BOSTEC 2F33B 1D 1L User manual

BOSTEC LIMITED

Dry Filter Spray Booth Manual

Dry Filter Spray

Booth Manual

Volume

1

B O O T H O V E N & S T O V I N G T E C H N O L O G I E S

Operating, Servicing & Fault Finding

Sample Copy Ltd.

Model No. 2F33B 1D 1L

3

rd January 2020

©BOSTEC Limited

Jct 21 Trading Estate • Gorse Street

Chadderton • Oldham • OL9 9QH

T: 0161 620 4091 • E: info@bostec.co.uk

Table of Contents

Important Information............................................................... 1

WARNING................................................................................1

SAFETY INFORMATION .........................................................2

You should:.....................................................................................2

Appropriate PPE we would recommend:.........................................2

Spray Booth Operation.............................................................3

Maintenance Procedures .........................................................6

Daily:...............................................................................................6

Weekly:...........................................................................................6

Monthly: ..........................................................................................6

Annually (14 months maximum):.....................................................6

Fanset Information:.........................................................................7

Drawings................................................................................ 13

Commissioning Form .............................................................14

B O S T E C L I M I T E D .

1

Important Information

To ensure the safety of all personnel the booth must be

operated in accordance with this manual.

he equipment has been designed to offer simple, safe and reliable service to you

for many years. However it should be properly commissioned and serviced

regularly to ensure the equipment performs correctly over its lifetime.

We have tried to create a simple to follow manual. Please

use the icons for a quick guide to the most important

information.

If you have any questions please contact us at

info@bostec.co.uk .

WARNING

If incorrectly used or maintained Spray Booths can be hazardous. It is vital that this

manual is followed, the spray booth is only operated by trained personnel and only

serviced by Qualified Engineers.

Commissioning Report* - only available when commissioned by BOSTEC at time of installation.

Volume

1

T

I C O N K E Y

Valuable information

Contact Information

Technical Information

Commissioning Report*

B O S T E C L I M I T E D .

2

SAFETY INFORMATION

You should:

Always ensure the equipment is electrically isolated and ‘locked off’ prior to commencing

any maintenance or work on the equipment controls.

Never tamper with any electrical device or air proving device.

Ensure the equipment is regularly serviced (by Qualified Persons). The law requires you

to service any Spray Booth (LEV) every 14 months. Contact us to find out how we can

help with this.

Never consume food or drink in the Spray Booth area.

Ensure the area around the Spray Booth is kept clean and tidy.

Always check the operation of any safety equipment prior to use of the Spray Booth.

Appropriate PPE we would recommend:

Safety Glasses or Goggles.

Protective safety shoes with a suitable non-slip sole.

Suitable breathing apparatus such as a filtered or Air-fed Mask.

Disposable gloves.

B O S T E C L I M I T E D .

3

Spray Booth Operation

Check all safety devices are in good condition and operating correctly.

