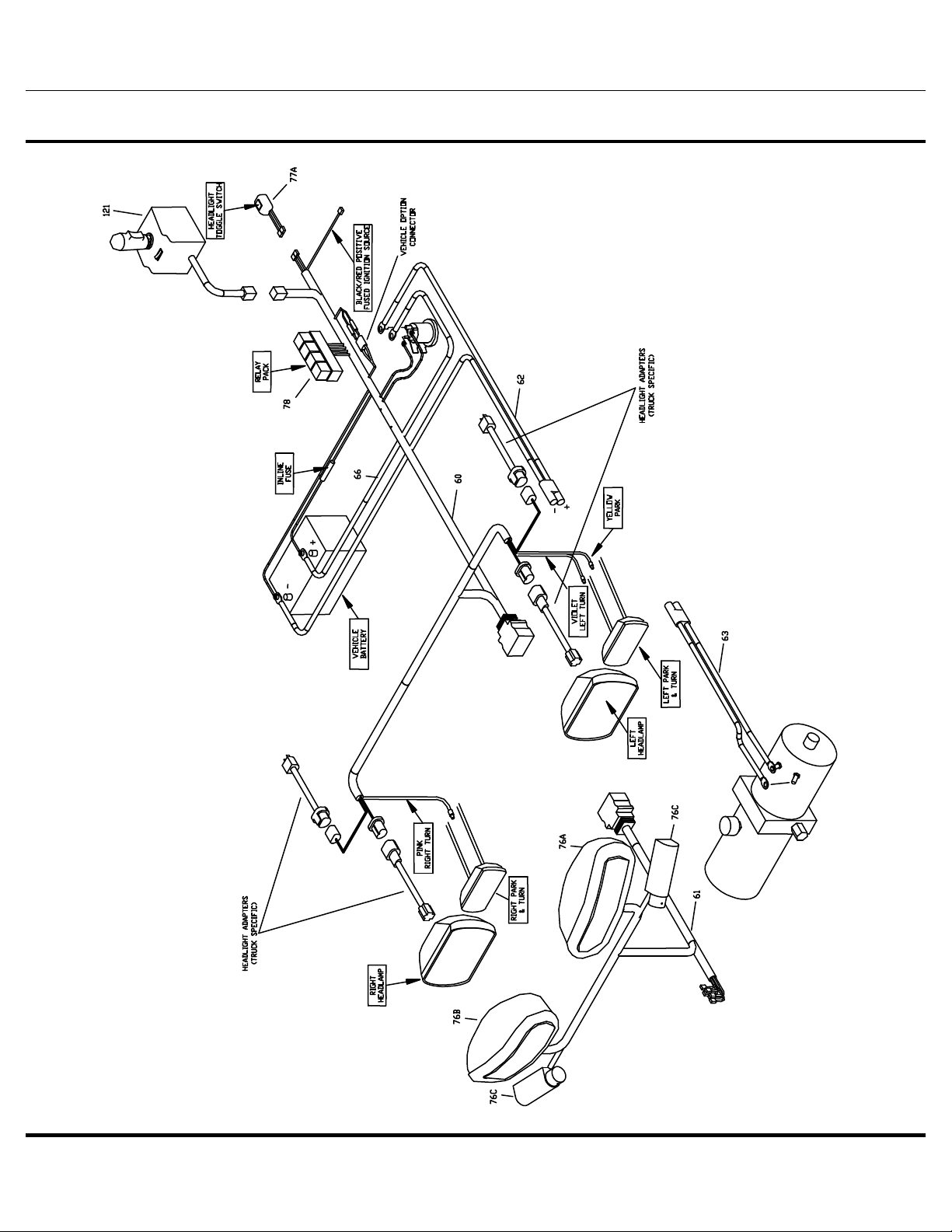

ELECTRICAL SYSTEM WIRING DIAGRAM ................................................................................ 17

RT3 V-BLADE MANIFOLD WIRING DIAGRAM ........................................................................... 18

HYDRAULIC VALVE ASSEMBLY PARTS LIST........................................................................... 19

HEADLIGHT AIMING PROCEDURE............................................................................................ 20

HYDRAULIC POWER UNIT FILL PROCEDURE ......................................................................... 21

V-BLADE CONTROLLERS ........................................................................................................... 22

TROUBLESHOOTING GUIDE...................................................................................................... 26

RECOMMENDED PUSHBEAM HEIGHT ..................................................................................... 32

RECOMMENDED BOLT TORQUE .............................................................................................. 32

BOSS PRODUCTS / Northern Star Industries, Inc. reserves the right under its continuous product improvement policy to change construction or

design details and furnish equipment when so altered without reference to illustrations or specifications used herein.

This product is covered under one or more of the following patents:

5,568,694 4,074,448 4,658,519 6,108,946 6,170,178 6,134,814

Other Patents Pending

BOSS PRODUCTS

A Division of Northern Star Industries, Inc.

P.O. Box 787 Iron Mountain MI 49801-0787

www.bossplow.com

WARNING

Many newer trucks are equipped with air bags. DO NOT under any circumstances disable or remove or

relocate any sensors or other components related to the operation of the air bags.

WARNING

Always follow the vehicle manufacturer’s recommendations relating to snowplow installation. For

recommended vehicle models refer to the BOSS Snowplow Application Chart and Selection Guide.

WARNING

Vehicles equipped with air bags are designed such that the air bags will be activated in a frontal collision

equivalent to hitting a solid barrier such as a wall) at approximately 14 mph or more, or, roughly speaking,

a frontal perpendicular collision with a parked car or truck of similar size at approximately 28 mph or more.

Careless or high speed driving while plowing snow, which results in vehicle decelerations equivalent to or

greater than the air bag deployment threshold described above, would deploy the air bag.

WARNING

Read this manual carefully before operating this snowplow.

WARNING

When transporting, position plow so as not to block vision or plow headlights.

WARNING

DO NOT change blade position when traveling.

WARNING

DO NOT exceed 40 mph when transporting plow.

WARNING

DO NOT exceed 14 mph when plowing.

WARNING

Always lower blade when vehicle is not in use.

WARNING

Make sure plow is properly attached before moving vehicle.

WARNING

To comply with Federal Regulations and to assure a safe vehicle, the Front Gross Axle Weight Rating

FGAWR), Rear Gross Axle Weight Rating RGAWR), and the Gross Vehicle Weight Rating GAWR) must

not be exceeded at any time.

WARNING

Due to the variety of equipment that can be installed on this vehicle, it is necessary to verify that the Front

Gross Axle Weight Rating FGAWR), Rear Gross Axle Weight Rating RGAWR), and the Gross Vehicle

Weight Rating GAWR) are not exceeded at any time. This may require weighing the vehicle and adding

ballast as necessary. It may also limit payload capacity of the vehicle. It is the operator’s responsibility to

verify that these ratings are not exceeded.

Snowplow Mounting Procedure

3

Figure 1. Mounting and Removal Instructions MSC04606

Snowplow Assem ly Procedure

4

Sn wpl w Assembly

Pr cedure

N te: This manual is used for the installation of all V-

Plows. Part numbers and illustrations may vary.

1. Begin the assembly procedure by cutting down

each corner of the plow box so that each wall of

the box will lie flat on the floor. Lay the top of the

box flat on the floor. The top of the box can be

used as a mat and will help prevent scratching the

blade halves during installation.

