Bravo 8105 User manual

Bravo 8105®

CONVECTION REFLOW SYSTEM

INSTALLATION GUIDE

Technical Manual P/N 111–00–0

Installation Manual P/N 3–9317–370–00–0

Bravo™ 8105 Installation Guide

2-9317-370-00-0 Bravo™ 8105 Installation Guide iii

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface

Overview

In this section This preface covers the following information:

Topic See Page

To Our Customers iv

Customer Support Structure vii

Before You Call viii

PREFACE

To Our Customers

iv Bravo™ 8105 Installation Guide Rev. 2

To Our Customers

This Guide The purpose of this guide is to help the customer obtain the greatest return on

investment. Speedline suggests that operators, supervisors, and technicians

responsible for operating and maintaining this equipment become familiar with the

contents of these Guides prior to using the equipment.

This Technical Manual includes safety information, a machine overview, an

applications overview, program development instructions, standard operating

instructions, advanced operating instructions, process troubleshooting, scheduled

maintenance overview, and a list of error messages and audible alarms with

solutions.

Other Guides

in the Set The following list of guides make up the entire information set:

†Not yet released

Guide Name Part Number

Bravo™ 8105 Installation Guide 3-9317-370-00-0

Bravo™ 8105 General Information Guide† 3-9317-371-00-0

Bravo™ 8105 Programming and Operations Guide 3-9317-372-00-0

Bravo™ 8105 Preventive Maintenance Guide 3-9317-373-00-0

Bravo™ 8105 Repair Guide† 3-9317-374-00-0

Bravo™ 8105 Options Guide† 3-9317-375-00-0

Bravo™ 8105 Drawings† 3-9317-376-00-0

. . . . .

PREFACE

Customer Support Structure

2-9317-370-00-0 Bravo™ 8105 Installation Guide v

Customer Support Structure

Introduction Speedline has a number of offices throughout the world ready to support your

needs:

• Main Offices

• Regional Service Centers (USA)

