Bravo OS V12 User manual

User Interface Manual

Rev 011520

2 of 127

Contents

Copyright Notice 6

BRAVO OS V12 Version Changes 7

v12.01.XXX 7

Cart Assembly 10

Optional Tray Assembly 14

Unpacking the Machine 15

Setting up the Machine 15

Install the Machine User Interface and X-Beam End Caps 18

Machine Overview 19

Software Activation & Deactivation 20

Lite 20

Product Activation 20

Product Deactivation 21

Machine Connections 22

Do Not Share Networks 22

Connecting the Power Cables 22

Connecting the Network Cable 23

Selecting The Connection 24

Powering Up the Machine 25

Initial Power Up Sequence 25

Upper Threading 26

Threading the Machine for the First Time 26

Quick Thread Change 28

Upper Thread Path 30

Bobbin Threading and Tensioning 34

Removing the Bobbin Case 34

Cleaning the Bobbin Case 34

Inserting a New Bobbin in the Bobbin Case & Checking the Tension 35

Table of Contents

3 of 127

Bobbin Case Tension Gauge 36

Inserting the Bobbin Case 39

Initial Maintenance 40

User Interface 41

Main Screen Overview 41

Machine Status 42

Loading A Design 43

Resetting a Design 46

Move & Rotate 47

Moving 47

Rotating A Design 48

Move to Color 48

Move to Stitch 48

Laser Alignment (Design Registration) 49

Color Sequence 51

Setting Up the Thread Tree 52

Setting the Color Sequence 54

Adding Machine Commands to the Sequence 56

Hoop Selection 58

Choosing the Appropriate Hoop for the Job 59

Material Thickness 61

Selecting a Material Thickness 61

Adjusting Material Thickness 62

Machine Speed 64

Settings 66

Bobbin Detect 66

Wide Angle Driver Color 66

Presser Foot Adjustment 67

Maintenance 67

Table of Contents

4 of 127

Advanced Settings 68

Advanced Settings Button 68

Connections 68

Restart in BRAVO OS Advanced Interface 68

Machine Reset 69

Check for Update 69

Deactivate Product 69

Hooping 70

Adjusting the Hoop Tension 70

Hooping the Garment or Fabric 72

Hooping Tips 74

Attaching or Moving the Hoop Support Arms 75

Attaching the Hoop Support Arms 75

Removing the Hoop Support Arms 77

Adjusting the Spring Clips 77

Loading a Hoop onto the Machine 78

Adjusting the Presser Foot 79

Keypad Operations 81

One Touch Controls 81

Key Combinations 82

LED Indicator 85

Needle Types and Replacements 86

Replacing a Needle 86

Choosing a Needle 87

Sewing Caps 90

Selecting the Wide Angle Driver and Hoop 90

Installing & Removing the Wide Angle Driver 91

Red Wide Angle Driver Cap Support Wings (Option) 95

Adjusting the Red Wide Angle Driver 100

Hooping a Cap on the Conventional Cap Frame 103

Hooping a Cap on the Wide Angle Cap Frame 108

Loading/Removing a Hoop with the Wide Angle Driver 117

Table of Contents

6 of 127

Copyright Notice

© Copyright Melco, 2020

ALL RIGHTS RESERVED. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in any form or by any means

(electronic, mechanical, photocopying, recording or otherwise) without pri-

or written approval from the author. The author reserves the right to revise

this publication and to make changes in it at any time without obligation

of the author to notify any person or organization of such revisions or

changes.

All precautions have been taken to avoid errors or misrepresentations of

facts, equipment, or products. However, the manufacturer does not assume

any liability to any party for loss or damage caused by errors or omissions.