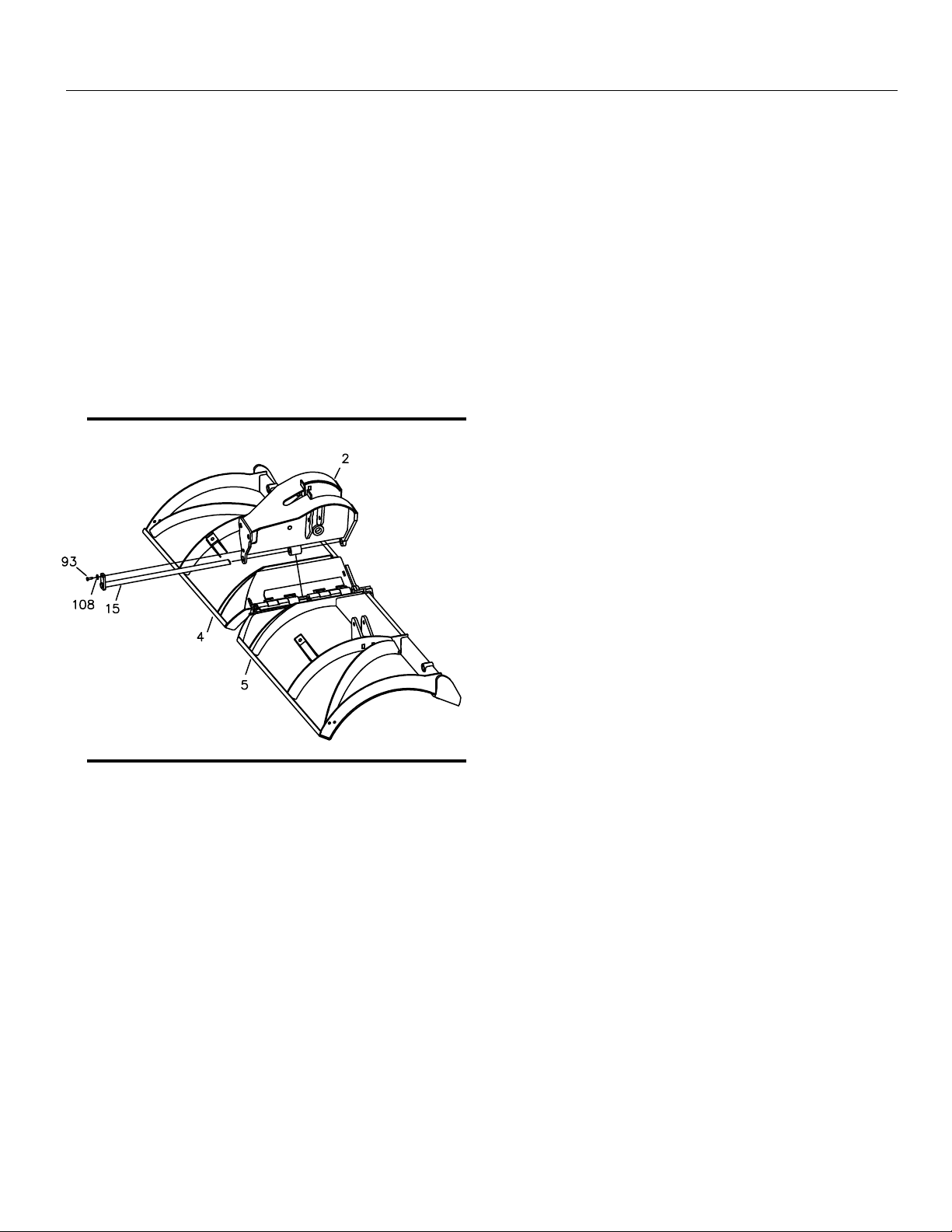

2. Remove Left Blade Half 5) and Right Blade Half

4) from the crate. Lay each blade half flat on the

box top, face down.

Figure 2. Blade Assembly Procedure. G10123

3. Align the center bushings on Left Blade Half 5)

with the center bushings on Right Blade Half 4).

Position CHA09716 Center Section 2) on top of

both blades so that all bushings align.

4. Insert MSC01507 Center Hinge Pin 15) through

Left Blade Half 5), Right Blade Half 4) and

Center Section 2).

5. Secure Center Hinge Pin 15) to the top of Center

Section 2) using one HDW01771 3/8”-16 X 1 ¼”

Hex Head Cap Screw 93), and one HDW01718

3/8” Split Lock Washer 108).

N te: Plow shoes are optional. If added they should

be mounted flush with the bottom of the cutting edge

when the plow is mounted on the truck to be used for

plowing. When plowing on a solid level area parking

lots, roads, and driveways) plow shoes can be raised

up to increase cutting edge contact on the plowed

surface. When plowing dirt, gravel, or grass plow

shoes should be lowered below the cutting edge

surface to prevent the plow from digging into the

plowed surface.

Snowplow Assem ly Procedure

5

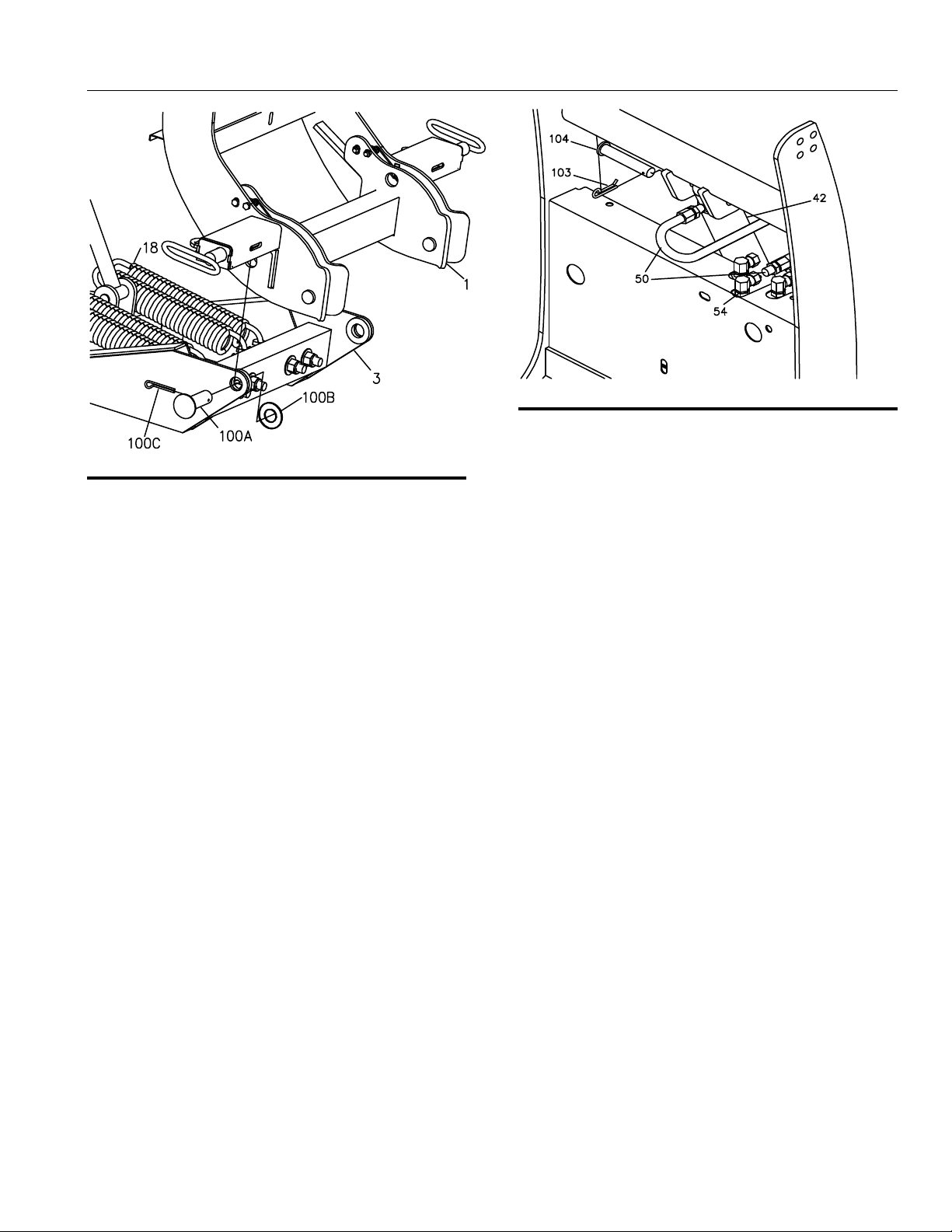

Figure 3. Push Frame Assembly Procedure. G10122

6. Stand Blade Assembly and Center Section 2) on

the Cutting Edges with both wings forward in the

scoop position.

