Brahms proxinet8 User manual

INSTALLATION MANUAL

SECURITY ALARM CONTROL UNIT

English

EN

English

EN

Page 2- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

INDEX

1 SYMBOLS AND GLOSSARY .................................................................................PAGE 4

2 TERMS OF USE ............................................................................................PAGE 4

3 IMPORTANT FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 4

3.1 INTENDED USE ......................................................................................................4

3.2 WARRANTY AND LIMITS TO LIABILITY ................................................................................4

4 SYSTEM INSTALLATION....................................................................................PAGE 5

4.1 SYSTEM WIRING .....................................................................................................5

4.2 WIRING BUS RS-485..................................................................................................6

TRADITIONAL CABLING (enter- output) .......................................................................................................6

BRANCHED-OUT CABLING....................................................................................................................6

DOUBLE-BRANCH CABLING ..................................................................................................................7

BUS AMPLIFIER CABLING .....................................................................................................................8

APPLICATIVE NOTES ON CABLING OF THE RS-485 BUS .........................................................................................9

CHOOSING THE CABLE SECTION FOR THE RS-485 BUS..........................................................................................9

4.3 WIRING THE INPUTS ................................................................................................11

5 INSTALLING THE CONTROL UNIT ...........................................................................PAGE 12

5.1 FEATURES ..........................................................................................................12

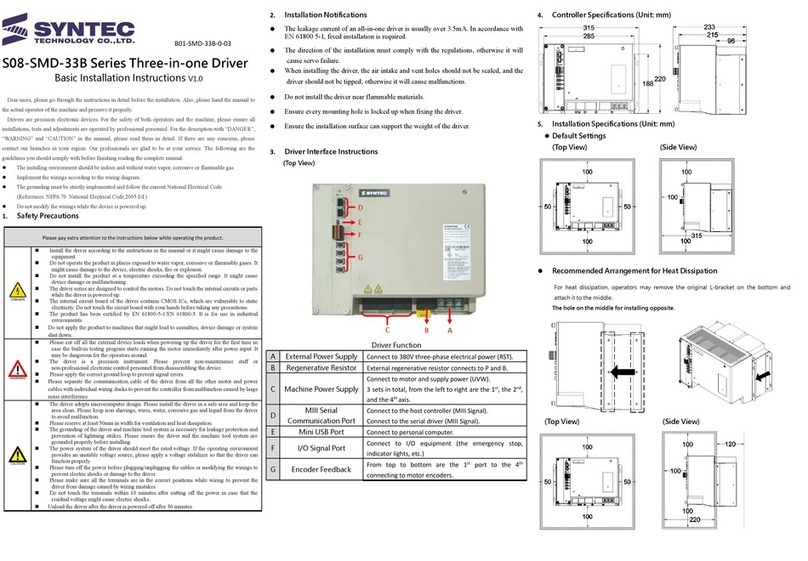

5.2 CONTROL UNIT .....................................................................................................13

5.3 CARD DESCRIPTION ................................................................................................13

5.4 ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.5 CABLING ...........................................................................................................15

BATTERY ...................................................................................................................................16

TAMPER ....................................................................................................................................16

BUS RS-485.................................................................................................................................17

INPUTS.....................................................................................................................................17

U1 PROGRAMMABLE OUTPUT (positive) .....................................................................................................17

U2, U3, U4 (Open Collector) PROGRAMMABLE OUTPUTS ......................................................................................17

GENERAL ALARM RELAY OUTPUT RELAY 1....................................................................................................18

PSTN TELEPHONE LINE WITH PXTEL BOARD ..................................................................................................18

LANGUAGE UPDATE BOARD PXLNG for control unit...........................................................................................18

6 PXKWD KEYPAD ..........................................................................................PAGE 19

6.1 FEATURES ..........................................................................................................19

6.2 CARD DESCRIPTION ................................................................................................19

6.3 USER INTERFACE ...................................................................................................20

KEYPAD DISPLAY ...........................................................................................................................20

LIGHT WARNINGS ...........................................................................................................................20

ALPHANUMERIC KEYPAD....................................................................................................................21

6.4 KEYPAD MENU .....................................................................................................21

7 PXITXXXX INSERTERS .....................................................................................PAGE 22

7.1 FEATURES ..........................................................................................................22

7.2 CARD DESCRIPTION ................................................................................................22

7.3 USER INTERFACE ...................................................................................................22

LIGHT WARNINGS ...........................................................................................................................23

7.4 AIMING ............................................................................................................23

7.5 PXTAG KEY .........................................................................................................23

ACCEPTANCE ...............................................................................................................................23

KEY CHECK .................................................................................................................................23

8 ACCESSORIES .............................................................................................PAGE 24

8.1 PXV64..............................................................................................................24

INSTALLING ................................................................................................................................24

8.2 PXGSM .............................................................................................................24

CARD DESCRIPTION.........................................................................................................................24

INSTALLING ................................................................................................................................25

8.3 PXTEL ..............................................................................................................25

CARD DESCRIPTION.........................................................................................................................25

INSTALLING ................................................................................................................................25

9 STARTING UP THE SYSTEM.................................................................................PAGE 26

9.1 FIRST START UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

PRELIMINARY CHECKS ......................................................................................................................26

SYSTEM UNDERGOING MAINTENANCE / OPERATIONAL .......................................................................................26

CHANGE CONTROL UNIT LANGUAGE.........................................................................................................26

POWER ON CENTRAL........................................................................................................................26

OPENING/CLOSING THE CONTROL UNIT......................................................................................................27