The machine technology is protected by - but not limited to - the following

patents:

• Pat. US 6,445,970 B1

• Pat. US 6,823,807

• Pat. CH 693569 A5

• Pat. US 6,736,077 B2

• Pat. US 6,732,668 B2

• Pat. US 6,871,605

• Pat. US 6,983,192 B2

• Pat. US 7,308,333 B2

• Pat. US 7,513,202

• Pat. US 8,851,001 B2

• Pat. US 9,702,070

• Other patents pending

Table of Contents

7 of 127

BRAVO OS V12 Version Changes

v12.01.XXX

• Simplied user view along with tradition BRAVO OS view. This is

optimized for a touch screen Windows device.

• Time based maintenance (this is done while in the simplied user

view in BRAVO OS)

• Simplied hoop selection by hoop type categories. For example:

square hoops, round hoops, etc. (Simplied user view in BRAVO

OS)

• Simplied acti-feed selection by just selecting a product type. For

example: if the user is sewing a polo shirt they can just select the

t-shirt in product type in the simplied user view in BRAVO OS.

• Simplied position screen. User can easily do things like rotate a

design 180 degrees by just a single click (Simplied user view in

BRAVO OS)

• Simplied load design window (Simplied user view in BRAVO OS)

• Simplied color sequence window. This also includes a color se-

quence repeat function. This can be applied when doing applica-

tions like step and repeat (Simplied user view in BRAVO OS)

• Thread break sensor calibration tool. This allows you to ne tune

the thread break sensor so that false thread breaks can be eliminat-

ed (Advanced Interface view in BRAVO OS)

• New colorized status bar. This allows the user to see from a dis-

tance what is going on with each machine without walking over to

the PC screen (Simplied user view in BRAVO OS)

• Presser foot adjustment button (Simplied user view in BRAVO OS)

• Removed the monthly maintenance from the recommended initial

maintenance steps.

• Security Updates

• Bobbin tension changes

• The machine may automatically slow for longer stitch movements in X,

Y, or now Z. Longer stitches, as well as higher thread feed values, may

affect speed.

Table of Contents

8 of 127

• Stitches in complex lls will no longer be removed upon rotation in OS.

• Corrected machine head up timeout issue.

• Corrected an issue that would allow the machine to move X/Y while the

needle was in the fabric.

• Resolved an issue that would occasionally cause a machine to fall ofine

from the software when a maintenance procedure was ignored.

• As of this update, the user must check for updates. No automatic noti-

cation will be presented.

• Corrected an issue that would cause the orientation of the design or

design elements on screen to be different than the design being sewn.

• Moving the hoop in X after a trace will no longer cause the hoop to

also move in Y.

• If closed early, the software will not prevent the user from launching

the software again.

• Corrected issue where acti-feed setting would change after a larger

number of color changes.

Table of Contents

9 of 127

• Added hoops:

• Allied Hoops:

• 7.0” x 6.5” (17 x 16 cm)

• 6.0” x 5.5” (15 x 14 cm)

• 3.5” (12 cm) round

• 5.9” (15 cm) round

• 7.1” (18 cm) round

• Mighty Hoops:

• 16.625” x 17.25” (41.3 x 43.8 cm)

• 10” x 5” (25.4 x 12.7 cm)

• 6” x 9” (15.25 x 22.86 cm)

• 12” x 15” (30.5 x 38.1 cm)

• 4.25” x 16” (10.8 x 40.6 cm)

• 19” x 10” (48.25 x 25.4 cm)

• 16” x 14” (40.6 x 35.6 cm)

• Slim Line 2:

• 6.5” x 6.5” (16.5 x 16.5 cm )

• 8” x 5” (20.3 x 12.7 cm)

• Slim Line 1:

• Hat Side Right Clamp

• Hat Side Left Clamp

• Red Driver

• Back of Cap Clamp XL

Table of Contents

10 of 127

Cart Assembly

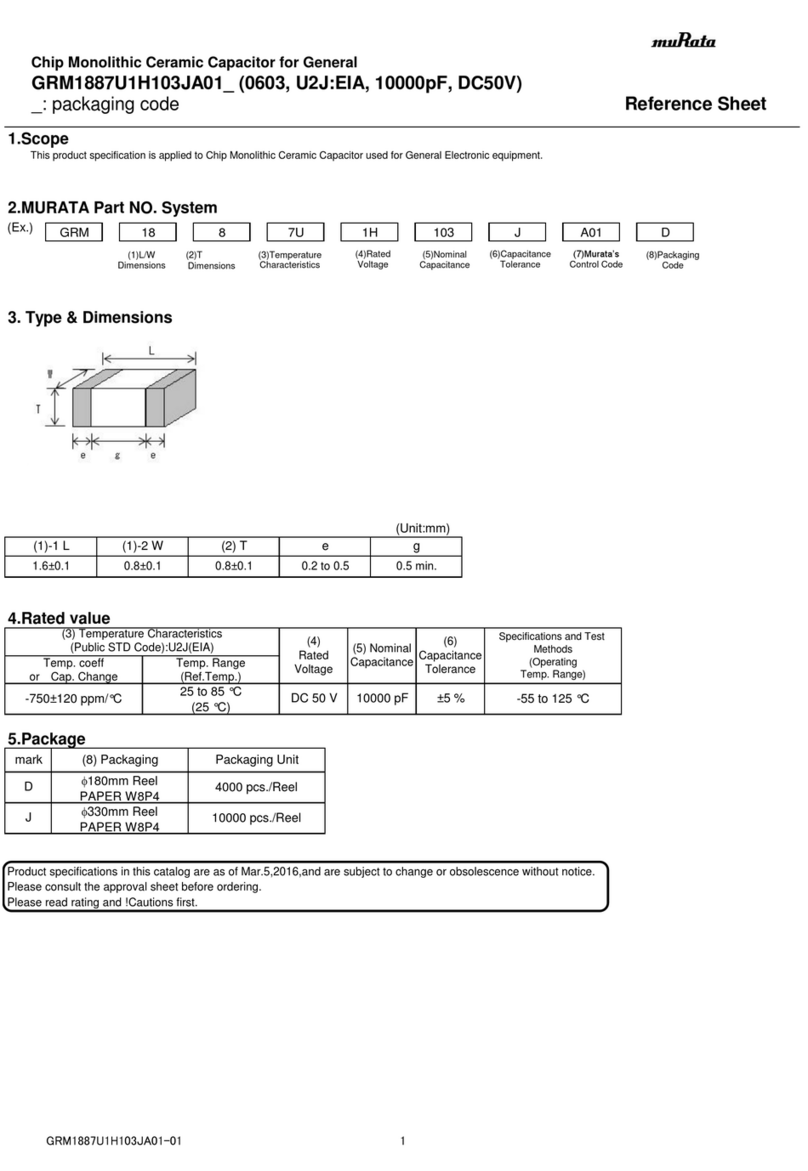

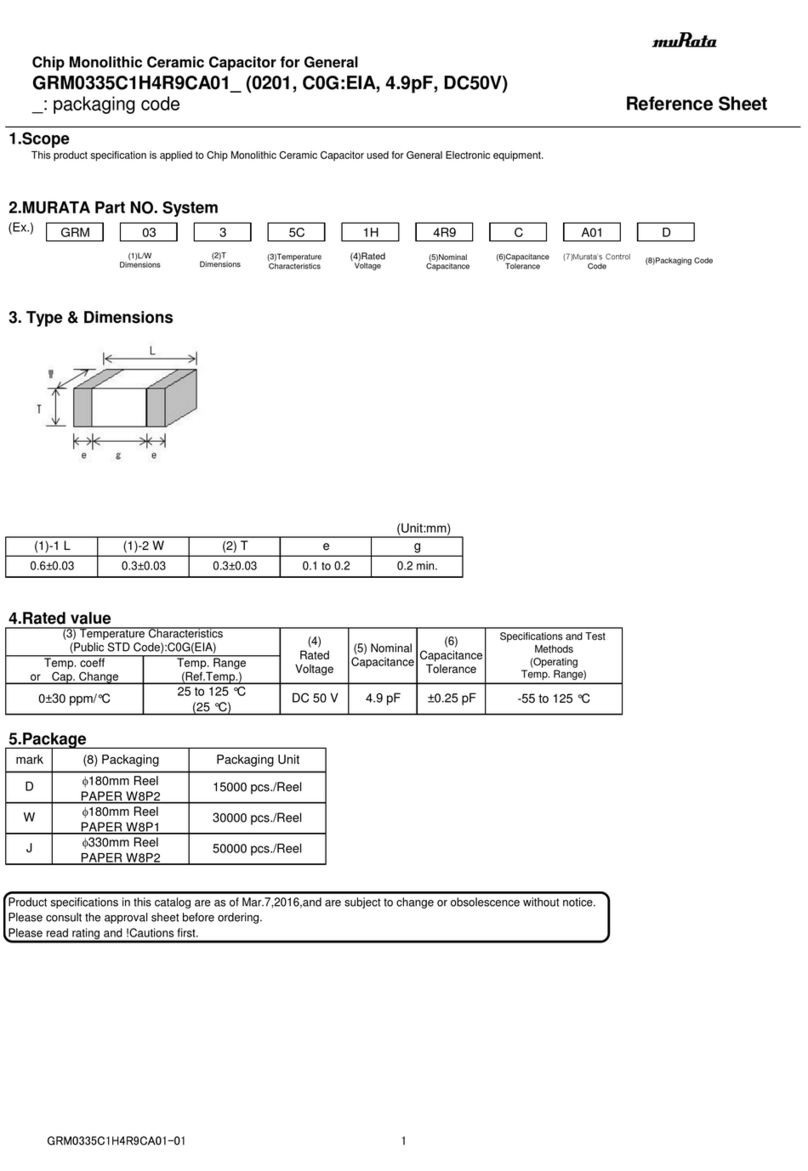

Item Qty. Description

1 1 Upper Support

Shelf (Tabs Up)

2 1 Lower Support

Shelf (Tabs Flat)

3 2 Cart Leg

4 2 Swivel Caster

5 2 Swivel Caster with

Lock

6 16 M5 Button Head

Screw

7 16 M6 Socket Head

Screw

8 16 M6 Split Lock

Washer

9 16 M6 Fender Washer

The cart (Melco PN: 34262) consists of the items assembled as shown in

the gure to the right. This assembly requires a 3mm and 5mm hex wrench

included in your Operator’s Kit.

Note: If you did not purchase the cart option with your machine, you will

nd a bench top pad (Melco PN: 33423) in the options box. Please ensure

that you place the machine on this pad to secure the machine.