7. Remove the loose Horizontal Hinge Pin 102C)

that is inserted in the Center Section 2).

8. Slide TFR09708 Push Frame 3) into Center

Section 2). Re-insert Horizontal Hinge Pin 102C)

through Center Section 2) and Push Frame 3)

then secure with washer 102B) and nut 102A).

9. Attach Lift Cylinder 42) to Push Frame 3) with

HDW05563 Clevis Pin 104) and HDW05544

Hairpin Cotter 103).

10. Hook MSC04200 Spring Yoke 11) to the cross

rod inside Center Section 2).

11. Hook one end of MSC01509 Trip Spring 18) to

Spring Yoke 11). Attach the opposite end of Trip

Spring 18) to the rear angle of Push Frame 3)

using HDW05601 Eyebolts 98), 5/8” Flat

Washers 112) and 5/8” Self-Locking Nuts 111) .

Tighten Self-Locking Nuts 111) finger tight.

12. Attach HYD09731 Angle Cylinders 40) to Center

Section 2) using HDW01706 5/8”-11 X 4” Hex

Head Cap Screws 90) and HDW01709 5/8”-11

Self Locking Nuts 111). DO NOT over-tighten the

nuts.

N te: You should be able to slightly slide the cylinder

up and down on the bolt after it has been tightened.

Figure 4. Angle Cylinder Installation. G10121

13. Pull both wings back into the ‘V’ position.

14. Hook one end of Return Spring 19) to the top

hole on Center Section 2). Hook the opposite end

of Return spring 19) to the blade spring mounting

bracket using ½” Spadebolt 97A), ½” Flat Washer

97C), and ½” Self-Locking Nut 97B). Tighten

Spring 19) until there is a 1/32” space between

spring coils. Repeat this process for Return Spring

19) on the opposite side of the plow.

15. Install one Push Nut Retainer 97D) on each end

of the Return Spring 19).

N te: Be sure Push Nut Retainer’s flanges are

pointing away from the Eyebolt and toward the open

end of the Return Spring.

16. Bolt the rod end of Angle Cylinder 40) to each

blade half using 5/8”-11 X 4” Hex Head Bolt 90)

and 5/8”-11 Self Locking Nuts 111). DO NOT

over tighten bolts. Repeat this process for Angle

Cylinder 40) on the opposite side of the plow.

N te: You should be able to slightly slide the cylinder

up and down on the bolt after it has been tightened.

Snowplow Assem ly Procedure

6

Figure 5. Coupler Assembly to Push Frame. G10119

17. Align pivot holes of Coupler Assembly 1) and

pivot holes of Push Frame 3).

18. Insert 1” X 2 ½” Pivot Pin 100A) through Coupler

Assembly 1) and Push Frame 3). Secure with 1”

Flat Washer 100B) and 3/16” Cotter Pin 100C).

N te: The 10’ V-Blade plow uses a 5/16” x 2” Bolt

and a 5/16” Locknut in place of 3/16” Cotter Pin

100C).

19. Tighten the four Trip Springs 18) on Push Frame

3) until there is a 1/32” space between each

spring coil.

Figure 6. Assembly of Lift Cylinder Hydraulics. G10138

20. Remove the plug from the top end of Lift Cylinder

42).

21. Attach one end of Hydraulic Hose 50) to Lift

Cylinder 42). Be sure to apply thread sealant

compound to the pipe threads on Hydraulic Hose

50). Tighten connection securely.

22. Attach the top end of Lift Cylinder 42) to Coupler

Assembly 1) using HDW05563 Clevis Pin 104)

and HDW05544 Hairpin Cotter 103).

23. Route Hydraulic Hose 50) in “S” shape and

connect the loose end to the rear Hydraulic Fitting

54). Tighten connection securely.

Snowplow Assem ly Procedure

7

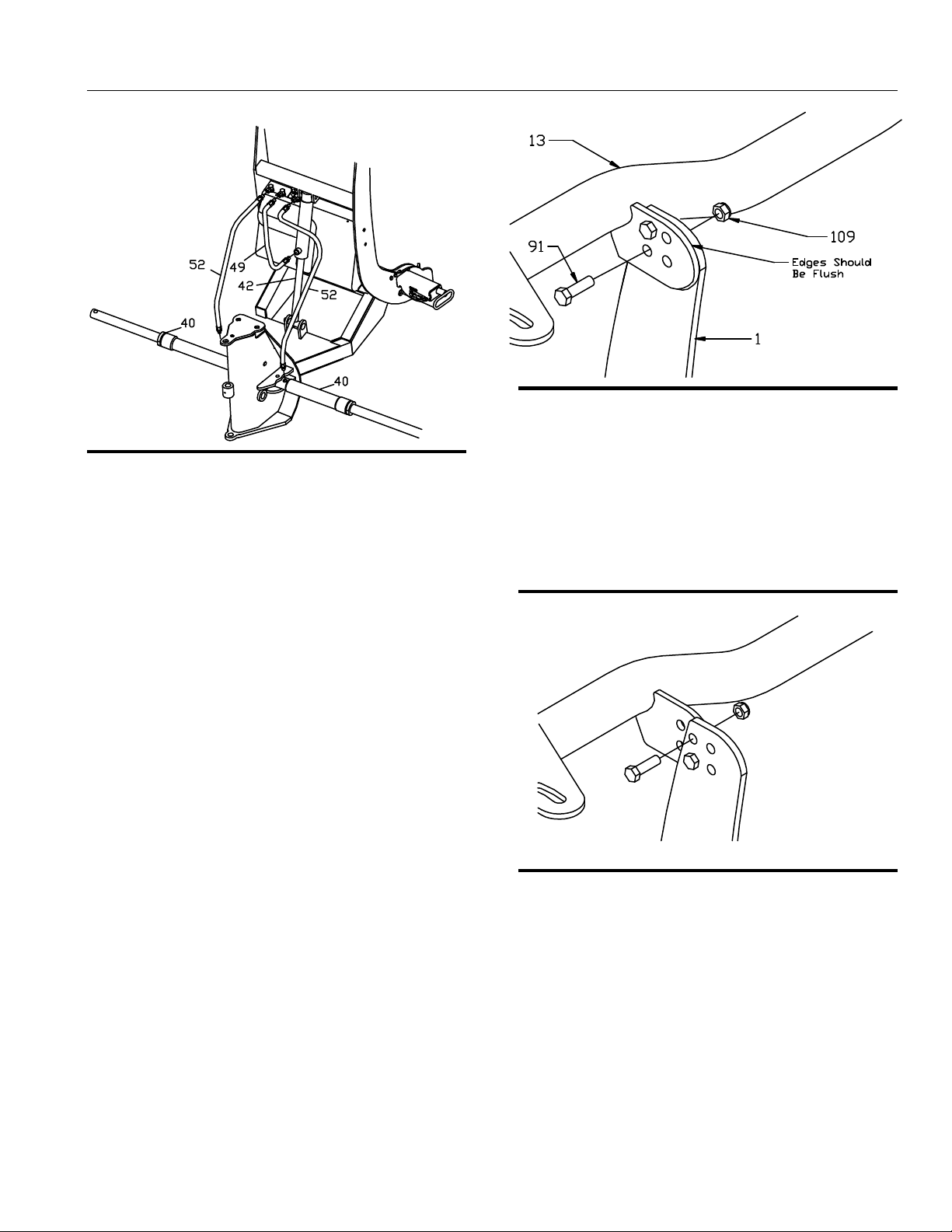

Figure 7. Assembly of Hydraulic Connections. G10013

24. Attach one end of Hydraulic Hose 49) to the

lower port of Lift Cylinder 42). Attach the

opposite end of Hydraulic Hose 49) to the center

Hydraulic Fitting 54). Tighten connection

securely.