9.2 USING THE CONTROL UNIT KEYPAD .................................................................................27

ACCESSING THE TECHNICAL MENU...........................................................................................................28

Page 3- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

9.3 PROGRAMMING MODE (EASY, NORMAL, ADVANCED) ................................................................28

Easy MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Standard mode .............................................................................................................................29

ADVANCED MODE ..........................................................................................................................29

9.4 ADDRESSING AND ACQUIRING PERIPHERALS ........................................................................30

ACQUIRING REMOTE KEYPADS...............................................................................................................30

ACQUIRING REMOTE INSERTERS .............................................................................................................31

9.5 DEFINITION OF SYSTEM AREAS......................................................................................32

9.6 PROGRAMMING SCENARIOS ........................................................................................33

CREATING SCENARIOS ......................................................................................................................33

ASSOCIATING SCENARIO VIA KEYPAD ........................................................................................................35

ASSOCIATING SCENARIOS AND INSERTERS ...................................................................................................36

9.7 PROGRAMMING INPUTS ............................................................................................37

9.8 PROGRAMMING OUTPUTS ..........................................................................................38

9.9 PROGRAMMING TELEPHONE CALLS AND SMS TEXT MESSAGES (PSTN/GSM) ..........................................38

PROGRAMMING THE PSTN - GSM PRIORITY ..................................................................................................38

PROGRAMMING THE TELEPHONE NUMBERS..................................................................................................38

SET COMMON VOICE MESSAGE FROM PC.....................................................................................................40

SET VOICE MESSAGES ASSOCIATED WITH INPUTS, AREAS, OUTPUTS AND SCENARIOS FROM PC.................................................40

SEND VOICE MESSAGES .....................................................................................................................40

9.10 CREATING USER CODES ............................................................................................41

9.11 ACQUIRING KEYS ..................................................................................................42

9.12 SYSTEM TEST......................................................................................................43

FROM CONTROL UNIT KEYPAD...............................................................................................................43

10 PC – CONTROL UNIT CONNECTION ........................................................................PAGE 44

10.1 LOCALLY PROGRAMMING THE RS-232 ..............................................................................44

11 RESTORE SYSTEM ........................................................................................PAGE 45

11.1 RESTORING CODES AND KEYS......................................................................................45

11.2 FACTORY SETTINGS ...............................................................................................46

12 DECLARATION ...........................................................................................PAGE 47

Page 4- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

2.1 Intended use

1 Symbols and glossary

This symbol indicates the parts which describe safety issues.

This symbol indicates parts which must be read with care.

Permanently on warning light.

Warning light off.

Rapidly flashing warning light.

INSTALLER: any person or business responsible for designing and installing the system.

USER: any persons using the security alarm system.

2 Terms of use

The PROXINET 8 security control unit is designed to boost security in residential and service-sector businesses.

Any installation and use other than that specified in this manual is forbidden.

2.2 Warranty and limits to liability

Our product warranty refers to restoring compliance to the products through repairs or free replacement of any materials found to be

non-compliant due to defect resulting from errors in the manufacturing process, including any expenses incurred due to replacement

actions (job orders, shipping, etc...).

Resellers of BPT S.p.A products are directly liable to consumers of said products, and have the function of upholding this right of

warranty in favour of said consumers. Consumers must address the seller, and only the seller, when upholding this right, and clearly

communicate any product flaws or shortcomings within two months of noticing.

The warranty loses validity if any user fails to communicate any flaws within the above mentioned terms. Any claim is no grounds for

customers to cancel or reduce orders, nor for reimbursements of sorts on our part. Our warranty is void if any of the parts as flawed

is tampered with or repaired.

BPT S.p.A a socio unico cannot be held liable in case of damage caused by improper use of its products. Given that it’s the installer

that designs and installs the security alarm system using BPT S.p.A a socio unico original parts and third-party parts, our company

cannot therefore vouch for the reliability of the security alarm system. BPT S.p.A a socio unico denies any liability for claims made by

users, installers or any third parties as concerns use and installation of our products.

3 Important for SAFETY

If properly designed, the security alarm system provides high levels of safety to the areas it is meant to protect and to the consumers

that use it. To ensure this, certain rules must be followed:

The installation must be carried out by qualified, expert staff and in full compliance with applicable laws.

Check main power source connections and relative ground connections.

Once the system is up and running, make sure users have changed the Factory User Code (123456).

Maintenance on the system must only be carried out by qualified personnel; do not try to tamper with the system, you risk

compromising its proper working order, and risk electrocution due to the voltage.

