X35 Console (v 4.02) Quick Reference Guide X35 Console (v 4.02) Quick Reference Guide

1. Specific Seeding Scenario Setup

1.

Go to Settings page (wrench icon

in bottom left corner).

2. Select appropriate tank grouping

(how the tanks are actually inter-

connected together) - go to Implement

/Seeder/Granular/Tank Grouping.

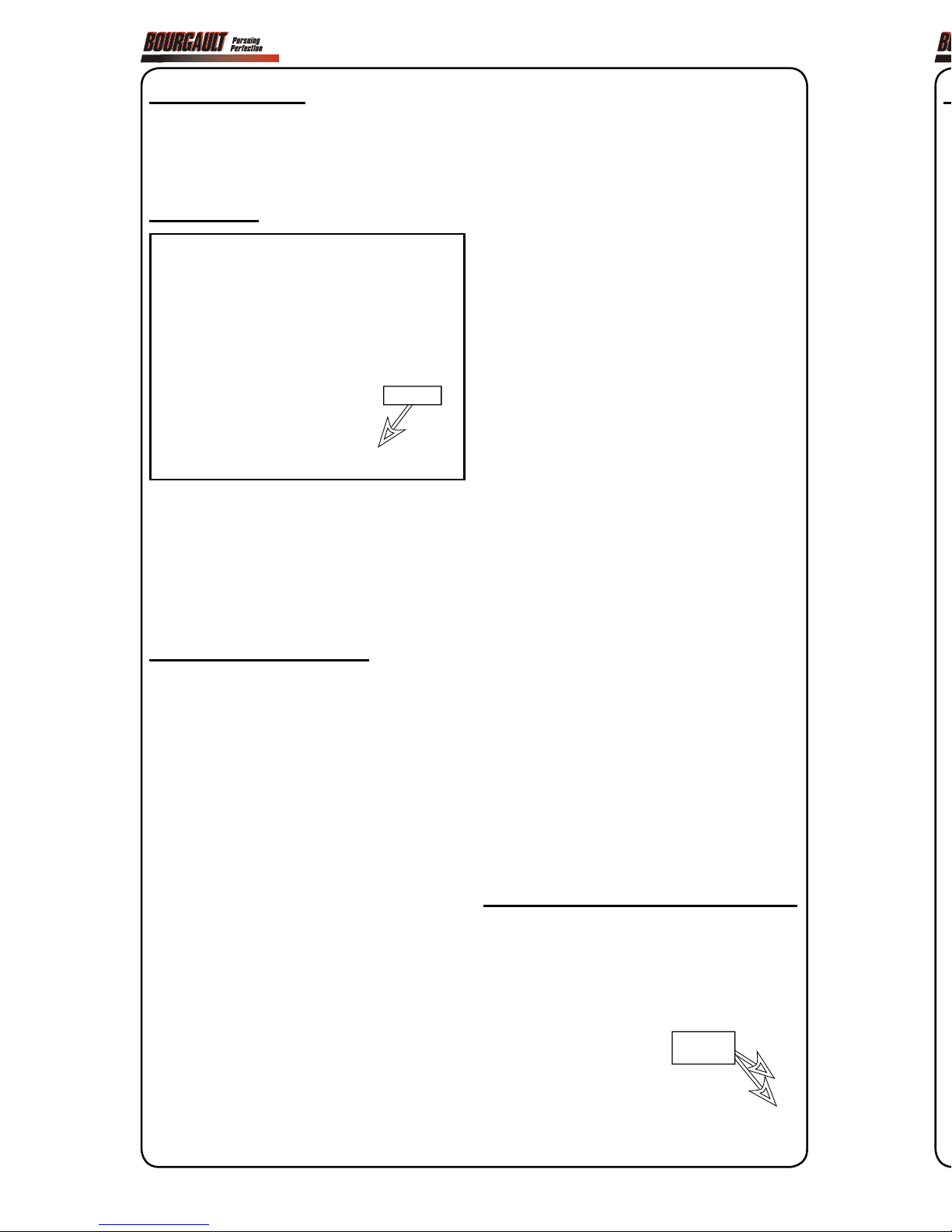

Console Toolbar

The lower Console Toolbar can be accessed

by swiping up from the bottom of the

screen. It will pop up on the bottom of the

screen with the available functions.

Quick Help

Question mark button on the

Console Toolbar toggles on/off

help mode. While in the help mode

a blue question mark is displayed

beside each icon on the screen. To see

description for icon touch blue question

mark beside it. To continue to work turn off

help mode.

Initial One-Time Setup

Select wrench icon to go to Settings page.

1. Change units settings - go to User/

Units.

2. Enable Auto Section Control (ASC)

if using coverage map to turn seeder

on/off. Go to System/Features/

Implement. Also enable Area Counters

to record treated areas for each tank.

3. GPS settings (if used) - go to System/

GPS, enter appropriate GPS settings to

get GPS signal into X35 console.

Note: GPS is the preferred ground speed

source to achieve the best accuracy.

4. Create your specific tractor profile - go

to Vehicle/New and follow prompts.

5. Create your specific airseeder tank and

drill profile - go to Implement/New/

Factory and follow prompts. Select

Apollo for ECU type.

6. Detect ECU’s following the procedure

in the X35 manual (Section 6.3.2

- ECU Manage).

7. Verify geometry for each boom. Go to

Implement/Geometry.

2. Calibration

1. Engage airseeder fan hydraulics.

2. Open Configuration panel.

3. Enter speed that you will be seeding

at, this will ensure that calibration is

performed at seeding speed.

4. Enter Calibration mode and follow

the prompts on the screen to perform

a calibration for all the enabled tanks,

refer to Section 8.4 - Calibration in the

X35 Operator’s Manual for calibrating.

3. Creating Field & Job

(units with GPS only)

If using GPS, Field and Job must be

created before seeding.

1. Open Guidance.

2. Create new Field.

3. Create new Job.

A) SELECT GUIDANCE ICON

B) SWITCH TO FULL SCREEN :

- TOUCH ICON IN THE CORNER

OR

- PRESS, HOLD & DRAG MINI-VIEW WINDOW

TO THE RIGHT

A) SELECT TO OPEN CALIBRATION

METHOD WINDOW

B) START

CALIBRATION

WIZARD

SELECT

GROUPING

P/N 0252-92-03

Assy P/N 0252-93-01

Important:

Granular Fertilizer & NH3/

Liquid boom geometry and section widths

are preset as a MRB layout. If that is not

the case adjust geometry and section widths

of booms accordingly. Also all boom

geometry is set as the latest configurations

coming from the factory so should be

verified for older units.

8. If using sectional control, set on/off times

for section valves for each boom. Go to

Implement/Section Control/Timing.

(Time from section valve to the ground).

9. Set up the in-cab & on frame switchbox.

Go to Implement/Keypad. Pick the ID

for the respective keypad.

10.

Set the on/off sequence time for each

tank. Go to Implement/Seeder/Granular

Tank. (For non-sectional it is time from

the meter to the ground, for sectional it is

time from the meter to the section valve).

11. For each tank select metering auger type

(stamped on the end of the shaft: 1X

- single flight, 2X - double flight, HX

- high output, LO - low output) - go to

Implement /Seeder/Granular/Drive

Setup.

12. Enable drill control (if installed)

- go to

Implement/Seeder/Drill Control.

13. Enable blockage monitoring (if installed)

- go to Implement/Seeder/Accessories/

Blocked Head.

14. Enable brakes (if installed) - go to

Implement/Seeder/Accessories/Brake

Control.

15. Configure weigh system (if installed)

- go to Implement/Seeder/Weigh Scales

16. Select speed source that will be used - go

to Implement /Seeder/Speed Source.

17.

Enter new products - go to Product/

Granular or Liquid, select New Product

and follow prompts.

Note: above are basic settings to be able to

seed. For special customized features refer

to supplied Operator’s Manuals.

A) SELECT

CONFIGURATION

BUTTON TO OPEN

CONFIGURATION

PANEL

B) SELECT

MANUAL SPEED

C) ENTER

SPEED VALUE

D) DESELECT

MANUAL SPEED

Page 1Page 3

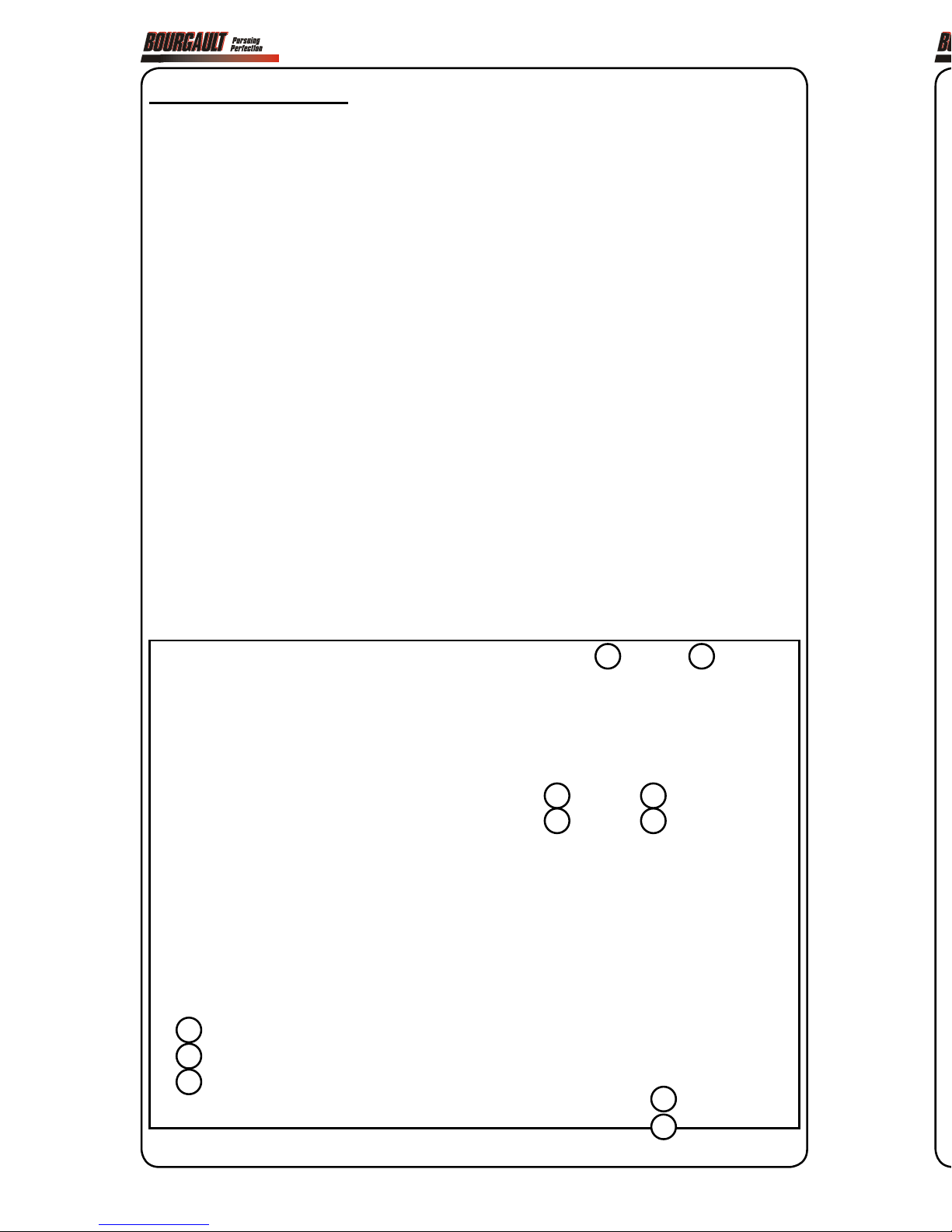