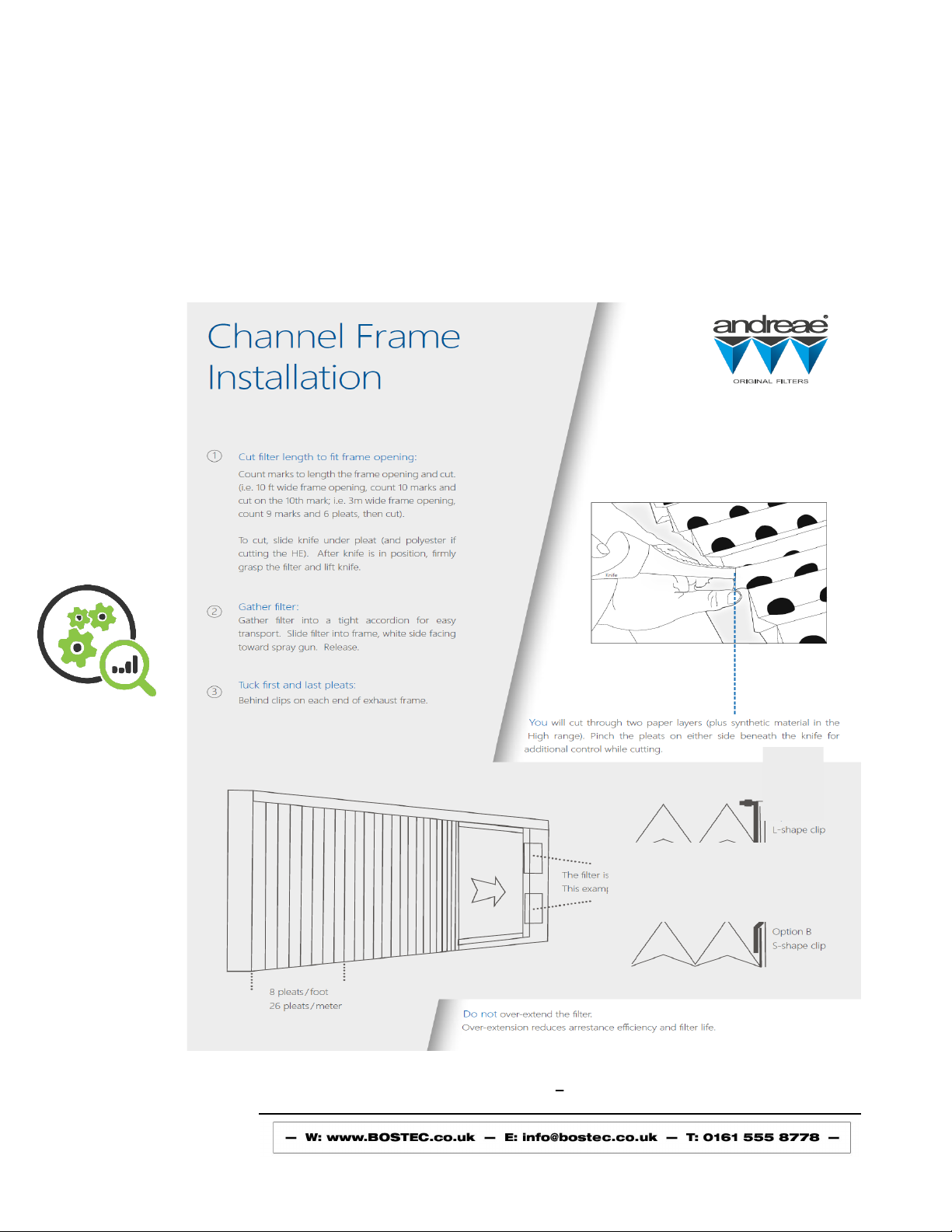

Check filters are installed correctly as follows:

Start up Procedure

B O S T E C L I M I T E D .

4

Start up Procedure cont…

Note

We only recommend the use of

Andrea Filters

–other inferior filters do

not offer the same performance. Contact us for further details on this.

Switch on the Mains Isolator.

Press the START button –in a few moments the LED Lights (if fitted) will

turn on and the extraction system will be ready.

Check the Manometer (if fitted) as this tells you if the filters require

changing.

If the RED Liquid moves into the RED Zone you must change the filters

immediately (see previous page on how to change filters).

If the RED Liquid is in the Green or Amber Zones you are ready to spray.

Shutdown Procedure

Press the STOP button –the booth will turn off the fans and the lights.

Note

We recommend leaving the Spray Booth switched on and extracting air

after the spraying has finished as many of the VOC Gases will still be

airborne for a significant period after the spraying has ceased.

B O S T E C L I M I T E D .

5

Optional

–On Spray Booths fitted with the optional Automatic Run-

Down Clearance Timer the booth will operate as follows:

Press the Stop button –the lights will switch off –the fan/s will

continue to run for a preset time to ensure the minimum clearance

time as set out in the commissioning report has been met.

When you want to start spraying again simply press the START

button again –this will override the timer system and turn the lights

back on.

When the booth is not in use isolate the power at the main electrical

isolator.

B O S T E C L I M I T E D .

6

Maintenance Procedures

Daily:

Check Filter condition using Manometer located on side of booth (see page 4).

Thoroughly clean down the Spray Booth area.

Weekly:

In addition to Daily checks:

Thoroughly clean glazing panels use for lighting (use thinners or other suitable

solvent if necessary).

Monthly:

In addition to Daily & Weekly checks:

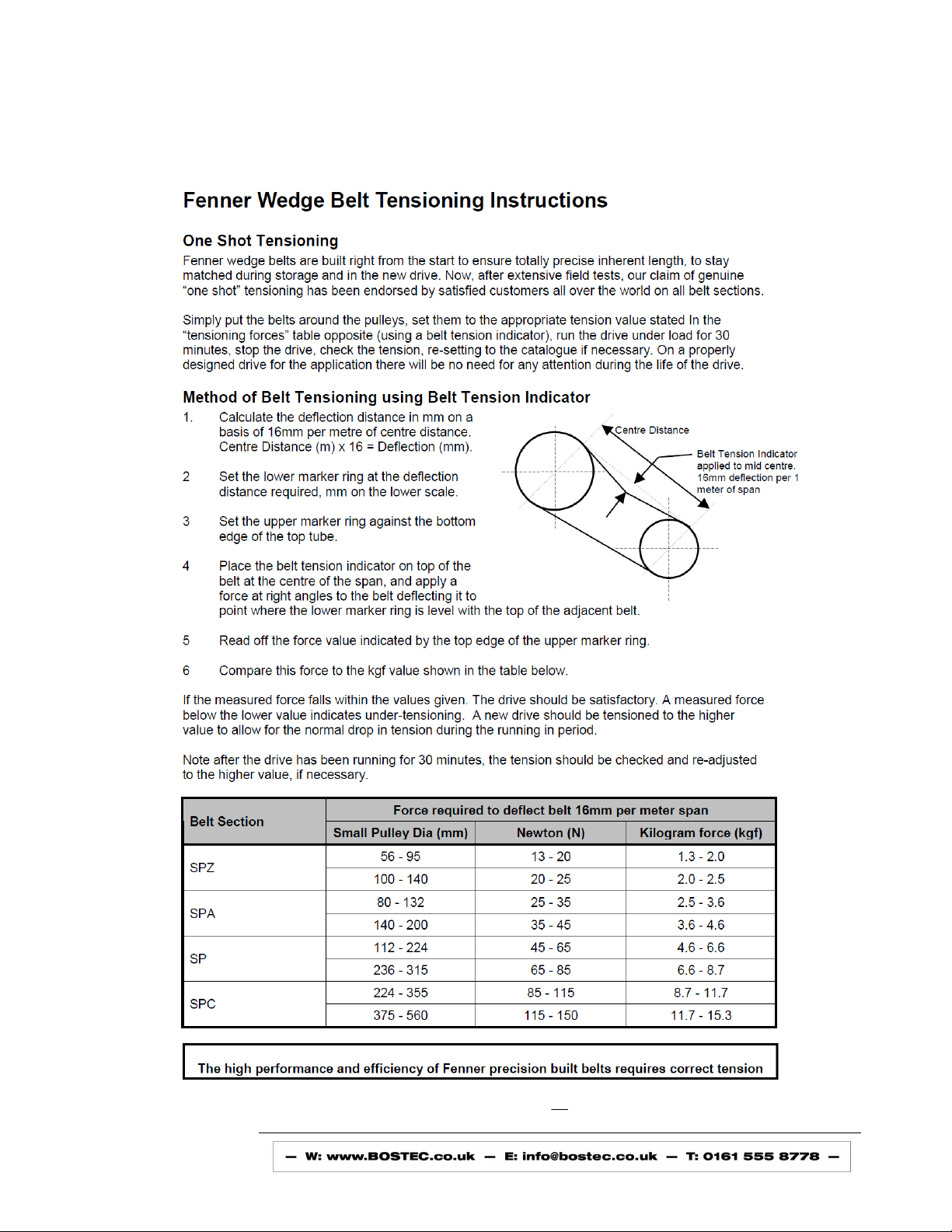

Check belt tension on extraction fansets –replace if required.

If belts are adjusted run for 15-20 minutes and then re-check and re-adjust as

required (as the belts may stretch as they become warm).

From inside the extraction chamber (where possible) inspect and clean the fan

impellor if any paint buildup is apparent. Following cleaning lightly grease each

impellor to aid easy cleaning next time.

Check and clean the internal finger guard if any paint buildup is apparent.