Table of Contents

11 of 127

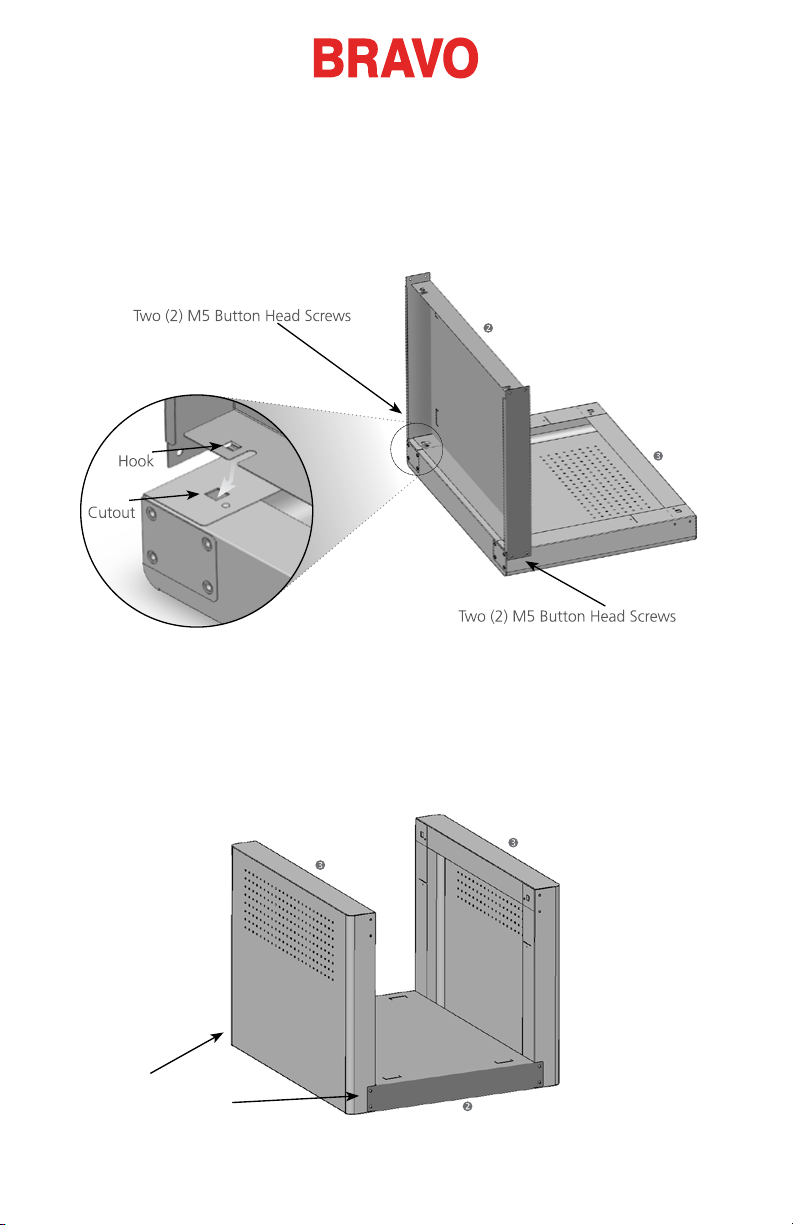

Step 1

Place a Cart Leg (Item 3) on a at surface like a carpet to prevent scratches.

Attach the Lower Support shelf (Item 2 with tabs at) by inserting the two

hooks into the cutouts of the cart leg as shown below. Loosely assemble four

M5 Button Head Screws (Item 6). They will be fully tightened in a later step.

Step 2

Place the Cart Leg and Lower Support Shelf upright as shown. Assemble

the other Cart Leg (Item 3) to the Lower Support Shelf as shown below

and loosely assemble four M5 Button Head Screws (Item 6). They will be

fully tightened in a later step.