Page 5- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

4 System installation

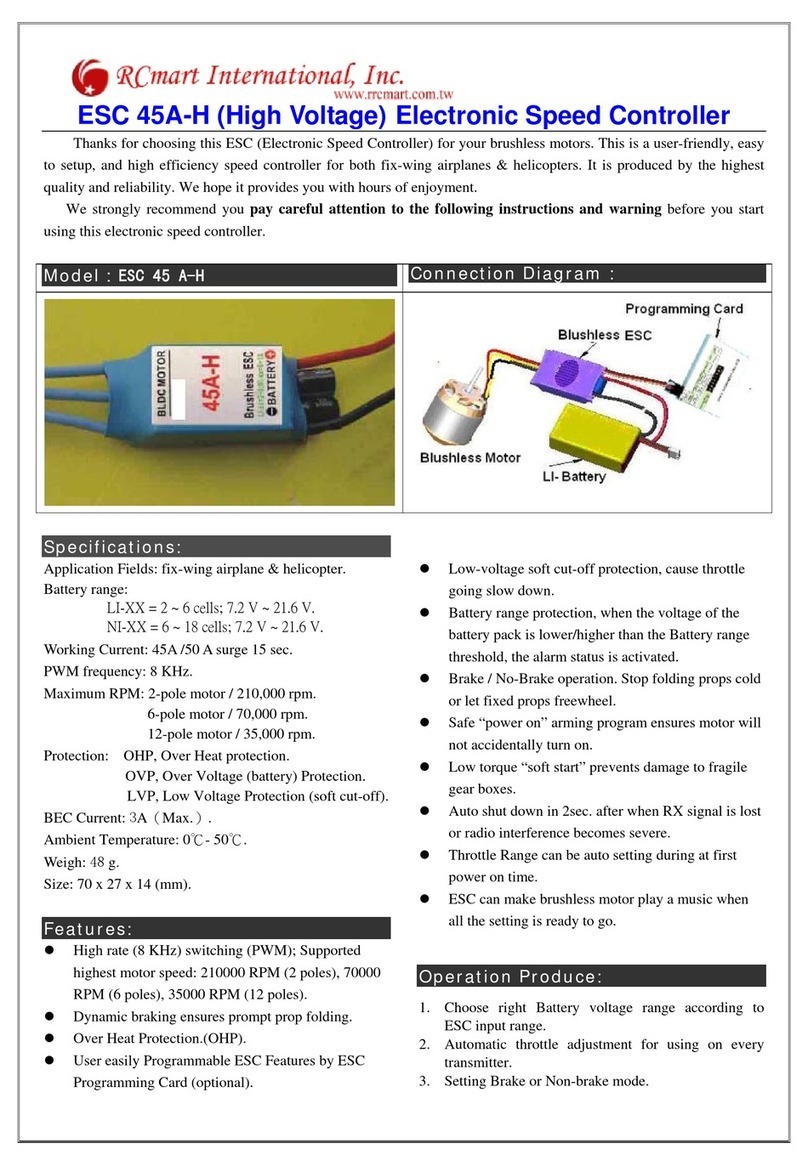

4.1 System wiring

Remote PC

SA10L

External siren

LAN Network

Local PC

PXWEB

LAN Interface

Switch

PXTEL

PSTN Combiner

PXGSM

GSM

Combiner

PXTAG

Transponder key

Bus RS485

PXKWD

LCD Keypad

PXKI

LED Keypad

sms

Modem

Router

Internet

PXMIF

RS232/422 Interface

OH/GW

gateway module

Modem

Router

PXTAG

Transponder key

(reader on-board

control unit)

Mitho

Terminal

PXV64

Voice board

PXITXXXX

Transponder key

reader up to 4

up to 4 key

pads

Page 6- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

4.2 Wiring bus RS-485

If remote devices are properly installed, all bus communication LEDs featured on each device should be flashing. If some are

not flashing, this means installation or programming was wrong (check cabling, address and programming in control unit).

TRADITIONAL CABLING (enter- output)

BRANCHED-OUT CABLING

Branching out consists of a cable with three pairs, two of which are twisted (each pair is made up of conductors A and B).

An analysis of this circuit shows that the structure of the RS-485 bus continues to be linear (enter-output).

Page 7- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

DOUBLE-BRANCH CABLING

Page 8- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

BUS AMPLIFIER CABLING

Page 9- Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

APPLICATIVE NOTES ON CABLING OF THE RS-485 BUS

Cabling of the bus connecting the control unit to the remote modules, inserters, and keypads must follow the rules dictated by the RS-485.

Only use a screened and twisted cable with section of at least:

• 2x0.5mm²forpowersupplyand2x0.22mm²twistedfordata.

• 2x0.5mm²forpower supplyand2x2x0.22mm²twisted fordata

(used to perform branching).

The sock must always be continuous and connected to the control unit’s

negative (-) terminal.

Themaximumlengthofthecable(maxstretchesof800m)andtheconductor

sections depend on the number of modules and from the overall draw on

the different stretches of bus. When power draw increases the voltage drop

increases on the cables and so reduces the power supply current to the

devices on bus.

The voltage at all + and - terminals of the devices on bus (keypads, inserters,

modules, ...) must not fall below 12 V DC.

If less, add an auxiliary power source and disconnect the positive while

keeping the negative mutual.

In case of long stretches of bus always install 150 ohm resistors among

terminals A and B at both ends of the bus.

Always carry out cabling of the bus in “enter and output” mode. Do not cable

the bus when in star configuration.

If you need this configuration follow the directions in this chapter.

Greater than 12 Vdc

NO

CHOOSING THE CABLE SECTION FOR THE RS-485 BUS

For the RS-485 bus we suggest using the following cable:

• Twistedandgrade4-screenedcable(600/1000V).

• Atwistedpairfordatawithsection2x0.22mm².

• Onepairtopowerthe2x0.5mm2orgreatersectiondependingondistancesandvoltages(checktablebelow).

Below is the table for calculating the section of power cables with distance variances and power draws.

Any drops in power voltage must not exceed 1.4 V (voltage measured on terminals of the power source and those of the

devices with remotest bus).

MAXIMUM CABLE LENGTH BUS RS-485

POWER DRAW

SECTION

0,1A 0,25A 0,5A 1 A

0.5mm2175 m 70m 35 m 17 m

0.75mm2262 m 105m 52 m 26 m

1 mm2350m 140m 70m 35 m

1.5 mm2525 m 210m 105m 52 m

If a cable does not have the proper section additional auxiliary power sources must be added.

