BOSSCO Snowrator MAG User manual

FormNo.MSC23901RevA

Owner'sManual

48inSnowthrowerKit

SnowratorMAG

PartNo.STX24410—SerialNo.400000000andUp

Registeratwww.bossplow.com.

OriginalInstructions(EN)*MSC23901*

BOSSProductslimitedconsumerwarrantyandBOSS

Productscommercialwarrantypoliciesarelocatedat

www.bossplow.com.

Patentswww.ttcopats.com.

Introduction

Note:ThissnowthowerattachestotheSnowrator

MAG.

ThesnowthrowerisintendedtobeusedonaBOSS

stand-on,multi-purposemachine.Thisattachmentis

usedtoremovesnowfrompavedorgravelsurfaces,

suchasdrivewaysandsidewalks,andothersurfaces

fortrafconresidentialorcommercialproperties.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.bossplow.comforproductsafetyand

operationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineBOSSparts,or

additionalinformation,contactanAuthorizedBOSS

DealerorBOSST echnicalService(1-800-286-4155)

andhavethemodelandserialnumbersofyour

productready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethe

numbersinthespaceprovided.

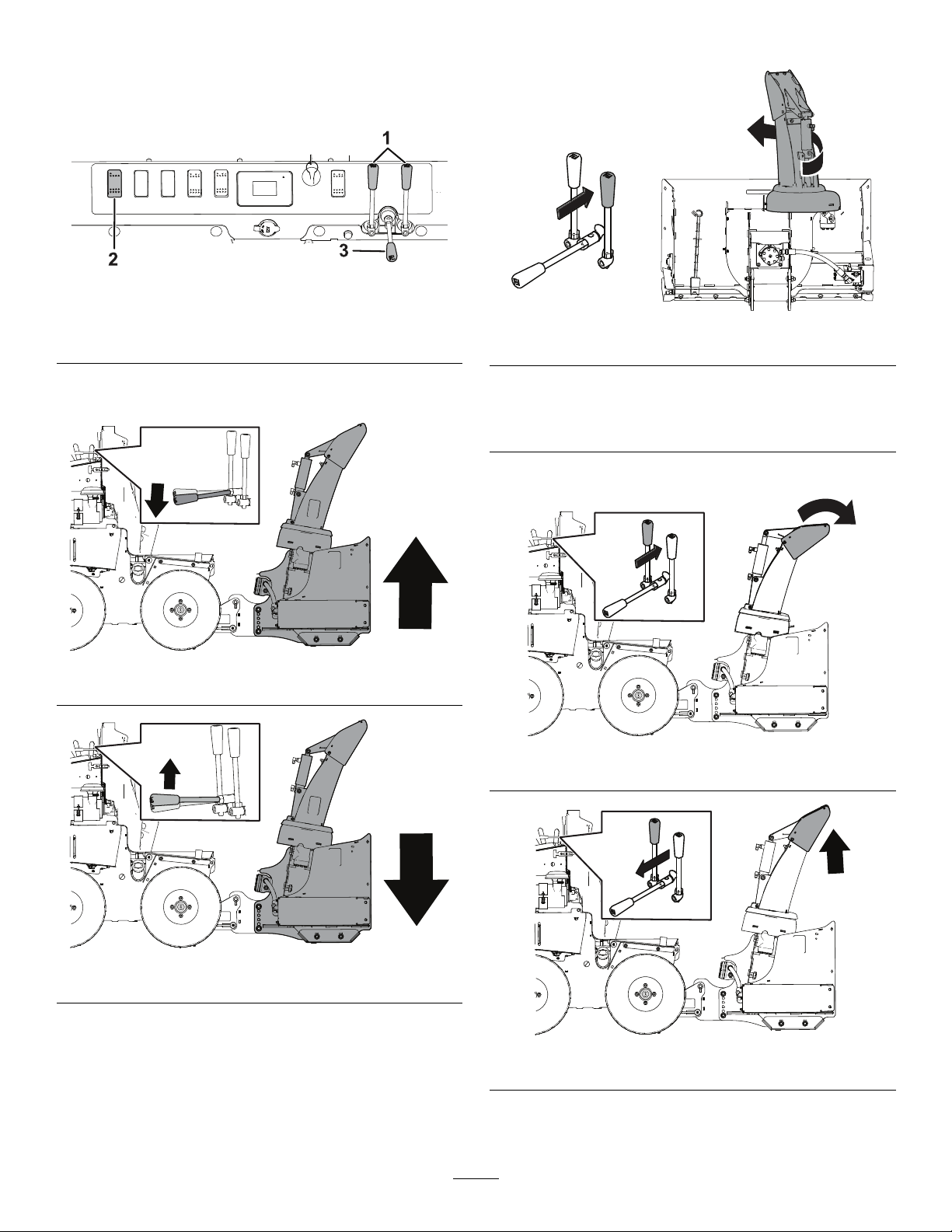

g383239

Figure1

1.Modelandserialnumberlocation

Date

Purchased

ModelNo.