25. Apply thread sealant compound do not use

Teflon Tape) to the threads of the 3/8” MNPT end

of HYD07042 Hydraulic Hose 52). Thread the

hose into the port on Angle Cylinder 40) and

tighten securely.

N te: Do not apply thread compound to the ¼” end of

the hose.

N te: Do not get thread compound on the end of the

hose since the compound will contaminate the

hydraulic system.

26. Attach the loose end of HYD07042 Hydraulic

Angle Hose 52) to the corresponding fitting on

the hydraulic manifold. Tighten all hydraulic

connections securely.

Figure 8. Light Bar Assembly. Standard) G10132

27. Attach Light Bar 13) to the top of Coupler

Assembly 1) using two Hex Head Cap Screws

91) and Hex Head Self Locking Nuts 109).

N te: The light bar should be positioned as close to

the Coupler Tower as possible. Only two holes will be

aligned for normal installations. Only two bolts per side

are needed to secure the light bar.

Figure 9. Light Bar Assembly Adjustment. G10131

N te: Figure 9 illustrates that the Coupler Assembly

and Light Bar have two sets of 1 inch adjustment holes

for mounting on different vehicles. These adjustment

holes may be needed in order to move the light bar

away from the vehicle’s hood.

Snowplow Assem ly Procedure

8

Figure 10. Headlight Mounting Assembly G10115

28. Insert Light Bar Seal 79) into the Light Bar and

seat it using the end of the Turn Signal 76C).

29. Attach Turn Signal 76C) into the end of Light Bar

13) using one Machine Screw 76F) and Nut

76G).

N te: Do not over tighten Machine Screw 76F).

30. Bolt Driver’s Side Headlight 76A) on to Light

Bar 13) using two bushings 76H), ½” Nuts

76D) and ½” Star Washers 76E) as shown

above.

31. Repeat Steps 28 through 30 for Passenger’s

Side Headlight 76B) and Passenger’s Side

Turn Signal 76C).

Figure 11. Secure Wiring Harness G10126

32. Secure Wiring Harness 61) to Light Bar 13)

as shown above.

33. Insert the unconnected ends of the Plow Wiring

Harness into the back of the coupler through

the rubber grommet.

34. Connect the Plow Side Wiring Harness to the

Hydraulic Valve Manifold as shown in Figure

26. HYD07044 with SmartHitch2

TM

Wiring

Diagram on page 18 of this manual.

N te: All wires need to be connected.

N te: The SmartHitch2

TM

switch is pre-wired from

the factory.

Figure 12. Assembly of Blade Guides. G10071

35. Attach Blade Guides 16) to Blade Assembly 4)

using Hex Head Cap Screws 94) and Self

Locking Nuts 115).

Electrical System Wiring Procedure

9

Electrical System Wiring

Pr cedure

WARNING!

WARNING!WARNING!

WARNING!

Before starting any Electrical Wiring Procedure

make sure that the engine is not running and that

the engine has had sufficient time to cool down.

Failure to do so may result in serious bodily injury

or death.

WARNING!

WARNING!WARNING!

WARNING!

Before starting any Electrical Wiring Procedure

make sure to disconnect the battery. Failure to

do so may result in serious bodily injury or death.

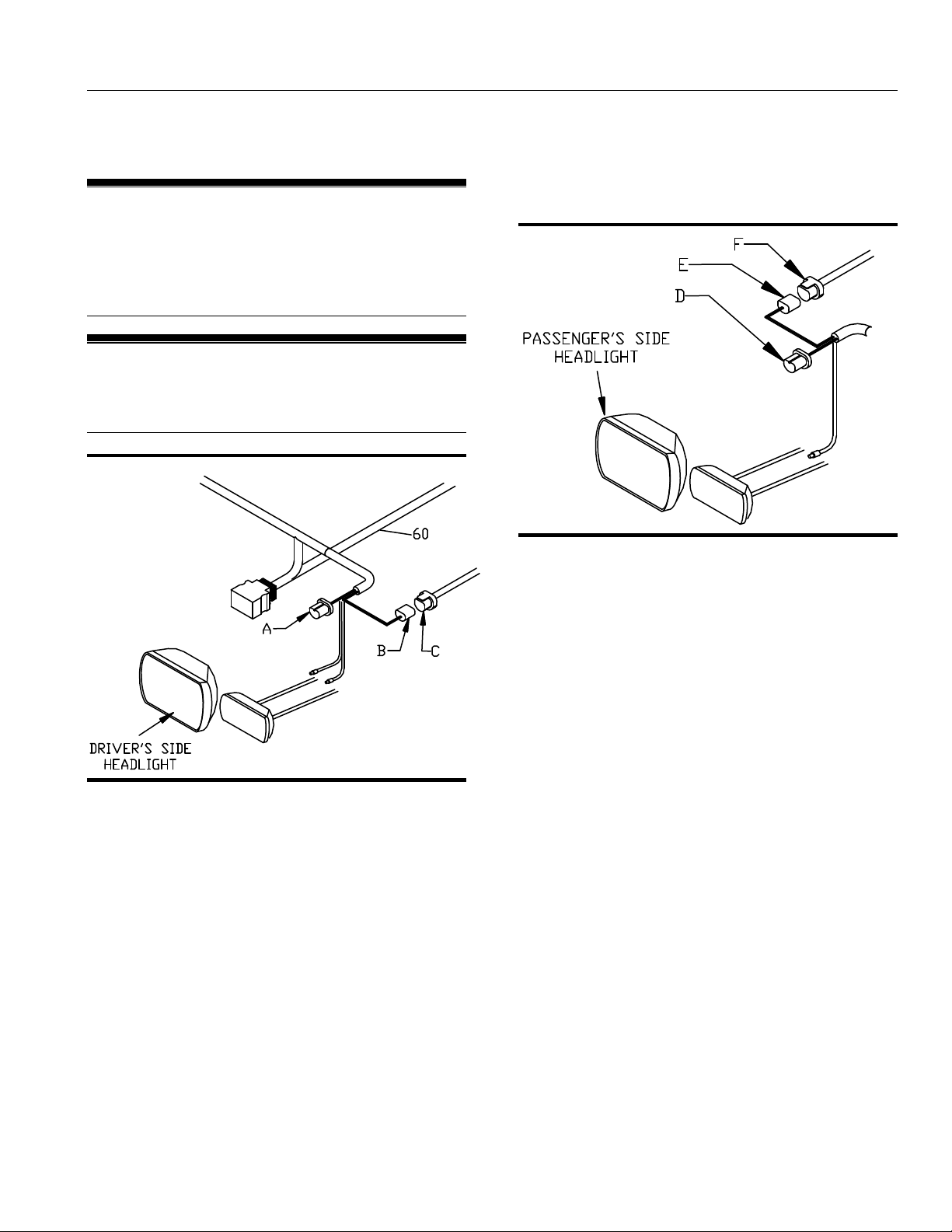

Figure 13. Driver’s Side Headlight G10140

N te: Dielectric grease should be applied to all

electrical connections.

1. Disconnect the driver’s side headlight connector

plug C) from the back of the driver’s side vehicle

headlight.

2. Connect the Blue Sealed Beam Connector A)

from Wiring Harness 60) into the back of the

driver’s side vehicle headlight.

3. Connect the Black Rubber Connector B) from

Wiring Harness 60) into the OEM Wiring Harness

C). OEM Wiring Harness C) is the vehicle

connector that was unplugged from the back of

the headlight in Step 1.

N te: If your connectors do not match the connectors

on the wiring harness or you have a four-headlight

system a Headlight Adapter Kit will be needed. If you

are installing a Headlight Adapter Kit, See “Headlight

Adapter Installation Procedure” located in this manual.

Figure 14. Passenger’s Side Headlight G10141

4. Disconnect the passenger’s side OEM Wiring

Harness F) from the back of the passenger’s side

vehicle headlight.

