Brand-Gaus 4705 User manual

Brand-Gaus Model 4705

Oxygen Analyzer

User’s Manual

Manual P/N: 1000-0400

September 2004

Brand

Gaus

www.brandgaus.com

2Important Precautions Brand-Gaus Oxygen Analyzer User’s Manual

Important Precautions

Safety Notice

This instrument operates from potentially lethal line voltage. In addition, some internal

components operate at high temperature and can cause serious burns. Observe all

precautions when using this device, and particularly be sure that all devices connected to

the instrument are safely wired and properly grounded. Always disconnect power to the

instrument before opening the enclosure or making any adjustments.

Where to Get More Information

We can be reached for further assistance at:

Brand-Gaus, LLC

15603 Delahunty Lane

Pflugerville, TX, 78660

Phone: 512-989-0149

www.brandgaus.com

Email: info@brandgaus.com

Brand-Gaus Oxygen Analyzer User’s Manual Specifications 3

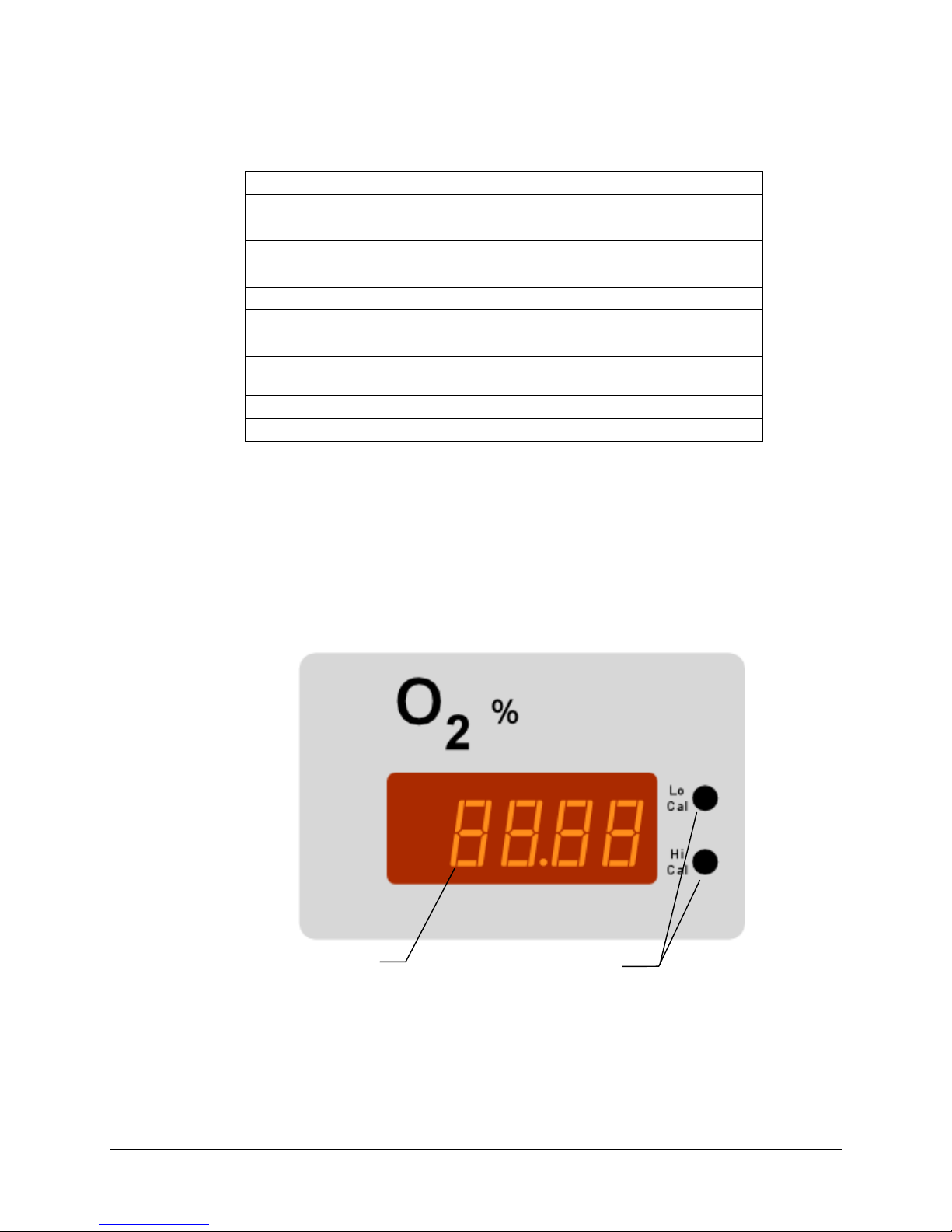

Specifications

Measurement technology Zirconium oxide cell

Measurement range 0 to 25 % O2

Full scale range 25.0 % O2

Zero noise < 0.02 %O2

Zero calibration drift Better than ± 0.1 %O2

Span noise < 0.02 %O2

Span calibration drift Better than ± 0.1 %O2

Linearity error < 1% of high calibration gas value

Interference (sum of all

interferences)