YES

Page 10 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

Example:

Let’s say we have:

• PROXINET8

• PXIT0(maxconsumption100mA)

• PX8IR(maxconsumption40mA)

• Connectiondistance200m.

Withmaxconsumptionof250mAinthiscaseweeitherusea1.5mm²sectioncable,ora0.5mm²cableplusanauxiliarypower

source at the end of the line as shown below:

CABLE RS-485

Screened2x1,5mm²+twisted 2x0,22mm²

CABLE RS-485

Screened2x0,5mm²+twisted 2x0,22mm²

Control unit Device on bus

Power source

auxiliary

Control unit Device on bus

Maximum communication performance is guaranteed by using the specified cable (PXC75). Maximum communication speed

betweenperipheralsis115,200baud.Ifnotusingthecablespecifiedorifthereareproblemsatinstallation,thecontrolunit

transferspeedcanbedecreased(38,400,9,600,4,800and2,400baud).Thespeedoftheperipheralswillautomaticallyset.

Page 11 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

4.3 Wiring the inputs

Balancing is performed with 4.7 kohm resistors.

Yellow 4

Violet 7

Red x100

Gold 5%

4.7 kohm 5% resistor

CONNECTING INPUTS

The U1 output gives a positive when output is active (ON =13,8Vdc). The U1 output is factory-programmed as TC (active output

with system shut down, disable during the output time and when at least one are is turned on).

(NO) NORMALLY OPEN (NC) NORMALLY CLOSED

(SB) SINGLE BALANCING (DB) DOUBLE BALANCING

(DB) DOUBLE BALANCING SENSOR WITH MICROWAVE BLOCK WHEN CONTROL UNIT IS OFF (TC)

Page 12 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

5 Installing the control unit

5.1 Features

GENERAL CHARACTERISTICS

Power Supply 230Vac-15%+10%50/60Hz

Power source 1 A

Transformer 25 VA

Card power draw (excluding battery recharge) 150/160mAAc@23,9Vac(displayOFF/ON)

Battery 7,2 Ah

Working temperature 0°-40°C

Relative humidity when active 25% - 75% without condensation

Dimensions (HxLxD) 305x230x85mm

IP IP30

Weight: (without battery) 1,9Kg

Container material Plastic

Operating temperature from0°Cto+40°C

Storage temperature from-10°Cto+50°C

Relative operating humidity 25% -75% R.H. No condensation

Relative storage humidity 25% -75% R.H. No condensation

Standard compliant CEIEN50131

WORK CHARACTERISTICS

Inputs in control unit 8

Alarm outputs 1

Outputs programmable (O.C.) from control unit 4

On-board key pad Yes

On board relay outputs Yes

Bus 1 Line RS485

Area 4

Scenarios 6

Inserters 4

Keypads 4

Keys 16

User code 16

Timer Daily On/Off control unit and outputs

Events 250

PSTN Combiner PSTN PXTEL board internal installation

GSM Combiner GSM PXTEL board internal installation

Control by SMS With GSM PXGSM board

Remote control with voice guide With PXV64 voice synthesis board and PXGSM O PSTN PXTEL combiner

Communications port RS232

LAN Network connection With LAN PXLAN or PXWEB board

Local programming via PC Yes

Internet remote programming With LAN PXLAN or PXWEB board

Connection to automation system With RS232/RS422 PXMIF interface board

a

b

c

+ 1 2 3 4 5 6 7 8 – + – U1 U2 U3 U4 NO C NC T –

F1

F5

+ A B

BUS

+

IN AUX POS

M2 M3

P1

CN6 M6 M7

SW1

JP3

O.C RELAY TAMPER

Vac

M1

CN3

CN2

CN1

1 2 3 4

ON

+BAT

–BAT

JP1

CN5

CN4

a b cd

e

f

g

h

ij

k

l

m

n

o

Page 13 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

5.2 Control unit

aProximity TAG reader

bDisplay

cControl key pad

5.3 Card description

Description Symbol LED

Colour Status Meaning

System

ready Green

On No input open

Blinking - - - - - - - - - - - - - - -

O Open inputs. Alarm is raised when a scenario is brought up

System

Status Green

On All areas are switched on (system switched on entirely).

Blinking

At least one associated area is switched on (system switched on partially).

O The areas are switched o (system switched o).

Alarm Red

On

At least one associated area is in alarm mode (system in alarm mode).

Blinking

The system has detected an alarm and dampened it. See event

history for alarm list. To remove notice see chapter on managing

the system.

O NO areas in alarm mode.

Out of order Yellow

On

230VACmainpowersupplyismissingorabsentGSMorPSTNline.

Contact your local Installer in case of a breakdown. Danger: high

voltage running through the control unit.

Blinking

Control unit battery breakdown.

Contact your local Installer in case of a breakdown. Danger high

voltage running through the control unit.

O No faults in the system.

Control unit visual notifications b

Control key pad description c

Meaning

aM2

RS-485 bus terminals for connecting keypads and inserters.

[+,-] power supply to bus

[A,B] data

BUTTON KEY LEGEND

*, #, ,

,

C

,

D

Menu navigation and selection keys.

+, -

Edit parameters keys.

*

After inserting the code it lets you access the User Menu or to confirm a selection.

A, B, C

Scenario launching key.

D

System switch-off button.

fig. 1 fig. 2

Page 14 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

5.4 Assembly

bM3

Control unit input terminals, can be of the NA, NC, SB, DB types.