Two (2) M5

Button Head Screws

on each side

Table of Contents

12 of 127

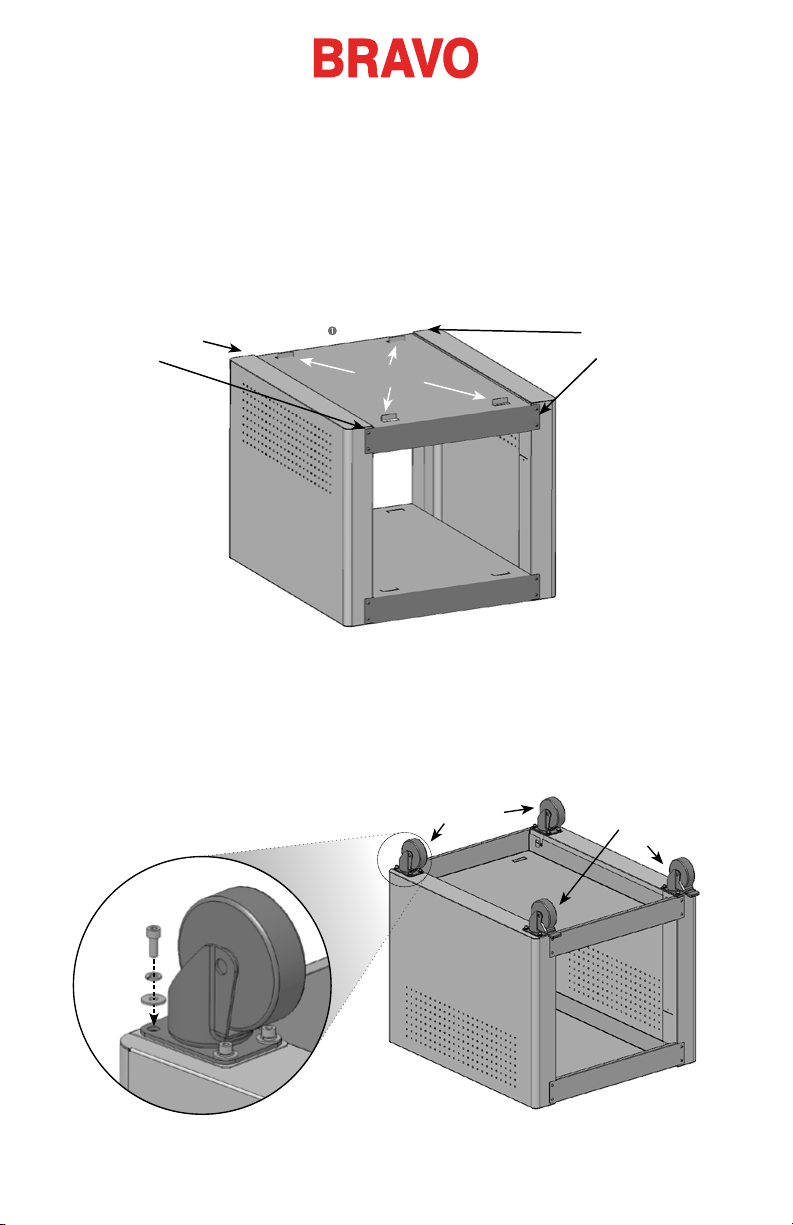

Step 3

Assemble the Upper Support Shelf (Item 1) to both Cart Legs as shown

by inserting the two hooks on each side to the cutouts of both cart legs

(Items 3). Loosely assemble eight M5 Button Head Screws (Item 6) and

then fully tighten them.

Fully tighten all the Item 6 screws from the previous two steps.

Two (2) M5

Button Head Screws

on each side

Tabs Up

Two (2) M5

Button Head Screws

on each side

Step 4

Position the cart assembly upside down and assemble the casters (Items 4

& 5) with hardware (Items 7, 8 & 9) as shown below. Flip the cart back

over with all four casters on the oor.

(4x) Item 7

(4x) Item 8

(4x) Item 9

Item 4

Caster without Brake Item 5

Caster with Brake

Table of Contents

13 of 127

Step 5

Position the cart behind the machine. Make

sure the caster brakes are engaged.

Remove the Base Cover from the machine.

Carefully lift the machine (two people are

required) using the hand-holds. Place the

machine in between the four bent up tabs on

top of the cart as show to the right. Make

sure the machine is centered between both

Cart Legs (Item 3). Place the Base Cover back

on the machine.

Important!

• When moving the machine with the cart, it is recommended that

you push near the bottom of the machine. Disengage the caster

brakes to move the machine.

• Remember to engage the caster brakes after the machine is in

the desired location.

• To optimize your cart’s functionality, keep thread away from

the wheels. When the cart is moved around, the wheels pick

up thread, which wraps around the wheel axle. This eventually

prevents the wheel from turning.

