SPOT SPRAYER

MODEL NO: SS37

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

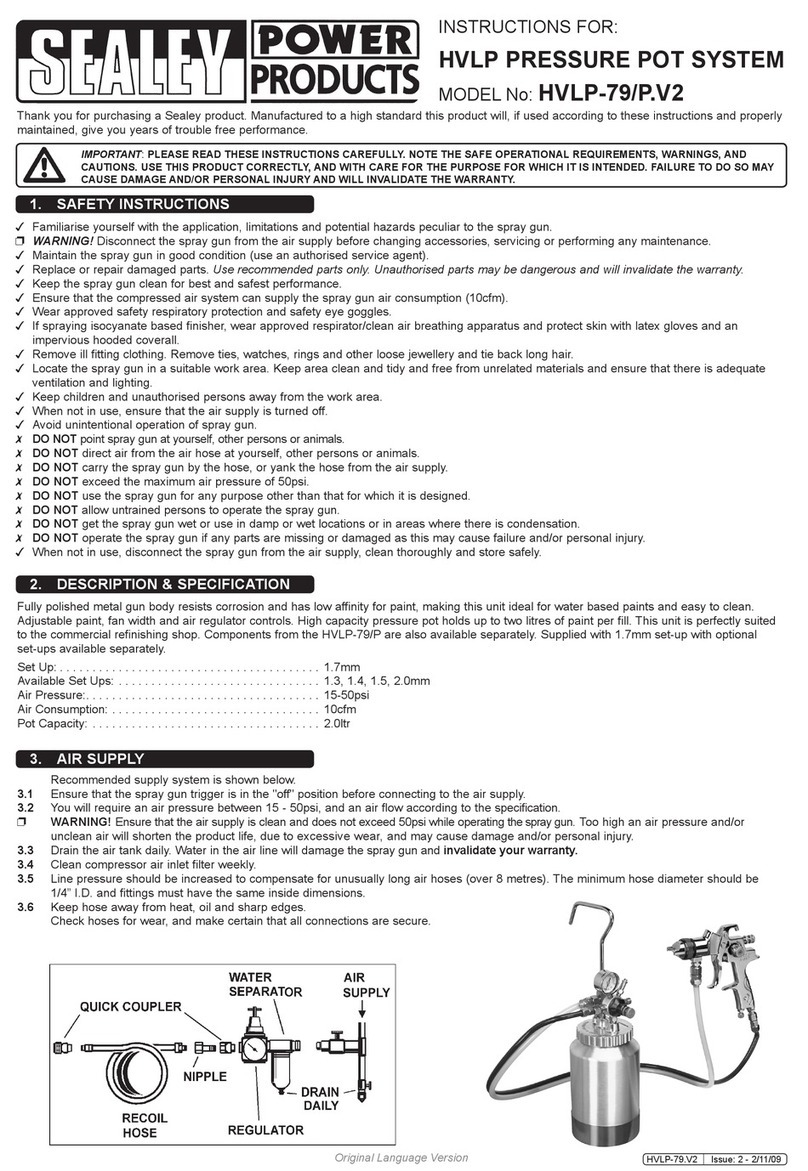

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. GENERAL SAFETY

9Only use the sprayer for its intended purpose.

9Familiarise yourself with the applications, limitations, and potential hazards of this product.

9Use original Sealey spare parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Ensure containers cannot easily be knocked over during filling.

9Always ensure good contact on the 12V battery.

9Mark fluid containers with hazard labels to show their contents.

9Keep any fluid containers in a well ventilated, lockable store, preferably outside the working area.

9Keep children and unauthorised persons away from the working area, especially when the sprayer is in operation.

9Keep the work area childproof by using padlocks and master switches.

9Maintain the sprayer in top condition. Keep it clean for best and safest performance.

9Follow the same precautions when transferring fluid from the sprayer back into other containers.

9Ensure the sprayer is securely fixed to the ATV.

9Always inspect and prepare the sprayer before use according to the directions provided in this manual.

9Keep the sprayer turned off. DO NOT turn on power to the sprayer until ready to spray in order to avoid unintentional spray release.

8DO NOT spray when wind speed exceeds 4mph in order to minimize spray drift.

8DO NOT over apply pesticide. Apply at a rate recommended by agents manufacturer. Excess pesticide can be dangerous to humans,

damage desirable plants, and contaminate soil and water sources.

8DO NOT point the spray gun at people or animals.

8DO NOT eat, drink, rub your eyes, or touch any part of your bare skin while handling agents and spraying.

8DO NOT spray near open flames or sources of heat.

9Always clean up spills immediately per instructions on the agent’s label.

9Turn off vehicle and set brake or block wheels, turn off power to sprayer and relieve system pressure before leaving sprayer

unattended.

8DO NOT use an open flame or smoke anywhere near the sprayer or around stored fluid.

8DO NOT spray fluid into dedicated workshop oil spray equipment.

8DO NOT use any electrical equipment on or near the vehicle while fluid spraying is in progress. This includes the use of inspection

lights, mobile phones or pagers.

8DO NOT use the sprayer if the pump is damaged in any way.