• International Service Centers

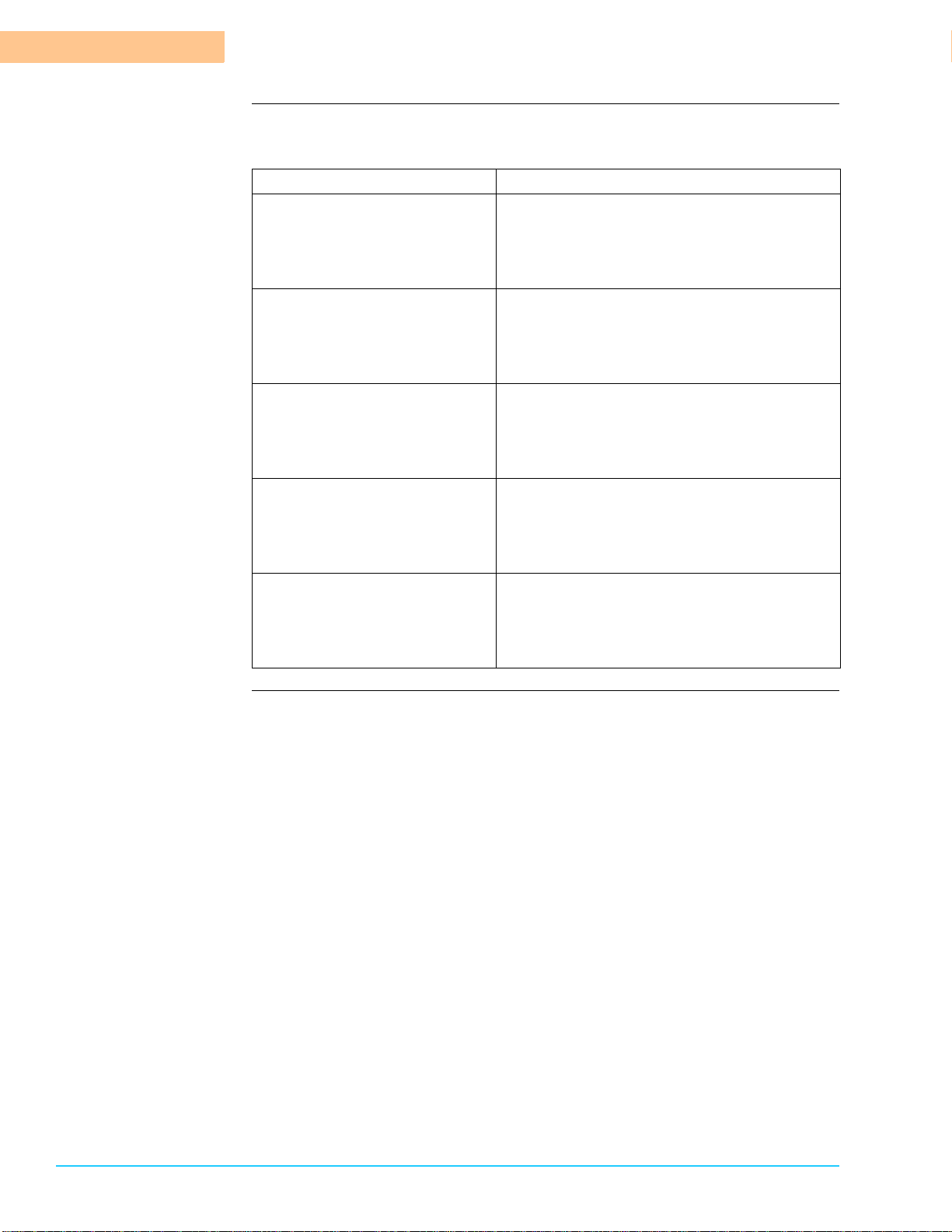

Main Offices Office Location

Speedline Technologies, Inc.

Electrovert Main Sales and

Service Office

Technical Service Support Group

P.O. Box 709, Hwy. 5 South

Camdenton, MO 65020-0709

Fax: 573-346-6878

Tel: 573-346-3341

or call Toll Free @ Tel: 1-800-737-8110

e-mail:

electrovert_tsc@speedline.cookson.com

Speedline Distribution Center Parts Sales

1605 Dundee

Elgin, IL 60120

Fax: 847-468-1029

Local Tel: 847-695-5750

Toll Free: 1-800-737-8110

Cookson Performance Solutions Training Center

580-A Tollgate Rd.