[+,-] power supply

[1,2, 3, 4, 5, 6, 7, 8] inputs. Negative reference.

cCN6 RS-232 female socket for connecting to OC (via RS-23w straight male/female cable) or to Ethernet interface.

dM6

Control unit output terminals

[+, -, AUX] power supply available via self-restoring-fuse protected output F5

[U1,POS] positiveprogrammableoutputprotectedby100ohmresistor(ON=13,8Vdc,OFF=NA)

[U2,U3,U4,O.C.]opencollectoroutputswhicharenegativeprogrammableandprotectedby100ohmresistor

(ON=0Vdc,OFF=NA)

[NO, C, NC, RELAY] general alarm relay with clean contacts.

e

f

M7

JP3

[T, –, TAMPER] terminals for connecting the control unit tamper

[JP3] bridge to activate / deactivate the tamper (position C deactivates the control unit tamper, and position O

activates it).

gSW1

For setting the Control Unit to

Maintenance

(ON = Maintenance, OFF = Service).

To restore the factory codes

Not used Programming the control unit firmware

hP1 Control unit reset button (the control unit parameters and configurations are NOT restored)

iCN3 Connector for PXTEL module connection (optional)

jCN2 Connector for PXGSM module connection

kCN1 Connection for connecting the voice board PXV64/PXV256 and language board.

lM1 Terminal board for transformer connection

mCN5

JP1

[CN5] Connector for PXSTB probe

[JP1] Bridge to activate (JP1 NOT INSERTED) or deactivate (JP1 NOT INSERTED) probe PXSTB

nF1 GlassACinputfuse:3.15A250Vac5x20mmdelay-type

oCN4 Battery connector

Control unit assembly must be performed in an area easily accessible at least during maintenance operations.

Tomeetthisneed,afreeareaofapproximately500mmalongtheentireperimeterofthecontainermustbeleftasleewayinorder

to allow easy assembly and disassembly of the cover, allow easy maintenance, and facilitate network cable routing and connection

to other devices.

Place the control unit in a dry clean area that is not subject to vibrations or impacts of any sort.

Control unit installation must proceed as follows:

•openthecoverbyundoingthescrewsonthebottomofthecontrolunit(g.1).

•releasethecoverfromthecontainerbyexertingslightpressureneartheside"tabsasshowninthegure(g.1).

•liftthecoverofthecontrolunit(g.2).

•usingthebottomofthecontrolunitasatemplate,markthepositionoftheanchoringholesshowningure3,makingsurethatthe

wall is plumb in the point selected;

•drillholesintothewallthatwillholdthecontainerandthreadinthecontainerwallanchors;

•securetherearsideofthecontainertothewall,makingsurethatthetamper-proofswitch(showning.4)movesfreely.

fig. 4

fig. 3

Page 15 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

Install the control unit far from access points and so That it is hard to find.

Secure onto a suitable wall that can permanently hold up the control unit.

Set holes and channels for the initial installation cables to pass through.

Use the specific four holes for securing to the wall.

5.5 Cabling

Cutoffthemagnetothermicswitchlinkedtothecontrolunitbeforethenetwork230Vacandfortheentiretimethecontrol

unit is open.

ConnecttheLinecableandtheNeutralofthe230Vactothetransformerterminals.

Blockthe230Vacpowersupplycableinthecontainersothatitcannotmoveeveniftheterminalsaredisconnected.

Before closing the control unit check that all of the metal parts are connected to the ground.

230 Vac

• Cables can be routed through the holes

located on the bottom of the container or

through the pre-formed slot on the top portion

of the container (use a handsaw to cut open).

•Positionthebatteryintoitsseatandroute

cables.

+

–

+12345678–

+ – U1 U2 U3 U4 NO C NC T –

F1

F5

+ A B

BUS

+

IN

AUX POS

M2 M4

P1

CN6

M6 M7

SW1

JP3

O.C RELAY TAMPER

Vac

M1

CN3

CN2

CN1

1 2 3 4

ON

+BAT

–BAT

JP1

CN5

CN4

JP1

+ 1 2 3 4 5 6 7 8 – + – U1 U2 U3 U4

NO C NC T –

F1

F5

+ A B

BUS

+

IN AUX POS

M2 M4

P1

CN6 M6

M7

SW1

JP3

O.C

RELAY TAMPER

Vac

M1

CN3

CN2

CN1

1 2 3 4

ON

+BA

–BAT

JP1

CN5

CN4

Non-opening

tamper

Non-removal

tamper

Connection to the other Tamper

contacts of the system

Control unit

tamper contacts

C O

JP3

+ 1 2 3 4 5 6 7 8 – + – U1 U2 U3

U4 NO C NC T –

F1

F5

+ A B

BUS

+

IN AUX POS

M2 M4

P1

CN6 M6

M7

SW1

JP3

O.C

RELAY TAMPER

Vac

M1

CN3

CN2CN1

1 2 3 4

ON

+BA

–BAT

JP1

CN5

CN4

Non-opening

tamper

Non-removal

tamper

Connection to the other

Tamper contacts of the system

Control unit

tamper contacts

C O

JP3

+

–

+ 1 2 3 4 5 6 7 8 – + –

U1 U2 U3 U4 NO C NC T –

F1

F5

+ A B

BUS

+

IN AUX

POS

M2 M4

P1

CN6 M6

M7

SW1

JP3

O.C RELAY TAMPER

Vac

M1

CN3

CN2

CN1

1 2 3 4

ON

+BAT

–BAT

JP1

CN5

CN4

PXSTB

JP1

Page 16 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

BATTERY

The battery works as secondary power source to the security alarm unit. To optimise recharging and its duration over time.

we suggest installing the PXSTB, a temperature probe which allows to regulate the battery recharge depending on the temperature

itself. Respect battery polarities while connecting.