SerialNo.

BladeCrate

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2022—BOSSProducts

P .O.Box787

IronMountain,MI498012

Contactusatwww.bossplow.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

Preparation.........................................................3

Operation............................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

MountingtheAttachment....................................5

RoutingtheHydraulicHoses..............................6

ProductOverview.....................................................9

Controls.............................................................9

Operation................................................................10

OperatingtheSnowthrower..............................10

RemovingtheAttachment................................10

OperatingTips..................................................11

Maintenance...........................................................12

RecommendedMaintenanceSchedule(s)...........12

.........................................................................12

Maintenance........................................................12

CheckingtheChainTension.............................12

OilingtheChain................................................12

ReplacingtheCuttingEdge..............................13

GreasingtheAttachment..................................13

AdjustingtheSkids...........................................13

Storage...................................................................15

StoringtheAttachment.....................................15

RemovingtheAttachmentfromStorage...........15

Troubleshooting......................................................16

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol,whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Preparation

•ReadtheOwner’sManualbeforeoperatingor

servicingtheattachment.

•Ensurethatonlytrainedpersonnelinstallsand

performsmaintenanceontheequipmentand

hydrauliccomponents.

•Alwayswearappropriatepersonalprotective

equipmentwhenloading,unloading,andservicing

theattachment.

Operation

•Usea500kg(1/2ton)minimumliftingdeviceto

moveheavycomponents.

•Donotexceed8km/h(5mph)whileoperating.

•Neverputanypartofyourbodybetweenthe

attachmentandthevehicle.

•Wearappropriateclothing,includinghearingand

eyeprotection,protectivegloves,andsubstantial,

slip-resistantfootwear.Tiebacklonghair,secure

looseclothing,anddonotwearloosejewelry.

•Whentransportingthemachine,ensurethatitis

properlysecured.Instructionsareavailableat

www.bossplow.com.

•Whentransportingthevehicle,positionthe

attachmentsothatitdoesnotblockyourvision

orheadlights.

•Alwayslowertheattachmentwhenthevehicleis

notinuse.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•RefertotheOwner’sManualforproperparking

procedures.

•Turnthevehicleandattachmentoffbeforelling,

servicing,orcleaningit.

•Donotclimbintoorrideontheattachment.

•Keepyourhands,feet,andclothingawayfrom

movingpartsandmountingpoints.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

3

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatetheattachmentnearbystanders.

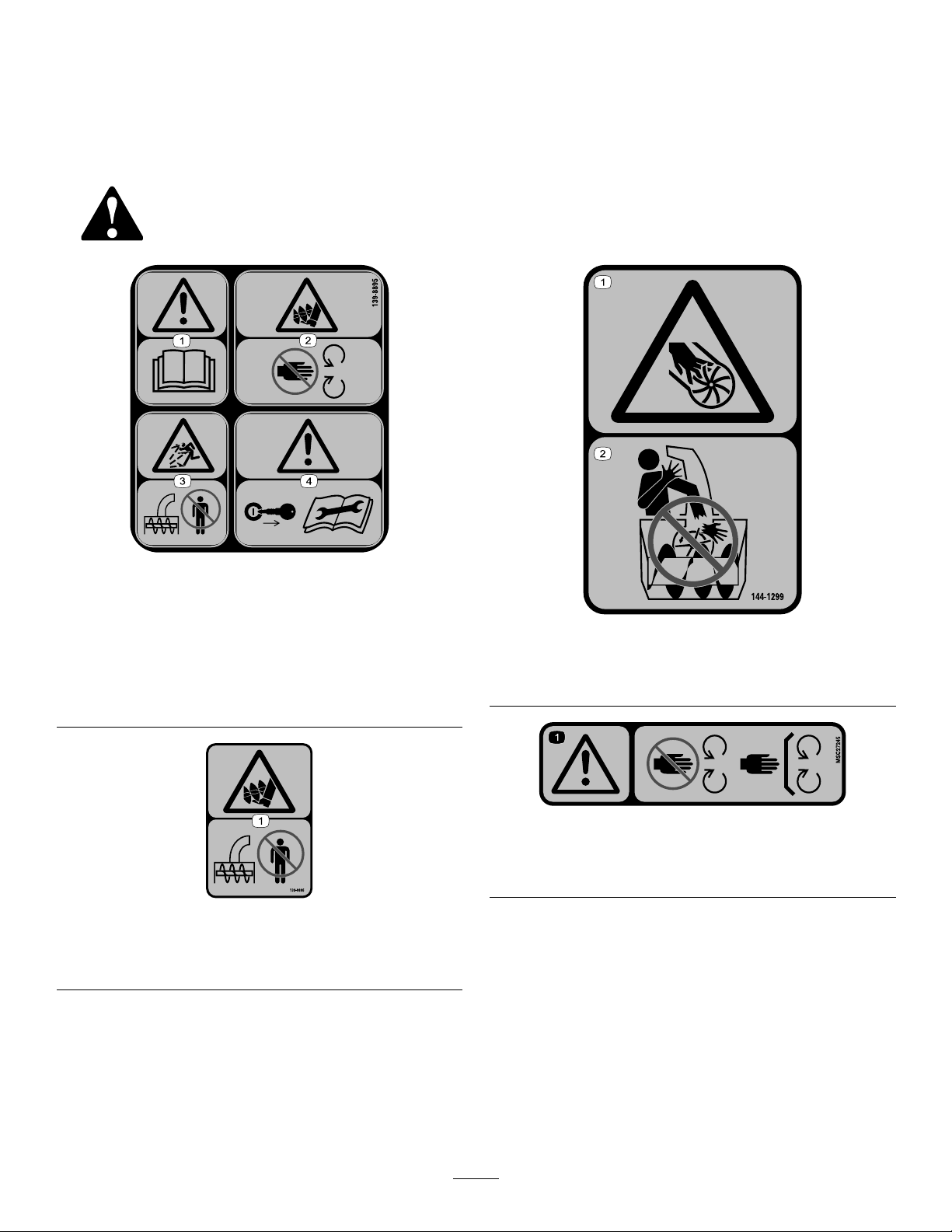

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal139-8895

139-8895

1.Warning—readthe

Operator’sManual.

3.Thrownobject

hazard—keepbystanders

away.

2.Cutting/dismemberment

hazardoffoot,

auger—stayawayfrom

movingparts.

4.Warning—removethekey

fromtheignitionbefore

servicingthemachine.

decal139-8896

139-8896

1.Cutting/dismembermenthazardoffoot,auger—keep

bystandersaway.

decal144-1299

144-1299

1.Cutting/dismemberment

hazardofhand;impeller

2.Donotplaceyourhandin

thechute.

decalmsc27245

MSC27245

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace

4

Setup

MountingtheAttachment

1.Parkthemachineonalevelsurface.

2.Pullthecouplerpinsoutwardandrotate90°to

lockinthedisengagedposition.

g373475

Figure3

3.Makesurethatthehydraulichosesdonotblock

theattachmentpoint.

4.Startthemachine.

5.Slowlydriveforwarduntilthecouplermeetsthe

attachmenthooks.Raisethecouplertohook

itontotheattachment.

g383235

Figure4

6.Rotatethecouplerpin90°sothatitengages

withtheattachmentassembly.

Note:Ensurethatthecouplerpinalsoinserts

throughtheholeinthepinchannelonthe

coupler.

g373477

Figure5

7.Lowertheattachmentcoupleruntilthe

attachmentrestsontheground.