< 1% of measured value for typical applications

Response time T95 < 10 seconds

Sample Flow rate 0.2 to 10 SLPM

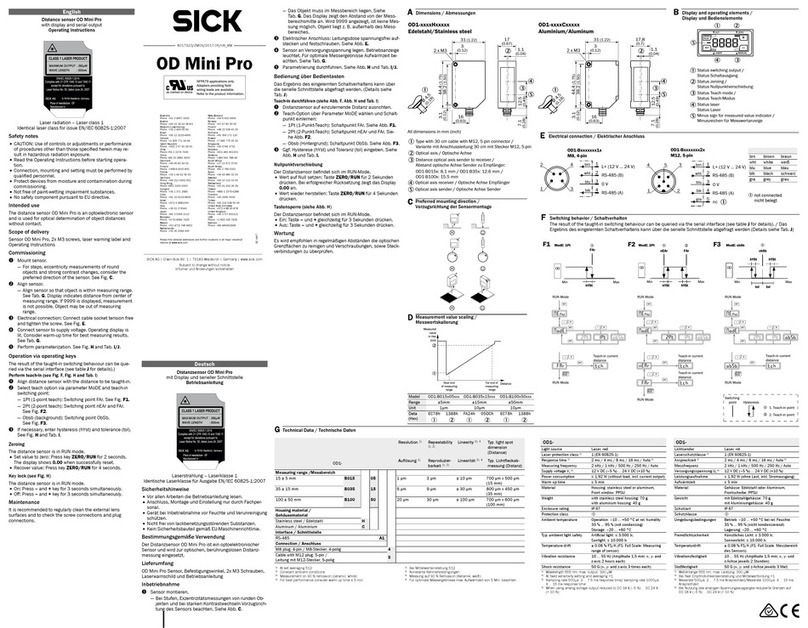

Front Panel Controls

Calibration Pots:

Used to adjust high-cal

and low-cal values

O2 Display:

Indicates oxygen

concentration

4Analyzer Setup Brand-Gaus Oxygen Analyzer User’s Manual

Analyzer Setup

To ensure the quickest and most reliable startup, please follow the steps below in the

order shown.