5. Connect the Blue Sealed Beam Connector D)

from Wiring Harness 60) into the back of the

passenger’s side vehicle headlight.

6. Connect the Black Rubber Connector E) from

Wiring Harness 60) into the OEM Wiring Harness

F). OEM Wiring Harness F) is the vehicle

connector that was unplugged from the back of

the headlight in Step 4.

Electrical System Wiring Procedure

10

Figure 15. Connecting Park and Turn G10143

N te: Some trucks require a turn signal relay kit.

7. Connect the PINK wire from Wiring Harness 60)

to the passenger’s side turn signal wire. Use the

splice connector provided to you in the hardware

kit.

8. Connect the VIOLET wire from Wiring Harness

60) to the driver’s side turn signal wire. Use the

splice connector provided to you in the hardware

kit.

9. Connect the YELLOW wire from Wiring Harness

60) to the driver’s side park light wire. Use the

splice connector provided to you in the hardware

kit.

N te: Be sure that the firewall is clear of obstructions

before drilling in Step 10.

10. Drill a 1-1/4" diameter hole through the firewall.

The hole should be located on the driver’s side, in

an easily accessible area.

Figure 16. Internal Cab Wires G10144

11. Pull the two BLACK wires H), BLACK/RED wire

I), and the 9 Pin Molex connector G) from the

engine compartment into the cab through the

1-1/4” diameter hole in the firewall.

12. Install MSC03761 Split Rubber Grommet Not

Shown) into the hole that was cut in the firewall.

13. Connect the Two Tab Connectors H) to

MSC04747 Headlight Toggle Switch 77A) as

illustrated in the figure above.

14. Choose an area of the vehicle’s dashboard for the

light toggle switch to be mounted. Clean the area

thoroughly. Allow the area to dry completely.

15. Remove the adhesive backing and apply the

switch to the clean area of the dashboard. Apply

pressure for 30 seconds.

NOTICE

Before splicing into any electrical circuit, identify

the circuit with a test lamp. Failure to test circuits

may result in vehicle damage.

NOTICE

Position the switch where it will not interfere

with driver’s ability to see and where it will not

affect the driver’s ability to operate the motor

vehicle.

Electrical System Wiring Procedure

11

16. Secure the 9 Pin Molex Connector G) and wire

loom underneath the dashboard.

17. Plug the controller into the 9 Pin Molex Connector

G).

18. Mount the plow control in a location that is

comfortable for the operator to reach, and where

the operator will not contact the control in the

event of a crash. See “V-Blade Controller

Mounting Instructions” located in this manual.)

19. Connect the BLACK/RED wire I) to a “keyed”

12V+ ignition source.

N te: This 12V+ source should only be active when

the key is in the ON position. Failure to wire to a

“keyed” source can allow a condition to occur causing

the battery to drain.

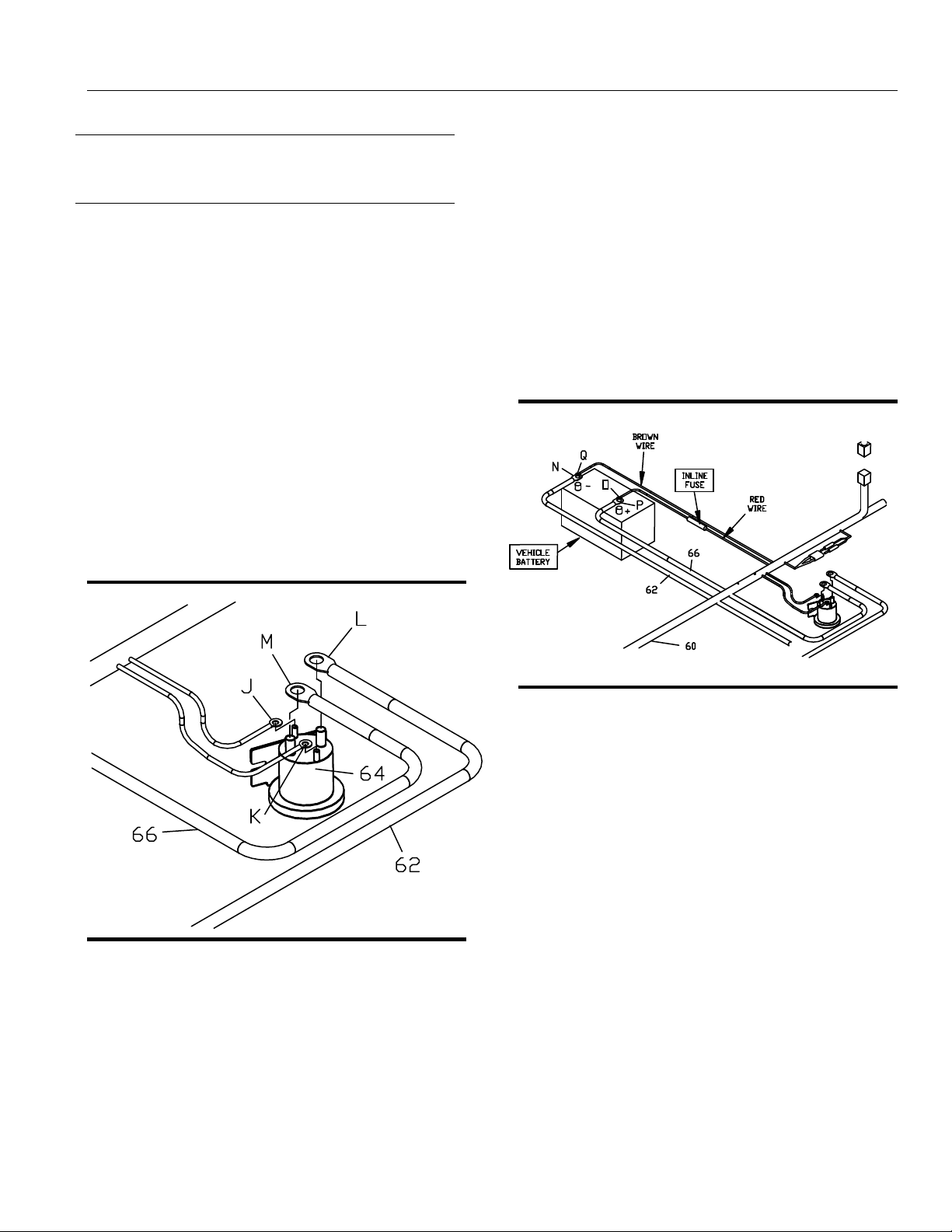

Figure 17. Solenoid Connections. G10145

20. Connect the WHITE/BLACK wire J) of Wiring

Harness 60) to the small terminal on Pump

Solenoid 64).

21. Connect the BROWN wire K) of Wiring Harness

60) to the small terminal on Pump Solenoid 64).

N te: Location of the wires on the small terminals

does not matter.

22. Attach Power Unit Solenoid 64) securely inside

the engine compartment. The Power Unit

Solenoid should be mounted in the upright

position as illustrated above.

N te: The solenoid must be installed so that the

solenoid posts do not contact the body, hood, or any

other conductive material on the vehicle.

23. Attach the eyelet end of RED Power/Ground

Cable 62) to the top of Pump Solenoid 64).

24. Connect Battery Cable 66) to the top post of

Pump Solenoid 64).

Figure 18. Battery Connections G10146

25. Attach the eyelet end N) of BLACK

Power/Ground Cable 62) to the negative battery

terminal.

26. Connect the BROWN wire Q) to the negative

battery terminal.

27. Connect the unattached end P) of Battery Cable

66) to the positive battery terminal.

28. Connect the RED Fused wire O) to the positive

battery terminal.

NOTICE

Be sure the wire loom does not interfere with the

operation of the vehicle’s pedals.

Electrical System Wiring Procedure

12

Figure 19. Vehicle Connections G10148

29. Mount the Black 15 Pin Control Harness

Connector to the lower area of the bumper using

MSC03813 Control Harness Mounting Bracket.