5

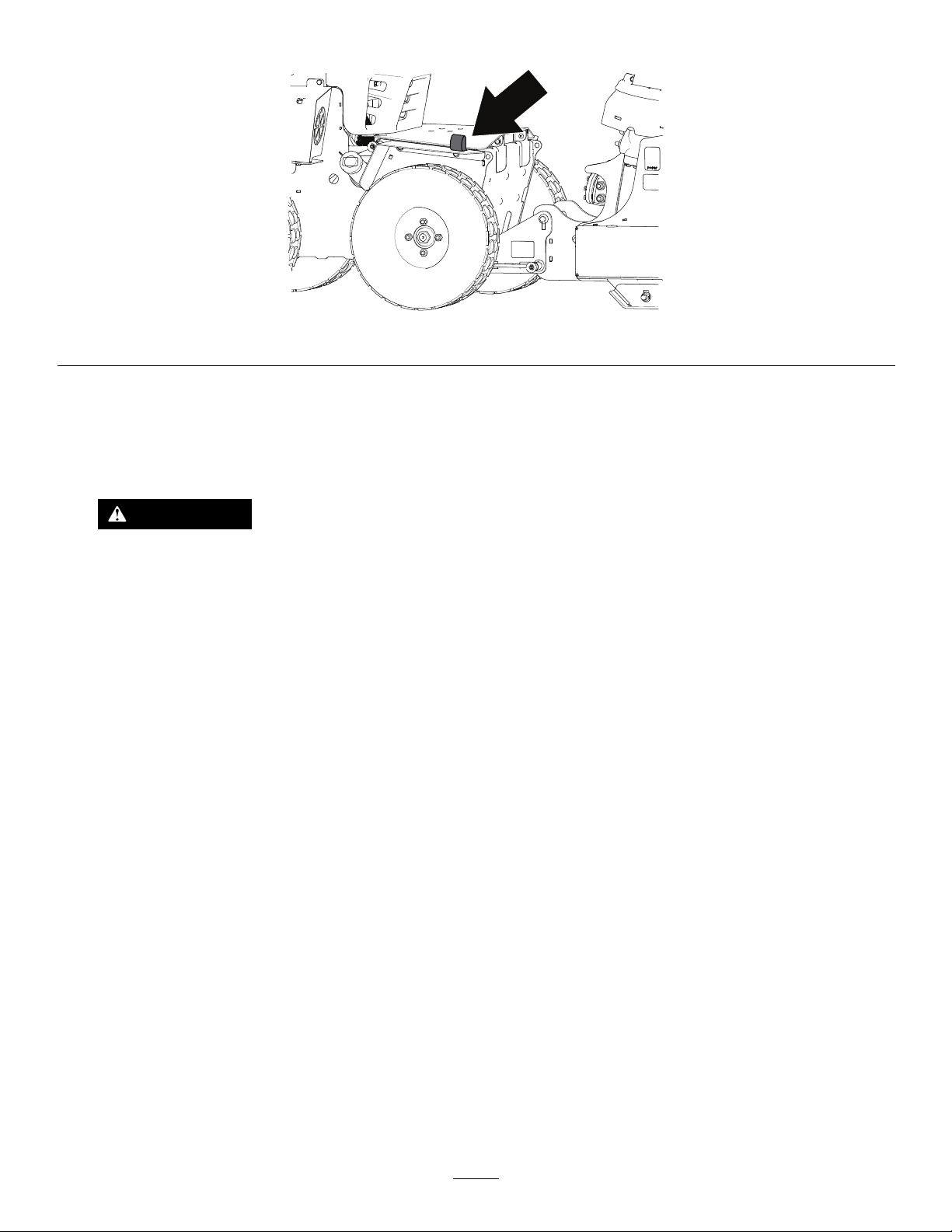

RoutingtheHydraulicHoses

1.Shutoffthemachineengine,waitforallmovingpartstostop,ensurethattheparkingbrakeisengaged,

andremovethekey.

2.Routethehydraulichoses.

Note:Whenchangingattachmentsonthemachineyoumayneedtorelievestoredhydraulicpressureby

slightlylooseninghydrauliclinesonthesnowthrowerorwigglethejoysticksonmachine.

g383236

Figure6

6

g383237

Figure7

g383238

Figure8

7

3.Gatherthehosesandsecuretheminthehosestraponthemachine.

g385655

Figure9

4.Startthemachine.

5.Usethecontrolstomovetheattachmentinalldirectionstocyclethehydraulicuid.

6.Lowertheattachmentandshutoffthemachine.

7.Checkandllthehydraulicuid;refertothemachineOwnersManual.

WARNING

Hydraulicuidescapingunderpressurecanpenetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskin,itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistypeofinjury.Gangrenemayresultifthisisnot

done.

•Keepyourbodyandhandsawayfrompinholeleaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystembeforeperforminganyworkonthe

hydraulicsystem.

•Makesurethatallhydraulic-uidhosesareingoodcondition,andallthatthehydraulic

connectionsandttingsaretightbeforeapplyingpressuretothehydraulicsystem.

8

ProductOverview

Controls

g383364

Figure10

1.Anglelevers3.Attachmentcouplerlever

2.Engagetheattachment

•Usetheattachmentcouplerlevertoraiseorlower

theattachment.

g383344

Figure11

g383342

Figure12

•Usetherightanglelevertorotatethechute.

g383346

Figure13

g383347

Figure14

•Usetheleftanglelevertomovethechutedeector.

g383343

Figure15

g383345

Figure16

9

Operation

OperatingtheSnowthrower

Important:Raisethesnowthrowerwhen

transportingit.