Installation of the PXSTB probe without opening jumper JP1 lowers battery charge voltage by 1 Volt thus impeding recharge.

TAMPER

Not using the unit tamper annuls the safety level of the system.

PXSTB NOT INSTALLED: JP1 INSERTED

TAMPER DEACTIVATED: JP3 IN POSITION C TAMPER ACTIVATED: JP3 IN POSITION O

PXSTB INSTALLED: JP1 NOT INSERTED

Page 17 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

BUS RS-485

For cabling to the RS-485 bus see chapter 4.2.

INPUTS

To cable the inputs see chapter 4.3.

U1 PROGRAMMABLE OUTPUT (positive)

A short circuit to the GND with active output for an extended time may lead to breakage of the protective resistor.

U1 is freely-programmable output that supplies a positive when

activated:

• U1ON=13.8Vdc

• U1OFF=notconnected

It is factory-programmed as a TC to abate microwaves when

system is switched off (U1 = OFF if at least one area is on during

out times; U1 = ON if the system is completely switched off.

Theoutputisprotectedbya100ohmresistor.

It may also be used to command sirens or other roles.

U2, U3, U4 (Open Collector) PROGRAMMABLE OUTPUTS

U2, U3, U4 are freely-programmable Open connector outputs

that provide a negative when activated:

• U2,U3,U4ON=0Vdc

• U2,U3,U4OFF=notconnected

Theoutputsareprotectedby100ohmresistors.

A 12 V DC short circuit with active output for an extended time may lead to breakage of the protective resistor.

Siren requiring power supply

If you wish to command a relay via an Open Collector output or

relayoutputyouwillneedtoaddthe1N4007diodeparallelto

the relay coil.

+ 1 2 3 4 5 6 7 8 – + – U1 U2 U3 U4 NO C NC T –

F1

F5

+ A B

BUS

+

IN AUX POS

M2 M3

P1

CN6 M6 M7

SW1

JP3

O.C RELAY TAMPER

Vac

M1

CN3

CN2

CN1

1 2 3 4

ON

+BAT

–BAT

JP1

CN5

CN4

A

B

C

D

E

ACTUAL LANGUAGE:

ITALIAN

SELECT LANGUAGE:

ITALIAN

LOADING LANGUAGE

WAIT FOR RESTART

+ – U1 U2 U3 U4 NO C NC T –

AUX POS

M6 M7

APF22

O.C RELAY TAMPER

TT

+ –

TAMPER

+ – U1 U2 U3 U4 C NC T –

AUX POS

M6 M7

O.C RELAY TAMPER

12Vcc MCA PCS MANS–

SA10L

Page 18 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

GENERAL ALARM RELAY OUTPUT RELAY 1

These relay outputs are for general alarm and are not programmable. They follow the general state of alarm and stay active for the

time programmed.