Elgin, IL 60123

Fax: 847-289-3797

Local Tel: 847-695-5750

Toll Free: 1-800-737-8110

PREFACE

Customer Support Structure

vi Bravo™ 8105 Installation Guide Rev. 2

Regional Service

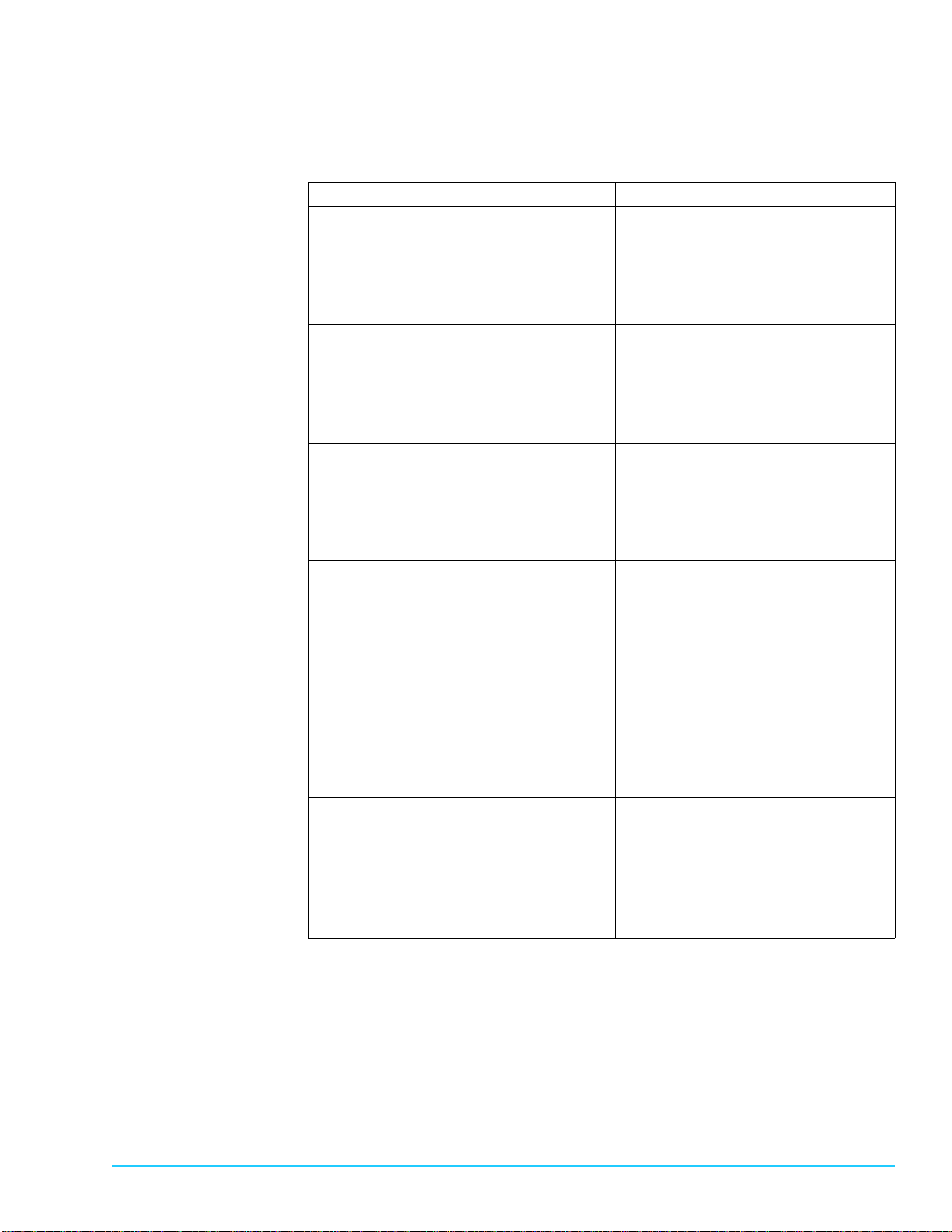

Centers (USA) The following Service Centers are located throughout the United States:

Office Location

North East Regional Service

Center 472 Amherst St. Suite 6

Nashua, NH 03063

Fax:603-880-8757

Phone: 603-883-2488

South East Regional Service

Center 1055 Windward Ridge Pkwy., Suite 140

Alpharetta, GA 30005

Fax: 770-442-1987

Phone: 770-619-5250 ext. 16

North Central Regional Service

Center 580-A Tolllgate Road

Elgin, IL 60123

Fax: 847-289-3797

Phone: 847-695-5750

North West Regional Service

Center 2968 Scott Blvd.

Santa Clara, CA 95054

Fax:408-727-0672

Phone: 408-727-4650

South West Regional Service

Center 1111 W. North Carrier Parkway

Grand Prairie, TX 75050

Fax:972-606-1700

Phone: 972-606-1900

. . . . .

PREFACE

Customer Support Structure

2-9317-370-00-0 Bravo™ 8105 Installation Guide vii

International

Service Centers The following centers serve the international community:

Office Location

Speedline Technologies, LTD Unit 1

Pincents Kiln Industrial Park

Reading Bershire RG317SD

Fax: 44 0 118 930 1401

Phone: 44 0 118 930 1400

Speedline Technologies, Gmbh Daimlerstrasse 1E

63303 Dreieich

Germany

Fax: 49 6103 832 299

Phone: 49 6103 832 0

Speedline Technologies, Italy Via Liguria 2/28

I-20068 Peschiera Borromeo (MI)

Italy

Fax: 39-2 - 5530. 8468

Phone: 39-2-5530. 8339

Speedline Technologies, Singapore 150 Kampong Ampat

KA Centre # 05-08

Singapore 368324

Fax: 65 289 9411

Phone: 65 286 6635

Speedline Technologies, Taiwan 1F, No. 11 Ching Kuo Road

Taoyuan

Taiwan, ROC

Fax: 886 3357 6247

Phone: 886 3357 5990

Speedline Technologies, Mexico Carretera a Base Aerea Militar

KM.5 No - 5850 Edificio #11

Zapopan, Jalixco C.P.