1. Apply power and sample to analyzer

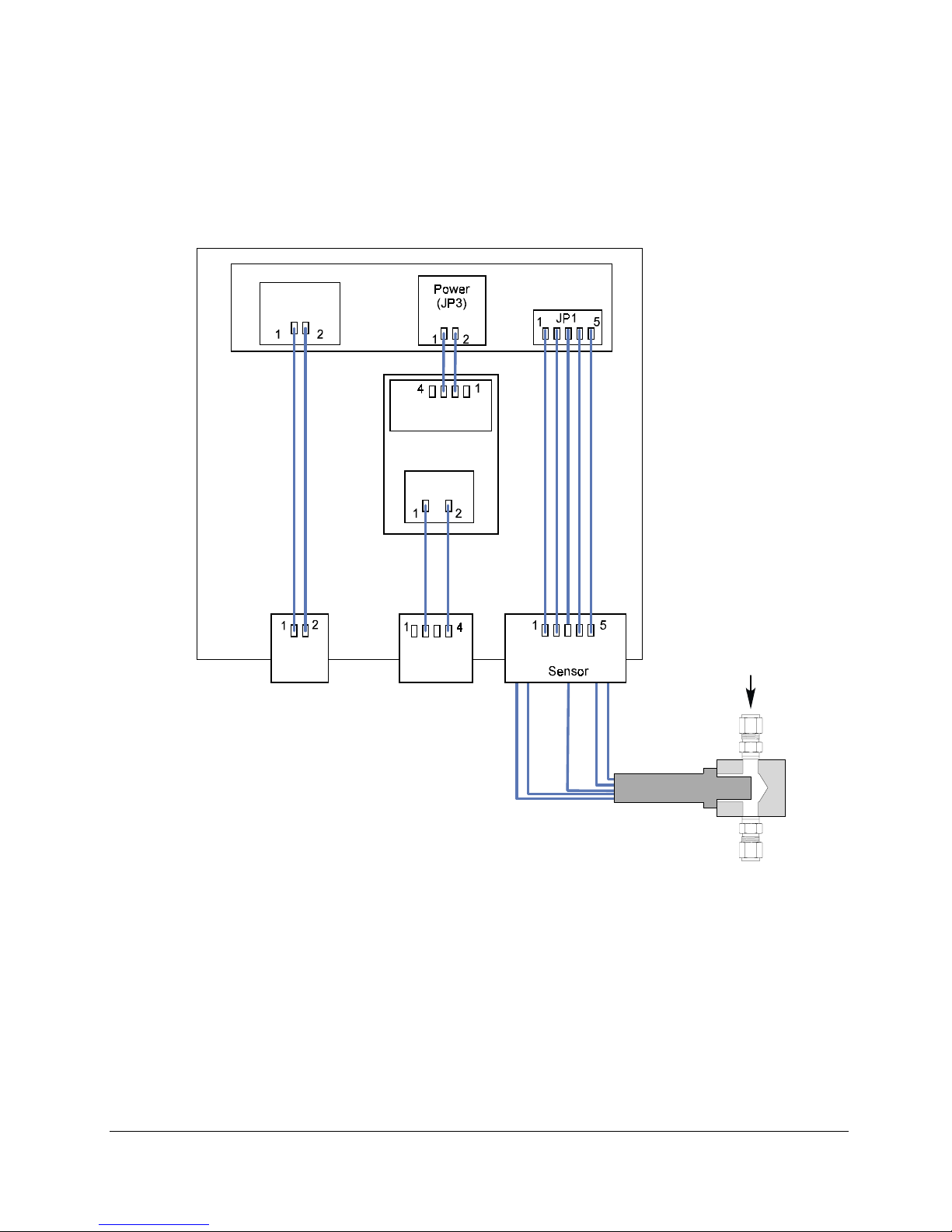

1. Connect sensor (if external), analog signals, and AC wiring to the analyzer as

depicted in the accompanying wiring diagram.

2. Supply a metered amount of sample to the analyzer and verify the Sample flow

meter should be between 0.2 and 10 SLPM.

3. Apply power to the instrument (85 to 250 VAC, 50-60 Hz).

Warning: This instrument is designed for use with 85 to 250 AC

input power only. Serious equipment damage and/or

injury will occur if it is connected to improper power.

4. After a few seconds, the oxygen concentration display will illuminate. The

display will move from zero up to the approximate sample value in about one

minute. It will fully warm-up in approximately 30 to 60 minutes.

2. Calibrate the analyzer

After installation and at least a 1-hour warm up period, the instrument can be calibrated

via the following procedure.

Note: The Brand-Gaus oxygen analyzer calibrations are generally very

stable. If the calibration appears to have drifted significantly, or

requires frequent adjustment, do not recalibrate the unit. Check

for analyzer malfunction and/or check the sample delivery

system for leaks or other problems.

1. Low calibration:

a. Flow low calibration gas (typically zero) through the sample handling system

and analyzer. Dry nitrogen or EPA protocol gas is recommended as a low

calibration gas.

b. Wait approximately two minutes or until reading settles

c. Adjust the “low cal” potentiometer on the front panel until the display reads

the desired concentration (typically zero).

2. High calibration:

a. Flow High calibration gas through the sample handling system and analyzer.

b. Wait approximately two minutes or until reading settles

c. Adjust the “high cal” potentiometer on the front panel until the display reads

the desired concentration.

Brand-Gaus Oxygen Analyzer User’s Manual Theory of Operation 5

3. Calibrate the voltage outputs

Warning: This operation should only be performed by qualified

service personnel. Some internal analyzer components

are at high temperature and/or at lethal line voltage.

If accuracy of the voltage outputs is critical, calibration may be performed. There are

trim potentiometers and the back of the large blue output module on the display board,

accessible by removing the top cover. Flow zero and span concentrations to the analyzer,

verify the display reads the proper value, and adjust the zero and span pots to calibrate

the analog output to correspond with the display values.

Theory of Operation

Zirconium Oxide Measurement of O2

The oxygen measurement makes use of the fact that zirconium oxide conducts oxygen

ions when heated above 600 °C. Platinum electrodes on the interior and exterior of a

zirconium oxide tube provide a catalytic surface for the exchange of oxygen molecules

and oxygen ions. As molecules encounter the platinum electrodes, they become ionized

and are transported through the body of the zirconium oxide. This charge transport

ultimately sets up an electric potential across the electrodes that is proportional to the log

of the ratio of oxygen concentrations on each side of the oxide. Thus, if a reference gas

(usually instrument air at 20.9 %O2) flows across the inner electrode, the concentration

of sample gas flowing across the outer electrode can be determined. In a conventional

zirconium-oxide oxygen analyzer, this voltage is exponentiated to determine the

concentration.