30. Mount the BLACK and RED 2 Pin Power Ground

Connector to the lower area of the bumper using

MSC03491 Power Ground Mounting Bracket.

N te: Installation location will vary depending on

truck.

Figure 20. Relay Mounting. G10152

31. Attach the Relay Pack securely to the inside of the

engine compartment using four HDW01766 Sheet

Metal Screws. The relays should be positioned

upright as illustrated above.

Electrical System Wiring Procedure

13

Figure 21. Vehicle Option Connector G10202

NOTICE

All plow wiring should be secured within the

engine compartment in a position that provides

sufficient room so that hot or moving parts will

not be contacted. Vehicle damage could occur if

wires are not properly secured.

32. Locate vehicle option connector. Align the

connector so that the arrow on the Vehicle Option

Connector is positioned to match the vehicle it is

installed on. This is illustrated in Figure 21.

N te: If your vehicle is not listed in the above figure

use the Standard Orientation. If the Vehicle Option

Connector is not properly connected the lights on the

plow will not function correctly.

33. Secure all plow harness wiring.

34. Attach the snowplow to the vehicle. Use the

“Snowplow Mounting Procedure” that is located in

this manual to properly attach the snowplow to the

vehicle.

35. Test for the proper operation of the Headlight

Wiring Harness. Follow the procedures below.

N te: To test plow lights, the IGNITION must be in

the ON position.

• LOW BEAM (Truck Lights)

♦ Vehicle Headlight Switch – ON

♦ Low Beam Lights on Truck Indicator

♦ Plow Headlight Toggle Switch –TRUCK

RESULTS - ONLY vehicle low beam headlights should be illuminated.

• HIGH BEAM (Truck Lights)

♦ Vehicle Headlight Switch – ON

♦ High Beam Indicator Light – ON

♦ Plow Headlight Toggle Switch –TRUCK

RESULTS - Only vehicle high beam headlights should be illuminated.

• LOW BEAM (Plow Lights)

♦ Ignition - ON

♦ Vehicle Headlight Switch – ON

♦ Low Beam Lights on Truck Indicator

♦ Plow Headlight Toggle Switch - PLOW

RESULTS - ONLY plow low beam headlights should be illuminated.

• HIGH BEAM (Plow Lights)

♦ Ignition - ON

♦ Vehicle Headlight Switch – ON

♦ High Beam Indicator Light – ON

♦ Plow Headlight Toggle Switch – PLOW

RESULTS - Only plow high beam headlights should be illuminated.

• TURN SIGNALS (Plow nd Truck)

♦ Left Turn Signal Indicator – ON

RESULTS - Both Left Plow and Left Truck turn signal bulbs should

be flashing.

♦ Right Turn Signal Indicator – ON

RESULTS - Both Right Plow and Right Truck turn signal bulbs

should be flashing.

• P rk Lights (Plow nd Truck)

♦ Park Lights on Vehicle – ON

RESULTS - All four, Left Plow, Right Plow, Left Truck, and Right

Truck Park Lights should be on.

N te: If any of the lights are not working properly, re-

check the wiring against the “Electrical Wiring

Diagram” located in this manual and make any

necessary corrections.

Headlight Adapter Installation Procedure

14

Headlight Adapter Installati n

Pr cedure

Figure 22. Single Headlight Adapter Connections G10149

N te: This is a general diagram for most 2-headlight

vehicles. All vehicles and headlight adapters may not

be identical. Installation will be very similar.

1. Disconnect the OEM Headlight Connector Plug

A) from the back of the vehicle headlight.

2. Connect one end of Headlight Adapter 73A) into

the back of the vehicle headlight.

3. Connect the Black Rubber Female Socket B) of

Headlight Adapter 73A) into the plow wiring

harness.

4. Connect the Blue Sealed Beam Connector C) of

Headlight Adapter 73B) into the plow wiring

harness.

5. Connect the opposite end of Headlight Adapter

73B) into the OEM Headlight Connector Plug A).

6. Repeat Steps 1 through 5 for the opposite side

headlight.

N te: In some older vehicles it is not necessary to

pull power from both sides of the headlights. In this

case only three adapters will be needed. Follow the

Headlight Adapter Installation Instructions that are

packaged with the Headlight Adapter Kit.

7. Continue with the Step 7 of “Electrical System

Wiring Procedure” located in this manual.

Figure 23. Dual Headlight Adapter Connections G10151

N te: This is a general diagram for most 4-headlight

vehicles. All vehicles and headlight adapters may not

be identical. Installation will be very similar.

1. Disconnect OEM Headlight Connector Plugs A

and D) from the back of the vehicle headlight.

2. Connect two ends of Headlight Adapter 73A) into

the back of the vehicle headlights.

3. Connect the Black Rubber Female Socket B) of

Headlight Adapter 73A) into the plow wiring

harness.

4. Connect the Blue Sealed Beam Connector C) of

Headlight Adapter 73B) into the plow wiring

harness.

5. Connect the opposite end of Headlight Adapter

73B) into the OEM Wiring Harness A).

6. Grease, tuck, and secure OEM Connector Plug

D). This connector is not used.

7. Repeat Steps 1 through 6 for the opposite side

headlight.

8. Continue with the Step 7 of “Electrical System

Wiring Procedure” located in this manual.

Electrical System Wiring Schematic (Plow Side)

15

Figure 24. Electrical System Wiring Schematic Plow Side) G10271

Electrical System Wiring Schematic (Truck Side)