8DO NOT use whilst under the influence of drugs, alcohol or other intoxicating medication, or if you are fatigued.

1.2. ELECTRICAL CONNECTION SAFETY

9If the battery terminals are corroded or dirty, clean them before using the Sprayer.

9Disconnect the power after every use to avoid accidental starting.

8DO NOT disassemble the remote switch for any reason. The sprayer must only be checked by qualified service personnel.

WARNING! To prevent the risk of sparking, short circuit and possible explosion DO NOT drop metal tools in the battery

area, or allow them to touch the battery terminals.

8DO NOT cross-connect remote switch clamps.

9Ensure positive (RED) clamp is to positive terminal and negative (BLACK) clamp is to negative terminal.

1.3. CHEMICAL SAFETY

9Ensure you read the safety data sheet of the substance you are going to spray.

9The sprayer is intended for use in spraying agricultural pesticides and other non-ammable liquids.

9Spraying pesticides - Pesticides are hazardous agents that must be handled with caution as directed throughout this manual and on the

pesticide label. The sprayer is intended for use in spraying pesticides in liquid form only. The sprayer is NOT intended for use in

spraying pesticides in dry or aerosolized form, or for use with fumigants.

9 Spraying Other Liquids - In addition to spraying pesticides, this sprayer may be used to spray other non-ammable liquids. Example

uses include: watering plants/trees or spraying water for dust control, applying ice control agents, applying water-based, non-ammable

sealant or stain to outdoor wood surfaces.

9WE RECOMMEND THAT THE SPRAYER NOT BE USED FOR OTHER PURPOSES ONCE IT HAS ALREADY BEEN USED FOR

SPRAYING PESTICIDES. Any agents will leave some residual in the tank liner or sprayer components, even after the sprayer has

been properly cleaned. These residual agents can have unexpected effects on future uses. For example, spraying water or

other liquids that are contaminated with residual pesticide may result in unforeseen hazards to plant or animal life.

SS37 | Issue 4 (HF) 03/04/18

Original Language Version

© Jack Sealey Limited

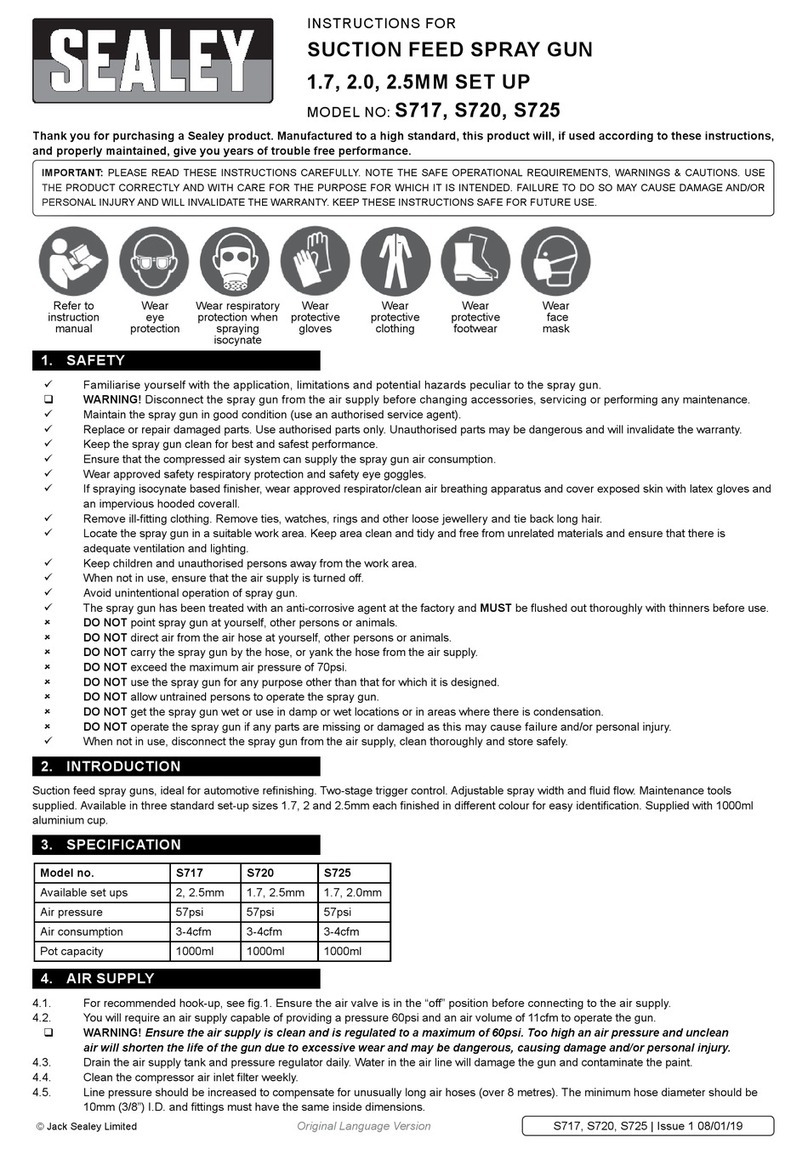

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear protective

clothing

Wear a mask