Siren requiring power supply Siren with on-board power supply

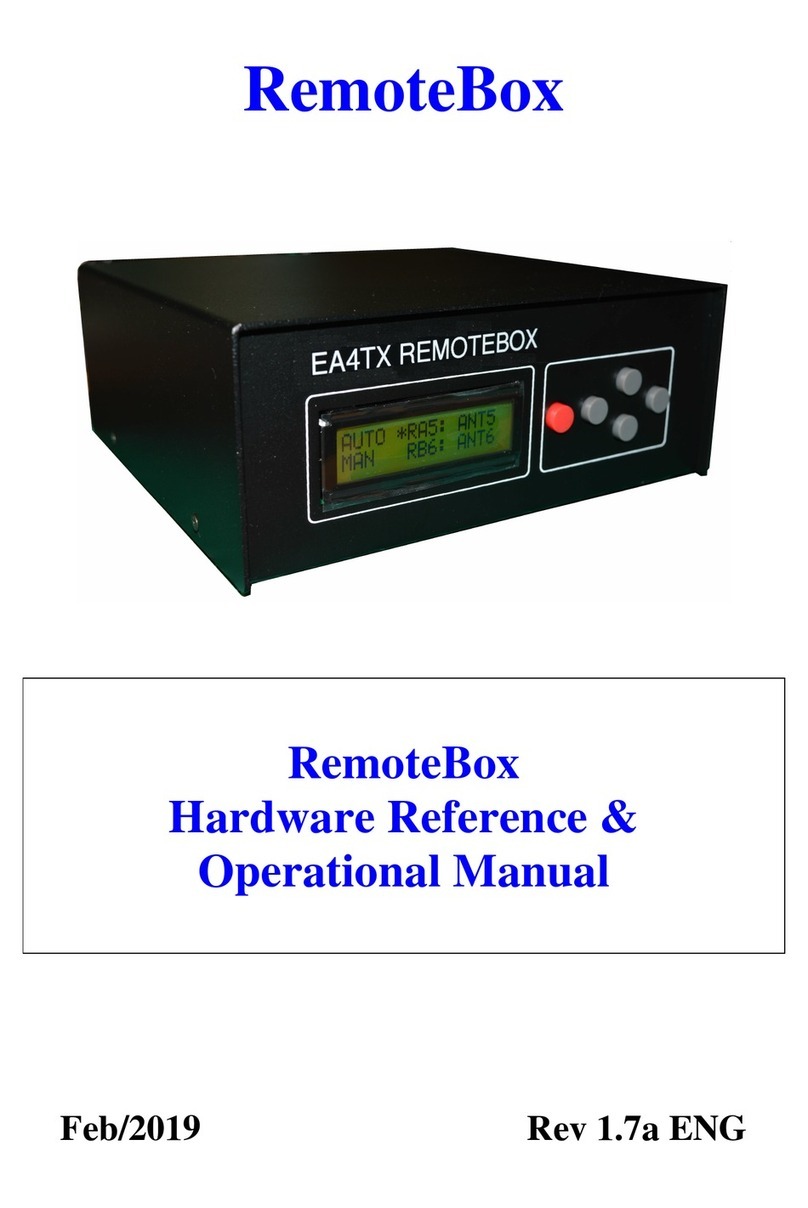

PSTN TELEPHONE LINE WITH PXTEL BOARD

LANGUAGE UPDATE BOARD PXLNG for control unit

The PSTN telephone line needs to be connected to terminals [L, L]

and in output, to terminals [T, T] for switch-boxes or telephones.

So-called simulated phone lines like ADSL ones can

disturb CONTACT-ID digital communications with Security Firms.

For modifying the control unit language and firmware update. A language board is available for each type of control unit.

Updateisavailablefromversion1.0.15ofcontrolunit.

Change language by:

Ainserting the board;

Bresetting the control unit by pressing the button;

Cthe keypad shows the current language: press the button ;

Dselect the language to install using the keys / ;

A standby message is displayed during installation;

CThe current language is displayed after the update is over;

Bremove the board and re-start the control unit by pressing the button.

A

B

E

C

D

Page 19 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

12345678910 11 12 13 14 15 16

6.1 Features

GENERAL CHARACTERISTICS PXKWD

Power supply voltage 12 Vdc - 15 Vdc

Max power draw 60mA

Working temperature 0°-40°C

Relative humidity 25% - 75% without condensation

Dimensions (HxLxD) 180x120x28(wall-surfacemounted)

IP IP40

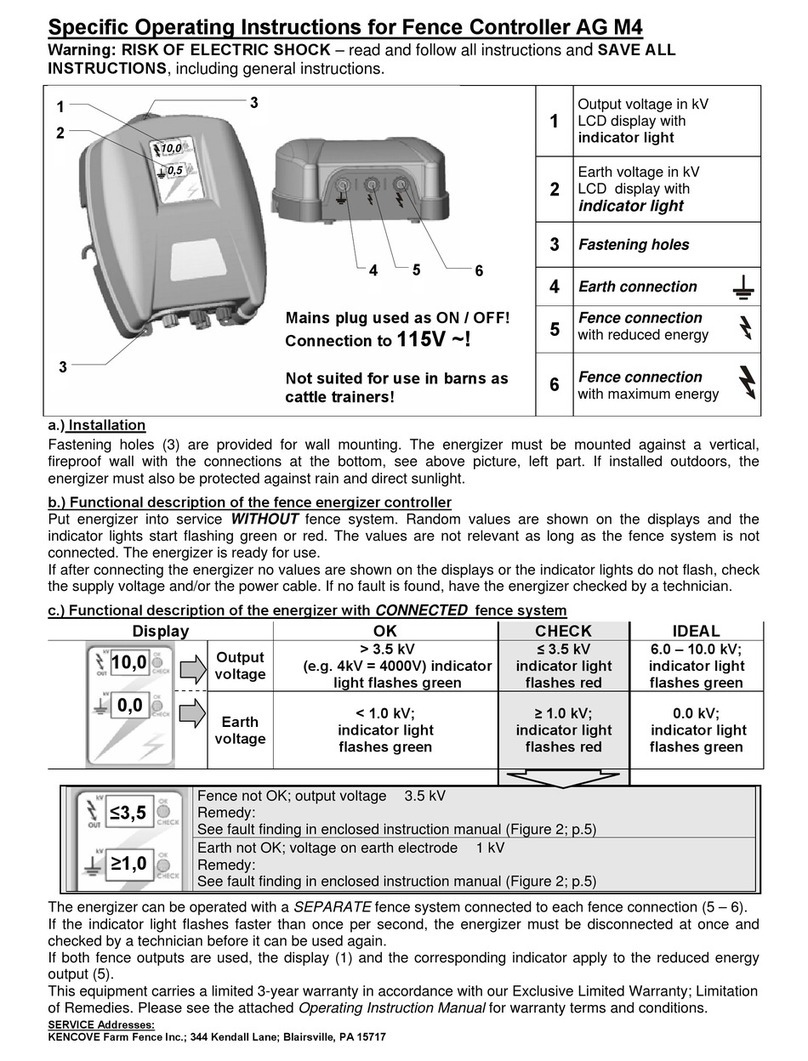

6.2 Card description

PXKWD

PXKWD DESCRIPTION

1

RS-485 bus terminals for connecting keypads, remote modules and inserters.

[+,-] power supply to bus.

[A,B] data.

2 [SW1] Anti opening / tearing tamper.

3 [JP1] Jumper to activate / deactivate the tamper (Jumper on = Tamper deactivated).

4BUZZERKeypadbuzzer.

5 DL18 BUS communication.

6 PXKWD Keypad

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

08:24 16 / 05/10

#UP-

Page 20 - Installation Manual 24805490/11-01-2013 319F90C ver. 1.2 - The data and information in this manual may be changed at any time with no obligation on BRAHMS’s part to notify anyone of this

ENGLISH

6.3 User interface

KEYPAD DISPLAY

The display has two lines of 16 graphic characters. When idle, the keypad goes into “Energy Saving” mode and reduces the light

intensity after a pre-set time.