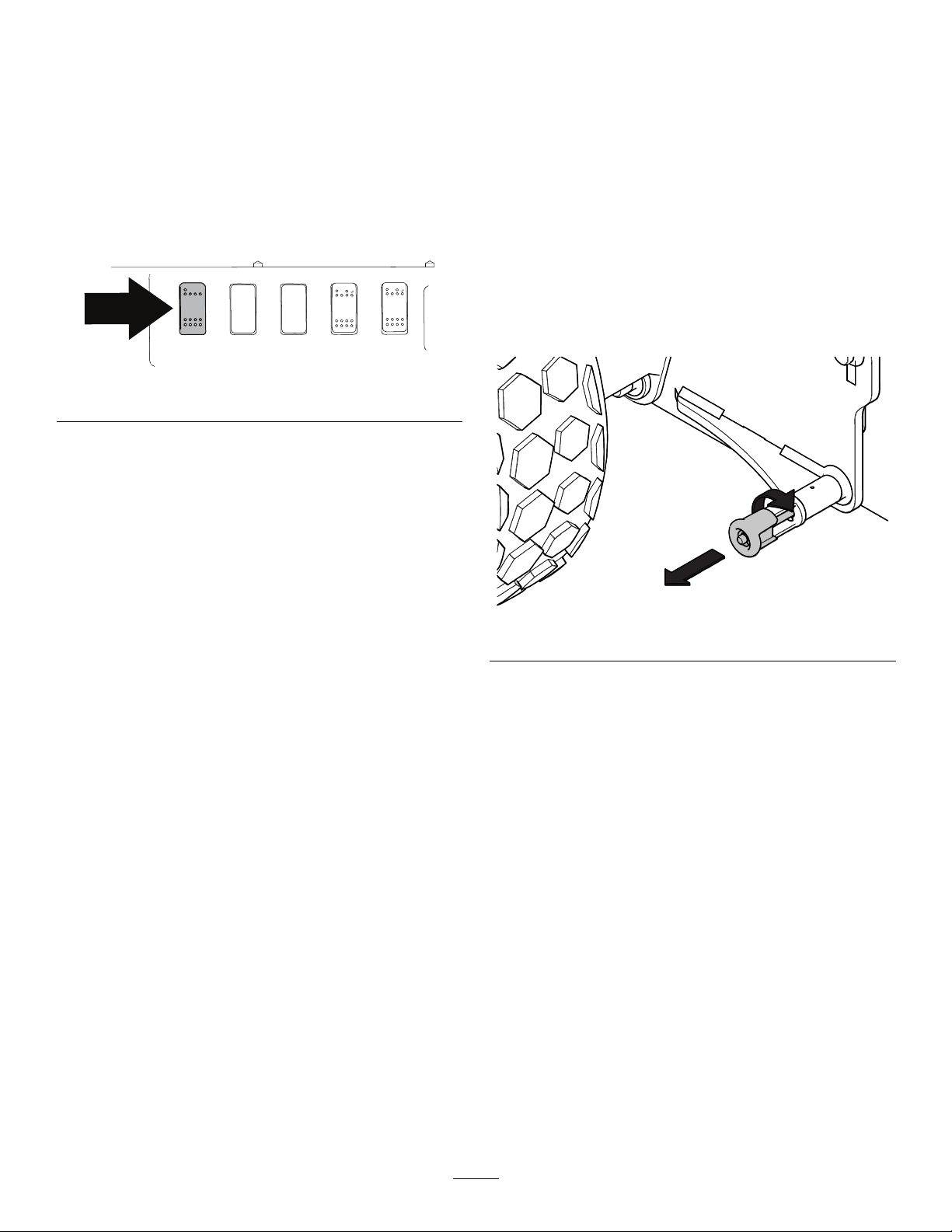

1.Startthemachine.

2.Pushthetopofthehighowengageswitchto

spinthebladesintheforwardposition.

g383377

Figure17

Note:Thebladesshouldspincounterclockwise

whenviewedfromtheleftsidefromthe

operatingposition.Ifthebladesspininthe

wrongdirection,switchthecouplersonthe

hydraulichosesconnectedtothehighow

hydraulicports.

Note:Toassistinremovingaclog,pushthe

bottomofthehighowengageswitchtospin

thebladesinreverse.

RemovingtheAttachment

1.Stopmachineonalevelsurface.

2.Lowertheattachmentuntiltheedgeis1-2

inchesfromtheground.

3.Shutofftheengine,waitforallmovingpartsto

stop,engagetheparkingbrake,andremove

thekey.

Note:Ifyouareremovingtheattachmentfor

storage,allowthemachinetowarmtotheindoor

temperaturebeforeshuttingofftheengine.

4.Disconnectthehydraulics.

5.Pullthecouplerpinsandturnit90°untilthe

attachmentisdisconnectedfromthemachine.

g373484

Figure18

6.Startmachine,lowerattachmentcoupler,and

slowlybackawayfromtheattachment.

7.Arrangethehydraulichosesanddisconnectsso

thattheyarenotrestingontheground.

Note:Wrapthehosestogetherandstickthem

downthechuteforstorage.

10

OperatingTips

•Becomefamiliarwiththeareayouareoperating

theattachment;hiddenobstructionssuchas

curbsandpipescandamageyourattachmentor

machine.

•Lowertheattachmentwhennotinusetoprevent

possibleinjury.

•Alwaysoperatethemachineatasafespeedin

caseyouhithiddenobstructions.

•Whentransportingthemachine,donotblockyour

visionwiththeattachment.

•Thesnowthowerwillcleanbetterwhenthelift

valveisintheoatposition.

•Machinetractionisimprovedwhentheattachment

isliftedslightlyorifitisnotintheoatposition.

•Loosentheskids,putthemachineinoat,then

tightentheskidstogetthemaximumscraping

performance.

•Formoretips,visitwww.bossplow.com.