In the Brand-Gaus Model 4705, a second zirconium-oxide cell is ganged together to

pump oxygen into the first cell, which is maintained at a constant voltage. The amount of

oxygen needed to maintain the primary cell at the operating point is a more sensitive

measurement of sample concentration, and allows for measurement at zero oxygen. This

pump signal is carefully measured and related back to the sample concentration.

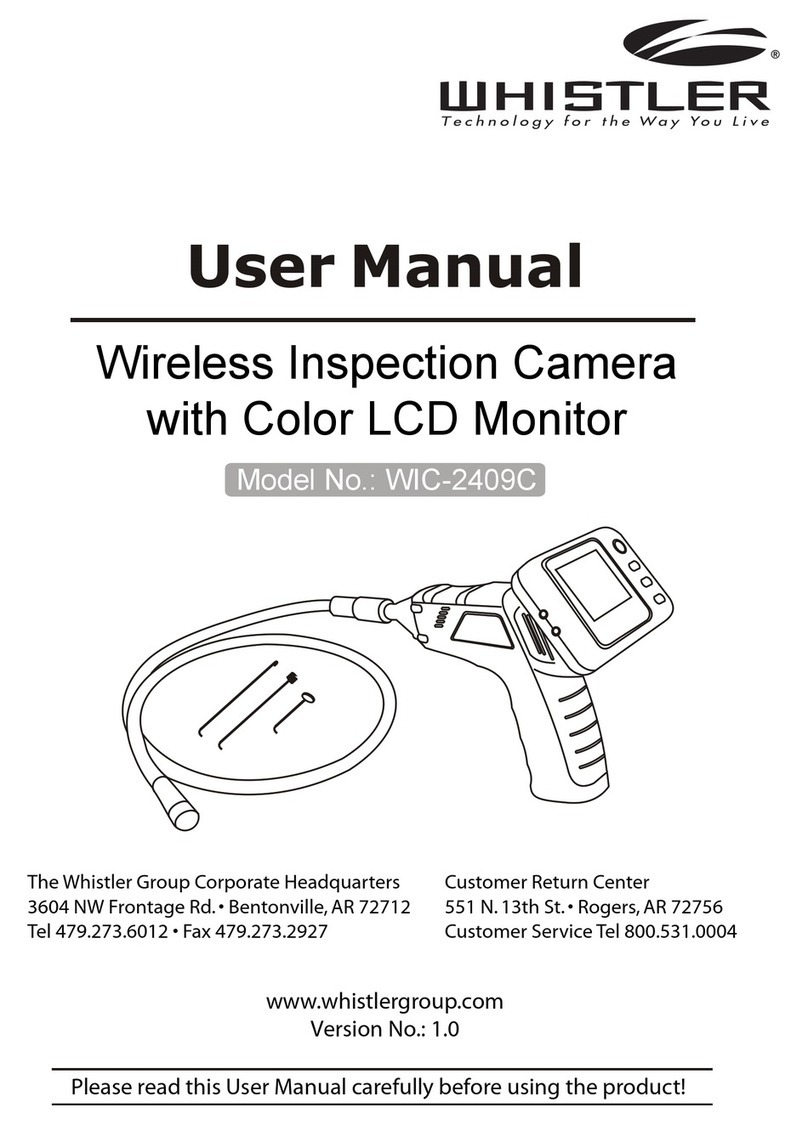

6Wiring Diagram Brand-Gaus Oxygen Analyzer User’s Manual

Wiring Diagram

-+

Output (J2)

Gnd 24V

AC In (J1)

NH

Power Supply

O2 Signal

Board

Analog output (0-10VDC)

1: Output low

2: Output high

Scaling:

0V = 0% O2

10V = full scale %O2

85-250

VAC

NH

Output (JP2)

white

grey

red

black

Gnd 12V

Supply

-+

Signal

Output

O2 Sensor

Sample flow rate

between .2 and 10 SLPM

Avoid pressurizing sample.

yel

Table of contents

Popular Analytical Instrument manuals by other brands

ADA INSTRUMENTS

ADA INSTRUMENTS ZVE 150SD operating manual

RIDGID

RIDGID SeeSnake Compact C40 Operator's manual

Zibra Corporation

Zibra Corporation CoreView 2.7 user manual

Teledyne

Teledyne 3010MB operating instructions

LaserLiner

LaserLiner VideoScope operating instructions

VOLTCRAFT

VOLTCRAFT PHT-600 operating instructions