16

Figure 25. Electrical System Wiring Schematic Truck Side) G10272

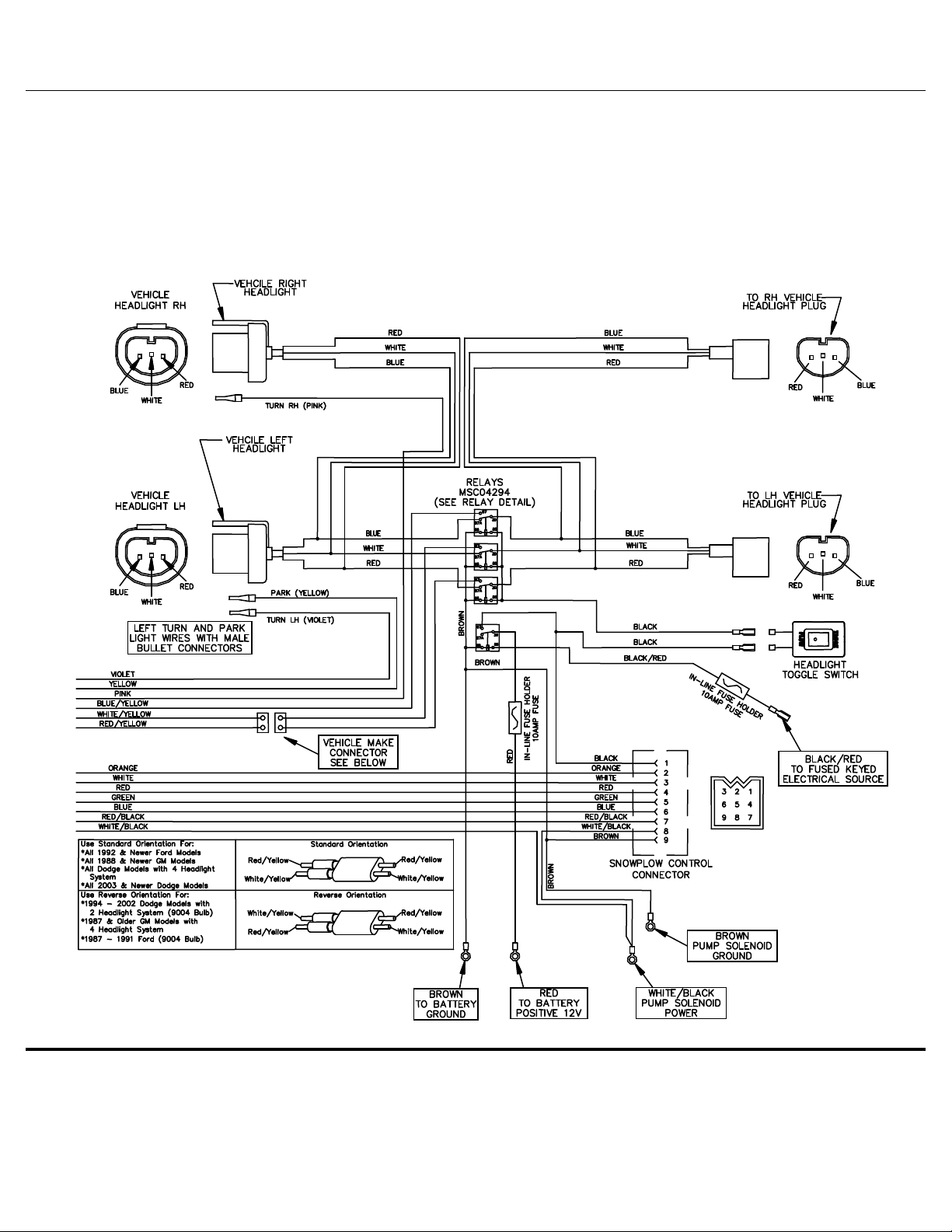

Electrical System Wiring Diagram

17

Figure 26. Electrical System Wiring Diagram G10134

SmartHitch 2

TM

Wiring Diagram

18

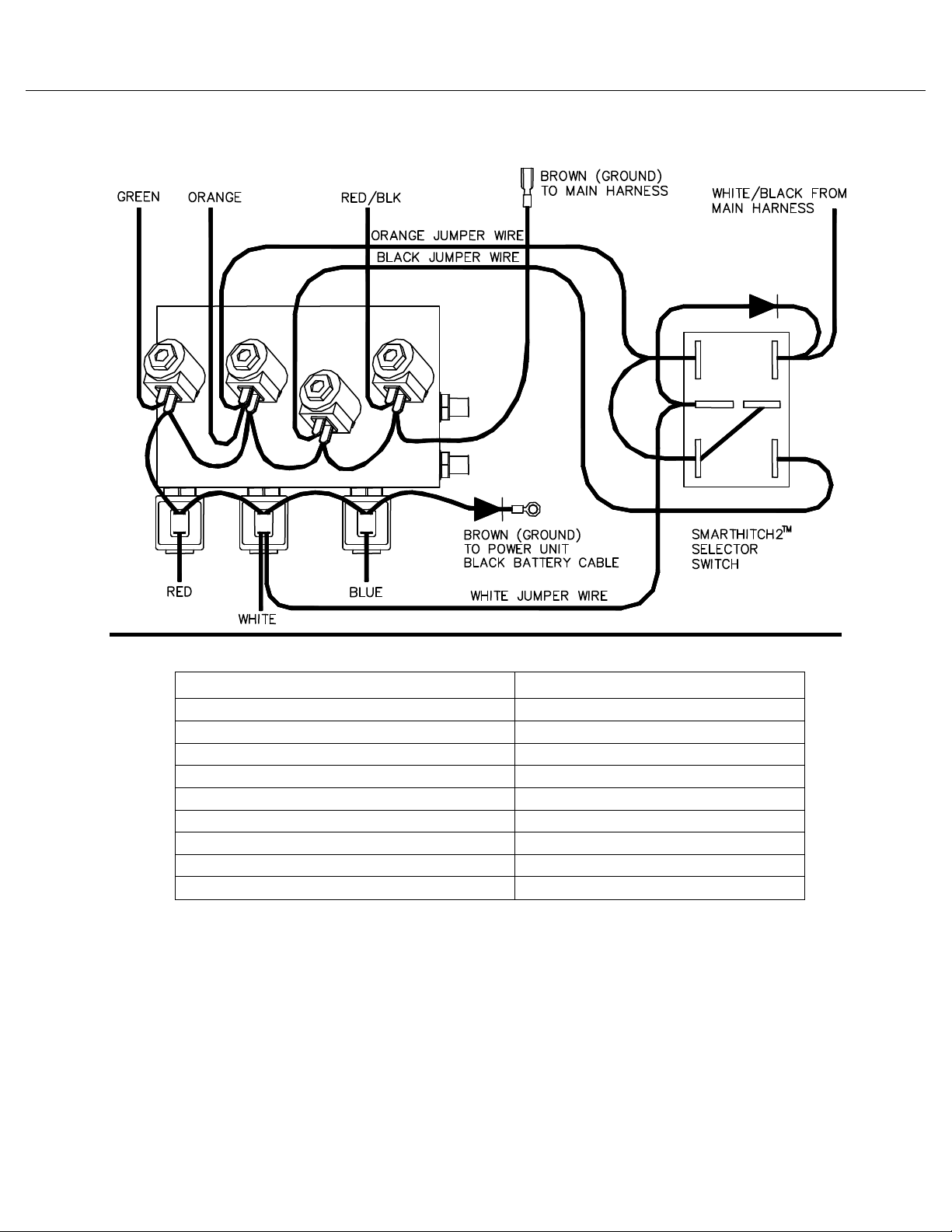

Figure 27. HYD07044 with SmartHitch2

TM

Wiring Diagram G10445

Wire C l r Wire Functi n

Green Right Wing In

Red Right Wing Out

White Lift

Orange Lower

Red/Black Left Wing In

Blue Left Wing Out

Black SmartHitch2

TM

12V)