45100 MEX

Fax: 013 818 9019

Phone: 013 818 9017

PREFACE

Before You Call

viii Bravo™ 8105 Installation Guide Rev. 2

Before You Call

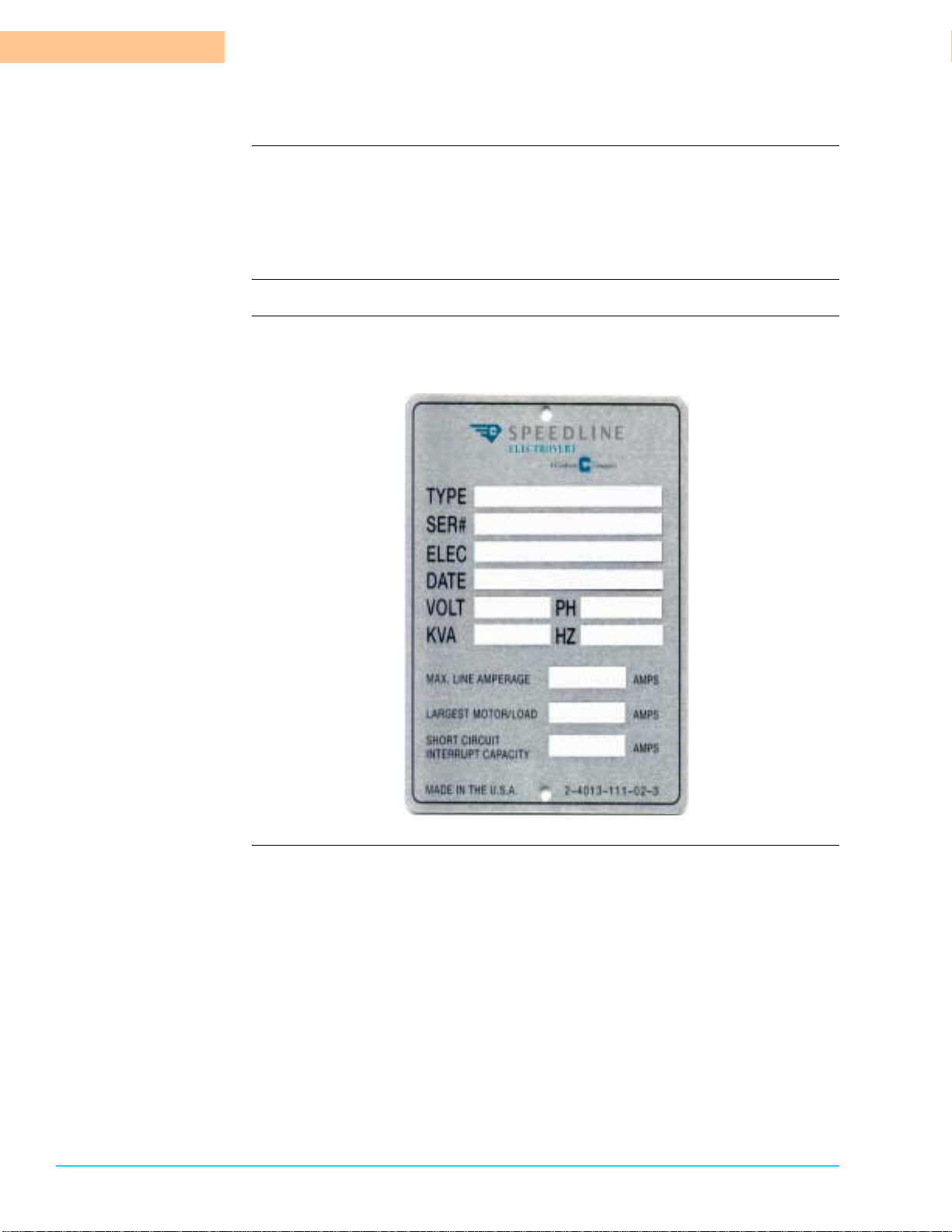

Introduction To help Electrovert support your machine in a timely fashion, have the following

specific information available when calling in:

• System Software Version

• Serial Tag Information

Machine Serial Tag The machine serial tag is located on side of the rear electrical panel. It provides

important information that will be helpful in servicing your machine.

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Preface

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

To Our Customers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Customer Support Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Before You Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Chapter 1. Safety Information

Hot Surface Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fire and Smoke Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mechanical Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Breathing Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inerting Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Other Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lock-Out Tag-Out

Attach Facility Lock-Out Tag-Out Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Attach Machine Lock-Out Tag-Out Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Perform Required Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Remove Lock-Out Tag Out Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2. Bravo™ 8105 Machine Installation

Bravo™ 8105 Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Before Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Crate and System Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Packing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Skid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing Leveling Feet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Location Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Inspection at Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Height and Leveling Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Install Computer and Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Facility Utility Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Nitrogen Machine Option — Turn Nitrogen On. . . . . . . . . . . . . . . . . . . . . . . . . . 39

TABLE OF CONTENTS

2 Bravo™ 8105 Installation Guide Rev. 2

Electrical Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Facility Power Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Verification of Options in Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Doors, Panels and Hood Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Exhaust Setup and Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Conveyor Operation and Speed Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Photocell Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Blower Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Test Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Nitrogen Machine Option — Verify Coolant Flow . . . . . . . . . . . . . . . . . . . . . . . . 68

Appendix A: Index

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1-1

1

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Information

Overview

Introduction Operation of this equipment exposes personnel to potential health and safety

hazards. Refer to the following information to ensure a safe operating

environment for machines and personnel.