11

Maintenance

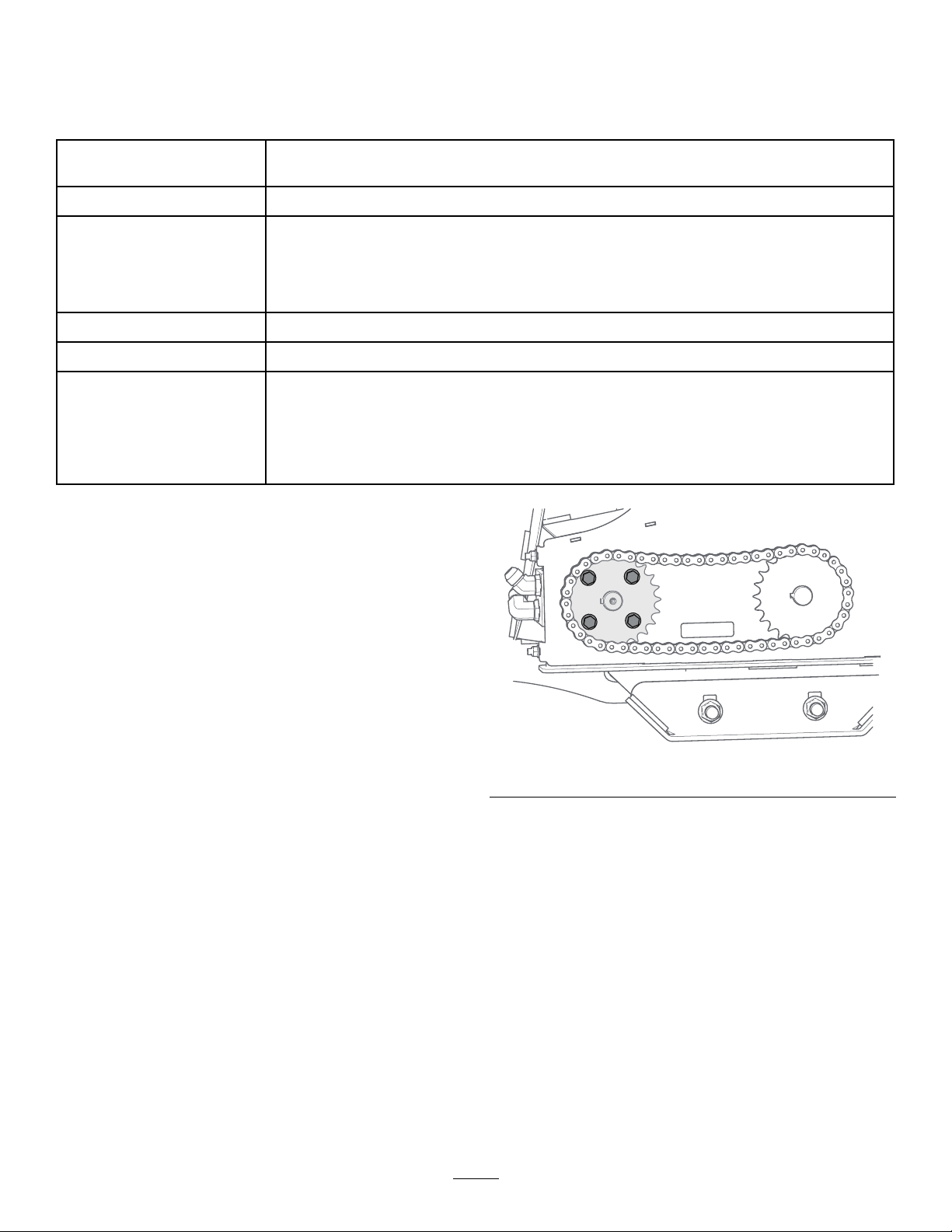

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst2hours•Tightenallhardware.

Beforeeachuseordaily

•Checkthehydrauliccylinders.

•Checkthehydrauliclinesandhoses.

•Checkallfasteners,pins,retainers,nuts,andbolts.

•Checkthecuttingedgeforwear.

•Oilthechain.

Every50hours•Greasetheattachment.

Every100hours•Checkthechaintension.

Beforestorage

•Lightlysandandusetouch-uppaintonpaintedareasthatarescratched,chipped,

orrusted.

•Oilthechain.

•Greasethehydrauliccylinderrods.

•Lightlysandandusetouch-uppaintonpaintedareasthatarescratched,chipped,

orrusted.

Maintenance

•Checkthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

•Checkthehydrauliccylindersdailyforleaks,rust,

orpittingontherods.Makeallnecessaryrepairs

beforeoperating.

•Checkthecuttingedgedailyforwear.Replacethe

cuttingedgeifitisworndown.

•Checkallfasteners,pins,retainers,nuts,andbolts

dailytoensurethattheyaresecure.Torquethem

totheappropriatevalueiftheyareloose.

CheckingtheChainTension

ServiceInterval:Every100hours

1.Removethechainguard.

2.Loosenthe4motorbolts.

g386209

Figure19

3.Pullbackthemotorandholdinplace.

4.Tightenthe4bolts.

5.Installtheguard.

OilingtheChain

ServiceInterval:Beforeeachuseordaily

Beforestorage

UseBossSnowratorHydraulicFluidorSAE20oil.