White/Black Pump Solenoid

Brown Ground

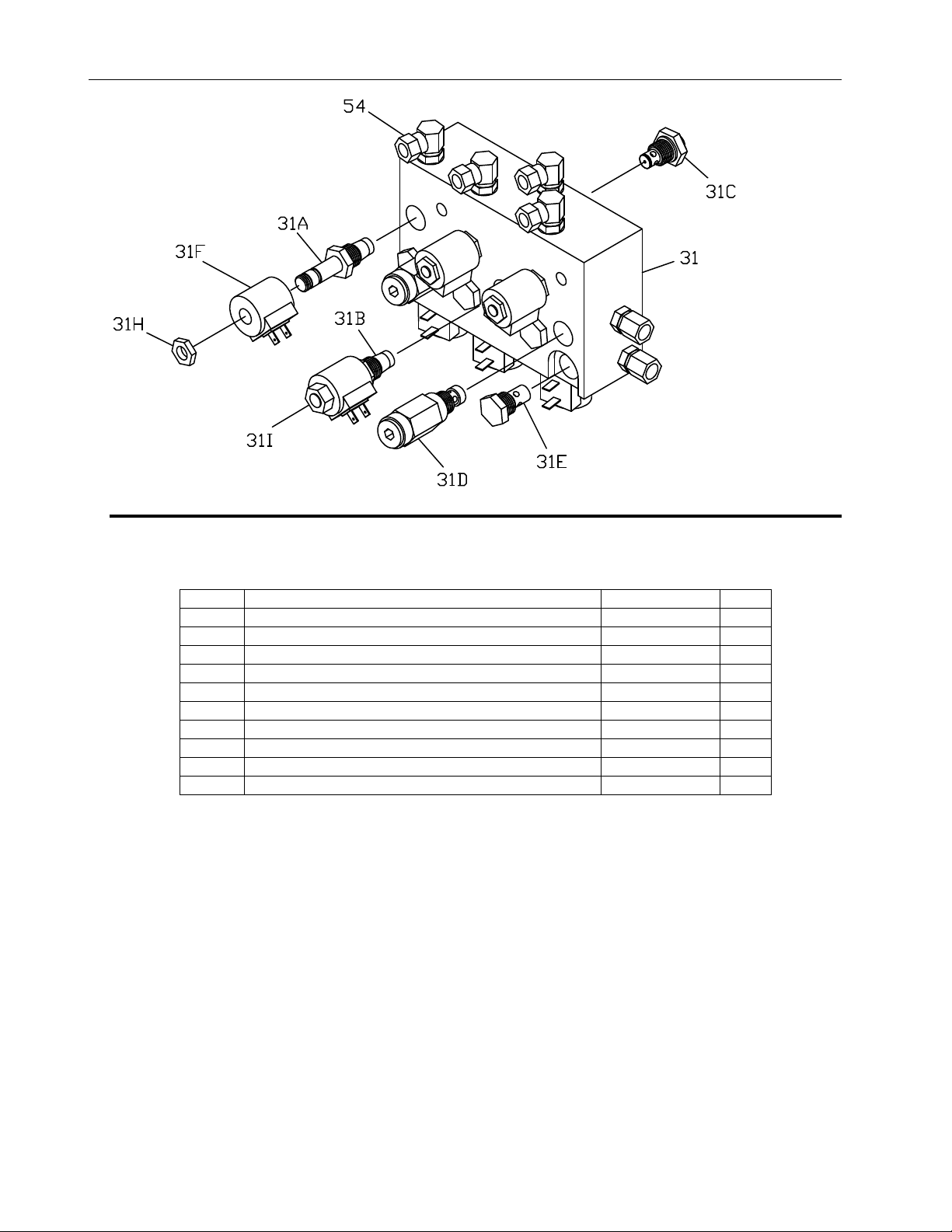

Hydraulic Valve Assem ly Parts List

19

Figure 28. Hydraulic Valve Manifold Assembly.

G10000

Ref. Descripti n Part Number Qty

31 Valve Manifold, RT3 V-Blade w/ SmartHitch2

TM

HYD07044 1

31A Valve, Lift / Angle HYD01637 6

31B Valve, SmartHitch2

TM

Attach HYD07047 1

31C Valve, Flow Control HYD07048 1

31D Valve, Relief V-Blade 2800psi) HYD01639 2

31E Valve, Check HYD01640 4

31F Valve Coil HYD01638 7

31H Coil Nut HYD07059 6

31I Coil Nut SmartHitch2

TM

Valve) HYD07060 1

54 Hydraulic Swivel Fitting HYD01620 4

RT3 Headlight Aiming Pr cedure

20

Headlight Aiming

Pr cedure

NOTICE

The installer of these snowplow lights must

certify that installation conforms to applicable

Federal otor Vehicle Safety Standards.

1) Place the vehicle on a level surface 25 feet in

front of a matte-white screen, such as a garage

door. The screen should be perpendicular to both

the ground and the vehicle.

2) The vehicle should be equipped for normal

operation. The snowplow blade should be in place

and in the raised position.

3) Below are some points listed by the Society of

Automotive engineers SAE) pertinent to headlight

aiming. These points can be found in publication

#SAEJ5991D.

Preparation for Headlight Aim or Inspection

Before checking beam aim, the inspector shall:

• Remove ice or mud from under fenders.

• See that no tire is noticeably deflated.

• Check vehicle springs for sag or broken

leaves.

• See that there is no load in the vehicle other

than the driver.

• Check functioning of any “level-ride” controls.

• Clean lenses and aiming pads.

• Check for bulb burnout, broken mechanical

aiming pads, and proper beam switching.

• Stabilize suspension by rocking vehicle

sideways.

4) Mark or tape) the vehicle centerline of the

headlights and the vehicle itself on the screen.

Mark the horizontal centerline of the headlights on

the screen distance from ground to headlight

centers).

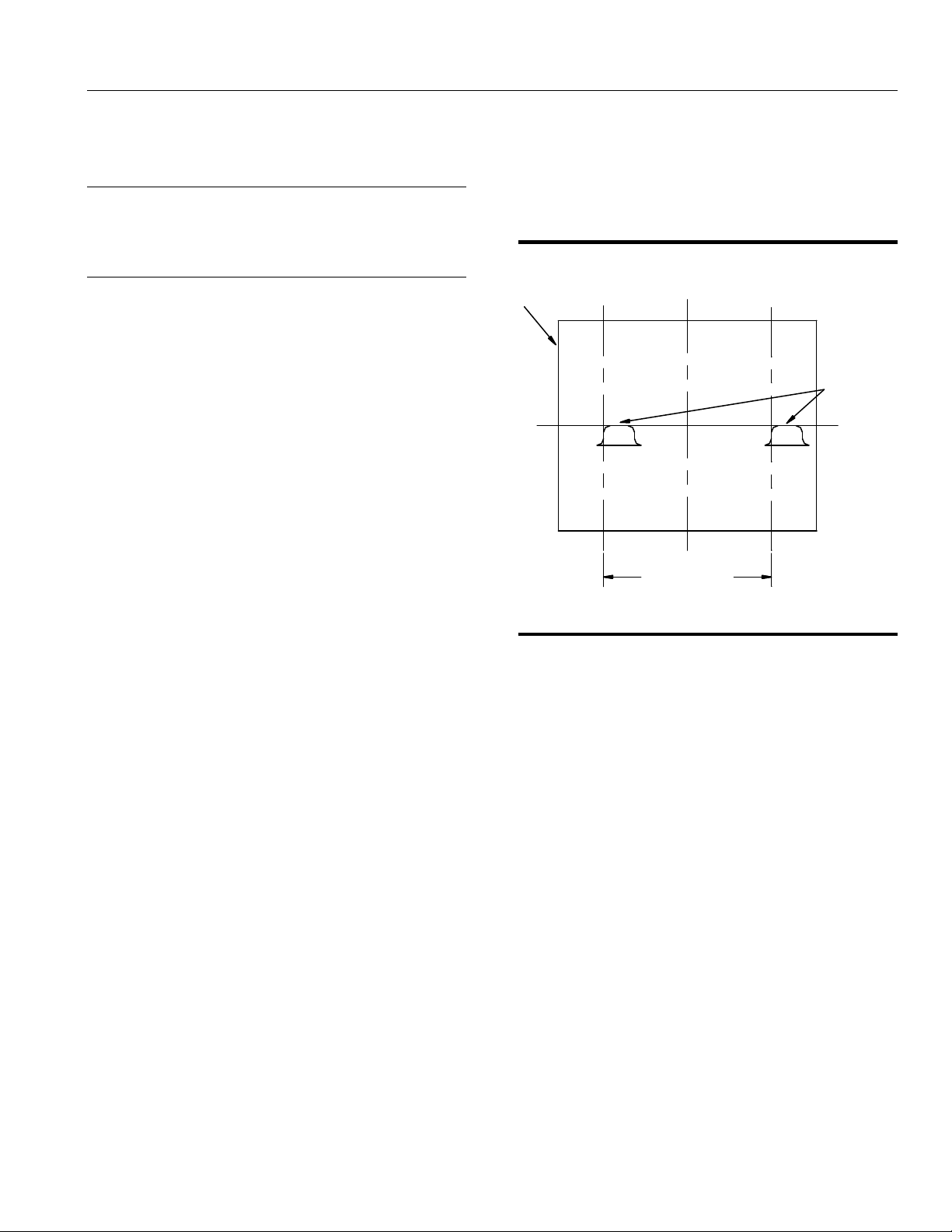

Figure 29. Headlight Aiming Procedure G10153

5) The correct visual aim for Type 2 headlights is

with the top edge of the high intensity zone of the

lower beam below the horizontal centerline and

the left edge of the high intensity zone on the

vertical centerline. See diagram above.

25' From Headlights

Screen Located

Align With Vehicle

Centerline

of Right Headlight

Vertical Centerline Ahead

High Intensity Zones

For Type 2 (Sealed Beam)

Headlights on Low Beam

Headlight Centers

Distance Between

Table of contents

Other BOSSCO Snow Blower manuals

Popular Snow Blower manuals by other brands

EINHELL

EINHELL BSF 55 operating instructions

Western

Western UltraMount MIDWEIGHT installation instructions

Toro

Toro Flex-Force Power System 31853 Operator's manual

Ariens

Ariens Sno-Thro 920021 compact 24 Operator's manual

Buhler

Buhler Farm king FK311 owner's manual

Simplicity

Simplicity 869 owner's manual