Safety To ensure personal safety and avoid equipment damage, observe the following:

ATTENTION

The information provided in the safety section of this document is not intended to

supersede rules and regulations governing health and safety in the local area or at

the installation site. Whenever there is a conflict between the information in this

section and local information, the local rules and practices govern.

In this chapter This chapter consists of the following:

Topic Section

Potential Hazards A

Safety Precautions B

Lock-Out Tag-Out C

SAFETY INFORMATION

1-2 Bravo™ 8105 Installation Guide Rev. 2

1

Section A: Potential Hazards

Overview

Introduction This section describes various hazards the operator may encounter while

operating an Bravo™ System. This section also describes warning tags installed

on the system and ways to avoid the hazards encountered.

In this section Refer to the following hazard descriptions

Topic See Page

Hot Surface Hazards 1 – 3

Flammable Hazards 1 – 4

Electrical Hazards 1 – 5

Mechanical Hazards 1 – 6

Breathing Hazards 1 – 7

Inerting Hazards 1 – 8

Other Hazards 1 – 9

. . . . .

SAFETY INFORMATION

Hot Surface Hazards

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1-3

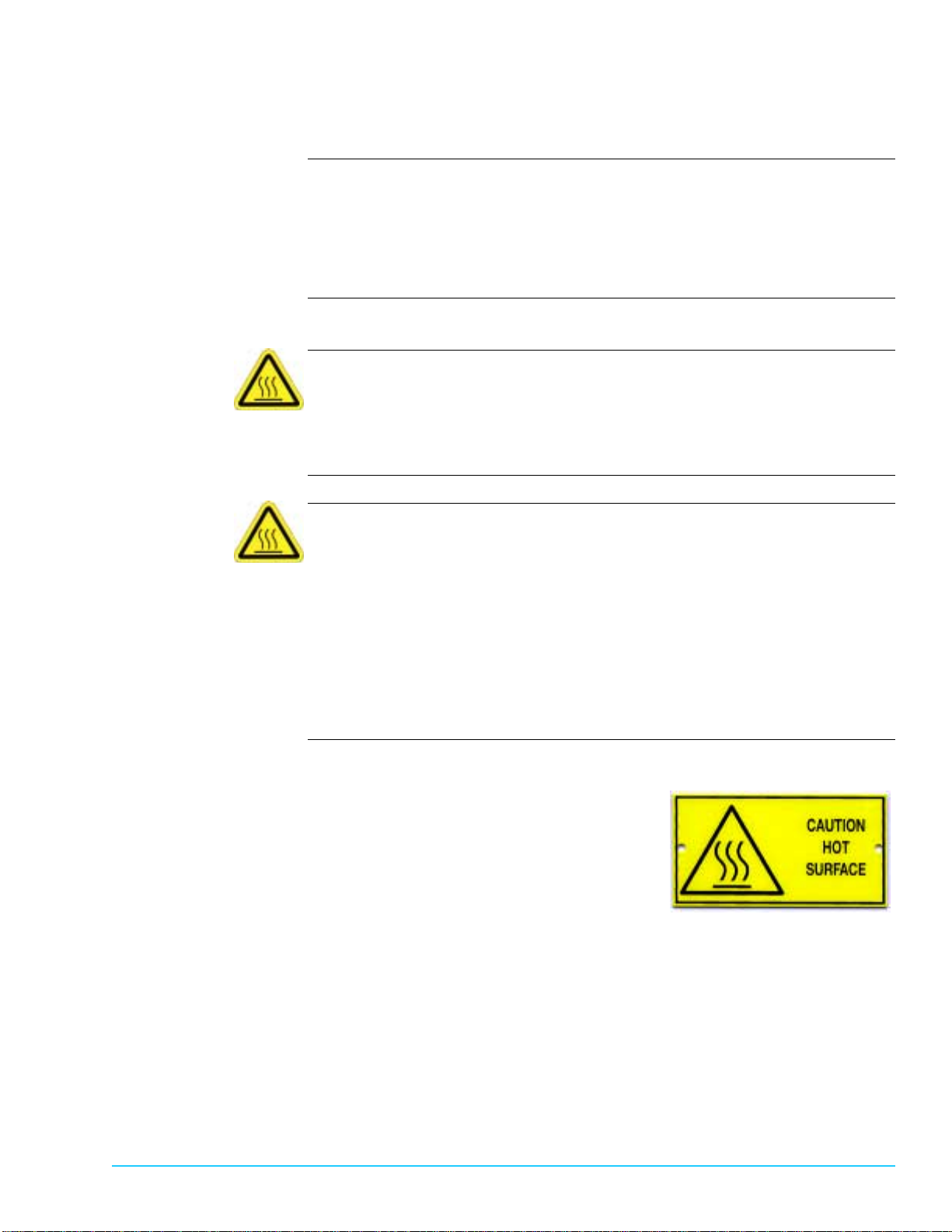

Hot Surface Hazards

Introduction During normal operation, some components of this equipment operate at