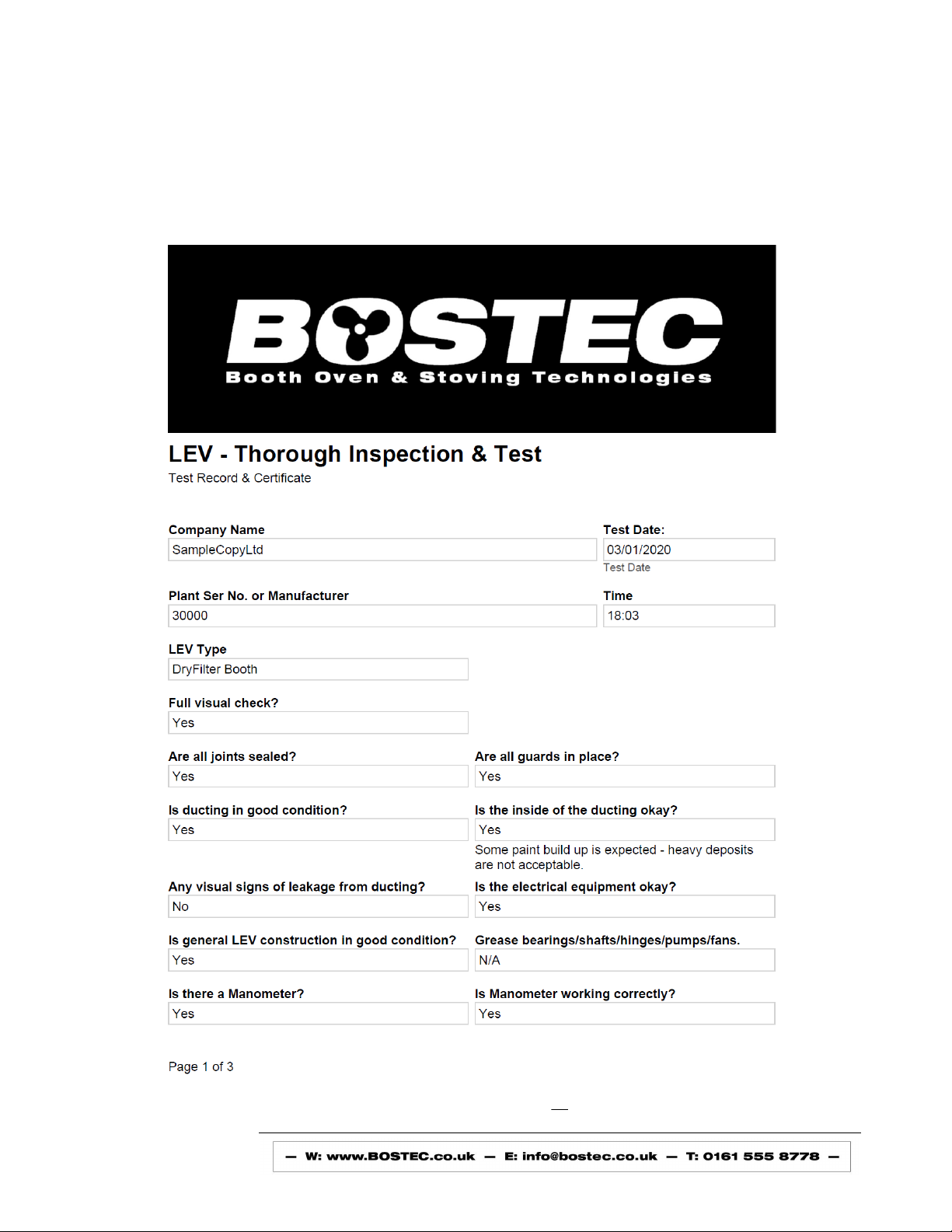

Annually (14 months maximum):

A full ‘Thorough Inspection and Test’ of all LEV equipment is required in

accordance with HSG258 every 14 months.

This check and certification should be carried out by a competent person and

can be carried out by BOSTEC for you.

Contact us for a quotation for this Inspection, Service and Certification.

B O S T E C L I M I T E D .

7

Fanset Information:

B O S T E C L I M I T E D .

8

B O S T E C L I M I T E D .

9

B O S T E C L I M I T E D .

10

B O S T E C L I M I T E D .

11

B O S T E C L I M I T E D .

12

Basic Fault Finding

The extraction works but there are no lights:

1. Check switch/starter for lights

2. Check tubes

3. Check fitting

There is no lighting and the fans are not working:

1. Check the power is switched on

2. Check the starter is operating correctly

The lights are on but there appears to be no extraction:

1. Check the starter for the fans is working

2. Check the belts on the fans are not slipping or broken

3. Check the fanset is free to rotate

There is only partial or reduced extraction:

1. Check the condition of the filters

2. Check the fan is rotating in the correct direction

3. Check all fans are working at the same time (only on multi-fan

booths)

4. Check ducting for damage or blockage

B O S T E C L I M I T E D .

13

Drawings

B O S T E C L I M I T E D .

14

Commissioning Form

p

B O S T E C L I M I T E D .

15

B O S T E C L I M I T E D .

16

Table of contents

Popular Paint Sprayer manuals by other brands

Titan

Titan PowrTwin Plus PT4900 operating manual

Silvan Selecta

Silvan Selecta Supaflo 2000L Operator's manual

DEWESOFT

DEWESOFT DS-IS-5 product manual

Norac

Norac UC5 Topcon X30 installation manual

Campbell Hausfeld

Campbell Hausfeld DH5000 Specifications and features

Task Force Tips

Task Force Tips Ultimatic INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE