BRABUS 1300 R Manual

SETUP INSTRUCTIONS 2022

Art. no. 3214662en

INTRODUCTION

*3214662en*

3214662en

02/2022

INTRODUCTION

Perform the work described in these setup instructions before the vehicle is delivered to the customer.

Read the setup instructions in their entirety before beginning work.

These setup instructions were written to correspond to the latest state of this series. We reserve the right to make

modifications in the interest of technical advancement without at the same time updating these setup instruc-

tions.

We shall not provide a description of general workshop methods. Likewise, safety rules that apply in a workshop

are not specified here. It is assumed that the work will be performed by a fully trained mechanic.

All specifications contained herein are non-binding. KTM Sportmotorcycle GmbH specifically reserves the right

to modify or delete technical specifications, prices, colors, forms, materials, services, designs, equipment, etc.,

without prior notice and without specifying reasons, to adapt these to local conditions, as well as to stop produc-

tion of a particular model without prior notice. KTM accepts no liability for delivery options, deviations from fig-

ures and descriptions, misprints, and other errors. The models portrayed partly contain special equipment that

does not belong to the regular scope of supply.

© 2022 KTM Sportmotorcycle GmbH, Mattighofen Austria

All rights reserved

Reproduction, even in part, as well as copying of all kinds, is permitted only with the express written permission

of the copyright owner.

ISO 9001(12 100 6061)

KTM applies quality assurance processes that lead to the highest possible product quality as

defined in the ISO 9001 international quality management standard.

Issued by: TÜV‑Management Service

KTM Sportmotorcycle GmbH

Stallhofnerstraße 3

5230 Mattighofen, Austria

This document is valid for the following models:

BRABUS 1300 R (F9999V4, F9999V5)

1 MEANS OF REPRESENTATION

2

1.1 Symbols used

The meaning of specific symbols is described below.

Indicates an expected reaction (e.g. of a work step or a function).

Indicates an unexpected reaction (e.g. of a work step or a function).

Indicates a page reference (more information is provided on the specified page).

Indicates information with more details or tips.

Indicates the result of a testing step.

Indicates a voltage measurement.

Indicates a current measurement.

Indicates a resistance measurement.

Indicates the end of an activity including potential rework.

1.2 Formats used

The typographical formats used in this document are explained below.

Proprietary name Indicates a proprietary name.

Name®Indicates a protected name.

Brand™ Indicates a brand available on the open market.

Underlined terms Refer to technical details of the vehicle or indicate technical terms, which

are explained in the glossary.

SETUP 2

3

2.1 Transport mode

H02713-01

This vehicle was blocked for transport in the software.

To operate the vehicle, the vehicle electronics must be enabled.

This process is conducted during initial setup in KTM Dealer.net.

Enabling ensures that the initial setup in KTM Dealer.net is docu-

mented.

Enabling can be performed either temporarily, e.g. for a test ride,

or permanently for vehicle handover.

Info

Make sure that the vehicle is permanently enabled before

handing it over to the customer.

2.2 Diagnostics connector

H01949-01

The diagnostics connector is located under the front rider's seat.

2.3 Unpacking and setting up the vehicle

Preliminary work

–Remove the box.

H05199-01

Main work

–Remove the separate enclosure and unpack it. Check that the

scope of supply is complete using the enclosed packing list.

Info

The procedure for missing components is described in

the Customer Service Manual.

–Check the vehicle for transport damage.

Info

The procedure in the event of transport damage is

described in the Customer Service Manual.

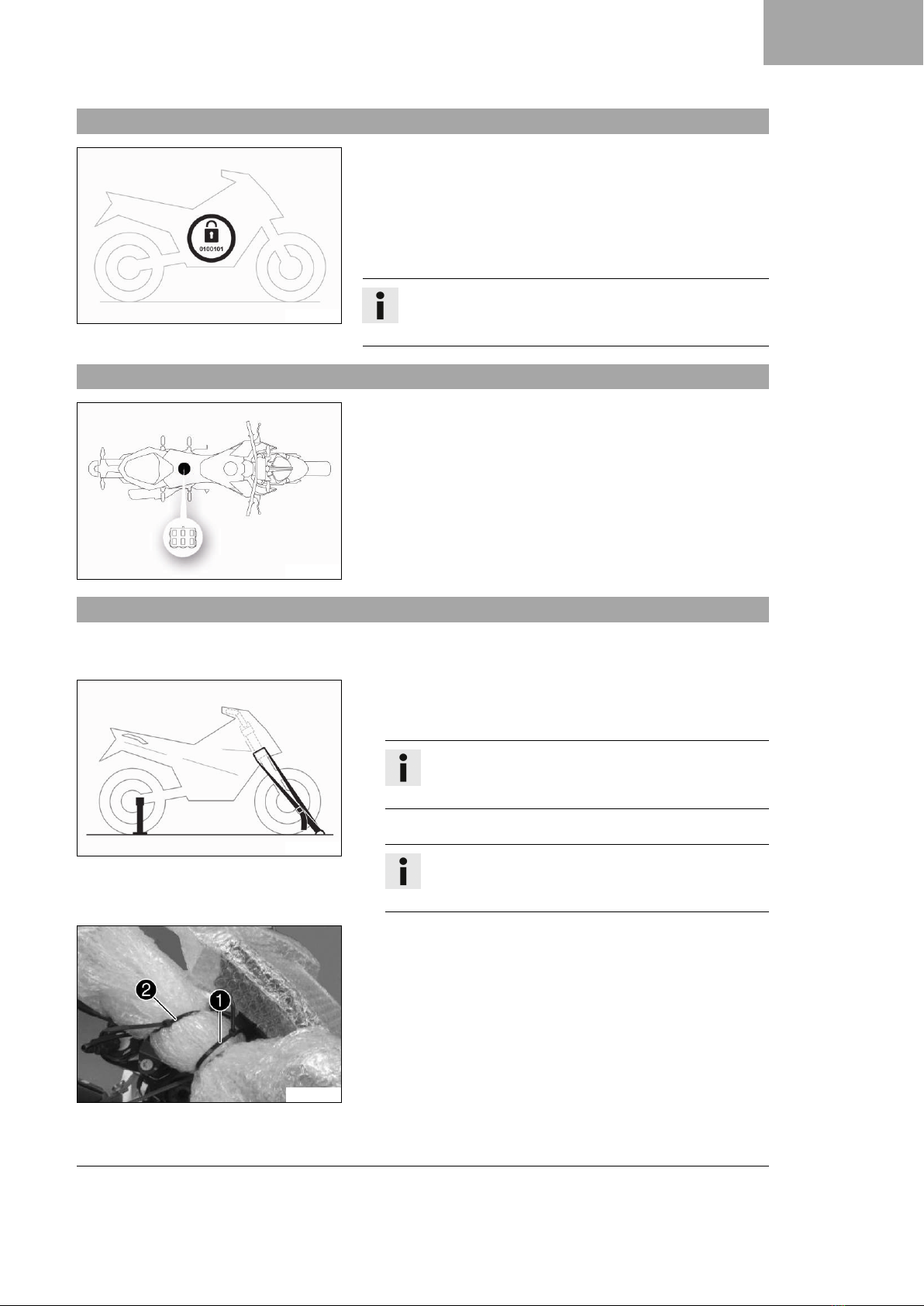

S05294-10

–Remove cable ties 1and hang the combination instrument

to the side.

–Remove cable ties 2and hang the handlebar to the side.

2 SETUP

4

S05295-10

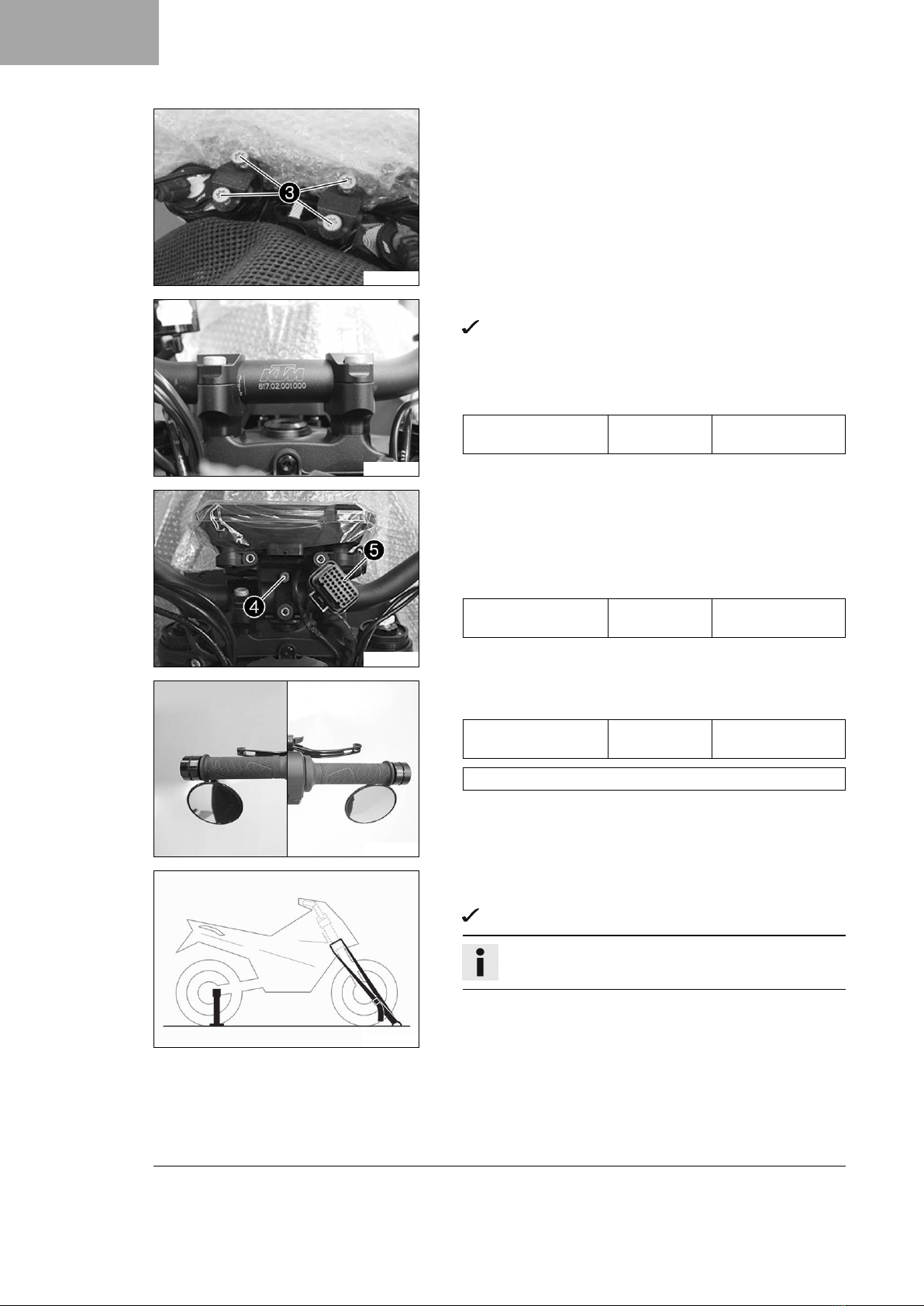

–Remove the handlebar clamp screws 3.

–Take off the handlebar clamp.

S05296-10

–Position the handlebar.

The markings of the handlebar scale are located centrally

between the handlebar clamp.

–Position the handlebar clamp. Mount and tighten the screws

evenly.

Guideline

Screw, handlebar

clamp

M8 20 Nm (14.8 lbf ft)

S05297-10

–Position the combination instrument rack on the handlebar.

–Mount screw 4, but do not tighten it yet.

–Move the combination instrument into the desired position.

–Tighten screw 4.

Guideline

Screw, combination

instrument clamping

M6 2 Nm (1.5 lbf ft)

–Plug in connector 5with sleeve.

S05298-10

–Mount and tighten the rear mirror on both sides.

Guideline

Screw, handlebar

end mirror

M6x35 13 Nm (9.6 lbf ft)

Mount the rear mirror facing downward.

H05199-01

–Carefully loosen and remove the tension belts around the fork

legs.

The vehicle is released at the front.

Info

An assistant prevents the motorcycle from falling over.

–Remove the tension belt on the rear wheel.

–Together with an assistant, take the vehicle off the pallet.

–Remove the radiator shield.

SETUP 2

5

S05299-10

–Remove the front rider's seat. ( p. 6)

–Remove the black ignition key and KEYCODECARD and keep in a

safe place for the handover.

–Remove cover 6.

–Plug in the connector of starter relay 7.

–Mount the cover.

–Charge the 12-V battery. ( p. 10)

Guideline

The 12-V battery must be fully charged before it is handed

over to the customer.

Info

The first charging process may take longer with a new

12-V battery.

–Remove the protective film.

–Refuel. ( p. 12)

–Prepare the vehicle according to the specifications in

KTM Dealer.net for handover to the customer.

Info

Transport mode must be deactivated to be able to start

the motorcycle.

3 WORK

6

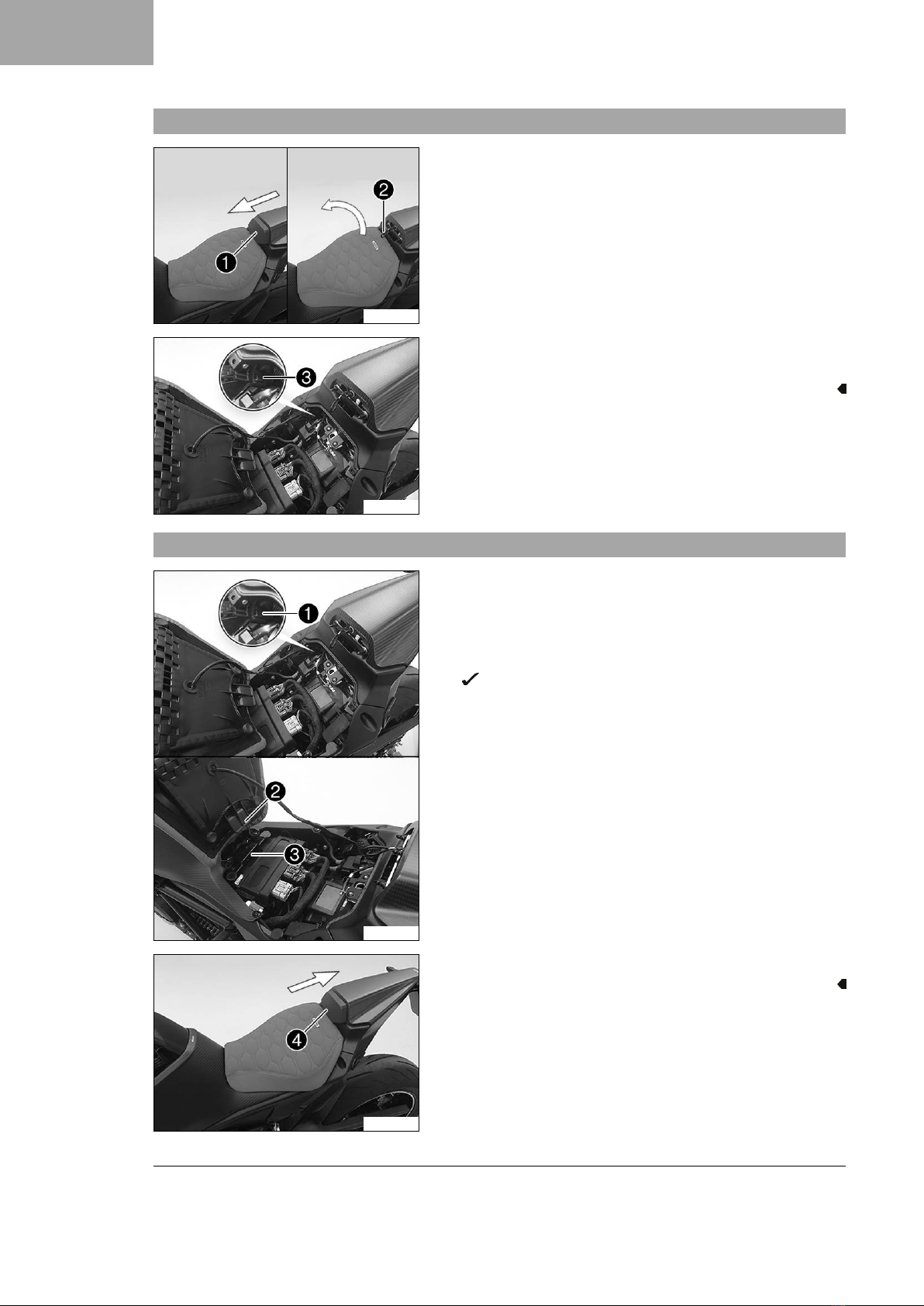

3.1 Removing the front rider's seat

S05188-10

–Pull off back cushion 1toward the front.

–Unlock the front rider's seat with loop 2.

–Lift the rear of the front rider's seat.

S05189-10

–Disconnect plug-in connector 3of the seat heating.

–Remove the front rider's seat.

3.2 Mounting the front rider's seat

S05190-10

–Join plug-in connector 1of the seat heating.

–Hook recess 2of the front rider's seat into guide 3, lower it

at the rear and push it forward.

–Position the locking pin in the lock housing and push down the

front rider's seat at the rear.

The locking pin engages with an audible click.

–Check that the front rider's seat is mounted correctly.

S05191-10

–Position back cushion 4and push it into holding lugs.

WORK 3

7

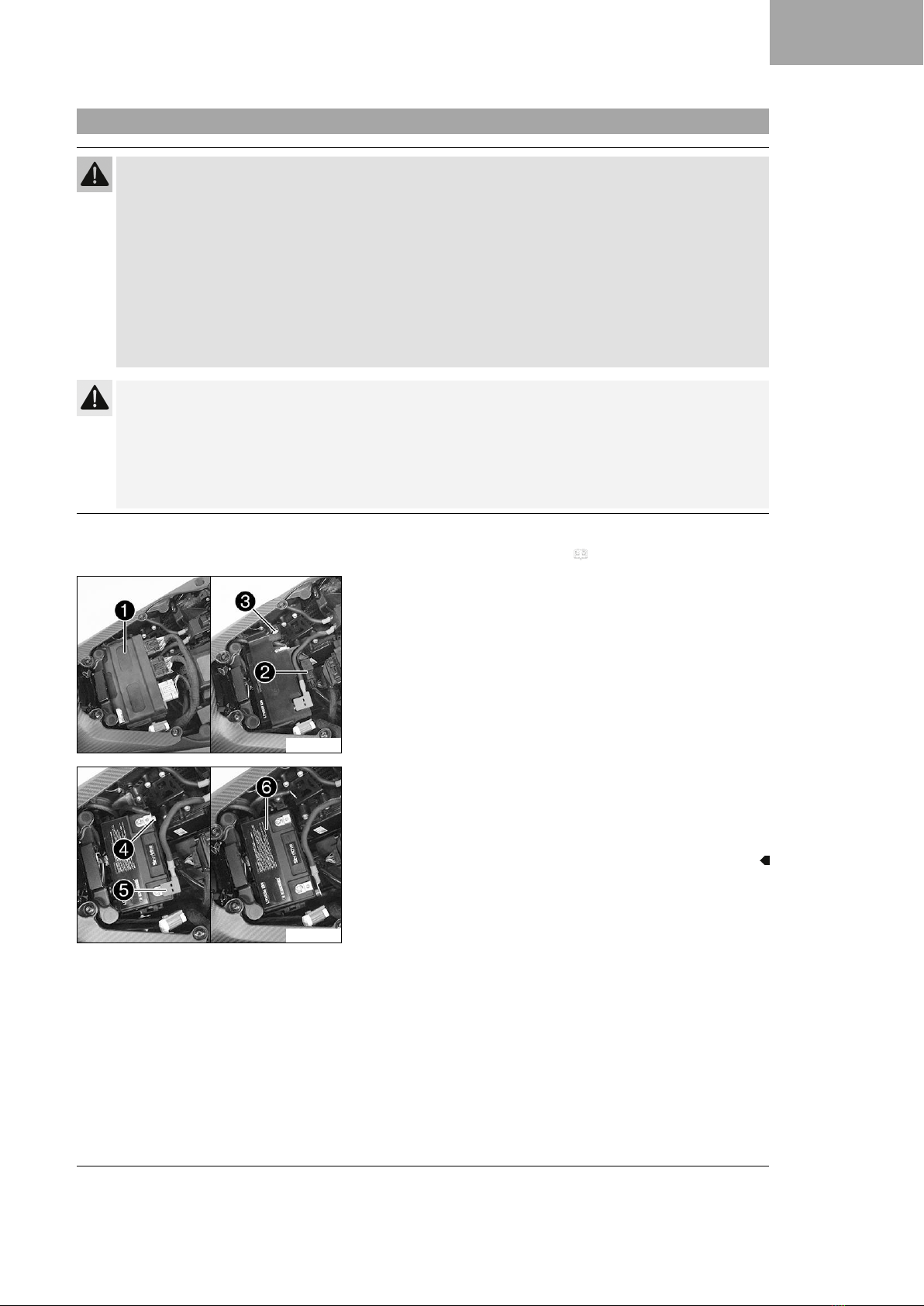

3.3 Removing the 12-V battery

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep 12 V batteries out of the reach of children.

–Wear suitable protective clothing and safety glasses.

–Avoid contact with battery acid and battery gases.

–Keep sparks or open flames away from the 12 V battery.

–Only charge 12 V batteries in well-ventilated rooms.

–Rinse the affected area immediately with plenty of water in the event of contact with the skin.

–Rinse eyes with water for at least 15 minutes and consult a doctor immediately if battery acid and

battery gases get into the eyes.

Caution

Danger of accidents Electronic components and safety devices will be damaged if the 12-V battery is dis-

charged or missing.

If the 12-V battery is discharged or defective, malfunctions in the vehicle electronics can occur, espe-

cially when starting.

–Never operate the vehicle with a discharged 12-V battery or without a 12-V battery.

Preparatory work

–Remove the front rider's seat. ( p. 6)

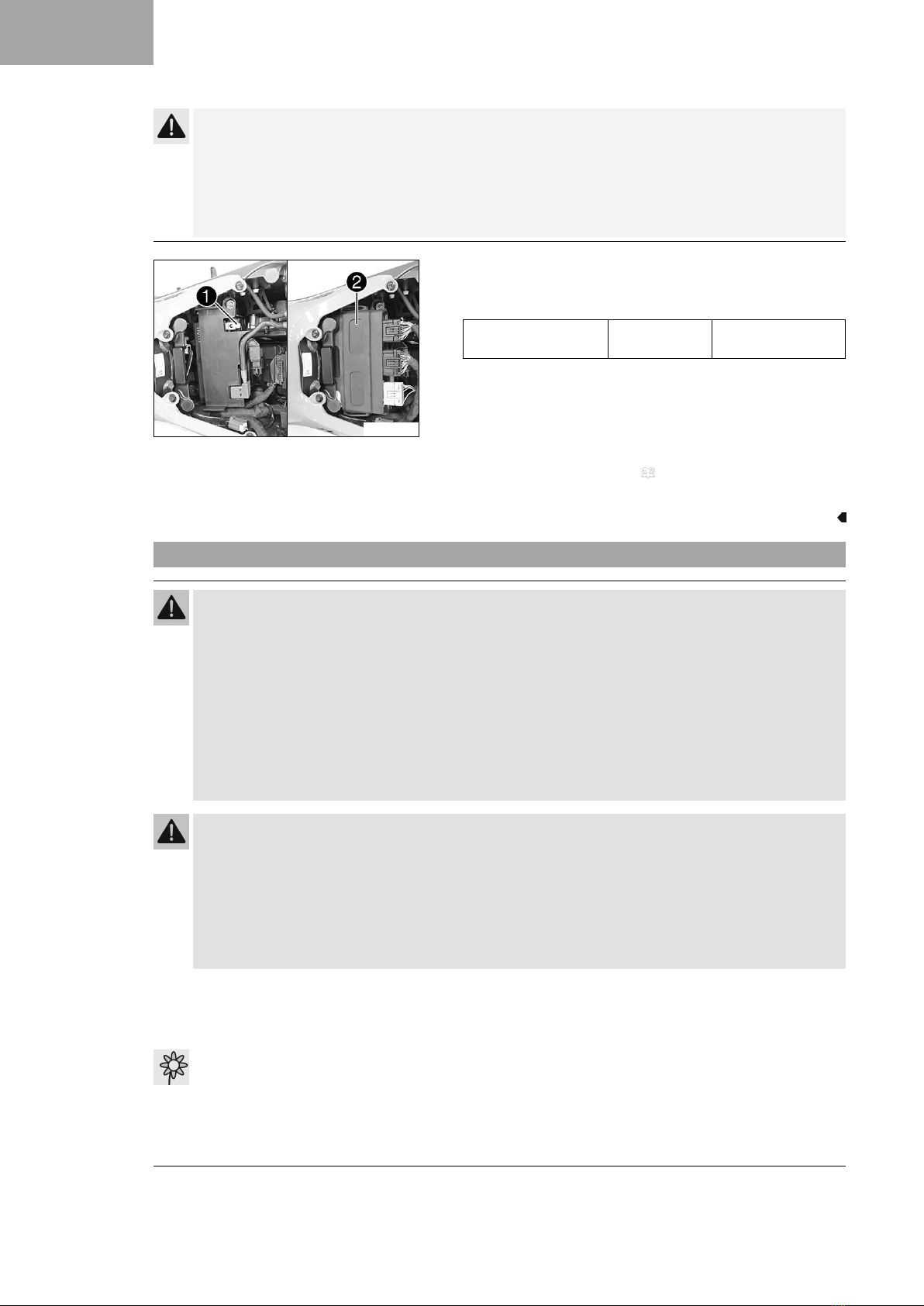

S05221-10

Main work

–Remove control unit 1and hang to the side.

–Disconnect plug-in connector 2.

–Remove screw 3and take off the battery cover.

S05222-10

–Disconnect negative cable 4from the 12-V battery.

–Take off positive terminal cover 5and disconnect the posi-

tive cable from the 12-V battery.

–Take the 12-V battery 6out of the battery compartment.

3 WORK

8

3.4 Installing the 12-V battery

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep 12 V batteries out of the reach of children.

–Wear suitable protective clothing and safety glasses.

–Avoid contact with battery acid and battery gases.

–Keep sparks or open flames away from the 12 V battery.

–Only charge 12 V batteries in well-ventilated rooms.

–Rinse the affected area immediately with plenty of water in the event of contact with the skin.

–Rinse eyes with water for at least 15 minutes and consult a doctor immediately if battery acid and

battery gases get into the eyes.

Caution

Danger of accidents Electronic components and safety devices will be damaged if the 12-V battery is dis-

charged or missing.

If the 12-V battery is discharged or defective, malfunctions in the vehicle electronics can occur, espe-

cially when starting.

–Never operate the vehicle with a discharged 12-V battery or without a 12-V battery.

S05222-11

Main work

–Insert 12-V battery 1into the battery compartment.

12-V battery (HJTZ14S-FPI)

–Position the positive cable and mount and tighten the screw.

Guideline

Screw, battery termi-

nal

M6 4.5 Nm

(3.32 lbf ft)

–Position positive terminal cover 2.

–Position negative cable 3and mount and tighten the screw.

Guideline

Screw, battery termi-

nal

M6 4.5 Nm

(3.32 lbf ft)

S05221-11

–Position the battery cover, mount screw 4, and tighten.

Guideline

Remaining screws,

chassis

M5 5 Nm (3.7 lbf ft)

–Join plug-in connector 5.

–Position control unit 6.

Finishing work

–Mount the front rider's seat. ( p. 6)

–Set time and date.

WORK 3

9

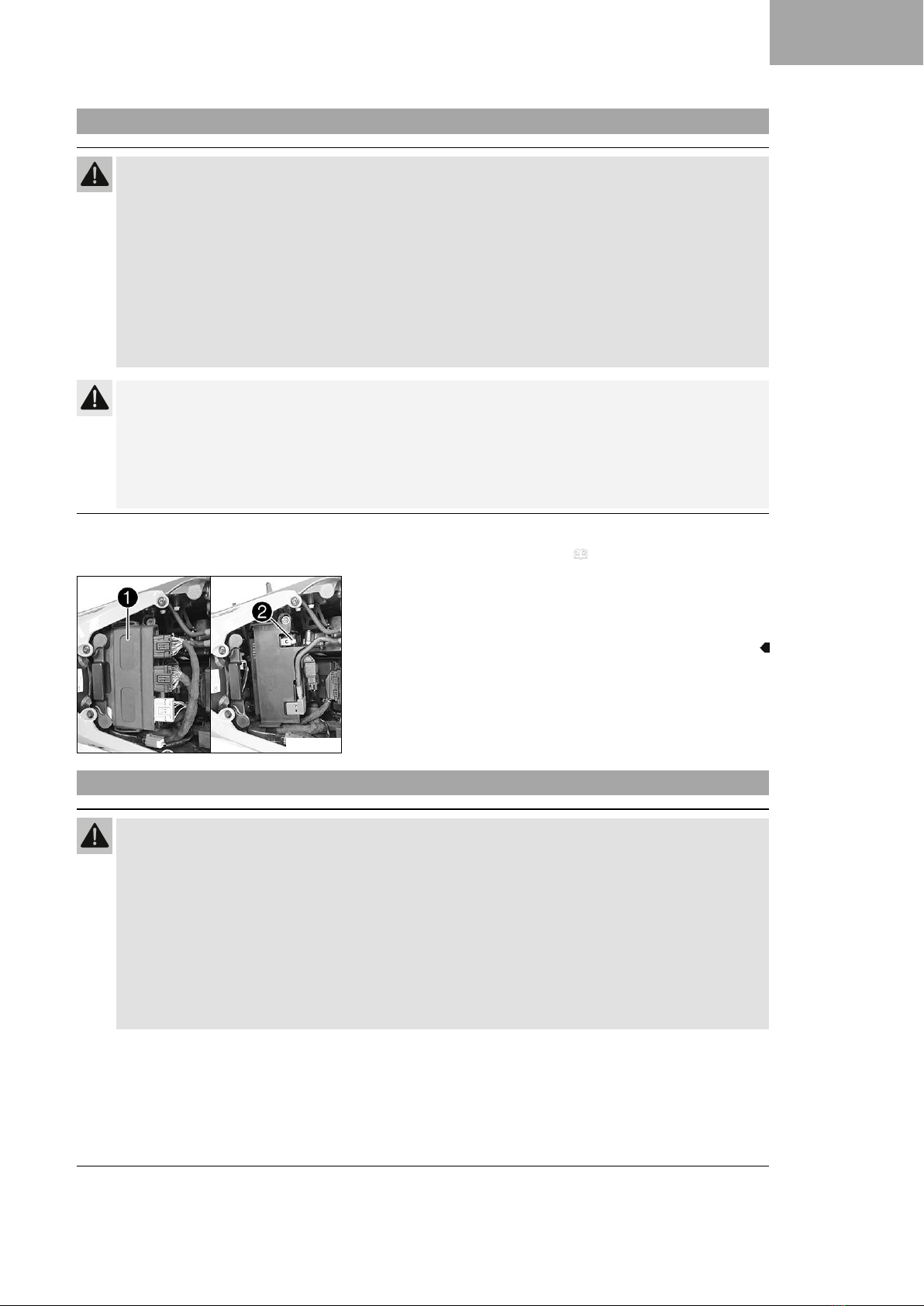

3.5 Disconnecting the negative cable of the 12-V battery

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep 12 V batteries out of the reach of children.

–Wear suitable protective clothing and safety glasses.

–Avoid contact with battery acid and battery gases.

–Keep sparks or open flames away from the 12 V battery.

–Only charge 12 V batteries in well-ventilated rooms.

–Rinse the affected area immediately with plenty of water in the event of contact with the skin.

–Rinse eyes with water for at least 15 minutes and consult a doctor immediately if battery acid and

battery gases get into the eyes.

Caution

Danger of accidents Electronic components and safety devices will be damaged if the 12-V battery is dis-

charged or missing.

If the 12-V battery is discharged or defective, malfunctions in the vehicle electronics can occur, espe-

cially when starting.

–Never operate the vehicle with a discharged 12-V battery or without a 12-V battery.

Preparatory work

–Remove the front rider's seat. ( p. 6)

S04104-10

Main work

–Remove control unit 1and hang to the side.

–Disconnect negative cable 2from the 12-V battery.

3.6 Connecting the negative cable of the 12-V battery

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep 12 V batteries out of the reach of children.

–Wear suitable protective clothing and safety glasses.

–Avoid contact with battery acid and battery gases.

–Keep sparks or open flames away from the 12 V battery.

–Only charge 12 V batteries in well-ventilated rooms.

–Rinse the affected area immediately with plenty of water in the event of contact with the skin.

–Rinse eyes with water for at least 15 minutes and consult a doctor immediately if battery acid and

battery gases get into the eyes.

3 WORK

10

Caution

Danger of accidents Electronic components and safety devices will be damaged if the 12-V battery is dis-

charged or missing.

If the 12-V battery is discharged or defective, malfunctions in the vehicle electronics can occur, espe-

cially when starting.

–Never operate the vehicle with a discharged 12-V battery or without a 12-V battery.

S04105-10

Main work

–Position negative cable 1and mount and tighten the screw.

Guideline

Screw, battery termi-

nal

M6 4.5 Nm

(3.32 lbf ft)

–Position control unit 2.

Finishing work

–Mount the front rider's seat. ( p. 6)

–Set time and date.

3.7 Charging the 12-V battery

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep 12 V batteries out of the reach of children.

–Wear suitable protective clothing and safety glasses.

–Avoid contact with battery acid and battery gases.

–Keep sparks or open flames away from the 12 V battery.

–Only charge 12 V batteries in well-ventilated rooms.

–Rinse the affected area immediately with plenty of water in the event of contact with the skin.

–Rinse eyes with water for at least 15 minutes and consult a doctor immediately if battery acid and

battery gases get into the eyes.

Warning

Risk of injury 12 V batteries contain harmful substances.

–Keep 12 V batteries out of the reach of children.

–Keep sparks and open flames away from 12 V batteries.

–Only charge 12 V batteries in well-ventilated rooms.

–Maintain a minimum clearance from inflammable materials when charging 12 V batteries.

Minimum clearance 1 m (3 ft)

Note

Danger of damage An incorrectly selected charging mode will damage the 12-V battery.

–Always select a charging mode that is compatible with the type of battery.

Note

Environmental hazard 12 V batteries contain environmentally hazardous materials.

–Do not dispose of 12 V batteries as household waste.

–Dispose of 12 V batteries at a collection point for used batteries.

WORK 3

11

Note

Environmental hazard Hazardous substances cause environmental damage.

–Dispose of oils, grease, filters, fuel, cleaning agents, brake fluid, etc., correctly and in compliance with

the applicable regulations.

Info

Even when there is no load on the 12-V battery, it discharges steadily each day.

The charging level and the method of charging are very important for the service life of the 12-V battery.

Rapid recharging with a high charging current shortens the service life of the battery.

If the charging current, charging voltage, or charging time is exceeded, the 12 V battery will be destroyed.

If the 12-V battery is depleted by repeated starting, the 12-V battery must be charged immediately.

If the 12-V battery is left in a discharged state for an extended period, it will become deeply discharged

and suffer a loss of capacity, destroying the battery.

The 12-V battery is maintenance-free.

Preparatory work

–Remove the front rider's seat. ( p. 6)

–Disconnect the negative cable of the 12-V battery. ( p. 9)

311910-10

Main work

–Connect a battery charger to the 12-V battery. Adjust the bat-

tery charger.

EU battery charger XCharge‑professional (00029095050)

Alternative 1

US battery charger XCharge‑professional

(00029095051)

Alternative 2

UK battery charger XCharge‑professional

(00029095052)

Info

Follow the instructions of the charger and the manual.

–Disconnect the battery charger after charging the 12-V battery.

Guideline

The charging current, charging voltage, and charging time

must not be exceeded.

Recharge the 12-V battery

regularly when the motorcy-

cle is not being used

3 months

Finishing work

–Connect the negative cable of the 12-V battery. ( p. 9)

–Mount the front rider's seat. ( p. 6)

–Set time and date.

3 WORK

12

3.8 Refueling

Danger

Fire hazard Fuel is highly flammable.

The fuel in the fuel tank expands when warm and can escape if overfilled.

–Do not fuel the vehicle in the vicinity of open flames or lit cigarettes.

–Switch off the engine for refueling.

–Make sure that no fuel is spilled; particularly not on hot parts of the vehicle.

–If any fuel is spilled, wipe it off immediately.

–Observe the specifications for refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

–Avoid skin, eye and clothing contact with fuel.

–Immediately consult a doctor if you swallow fuel.

–Do not inhale fuel vapors.

–In case of skin contact, rinse the affected area with plenty of water.

–Rinse the eyes thoroughly with water, and consult a doctor in case of fuel contact with the eyes.

–Change your clothing in case of fuel spills on them.

Note

Material damage Inadequate fuel quality causes the fuel filter to quickly become clogged.

In some countries and regions, the available fuel quality and cleanliness may not be sufficient. This will result in

problems with the fuel system.

–Refuel only with clean fuel that meets the specified standards.

Note

Environmental hazard Improper handling of fuel is a danger to the environment.

–Do not allow fuel to enter the groundwater, the soil, or the sewage system.

S05186-10

–Switch off the engine.

–Open fuel tank filler cap. ( p. 13)

–Fill the fuel tank with fuel up to the lower edge Aof the filler

neck.

Total fuel tank

capacity, approx.

16 l

(4.2 US gal)

Super unleaded

(ROZ 95)

( p. 20)

–Close the fuel tank filler cap. ( p. 14)

WORK 3

13

3.9 Opening fuel tank filler cap

Danger

Fire hazard Fuel is highly flammable.

The fuel in the fuel tank expands when warm and can escape if overfilled.

–Do not fuel the vehicle in the vicinity of open flames or lit cigarettes.

–Switch off the engine for refueling.

–Make sure that no fuel is spilled; particularly not on hot parts of the vehicle.

–If any fuel is spilled, wipe it off immediately.

–Observe the specifications for refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

–Avoid skin, eye and clothing contact with fuel.

–Immediately consult a doctor if you swallow fuel.

–Do not inhale fuel vapors.

–In case of skin contact, rinse the affected area with plenty of water.

–Rinse the eyes thoroughly with water, and consult a doctor in case of fuel contact with the eyes.

–Change your clothing in case of fuel spills on them.

–Keep fuels correctly in a suitable canister, and out of the reach of children.

Note

Environmental hazard Improper handling of fuel is a danger to the environment.

–Do not allow fuel to enter the groundwater, the soil, or the sewage system.

Condition

The motorcycle is stationary.

The engine is switched off.

The ignition has been switched on or off for less than 1 minute.

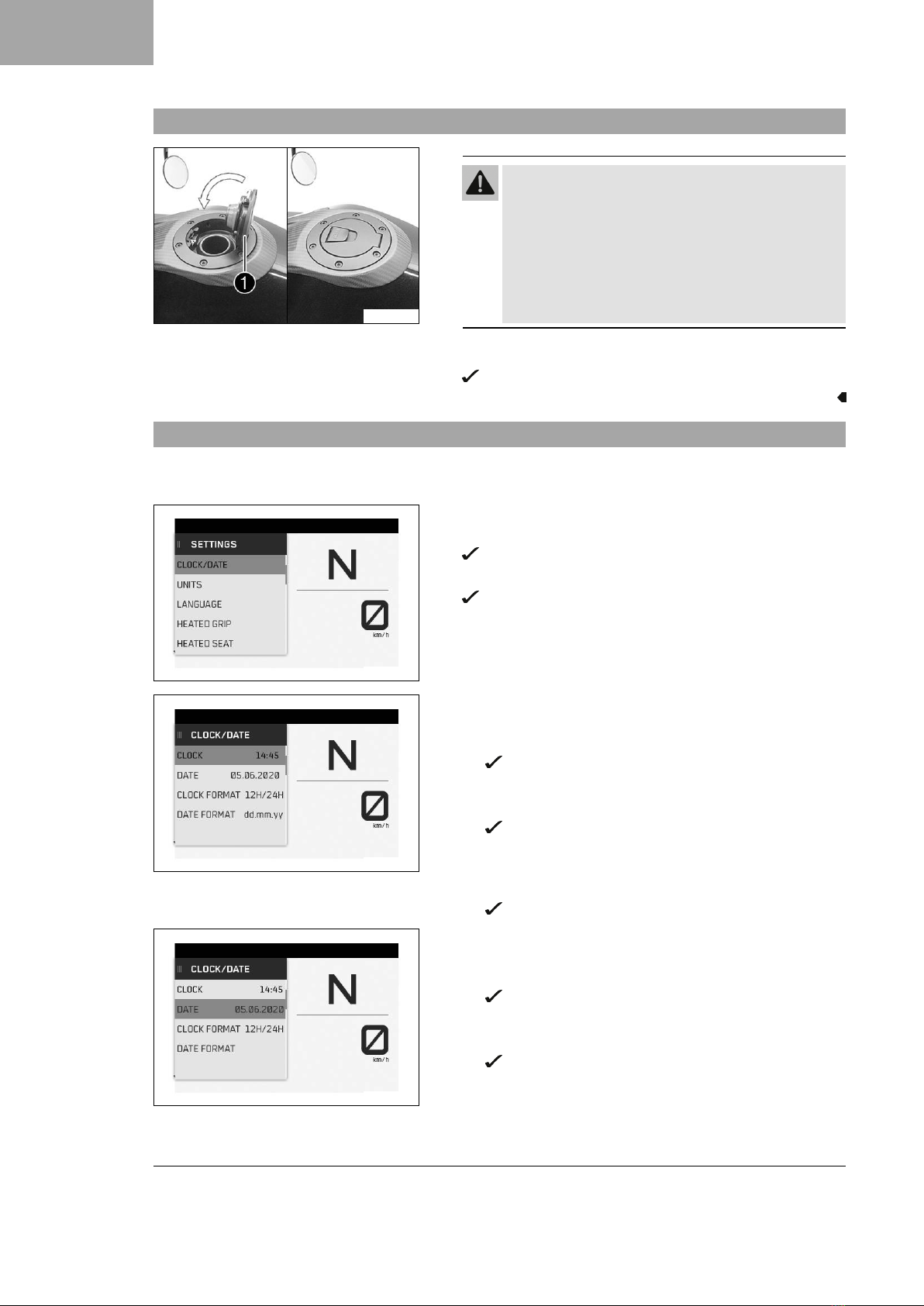

S05165-10

–Fold up cover 1slowly.

The fuel tank filler cap is unlocked.

–Fold up fuel tank filler cap 2.

3 WORK

14

3.10 Closing the fuel tank filler cap

S05165-11

Warning

Fire hazard Fuel is highly flammable, toxic and a

health hazard.

–Check that the fuel tank filler cap is locked cor-

rectly after closing.

–Change your clothing if fuel spills on them.

–Rinse the affected area immediately with plenty of

water in the event of contact with the skin.

–Fold down fuel tank filler cap 1and push it down.

The fuel tank filler cap locks audibly in place.

3.11 Setting the time and date

Condition

The motorcycle is stationary.

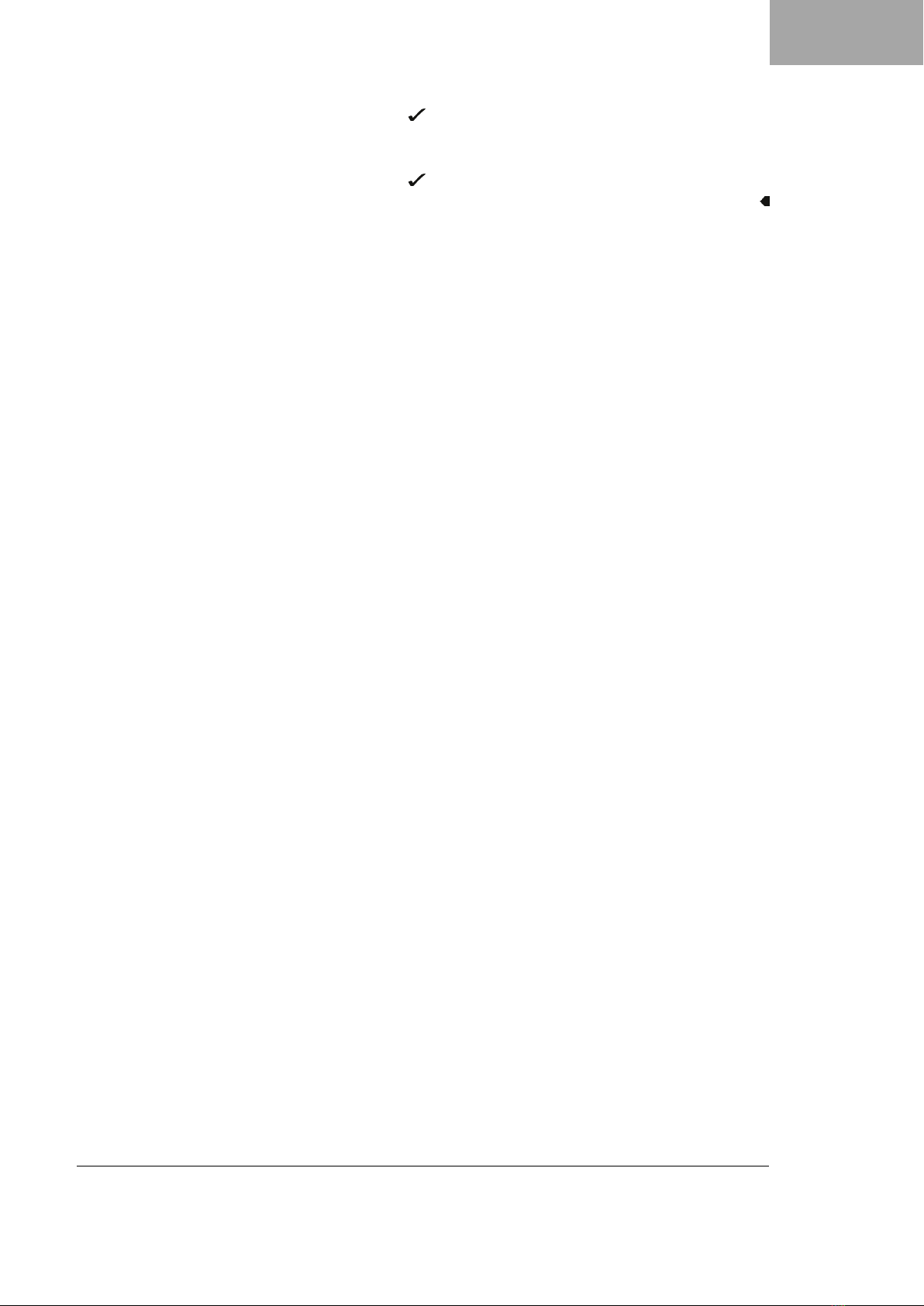

S03821-01

–Press RIGHT button when the menu is closed.

–Press the UP or DOWN button until Settings is marked.

Press the RIGHT button to open the menu.

–Press the UP or DOWN button until Clock/Date is marked.

Press the RIGHT button to open the menu.

S03820-01

Setting the clock

–Press the UP or DOWN button until the time is marked.

–Press the SET button.

The hour next to Clock flashes.

–Press the UP or DOWN button until the current hour is set.

–Press the RIGHT button.

The minute next to Clock flashes.

–Press the UP or DOWN button until the current minute is

set.

–Press the SET button.

The time is stored.

S03822-01

Setting the date

–Press the UP or DOWN button until the date is marked.

–Press the SET button.

The day next to Date flashes.

–Press the UP or DOWN button until the current day is set.

–Press the RIGHT button.

The month next to Date flashes.

–Press the UP or DOWN button until the current month is

set.

–Press the RIGHT button.

WORK 3

15

The year next to Date flashes.

–Press the UP or DOWN button until the current year is set.

–Press the SET button.

The date is stored.

4 TECHNICAL DATA

16

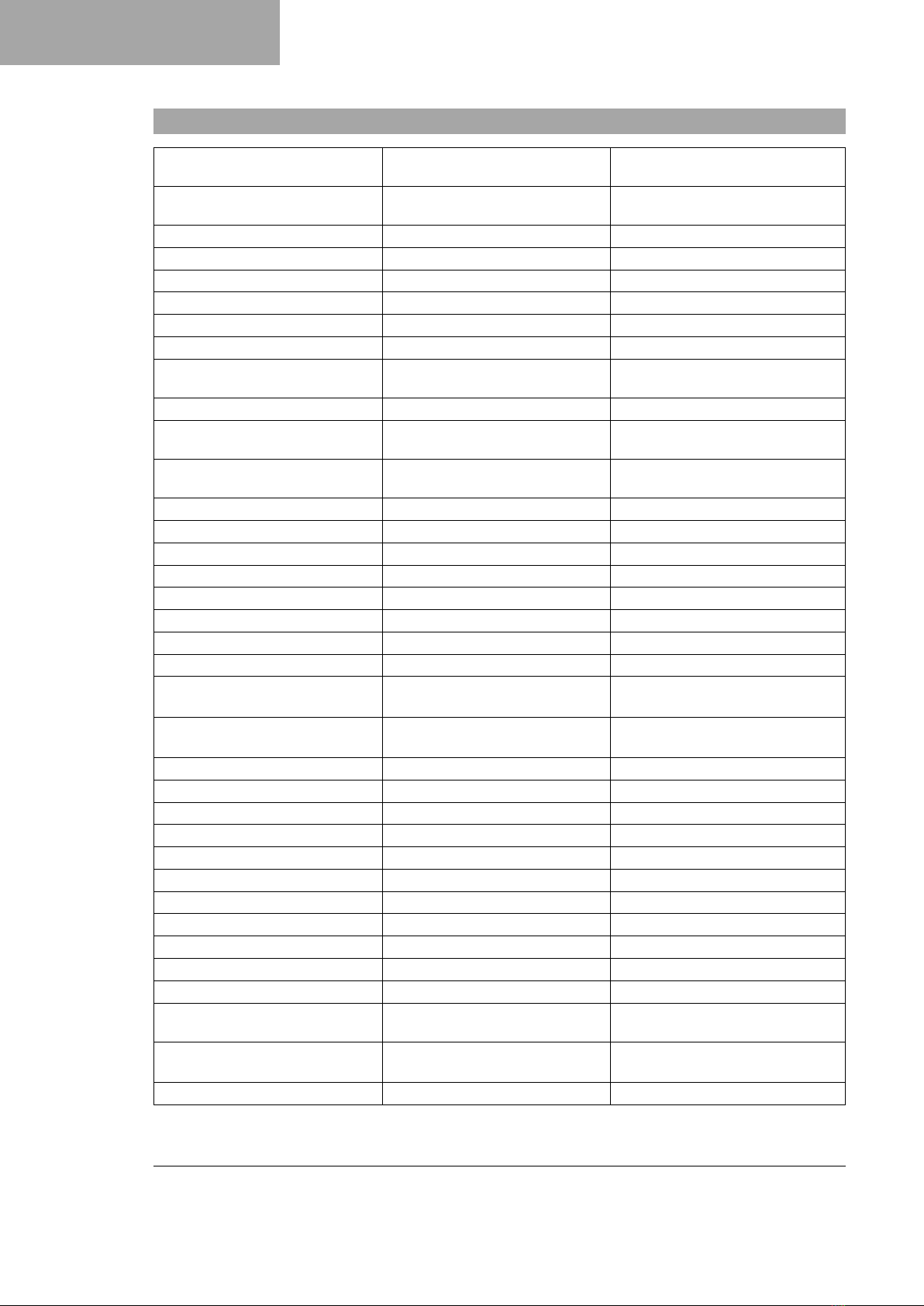

4.1 Chassis tightening torques

Brake fluid reservoir for front brake

cover

‑1 Nm (0.7 lbf ft)

Brake fluid reservoir for rear brake

cover

‑3.5 Nm (2.58 lbf ft)

Remaining screws, chassis EJOT PT®K50x12 1 Nm (0.7 lbf ft)

Remaining screws, chassis EJOT PT®K50x14 1 Nm (0.7 lbf ft)

Remaining screws, chassis EJOT PT®K50x16 2 Nm (1.5 lbf ft)

Remaining screws, chassis EJOT PT®K50x18 2 Nm (1.5 lbf ft)

Remaining screws, chassis EJOT PT®K45x12 1 Nm (0.7 lbf ft)

Screw, air filter box cover EJOT PT®K60x30 2.5 Nm (1.84 lbf ft)

Screw, ball head holder on head-

light

EJOT ALtracs®50x12 7 Nm (5.2 lbf ft)

Screw, brake assembly 5 Nm (3.7 lbf ft)

Screw, exhaust valve cover fasten-

ing

EJOT SF®M4x6‑K 4 Nm (3 lbf ft)

Screw, intake air temperature sen-

sor

EJOT PT®K50x16 2 Nm (1.5 lbf ft)

Screw, radiator fan cover EJOT DELTA PT®40x46/10 1 Nm (0.7 lbf ft)

Screw, SAS on air filter box EJOT PT®K50x16 2 Nm (1.5 lbf ft)

Screw on handle M4 6 Nm (4.4 lbf ft)

Screw, fixed grip, left M4 3 Nm (2.2 lbf ft)

Screw, side stand sensor M4 2 Nm (1.5 lbf ft)

Remaining nuts, chassis M5 5 Nm (3.7 lbf ft)

Remaining screws, chassis M5 5 Nm (3.7 lbf ft)

Screw for throttle grip M5 3.5 Nm (2.58 lbf ft)

Screw, 6D sensor holder M5 2.7 Nm (1.99 lbf ft)

Loctite®243™

screw, absorbing element, combi-

nation instrument

M5 2 Nm (1.5 lbf ft)

Loctite®243™

Screw, cable channel M5 5 Nm (3.7 lbf ft)

Screw, chain sliding guard M5 5 Nm (3.7 lbf ft)

Screw, combination instrument M5 1 Nm (0.7 lbf ft)

Screw, combination switch, left M5 5 Nm (3.7 lbf ft)

Screw, combination switch, right M5 5 Nm (3.7 lbf ft)

Screw, front turn signal bracket M5 3.5 Nm (2.58 lbf ft)

Screw, fuel level sensor M5 3 Nm (2.2 lbf ft)

Screw, fuel tank filler cap M5 3 Nm (2.2 lbf ft)

Screw, fuel tank spoiler M5 2.5 Nm (1.84 lbf ft)

Screw, fuse box support M5 6 Nm (4.4 lbf ft)

Screw, headlight locking cap M5 3.5 Nm (2.58 lbf ft)

Screw, heat protector on main

silencer

M5 4 Nm (3 lbf ft)

Screw, injection valve M5 4 Nm (3 lbf ft)

Loctite®243™

Screw, intake trumpet M5 6 Nm (4.4 lbf ft)

TECHNICAL DATA 4

17

Screw, license plate holder on

lower rear panel

M5 8 Nm (5.9 lbf ft)

Screw, radiator fan cover M5 3.5 Nm (2.58 lbf ft)

Screw, rear turn signal bracket M5 3.5 Nm (2.58 lbf ft)

Screw, trim M5 3.5 Nm (2.58 lbf ft)

Screw, wiring harness holding

bracket

M5 3.5 Nm (2.58 lbf ft)

Cable disk nut, exhaust valve con-

trol unit

M6 14 Nm (10.3 lbf ft)

Ground fitting on frame M6 10 Nm (7.4 lbf ft)

Remaining nuts, chassis M6 10 Nm (7.4 lbf ft)

Remaining screws, chassis M6 10 Nm (7.4 lbf ft)

Screw, 6D sensor M6 6 Nm (4.4 lbf ft)

Screw, ABS module fastening M6 8 Nm (5.9 lbf ft)

Screw, ball joint of push rod on

foot brake cylinder

M6 5 Nm (3.7 lbf ft)

Loctite®243™

Screw, battery holder M6 6 Nm (4.4 lbf ft)

Screw, battery terminal M6 4.5 Nm (3.32 lbf ft)

Screw, cable on starter relay M6 6 Nm (4.4 lbf ft)

Screw, clutch assembly M6 5 Nm (3.7 lbf ft)

Loctite®243™

Screw, cooler retaining bracket M6 7 Nm (5.2 lbf ft)

Screw, engine sprocket cover M6 8 Nm (5.9 lbf ft)

Screw, exhaust clamp on main

silencer

M6 10 Nm (7.4 lbf ft)

Screw, foot brake cylinder M6 10 Nm (7.4 lbf ft)

Loctite®243™

Screw, front fuel tank M6 8 Nm (5.9 lbf ft)

Screw, front wheel speed sensor M6 4 Nm (3 lbf ft)

Screw, fuel pump M6 6 Nm (4.4 lbf ft)

Screw, fuel tank bridge M6 8 Nm (5.9 lbf ft)

Screw, fuel tank cover M6 5 Nm (3.7 lbf ft)

Screw, fuel tank spoiler M6 6 Nm (4.4 lbf ft)

Screw, handlebar end mirror M6x35 13 Nm (9.6 lbf ft)

Screw, headlight on retaining

bracket

M6 5 Nm (3.7 lbf ft)

Screw, heel guard M6 12 Nm (8.9 lbf ft)

Loctite®243™

Screw, instrument support M6 2 Nm (1.5 lbf ft)

Screw, presilencer exhaust clamp M6 10 Nm (7.4 lbf ft)

Screw, radiator bracket M6 5 Nm (3.7 lbf ft)

Screw, radiator hose clip M6 3 Nm (2.2 lbf ft)

Screw, rear wheel speed sensor M6 4 Nm (3 lbf ft)

Screw, shift lever stub M6 10 Nm (7.4 lbf ft)

Loctite®243™

Screw, shift rod M6 5 Nm (3.7 lbf ft)

Loctite®243™

4 TECHNICAL DATA

18

Screw, shift shaft deflector on shift

shaft

M6 18 Nm (13.3 lbf ft)

Loctite®243™

Screw, steering damper bracket on

frame

M6 8 Nm (5.9 lbf ft)

Loctite®243™

Screw, step plate for foot brake

lever

M6 10 Nm (7.4 lbf ft)

Loctite®243™

Screw, voltage regulator M6 6 Nm (4.4 lbf ft)

Nut, exhaust valve throttle cable M6x1 5 Nm (3.7 lbf ft)

Screw, footrest unit adjustment M6x17 10 Nm (7.4 lbf ft)

Loctite®243™

Cable disk nut, exhaust valve M8 7 Nm (5.2 lbf ft)

Nut, rear sprocket M8 36 Nm (26.6 lbf ft)

Loctite®243™

Nut, shift rod M8 12 Nm (8.9 lbf ft)

Nut, valve M8 6 Nm (4.4 lbf ft)

Loctite®243™

Remaining nuts, chassis M8 25 Nm (18.4 lbf ft)

Remaining screws, chassis M8 25 Nm (18.4 lbf ft)

Screw, axle clamp M8 15 Nm (11.1 lbf ft)

Screw, bottom triple clamp M8 15 Nm (11.1 lbf ft)

Screw, foot brake lever M8 20 Nm (14.8 lbf ft)

Loctite®243™

Screw, front brake disc M8 28 Nm (20.7 lbf ft)

Loctite®2701™

Screw, front rider footrest bracket M8 25 Nm (18.4 lbf ft)

Loctite®243™

Screw, handlebar clamp M8 20 Nm (14.8 lbf ft)

Screw, ignition lock (tamper-proof

screw)

M8 25 Nm (18.4 lbf ft)

Screw, passenger footrest unit M8x25 25 Nm (18.4 lbf ft)

Loctite®243™

Screw, passenger footrest unit M8x35 25 Nm (18.4 lbf ft)

Loctite®243™

Screw, rear brake caliper M8 25 Nm (18.4 lbf ft)

Loctite®2701™

Screw, rear brake disc M8 28 Nm (20.7 lbf ft)

Loctite®243™

Screw, shift lever on footrest sup-

port

M8 20 Nm (14.8 lbf ft)

Loctite®243™

Screw, side stand bracket M8 25 Nm (18.4 lbf ft)

Loctite®243™

Screw, side stand spring M8 15 Nm (11.1 lbf ft)

Loctite®2701™

Screw, steering damper on holder M8 8 Nm (5.9 lbf ft)

Loctite®243™

Screw, steering damper on triple

clamp

M8 8 Nm (5.9 lbf ft)

Loctite®243™

Screw, steering stem clamp M8 20 Nm (14.8 lbf ft)

Loctite®243™

Table of contents

Other BRABUS Motorcycle manuals