temperatures up to 300 °C (572 °F). The operator must use extreme caution and

wear the recommended safety garments prior to coming in contact with hot

surfaces or components. Closely follow and adhere to the warnings in this

document which pertain to hot surfaces.

Safety To ensure personal safety and avoid equipment damage, observe the following:

Hot Surface

The conveyor, conveyor rails, rail guards and boards moving through the system

are burn hazards and can cause severe skin burns.The heat–exposed surfaces of

the system (rails, conveyor surfaces, etc.) can become very hot.

Hot Surface

Use extreme caution when working around or with hot components. Allow hot

components to cool before handling whenever possible. Always wear heat

resistant gloves and protective clothing on or around the active system. Do not

touch the cover of the system or handle finished boards without wearing

protective gloves. Allow time for the system to cool prior to servicing. If

operations require working on any part of the system while it is still hot,

protective clothing is required. If in doubt whether something is hot or not,

assume it is hot and take the necessary steps to avoid a burn hazard. Never place

any foreign materials on the machine.

Photograph The following Photograph shows the hot surface warning tag.

Figure 1–1

SAFETY INFORMATION

Fire and Smoke Hazard

1-4 Bravo™ 8105 Installation Guide Rev. 2

1

Fire and Smoke Hazard

Introduction There are two (2) inherent fire hazards present in the reflow system.

Safety Use good housekeeping techniques and follow the operating instructions and the

suggested maintenance schedule to avoid fires. Keep flammable materials and

solvents clear of the Bravo™ System. Never stop the system with boards in the

machine.

Flammable

Motors:

Fire and Smoke Hazard. Under normal circumstances, motors tend to create

sparks during operation. Should a serious problem ever develop in a motor,

sparking may ignite flammable materials.

Flammable

Heaters:

Fire and Smoke Hazard. If boards are stationary inside the system, the high

temperatures created by the heaters may cause the boards to ignite. Additionally,

if a board drops onto a heater, it may ignite.

. . . . .

SAFETY INFORMATION

Electrical Hazards

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1-5

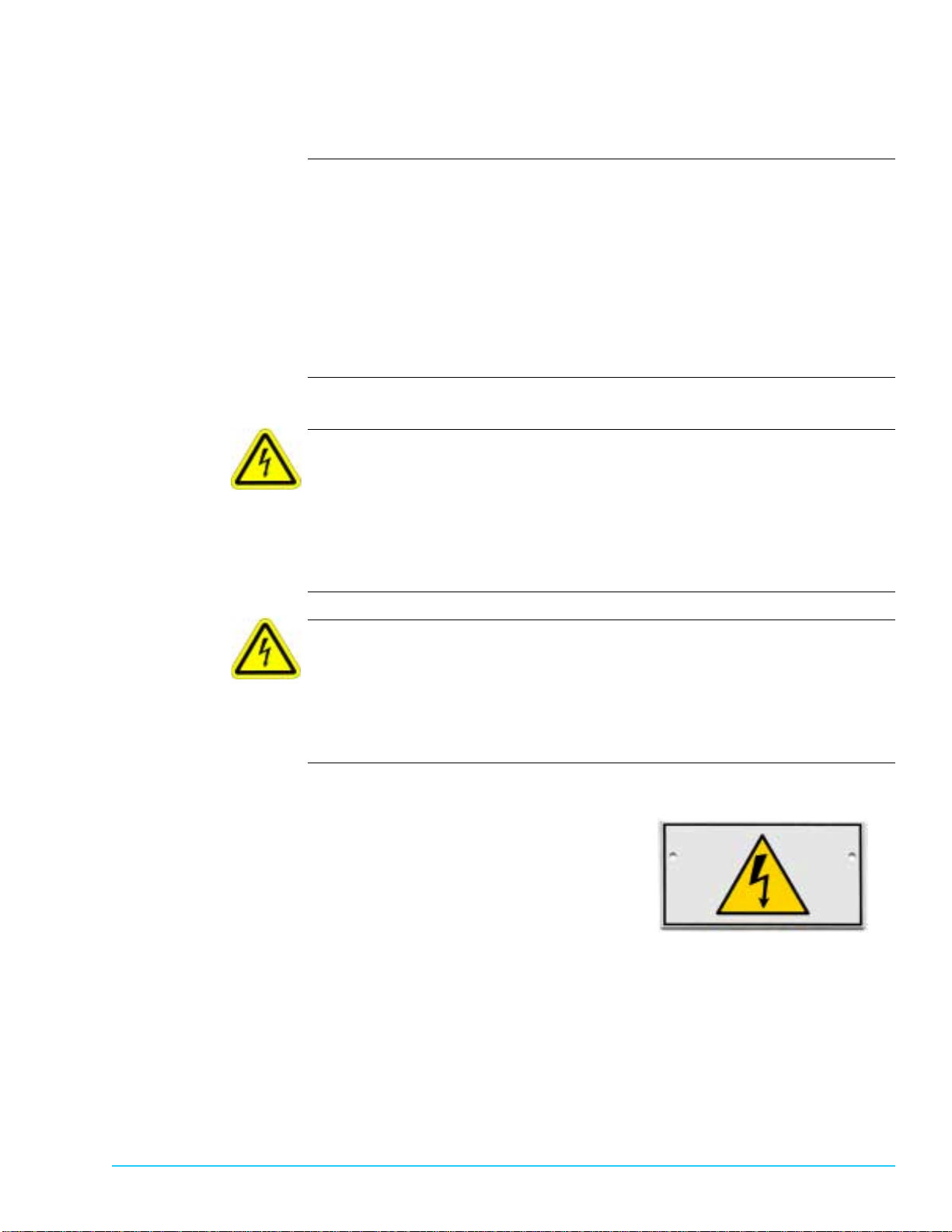

Electrical Hazards

Introduction Installation of this equipment involves exposure to situations which may result in

electrical shock if procedures are not properly followed. Pay close attention to

warnings of this nature throughout the context of this Guide.

Electrical work should only be performed by a qualified electrician.

Prior to applying power for the first time, ensure that the system is properly

grounded.

The power panels and terminal blocks of the reflow system present an electrical

hazard. High voltages are present on various parts of the system.

Safety To ensure personal safety and avoid equipment damage, observe the following:

Electrical Hazard

Installation of this equipment involves exposure to High Voltage. High Voltage

can shock, burn, or cause death. Use extreme caution when performing voltage

and amperage tests on live voltage. These procedures must be performed only by

an authorized electrician, electrical engineer, or service technician familiar with

testing live voltage.

Electrical Hazard

When performing tests using AMP meters, volt meters, or ohm meters, electrical

shock hazard is present. These procedures must be performed only by an

authorized electrician, electrical engineer, or service technician familiar with

testing live voltage.

Photograph The following Photograph shows the electrical hazard warning tag:

Figure 1–2

SAFETY INFORMATION

Mechanical Hazards

1-6 Bravo™ 8105 Installation Guide Rev. 2

1

Mechanical Hazards

Introduction Stop all moving parts when making adjustments or performing maintenance.

When the system is running, avoid moving mechanisms. Use caution when

working on or near moving parts and wear safety gear.

Safety To ensure personal safety and avoid equipment damage, observe the following:

Entanglement Hazard

All moving parts of the Bravo™ System represent potential hazards. Use caution

and avoid having hands or fingers caught in any moving mechanism. Long hair,

jewelry, and other parts of loose attire could be caught in moving mechanisms

and cause injury.

Photograph The following Photograph shows the pinchpoint warning tag:

Figure 1–3

. . . . .

SAFETY INFORMATION

Breathing Hazards

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1-7

Breathing Hazards

Introduction The lubricants used on the moving parts of the machine contain chemicals that

may be harmful if contacted directly or for a prolonged period of time. Refer to

the manufacturer MSDS (Material Safety Data Sheet) for information and safety

precautions concerning their products and system exhaust specifications.

Safety To ensure personal safety and avoid equipment damage, observe the following:

Respirator

All operators should be provided with an NIOSH or MSHA approved Respirator to

provide effective protection from airborne residue resulting from certain

saponifiers, defoamers, descalers, cleaning solvents or other chemicals used

during operation.

CAUTION

Noxious fumes are created during the normal heating process of reflow soldering.