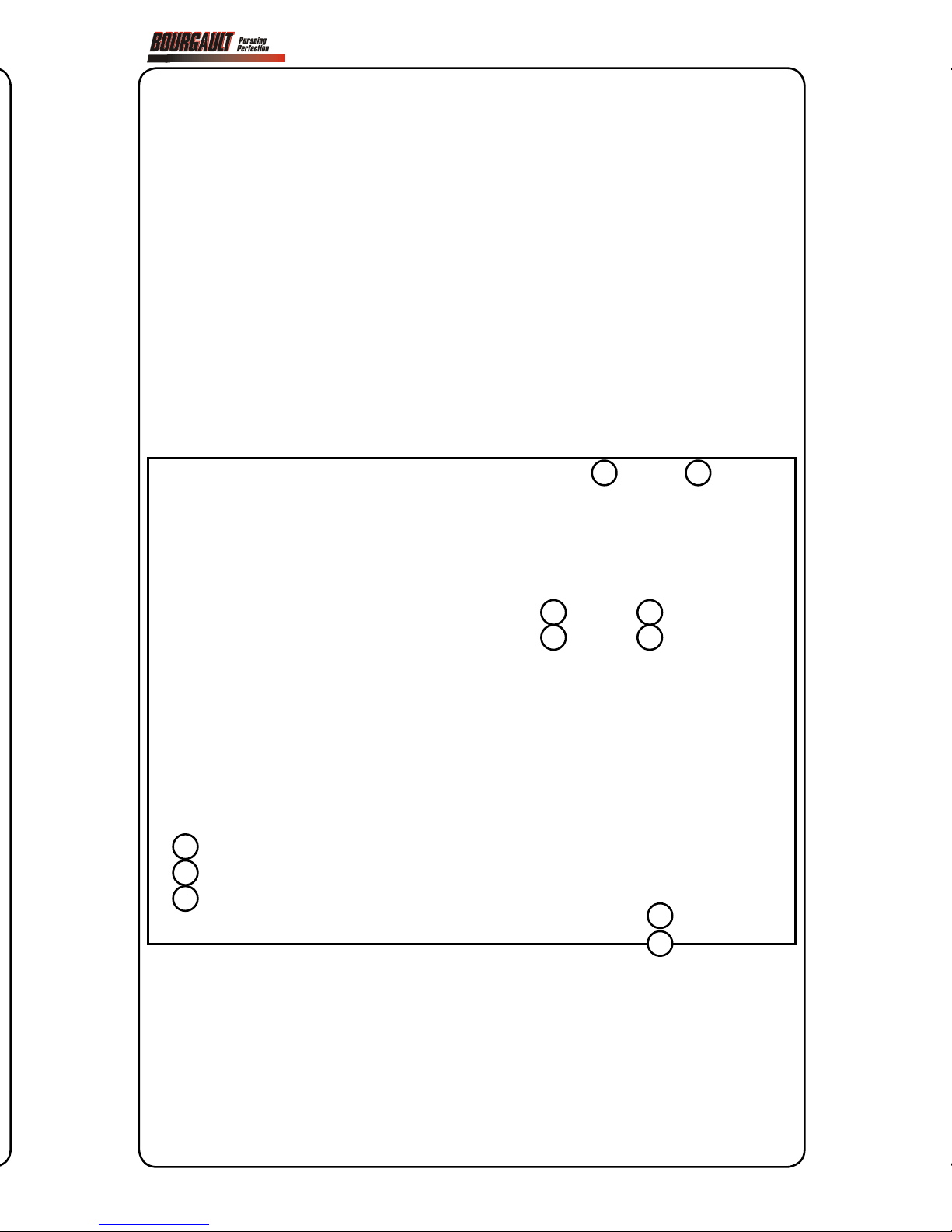

A) OPEN FIELD MENU

B) OPEN NEW FIELD

WINDOW

C) ENTER CLIENT

D) ENTER FARM

E) ENTER FIELD

A) OPEN JOB MENU

B) OPEN NEW JOB

WINDOW

C) ENTER JOB

NAME

TOOLBAR