Below the display there are 16 numbers that facilitate interpretation of the second line of display.

#

= area switched on.

U

= area in switching on phase (exit time) without open inputs.

X

= area in switching on phase (exit time) but not ready for adding presence of open inputs.

P

= area partially on (there is at least one temporarily excluded input associated to the area).

-

= area off.

= area not managed by the keypad.

Example:

Referring to the above shown display:

• Managedareas:1,2,3,4

• Switched-onareas:1,3

• Areasbeingswitched-on:2

• Switched-offareas:4

LIGHT WARNINGS

LED STATUS LEGEND OF LIGHT SIGNALS

When off it means there are open entrances associated to the keypad. Alarm is raised when a

scenario is brought up. Check open entrances when starting up scenarios.

Steadily on means there are NO open entrances associated to the keypad. The system can be

switched on without any problems.

When off it means that the associated areas are switched off (system switched off).

When on it means that all of the associated areas are switched on (system switched on entirely).

When flashing it means that at least one associated area is switched on (system switched on

partially).

When off it means that the associated areas are NOT in alarm mode.

When on it means that at least one associated area is in alarm mode (system in alarm mode).

When flashing it means that the associated system has detected an alarm and dampened. See

event history for alarm list. To remove notice see chapter on managing the system.

When off it means that there are faults in the system.

Nomain230VACpowersupplyifonandfixed,oratransmitterhasadischargedbattery

When flashing it means that the control unit battery is flat.

(always on, flashing on,

off).

Table of contents

Popular Controllers manuals by other brands

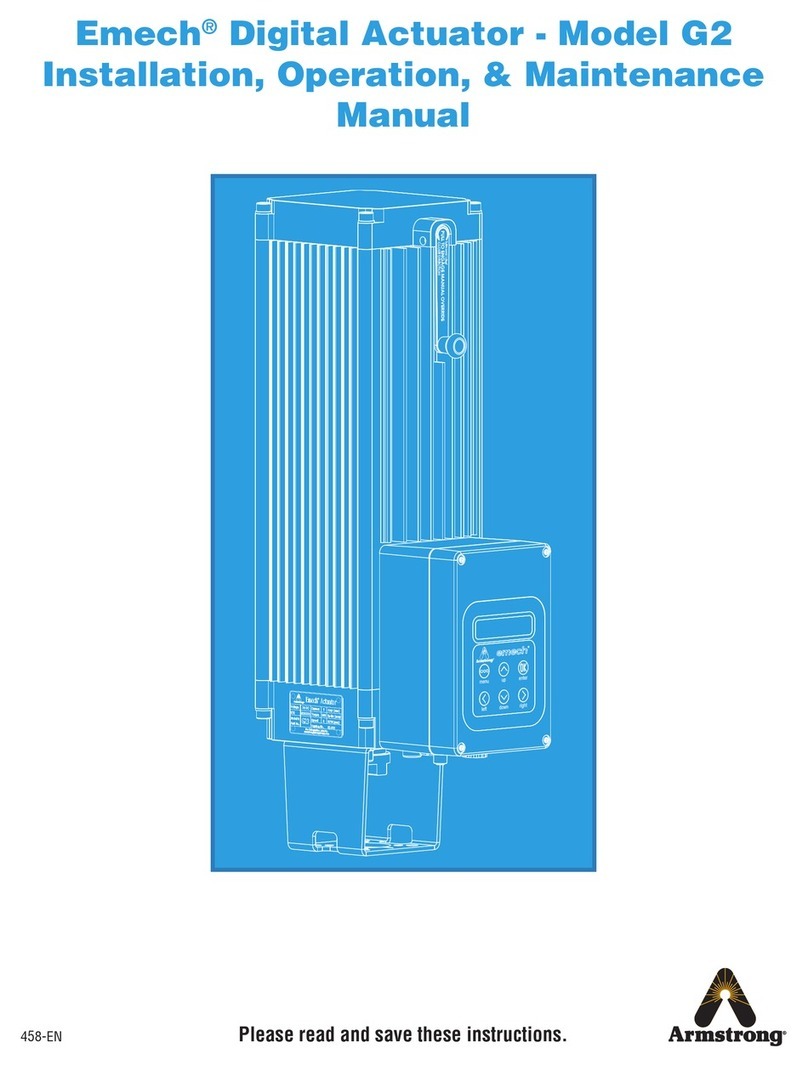

Armstrong

Armstrong Emech G2 Installation, operation & maintenance manual

Jflow controls

Jflow controls IQL Installation & operation manual

Purkeys

Purkeys SOLAR BOLT installation guide

Extron electronics

Extron electronics FPC 6000 user guide

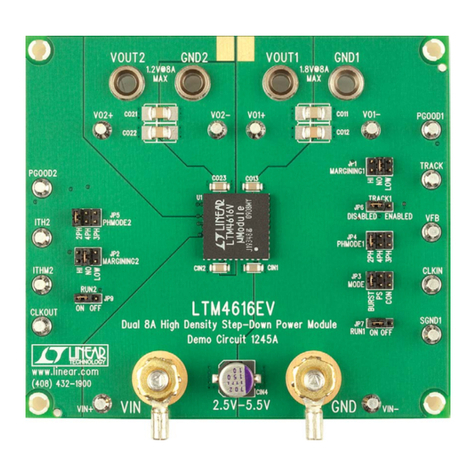

Linear Technology

Linear Technology LTM4616 Demo Manual

DH Instruments

DH Instruments GPC1-10000 Operation and maintenance manual