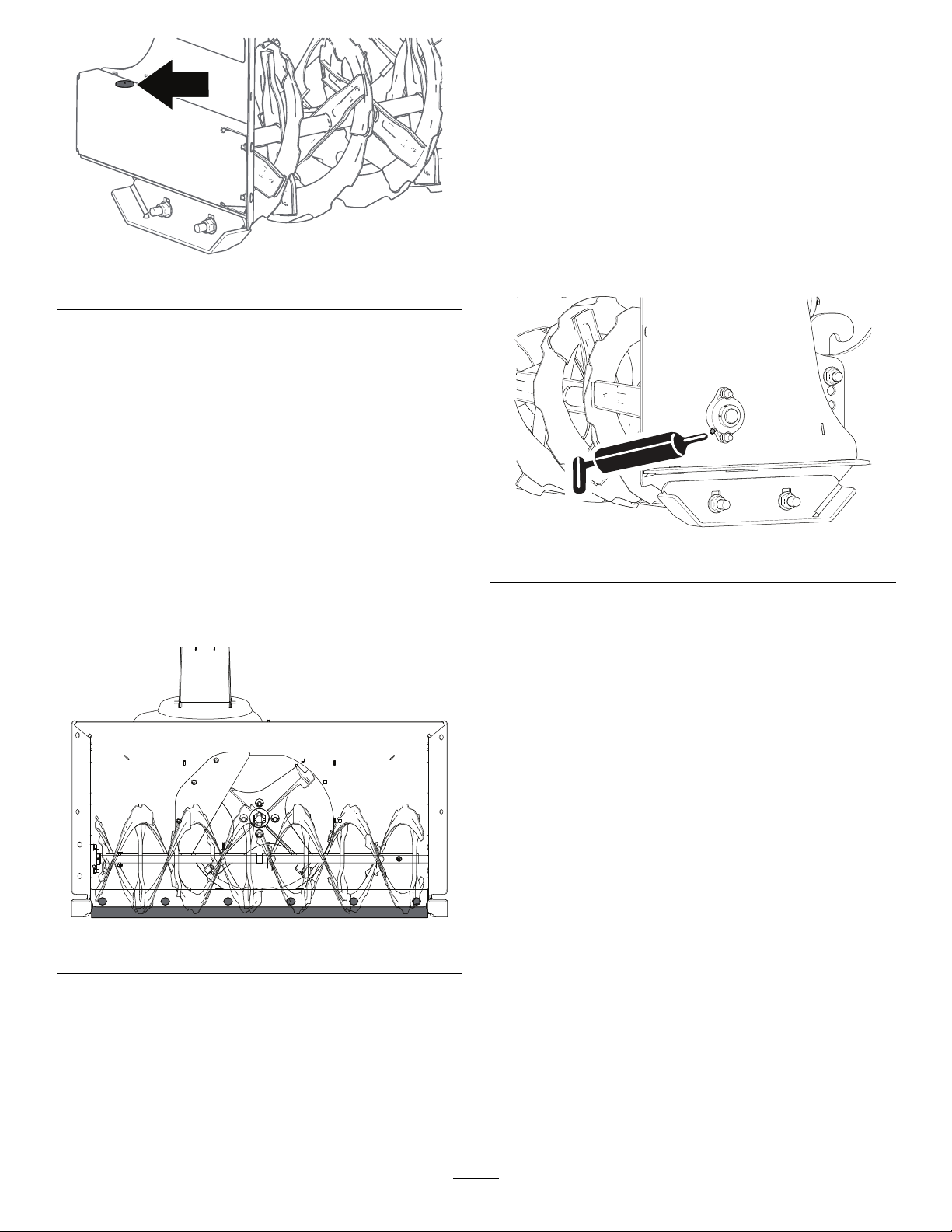

1.Raisetheattachmentallthewayupusingthe

hydrauliccontrols.

2.Removetherubberplugonthechainhousing

andinsertitintothehousingwiththecupside

up.

12

g385752

Figure20

3.Filltherubberplugwithoil.

4.Startthemachineandrunitatlowidle.

5.Operatethesnowthroweratlowidleuntilthe

plugisoutofoil.

6.Removetheplugandinstallitwiththeatface

uptopreventitfromllingwithdebrisduring

operation.

ReplacingtheCuttingEdge

Note:Replacementhardwareisavailablethroughan

AuthorizedBossDealerorBossTechnicalService.

1.Removethehardwareholdingthecuttingedge

totheblade.

g385776

Figure21

2.Flipthecuttingedgeover.

Note:Ifthecuttingedgehasalreadybeen

ipped,discarditanduseanewedge.

3.Installnewcuttingedgewithexistinghardware.

Torqueto101N·m(75ft-lbs).

GreasingtheAttachment

ServiceInterval:Every50hours

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Cleanthegreasettingwitharag.

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

5.Wipeupanyexcessgrease.

g383365

Figure22

AdjustingtheSkids

Checktheskidstoensurethattheaugerdoesnot

contactthepavedorgravelsurface.Adjusttheskids

asneededtocompensateforwear.

Ifthepavementiscracked,rough,oruneven,adjust

theskidstoraisethepolyedges.Forgravelsurfaces,

adjusttheskidsfurtherdowntopreventthemachine

frompickinguprocks.

LoweringtheSkids

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily.