The gases and vapors emitted from the solder and flux are contained in the reflow

chamber and should be avoided. Inhaling noxious vapors may cause headaches,

eye redness, stomach aches and breathing problems.

SAFETY INFORMATION

Inerting Hazards

1-8 Bravo™ 8105 Installation Guide Rev. 2

1

Inerting Hazards

Introduction Nitrogen can smother if the gas is not properly exhausted. Nitrogen has two

distinct hazards associated with its use, asphyxiation and compressed gas

hazards.

Asphyxiation Hazard Symptoms. The warning signs of asphyxia are dizziness, headache, fainting, and

nausea. If you feel any of these symptoms, move to an area that is ventilated

with fresh air immediately.

Compressed Gas

Hazard Compressed Nitrogen - Excessive pressure could cause explosion of Nitrogen

Flow Meters.

Do not connect the Nitrogen Flow Control unit to a nitrogen source that exceeds

690 kPa (100 psi). Exploding flow meters are a potential hazard to workers

stationed in front of the control panel. Compressed gas can cause projectiles, gas

burns to exposed areas of the body, and asphyxiation. It is recommended that

nitrogen is delivered at a regulated pressure, at least 103 kPa (15 psi) less than

the supply line pressure.

. . . . .

SAFETY INFORMATION

Other Hazards

2-9317-370-00-0 Bravo™ 8105 Installation Guide 1-9

Other Hazards

Introduction Additional hazards include weight considerations when moving or adjusting the

equipment and possible exposure to lead.

Safety To ensure personal safety and avoid equipment damage, observe the following:

CAUTION

To avoid damage to the equipment, adjust the fork lift forks to their widest

position. Use fork extensions on forks if the forks do not extend at least seven (7)

feet.

Heavy Objects When attempting to move heavy equipment or components, it is imperative to

use the proper rigging equipment. Do not attempt to move skids or large

assemblies without the use of a fork lift or other rigging equipment. Hand lifting

will cause serious personal injury.

Skin Irritation When using certain chemicals such as lubricants or solvents, it is important to

follow the MSDS (Material Safety Data Sheet) guidelines for proper handling and

usage. Wear appropriate clothing and safety articles when using descaler and

saponifier solutions. Skin or eye irritation can occur if not handled properly.

CAUTION

Exposure to lead in any form may cause serious heath hazards. Breathing lead

dust, which is nearly invisible, can cause lead poisoning.

SAFETY INFORMATION

1-10 Bravo™ 8105 Installation Guide Rev. 2

1

Section B: Safety Precautions

Recommended Precautions

Introduction Refer to the following general precautions and recommendations.

Safety To ensure personal safety, observe the following:

ATTENTION

Please refer to specific chemical manufacturer Material Safety Data Sheet

(MSDS) for specific use, handling, and safety procedures for chemical and

cleaning agent applications.

Safety Lock-Out Tag-

Out Procedures Post electrical safety tag-out and lock-out procedures in the work place and

ensure that all electrical, service, and maintenance personnel are familiar with the

appropriate procedures. Mark and label all power supply sources used for the

equipment to ensure that the lock-out and tag-out process is easily accomplished.

See Section C: on page 13.

No Smoking Post No Smoking signs in the work area and provide measures for enforcement.

Fire Extinguisher Keep an approved fire extinguisher near the machine at all times. Familiarized all

personnel with the operation and use of the fire extinguisher.

Flammables Never store flammable material on or around the Bravo™ machine. Exposing

flammables to heating elements or hot surfaces presents a fire hazard due to the

operating temperature of the machine.

Electrical Precautions During operation, ensure that the interlocks and protective panels are closed and

remain secure.

Before working on any electrical circuit, shut down the main power, lockout /

tagout the source, and check that power is Off with a voltmeter at the main

power disconnect switch.

Electrical work should only be performed by qualified electricians and

maintenance personnel. Always shut Off main power before performing any

repairs on electrical circuits.

Prior to applying power to the machine for the first time, ensure that the machine

is properly grounded.

Do not disable safety interlocks or panels that restrict access to possible

energized circuits.

Table of contents

Popular Convection Oven manuals by other brands

TriStar

TriStar OV-2910 user manual

Eloma

Eloma ELH 10-1 Installation and operation manual

GE

GE JS760BL Dimensions and installation information

Electrolux

Electrolux air-o-convect Electric Hybrid Convection Oven... manual

Thor Kitchen

Thor Kitchen HRD3001U user manual

Moffat

Moffat Turbofan E27 Service manual