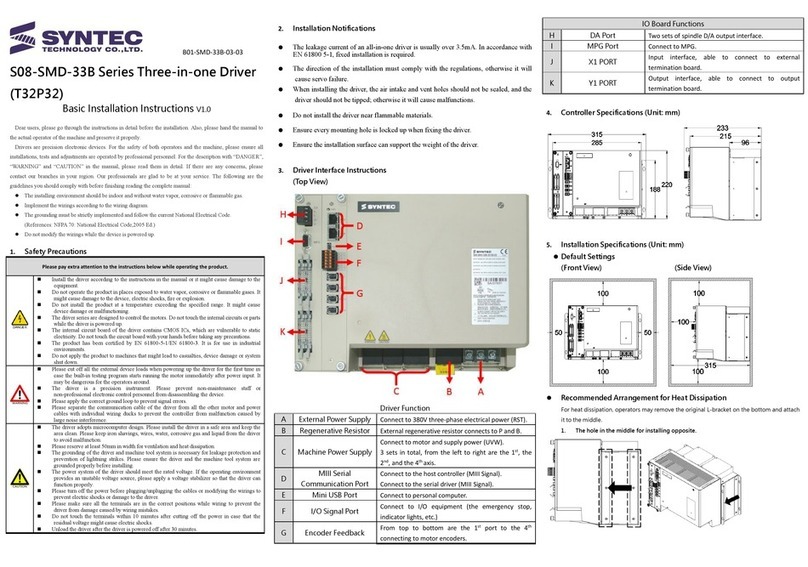

6. Mounting Hole Specification (Unit: mm)

Please install with M4 screws.

⚫Default Settings

⚫Recommended Arrangement of Heat Dissipation

7. Basic Wiring Diagram

Please Confirm whether the wiring of the U, V, W terminals output to the motor is

correct, otherwise it may cause reversal or abnormality, and the encoder must be

adjusted again.

When wiring the host controller, either the general servo signal or the serial servo

signal can be installed.

8. Interface Configurations

Please notice the value and polarities of voltages.

Serial Communication Mini USB Port Encoder Feedback

Port Arrangement Arrangement Arrangement

I/O Signal Port Arrangement

9. Driver Specifications

NOTE:

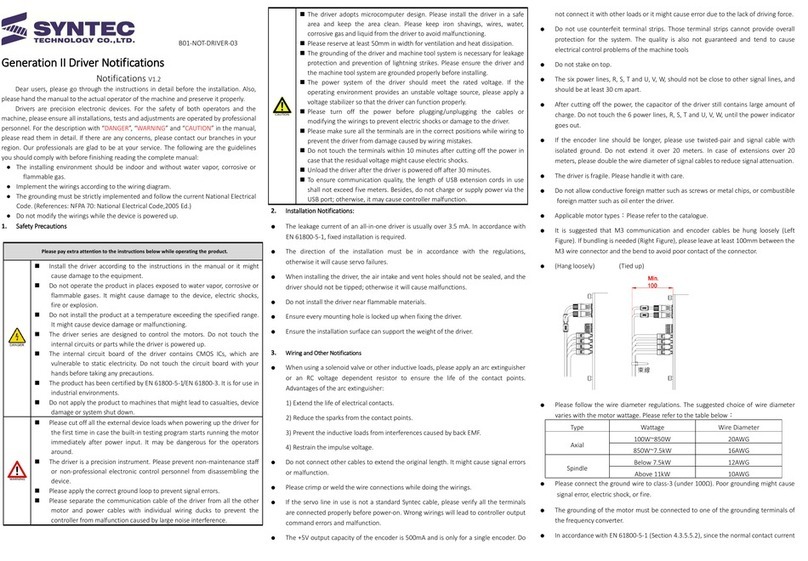

(1) TN System: The neutral point of the power system is grounded directly to earth, and the exposed metal components

are grounded by protective earthing conductors.

10. Wiring Notifications

⚫When using a solenoid valve or other inductive loads, please apply an arc

extinguisher, an RC varistor, or a flyback diode to ensure the life of the contact

points. Advantages of the arc extinguisher:

1) Extend the life of electrical contacts.

2) Reduce the sparks from the contact points.

3) Restrain the impulse voltage.

4) Prevent the inductive loads from interferences

caused by back EMF.

⚫

Suppose a client wants to drive four 1.2kW motors with 1kW*4 Servo Drive

Embedded Controller, it means the gross power should supply at most 4.8kW. Then

we reverse the formula and set the power factor at 0.7. If only Servo Drive

Embedded Controllers are used, the capacity should be at least 4.8/0.7=6.85kVA. In

addition, 10% of the backup capacity should be considered. Thus, 7.5kVA would be

more suitable. Moreover, if an inverter is used, and the power is supplied by an

isolation transformer, the capacity of the inverter should be considered.

Do not connect a cable with other cables to extend the length. It might cause signal

error or malfunction.

Please crimp or weld the wire connections while doing the wirings.

If the servo line in use is not a standard Syntec cable, please verify all the terminals

connected properly before power-on. Wrong wirings will lead to controller output

command errors and malfunctioning.

The +5V output capacity of the encoder is 500mA and is only for a single encoder.

Do not connect it with other loads or it might cause error due to the lack of driving

force.

Do not use counterfeit terminal strips. Those terminal strips cannot provide overall

protection for the system. The quality is also not guaranteed and tend to cause

electrical control problems of the machine tools.

The wiring of the driver and the motor cannot be pulled too tightly.

Do not stake on top.

The six power lines, R, S, T and U, V, W, should not be close to other signal lines,

and should be at least 30 cm apart.

After cutting off the power, the capacitor of the driver still contains large amount of

charge. Do not touch the 6 power lines, R, S, T and U, V, W, until the power

indicator goes out.

If the encoder line should be longer, please use twisted-pair and signal cable with

isolated ground. Do not extend it over 20 meters. In case of extensions over 20

meters, please double the wire diameter of signal cables to reduce signal attenuation.

To ensure the quality of communication, the USB extension cord in use should not

exceed 5 meters, and do not use for charging purposes to avoid controller failure.

The drive is fragile. Please handle it with care.

Do not allow conductive foreign matter such as screws or metal chips, or combustible

foreign matter such as oil enter the driver.