Important:Supporttheaugerbladesabove

thegroundusingtheskids.

4.Movetheskidsdownuntiltheyareevenwith

theground.

5.Firmlytightenthenutsthatsecurebothskids

totheaugersides.

13

Note:Toquicklyadjusttheskidsiftheyloosen,

restthepolyedgeonthepavement,thenadjust

theskidsdown.

g383363

Figure23

RaisingtheSkids

1.Parkthemachineonalevelsurfaceandraise

theattachment.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily.

Important:Supporttheaugerbladesabove

thegroundusingtheskids.

4.Placeaboard,ofyourdesiredthickness,under

thepolyedgeofthesnowthrower.

g385838

Figure24

5.Startthemachine,putitintheoatposition,and

tightentheskids.

14

Storage

StoringtheAttachment

1.Beforelongtermstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Placethechuteintheupwardsposition.

3.Checktheconditionofthescraperblade.

4.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanydamagedorwornparts.

5.Greaseanyexposedmetalonthehydraulic

cylinderrods.

6.Greasethechuteanglegear.

7.Lightlysandandusetouch-uppaintonpainted

areasthatarescratched,chipped,orrusted.

Note:Thepaintontheimpellerhousing,inside

ofchute,andimpellerdoesnotneedtobe

painted,applypenetratingoiltothesesurfaces.

8.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

RemovingtheAttachment

fromStorage

1.Checkthetorqueofallfasteners;tightenas

necessary.

2.Checkthehydrauliclinesandhosesforcracks

orleaks.

3.Checkthecuttingedgeforwear.

4.Lightlysandandusetouch-uppaintonpainted

areasthatarescratched,chipped,orrusted.

5.Attachtheattachmenttothemachine;referto

yourmachineOperator’sManual.

6.Movetheattachmentthroughitsrangeofmotion

tocheckthehydrauliccylinderrods.

15

Troubleshooting

ProblemPossibleCauseCorrectiveAction

1.Thechainbroke.1.Checkthechainforbreak.Replace

anydamagedcomponents.

2.Theaugercouldbejammed.2.Checktheaugerfordebris.

3.Theaugerboltsarebad.3.Inspecttheaugerbolts.Replaceany

damagedcomponents.

Theaugerisnotmovingbuttheimpeller

stillrotates.

4.Asprocketkeycouldbemissingor

bad.

4.Inspectthesprocketkeys.Replace

anydamagedcomponents.

Theimpellerisnotmovingbuttheauger

stillrotates.

1.Debrisiscaughtintheblades.1.Checktheimpellerfordebris.

1.Thehydraulicuidlevelislow.1.Checkthehydraulicuidlevel;referto

yourSnowratorMAGOwner'sManual.

2.Thehydraulicuidlevelislowandthe

SnowratorMAGwasstoppedquickly.

2.SlowtheSnowratorMAGgradually

beforecomingtoastopwhenthe

hydraulicuidislow.

3.Thepressurereliefvalveisbad3.Checkthepressurereliefvalve,

locatedontheSnowratorMAGtraction

unit.Ifthevalveiscontaminated,clear

orreplaceit.

4.Acylinderorhoseisbad.4.Checkthecylinders,hoses,andall

ttingsforleaks.Tightenanyloose

connections.Replaceanydamaged

components.

Theattachmentisnotfunctioningorthey

moveslowly.

5.Thehydrauliccouplingsarenot

attachedtothevehicle.

5.Connecttheattachmenthydraulicsto

thevehiclehydraulics.

1.Thereispressurebuildupinthe

snowthowercircuits.

1.Loosenthehydrauliclinesonthe

snowthrowertorelievethepressure.

Thehydraulicconnectionsdoesnot

connectortheyarehardtoconnect.

2.Thereispressurebuildupinthe

SnowratorMAGvalves.

2.WigglethejoysticksontheMAGto

relievethepressure.

1.Ahoseisbad.1.Checkhosesforleaks.Tightenany

looseconnections.Replaceany

damagedcomponents.

2.Acylinderisbad.2.Replacethecylinder.

Oilleaksfromthehydrauliccylinders.

3.Thecylinderrodispitted.3.Polishtherodwithsteelwool.Replace

thecylinderifthepittingistoobad.

Theattachmentdoesnotfollowthe

contouroftheground.

1.Theattachmentcouplerleverisnotin

theoatposition.

1.Ensurethattheattachmentcoupler

leverisintheoatposition.

16

This manual suits for next models

1

Table of contents

Other BOSSCO Snow Blower manuals

Popular Snow Blower manuals by other brands

Snapper

Snapper LE3171R (7085660 Safety instructions & operator's manual

Texas

Texas Snow Buster 450 user manual

MTD

MTD 500-Series L style Operator's manual

Ariens

Ariens Professional 21 938024-SSR Operator's manual

Texas

Texas 7011TGE manual

Toro

Toro 38360 - Power Shovel 7.5 Amp Snow Thrower/Electric... Operator's manual