Boyar-Schultz 6-12 Guide

CareandUseof....

BOYARSCHULTZMODEL6-12

SURFACEGRINDER

CAPACITY-Boyar-SchultzModel6-12Surface

Grinder,a 6 x 12machinewithactually7 inch

crossfeedtravel. . . oneinchmorethantheindi-

cated6 inches.Longitudinaltravelis13inchesand

verticaltravelofspindleis11½inches.

SPINDLE—Thisisthe"workingunit,"theveryheart

ofthemachine,andisdesignedforveryclose

tolerance,smoothfinishgrinding;supportedat

eachendbyover-size,pre-loaded,radialthrust,

superprecisionballbearings.Spindleismotivated

bya special½ H.P.motorandconnectedtomotor

byprecisionmadepulleysandV Belt.Sturdily

built,itwillabsorbtheheavydemandsputupon

itduringa longperiodoftime.

TABLE—Bestmaterial,stressandstrainrelieved.

MadewithoneVeewayandoneFlat,groundand

scrapedforsmoothoperation.

LONGITUDINALTABLEACTION-Obtainedbyconven-

tionalhandwheelandalsobyRapidTraverse

TableLever.Eithermaybedisengagedwhilethe

otherisinuse.LargeHandWheelprovidesextra

leverage.

TABLECARRIAGE—Tabletravelsontwoflatprecision

andhandscrapedways,mountedonmaingrinder

base.Crossfeedtravelisactuatedbyleadscrew

supportedbyballandneedlebearingsandlocated

betweentableways.NeopreneAccordionSleeve

sealsleadscrewfromdirtandabrasivedust.

ACross feed binding screw stopstransversemo-

tionwhendesired.

SPINDLEELEVATINGSCREW-Supportedbyballthrust

bearingsandoperatedbya setofcarefullyselected

bevelgears.Respondsinstantlytoslightestmove-

mentofhandwheelbecauseradialthrustbearing

providesconstanttensionbetweenhandwheel

shaftandverticalscrew.

HANDWHEELS—placedtoaffordgreatestconvenience

andarefittedwithneedlebearingsforeasyopera-

tion.Verticalfeedgraduatedinhalfthousandths;

crossfeedinthousandths.Workingpartenclosed

formaximumprotectionfromabrasivedust.

NEEDLEBEARINGS—Fivesetsofneedlebearingsare

usedinModel6-12SurfaceGrinderforlongwear

andeasyoperation.

OILINGOFTABLES-InkeepingwithBoyar-Schultz

progressivedesigningpolicy,theoilingsystemfor

thelongitudinalandcrossfeedtables,crossfeed

screwandlongitudinalhandwheelhasbeenim-

provedtoeliminate8 of9 oilcups,andatthesame

timeprovideforbetter,morepositiveonepoint

lubrication.(seeillustrationbelow)

ADJUSTABLELIGHT-Fullvisibilityispossiblewith

lightwhichisadjustabletoanyposition.

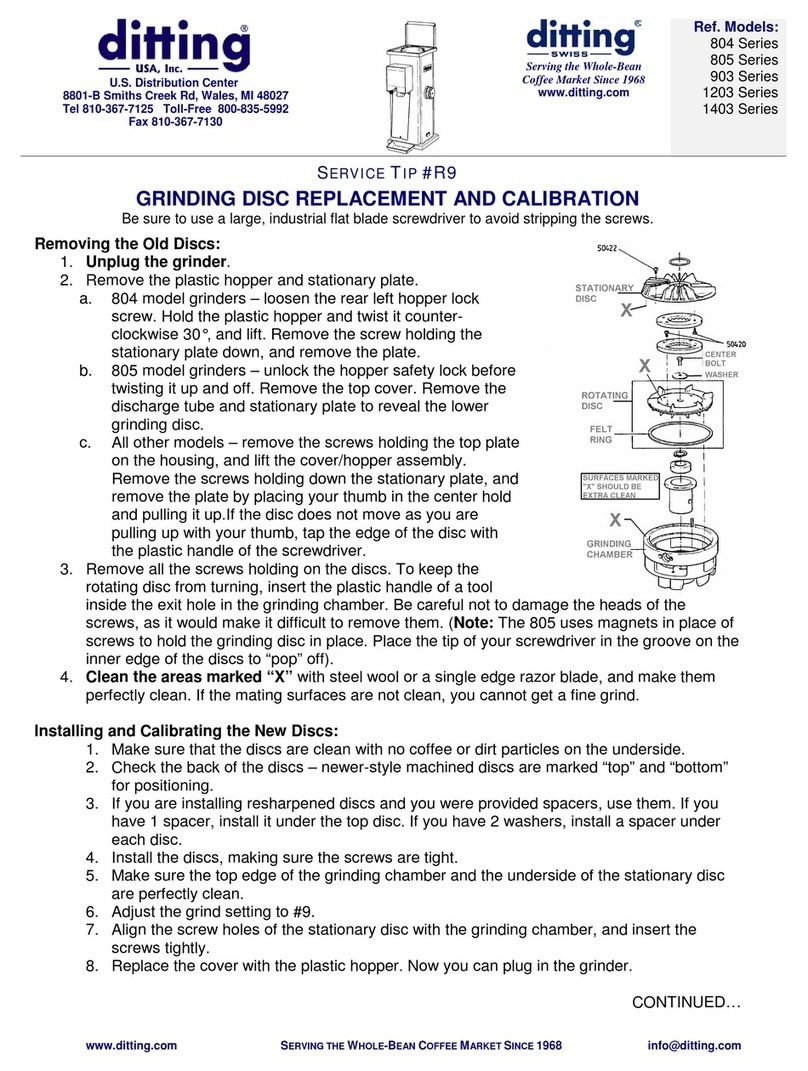

ShowingtheImprovedoilingsystemdeveloped

forModel6-12SurfaceGrinder.

Wheel Capacity. 7 inch

diameter,½ inchthick-

ness.1¼inchdiameter

holesize.

SpindleElevatingScrew.

Selectedbevelgears,sup-

portedinOilitebearings. ViewShowingthenew

Streamlinedstand.

GENERALINSTRUCTIONS

HANDLING

Removethetopandsidesofthemachinecrate.

Takeoutthescrewsthatsecurethemachineto

thecratebase.

Liftthemachinebymeansofthecrossfeed

handwheelhousingandthetwoliftingstudsfound

onthesides.Liftinginanyothermannermaydam-

agethemachine.Theliftingstudsmaybeun-

screwedwhenthemachineispermanentlysituated.

INSTALLATION

Special

wrenchesaresuppliedwitheachmachinetoadjust

itslegs.Themachinemustbeleveledtopermit

thelubricationsystemtooperateproperly.

Removethegrindertablefromitscrateand

cleanthoroughly.Oilthetablewaysandgreasethe

rackwiththelubricantsrecommendedinthelubri-

cationchart.Cleanthegrindercarriagewaysand

tablepinion.Setthegrindertableinplacegently,

movingitbackandforthuntilthetablepinion

engagestherack.

Loosenthetwowingnutsthatholdthecolumn

reardustcover.Removethedustcoverbysliding

itupward.Cleanthecolumnwaysandlubricate

themwiththesameoilusedonthetableways.

Replacethecolumnreardustcoverandsecure

thewingnuts.

LUBRICATION

Thetableoilcuplubricatesthecrossfeed

screwandthetableandcrossfeedways.Thelarge

oil-cupontopofthecolumncaplubricatesthe

columnways.

Theelevatinghandwheel,rapidtraversehandle

andspindlemotorhavetheirindividualoiling

points.

Followtherecommendationsfoundinthelubri-

cationchartforthelubricationofthemachine.

LUBRICATIONCHART

POSI-

TION

1

2

3

4

5

6

7

8

9

OILING

PERIOD

DAILY

TWICE

WEEKLY

WEEKLY

EVERY

1000

HOURS

DAILY

WHEN

USED

PERMANENT

AFTER6000

OPERATING

HOURS

SEMI

ANNUALLY

SEMI

ANNUALLY

LUBRICATING

INSTRUCTIONS

FILLCUP

FILLCUP

10

TO

20

DROPS

30TO

70

DROPS

LIBERALLY

ATTIMEOF

OVERHAUL

HAND

PACK

3GALS.

HAND

PACK

LUBRICANT

S0C0NYVACUUM

OIL

CO.

VACTRAOIL

HEAVYMEDIUM

"

"

"

"

B.R.B.LIFETIME

GREASE

••

D.T.E.LIGHT

OIL

SQUAREX

GREASE# 1

SHELL

OILCO.

T0NNA

OIL#33

»

•'

•'

"

ALVANIA

GREASE# 2

"

TELLUS

OIL#27

ALVANIA

E.P.GREASE# 2

THETEXAS

OILCO.

CAM0PUS

OIL-D

II

••

"

"

STARFAX

GREASE# 2

••

REGALOIL

A-(RSO)

NOVA

GREASE# 1

2 3

6 4

9

1

5

8

7

under the grinder and grinder stand.

SPINDLE

Thespindlehasbeendesignedandmanufac-

turedtomaintainlongaccuratelife.Itisperma-

nentlygreasepackedandisequippedwithpre-

loaded,superprecisionballbearings.Thespindle

isconnectedtothespindlemotorbymeansofa

"V"belt.Thetensionofthebelthasbeensetat

ourfactory.

Toreadjustthebelttension,removethecolumn

reardustcoverandloosenthefourboltsthathold

themotormountingbrackettothespindlehousing.

Themotormountingbracketmaynowbemoved

upordowntoproducethedesiredbelttension.

Tightenthemountingboltsandreplacethedust

cover.

NOTE:Itisrecommendedthatthespindlebe

sentbacktothefactoryasanassembledunitwhen

repairisdeemednecessary.Inspectionandrepair

isfacilitatedwhenthespindleisreceivedbyusin

thismanner.

TOREMOVESPINDLEHOUSING

ASSEMBLY

(1)Useelevatinghandwheeltomovespindle

verticallytocentrallocationonvertical

column.

(2)Removegrindingwheel,adapter,andwheel

guardfromspindle.Removefrontdust

cover.

(3)Removereardustcover.

(4)Removecoverattopofverticalcolumn.

(5)Driveouttaperpinsecuringelevatinghand-

wheelpiniongeartoelevatinghandwheel

shaftandremovegear.

(6)Remove(4)hex.headcapscrewssecuring

motormountingbracketassemblytospindle.

Liftupassemblytoreleasethemotorpulley

fromthebelt.Carefullyremovemotor

assembly.

(7)Removebeltfromspindlepulley.

(8)Placesupportblocksbetweenloweredgeof

spindleandtiebraceofspindlecolumnat

rearofmachine.Alsoplacesupportblocks

betweenloweredgeofspindlehousingand

tableatfrontofmachine.

(9)Insidetheverticalcolumnunderthebevel

gear,ontheelevatingscrewwillbefound

thethreadedheadelevatingscrewcollar.

Removethesetscrewthatsecuresthecollar

totheelevatingscrew.Youcanthenunscrew

collarandallowtopassoverelevatingscrew

threads.

(10)Attopofcolumn,unscrewhexnutandre-

movebevelgear.IMPORTANT:Caremast

betakentoeliminateallpossibilityofthe

spindlehousingfallingwhileremovingele-

vatingscrew.

(11)Removespindlehousingassemblyfromfront

ofmachine.Donotdisassemblethespindle

unitbeforeshipping,sucha procedurewill

makeitdifficulttodeterminethecauseof

failure.

GRINDINGWHEEL

Thewheelismountedonanadapterwhich,in

turn,ismountedonthespindle.A specialwheel

mountingwrench,furnishedwitheachmachine,

fitsthewheelnutwhichholdsthegrindingwheel

ontheadapterandthenutwhichholdstheadapter

onthespindle.Onegrindingwheelisfurnished

withyourmachine.Thevariousresponsiblemanu-

facturersofgrindingwheelswillgladlygiveyou

informationonspecialwheelneeds.

GRINDINGWHEELADAPTER

Awheelpullerhasbeenfurnishedtoremove

thegrindingwheeladapterfromthespindle.To

removetheadapter,removethewheelnutwith

thespannerwrenchprovidedandscrewthepuller

intothewheeladapter.Tightenthepullera screw

untilthewheeladapterslipsoff.

WETGRINDING

Allmachinesmaybeadaptedforwetgrinding,

butunlessotherwiseorderedthemachineissent

equippedfordrygrindingonly.Informationde-

scribingtheadditionalequipmentrequiredforwet

grindingwillbesentonrequest.

GRINDERTABLE

Thegrindertableisa rugged,closegrained

casting,controlledinhardnessandscientifically

heattreatedtorelieveallinternalstresses.The

tableslidesonhandscrapedways.One"V"and

oneflat.

Thetableworkingsurfacehasbeengroundand

checkedonthemachineitselftoinsureflatnessand

squarenesstothespindle.Thetablewaysare

groovedtopermitproperdistributionofthelubri-

catingoil.

Removeandcleanthetablewaysweekly.

GENERALINSTRUCTIONS

TABLEFEEDHANDWHEEL

Thetablefeedhandwheelisthelargehand-

wheelontheleftfrontofthemachine.Onecom-

pleterevolutionofthishandwheelmovesthetable

3-½".

Movingthehandwheeltransmitsmotionthrough

thetablefeedrackpiniontothetablerackwhich

isfastenedtotheundersideofthetable.Todis-

engagethetablefeedrackpinionfromthetable

rack,pullhandwheeloutward.Whileinthisout-

wardposition,thehandwheelcanbeturnedwith-

outmovingthetable.Thiswillenableyoutoplace

thehandwheelhandleina convenientpositionfor

handlingthedesiredstrokefortheworkyouare

grinding.

AUXILIARYTABLEFEED

(RAPIDTRAVERSELEVER)

Machinesequippedwithauxiliarytablefeed

havetheauxiliarytablefeedleverlocatedatthe

extremeleftofthecrossfeedcarriage.Whennot

inuse,auxiliaryfeedlevershouldbeindown

position.Tomovelevertothisposition,pullout-

ward,swingtotheleftanddown180°.Toutilize

thislever,centerthepartwhichyouintendto

grindundergrindingwheel,disengagetablefeed

handwheel.Toretainhandwheelindisengaged

positionturnhandwheeluntilhandleisinupposi-

tion,pullhandwheeloutwardasfaraspossible,

andturn180°,placinghandleindownposition.

Moveauxiliarytablefeedlevertoa verticalposi-

tionallowingthegeartoengagetherackofthe

table.Theauxiliarytablefeedisdesignedforfast

andaccurategrindingofworkupto6"inlength.

CROSSFEEDTABLECARRIAGE

Thecrossfeedtablecarriagetravelsontwo

groundandscrapedfiatways.Itisguidedand

heldinperfectalignmentbya hardenedandground

rectangularshapedkeywhichismountedinthe

centerontheundersideofthecarriage.Thisrec-

tangularshapedkeymovesbetweena stationary

gibonitsleftsideanda setoftaperedadjusting

gibsonitsrightside.Thegibshavebeenproperly

adjustedfora snugslidingfitatthefactorybut

shouldthenecessityariseforreadjustment,they

maybeadjustedbymeansofthescrewmounted

onthebaseandlocatedjustrightoftherectangular

shapedkey.

CROSSFEEDTABLECARRIAGELOCK

Thismachineisequippedwitha devicefor

lockingthetablecarriageinpositionwhenface

grinding.Youwillfindthecrossfeedtablelock

thumbscrewlocatedontherighthandsideofthe

basedirectlyunderthetablecrossfeedcarriage.

Tighteningthisthumbscrewlockstheadjusting

gibsupagainstthecrossfeedtablekey,prevent-

ingtransversemovement.

IMPORTANT:Thislockmustbereleased

whenoperatingthemachineundernormalcon-

ditions.

CROSSFEEDHANDWHEEL

Thecrossfeedhandwheelislocatedinthe

centeronthefrontofthemachine.Itisgraduated

to(.001").Onecompleteturnwillmovethecross

feedtablecarriage(.100").Thiswheelcontrols

thetransversemovementofthecrossfeedtable

carriage.

ELEVATINGHANDWHEEL

Theelevatinghandwheellocatedatthetopof

thecolumnontherightsideisusedtoraiseor

lowerthespindle.Itisgraduatedinonehalfthou-

sandths(.0005").Onecompleterevolutionraises

orlowersthespindle(.050").

Iftheelevatinghandwheelrotatestoofreely,it

canbeadjustedfortheproperrotatingtensionby

meansofthetensionadjustingdevicedesignedfor

thispurpose.Togainaccesstothisadjustment

removethe(4)flatheadscrewssecuringthe

columncovertothecolumn.Justtotherearand

rightofthehandwheel,youwillfindthesocket

headadjustingscrew.Toincreasethetensionon

thehandwheelturnclockwise.Todecreasethe

tensionturncounterclockwise.

VERTICALFEEDGEARS

Removecoverfromtopoftheverticalcolumn.

Thepinionissecuredtoelevatinghandwheelshaft

justbelowthebevelgearandbacklashisadjusted

bymeansofa lockingcollar.

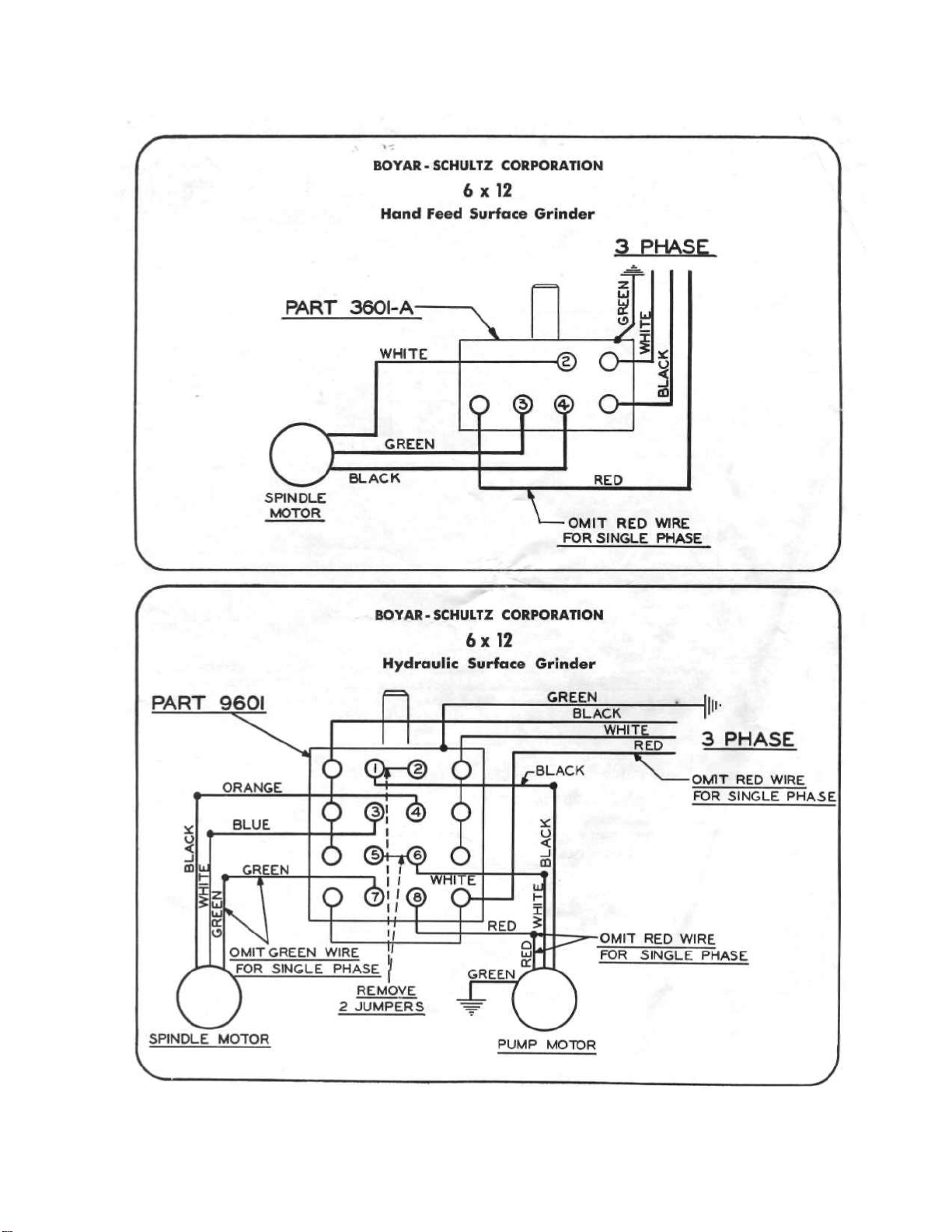

BOYAR-SCHULTZ6-12HYDRAULICSURFACEGRINDER

SeeBoyar-Schultzinstructionsforthehandfeed

model6-12surfacegrinderbeforeremovingthe

machinefromitscrate.Followinstructionsgiven

intheparagraphsdescribinghandling,installation

andlubrication.

HYDRAULICRESERVOIR

Thehydraulicpumpandthepumpmotorare

housedinthelowersectionofthehydraulicreser-

voir.Thepumpmotormustbeconnectedtothe

starterswitch.Thisisdonebyconnectingthe

multi-wiredcablethatextendsfromtherearof

thereservoirtothejunctionboxlocatedonthe

backofthegrinder.A fourwirecableisfurnished

forthreephaseinstallation.Matchuploosewires

bythecolorcode,secureeach,andinsulate.The

greenwireshouldbefastenedtotheclampscrew

insidethejunctionboxtocompletetheground.

Athreewirecableisfurnishedforsinglephase

installation.Matchupcolorcodedwiresand

groundthegreenwirestothejunctionboxclamp

screw.

Twohosesarefurnishedwiththemachine.The

intakehose(longhose)shouldbeconnectedtothe

lowerofthetwoelbowsthatprotrudefromthe

reservoir,tothefrontelbow,locatedontheright

sideofthegrindercarriage.Theexhausthose

(shorthose)shouldbeconnectedtotheupper

reservoirelbowandtotherearcarriageelbow.In

bothcases,tightenthehosetothecarriageelbows

first.Stationreservoironthefloorasshownin

accompanyingliterature.Thebackofthereservoir

shouldbeapproximatelyflushwiththebackofthe

grinderstand.

Removetopcoverofthereservoirandaddthe

threegallonsofhydraulicoilthatarefurnished

withthemachine— seeLubricationChartfor

recommendedoils.Thelevelofthehydraulicoil

shouldnotbepermittedtodropbelowthetopof

thefilterscreen.Toinsurelong,trouble-freeopera-

tionofthishydraulicmachine,thehydraulicoil

shouldbechangedeverysixmonths.Thereservoir

andthefilterscreenshouldbecleanedatthetime

oftheoilchange.

AUTOMATICOPERATION

Thestopdog,locatedonthefrontedgeofthe

grindertable,controlthelongitudinaltravelofthe

table.Thestopdogsmaybeadjustedbymeansof

a5/32"hexwrenchtosuitthelengthofstroke

desired.Thedogsmustbesetsothatthepilot

valvehead(thetwoprongedcastinglocatedonthe

topofthevalvebody)islocatedbetweenthem.

Thestopdogtotherightofthevalvemuststrike

theupperarmofthepilotvalveheadandthestop

dogtotheleftmuststrikethelowerarm.For

initialoperationofthemachine,thestopdogs

shouldbesetapproximatelysixinchesapart.

Connectcylinderrodtotableadapterhousing.

Thetableadapterhousingislocatedontheunder-

sideofthetableatitsrightend.Toengagethe

cylinderrod,raisethepinthatprotrudesfromthe

housingandinserttheballendofthecylinderrod.

Oscillatethetablehandwheelwhileexertinga

slightdownwardpressureontheadapterhousing

pinuntilthecylinderrodislockedintoplace.

Beforeoperatingthemachinehydraulically,the

tablehandwheelmustbedisengaged.Pulloutthe

knoboftheplunger,locatedontheleftsideofthe

carriage,andpulloutthehandwheel.Release

plungertolockhandwheelinthe"OUT"position.

CAUTION!

Checktoseethatthegrindingwheelclearsthe

workandthatthemagneticchuckisenergized.

Thestarterswitchislocatedontherightsideof

thegrinderbase.Theswitchhasthreepositions,

"MANUAL","OFF"and"AUTO".Tostart

spindleandhydraulicpumpmotor,placeswitch

intothe"AUTO"position.Tosetthetablein

motion,turntheshut-offvalvehandle(locatedon

topofthevalve)inthedirectionindicatedbythe

arrow.

Erraticactionofthetableinitsinitialoperation

orafterprolongedidlenessisduetoairinthe

hydraulicsystem.Theairwillworkoutandthe

actionwillimproveaftera shortrun-inperiod.

MANUALOPERATION

Placeshut-offvalveinthe"OFF"positionand

setstarterswitchinthe"MANUAL"position.

Manualoperationofthelongitudinaltablefeedis

simplifiedifthecylinderrodisdisengagedfromthe

table.Todisengagethecylinderrod,raisethepin

thatprotrudesfromtheadapterhousingandmove

thetabletotheright,allowingthepintodropafter

thecylinderrodisclearoftheadapterhousing.

Cylinderroddisengagementisrecommendedonly

whenprolongedmanualuseisanticipated.

TABLECUSHIONADJUSTMENT

Aneedlevalveadjustmenthasbeenprovided

ontherightsideofthemainvalvetocushionthe

tablereversals.Toadjust,loosenthelocknutand

screwtheneedlevalveintoincreaseoroutto

decreasethecushion.

Thisadjustmenthasbeenmadeatthefactory

andanyre-adjustmentshouldonlybemadeafter

therigidmountingofthemachinehasbeen

checked.

SPECIFICATIONS(6-12)FOR6x12HANDFEEDANDHYDRAULICSURFACEGRINDERS

HydraulicFeedHandFeed

TableTravel

Longitudinal

CrossFeed

WorkHeight(using7"diam.wheel)

TableWorkingSurface

("T"slot," width)

13"

7"

0"to11¼"

12"x 5 "

13"

7"

0"to11¼"

12"x 5 "

GrindWheel

Diameter

Thickness

HoleDiam.

Weight

Net

Shipping

7"

3/16"to½"

1¼"

485lb.

705lb.

7"

3/16"to½"

1¼"

SpindleSpeed

HandwheelGraduation

Vertical

CrossFeed

LongitudinalTableSpeed

SpindleMotor

HydraulicPumpMotor

FloorSpace

Height

(BenchModel)

(FloorModel)

3000rpm

.0005"

.001"

0-50fpm

½hp—3450rpm

¼hp-1725rpm

44"x 38"

32"

62"

3000rpm

.0005"

.001"

½hp—3450rpm

43"x 38"

32"

62"

415lb.

561lb.

ELECTRICALEQUIPMENT

Themotorfurnishedwiththismachineisa ½

H.P.,220volt,3 phase,60cycle,3450RPM,open

roundframe,sleevetypebearingmotor,precision

balanceddynamicallyforsmoothandvibration-

freeoperation.Witha minimumamountofcare,

motorshouldlastthelifeofthegrinder.Follow

lubricationchartexplicitlyforlubricatingthisunit.

Machinescanbewiredfor110V - 60cycle- 1

phaseor220V - 60cycle- 3 phase.Theyare

equippedwith300Voltwire.Machineswiredfor

440V - 60cycle- 3 phase— have600Voltwire.

Themachineiswiredfor220volt,3 phase,60

cycleoperationunlessotherwisespecified.(See

Fig.2 andFig.3}

Ifthemachineisequippedwiththeadjustable

bracketlamp,thelampissuppliedwithextension

cordfor110voltcircuit.

OPTIONALACCESSORIES

1.Metalpedestalbase.

2.Adjustablelongitudinaltablestops.

3.Rapidtraverseleverarm.

4.Mountedadjustableelectriclight.

5.5"x 10"Walkerpermanentmagneticchuck.

6.6"x 12"Walkerpermanentmagneticchuck.

7.Hanchett5"x 10"Magna-Lockelectricmag-

neticchuckcompletewithrectifier.

8.Hanchett6"x 12"electricmagneticchuck

completewithrectifier.

9.Diamondholderforwheeldressing.

10.Mounteddiamondtofitholder.

11.Wetgrindingsplashguard.

12.Coolanttankandpump.

13.Motorsavailable:

110volt,60cycle,singlephase(standard)

220volt,60cycle,threephase(standard)

440volt,60cycle,threephase(special)

14.Dustcollectorcompletewithnozzle.

NOTE:AssemblePartsinRelationshipShown.

REPLACEMENTPARTSLIST

NotShownonValveAssembly

9600

96O0-A

9600-X

9601

9603

9603-A

9604

9606

9608-A

9609

9609-A

9613

9618

HydraulicPumpandMolarUnit— 3 Phase220/440Volt

HydraulicPumpandMalarUnit—1Phase115/230Vail

HydraulicPumponly

DrumSwitch

HydraulicCylinder

HydraulicCylinderChevronPacking

HydraulicReiervoirFilter

IntakeHas*(LongHoiel

IntakeHoie(LongHose)forMath/notw/fftJ.I.C. EJecfricafControls

ExhaustHaie(ShortHose)

ExhaustHot*(ShortHotelforMachine*with J.I.C. ElectricalControls

HoseCoupling

FilterlineHose(5"Long)

Table of contents

Popular Grinder manuals by other brands

RODEX

RODEX RDX1031 instruction manual

Bosch

Bosch Professional GWX 18V-15 SC Original instructions

Ingersoll-Rand

Ingersoll-Rand Power Force PF450 instructions

Osaki Power Tools

Osaki Power Tools GB150-2 Operator's manual

SUHNER ABRASIVE

SUHNER ABRASIVE UWG 10-R125 Technical document

Expobar

Expobar PULSE 65 user manual