Table of Contents

14 of 127

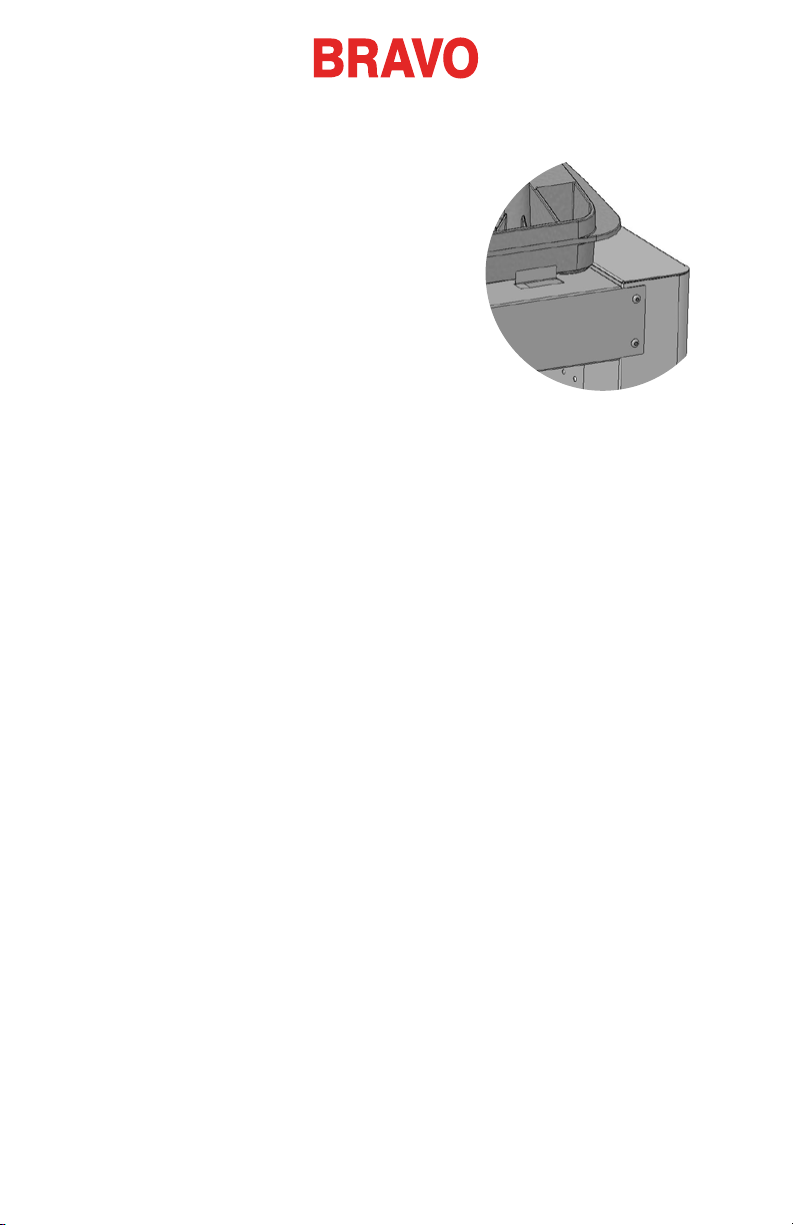

Optional Tray Assembly

The optional tray assembly (Melco

PN: 34272) is available on www.

shopmelco.com and contains the

following parts.

Item # Qty Description

1 1 Cart Tray

2 2 Sheet Metal Screw

3 1 Cart Tray Pad

Step 1

Place the tray inside the cart body

by rotating or tilting it between the

cart legs. Straighten the tray and

align the tray tabs with the slots in

the cart legs.

Slide the tray forward and into the

slots in each of the cart legs.

Step 2

Align the holes in the tray and the

cart legs. Tighten it into place using

the two sheet metal screws (Items

2).

Step 3

Place the pad into the tray.

Table of Contents

15 of 127

Unpacking the Machine

If your machine was delivered, this may have been completed by the deliv-

ery service. It is still recommended that you reconcile your shipment with

your packing list. It is important to check the packing list instead of the

invoice. The invoice will show all items that were ordered, but the packing

list will indicate if any items are on back order.

Setting up the Machine

If the machine was not delivered, the following instructions will walk you

through unpacking your machine. Please read these instructions completely

before proceeding.

1. Remove the outer packing/holding straps by cutting them.

2. Remove the options box and set aside.

3. Remove the main lid and carefully lift the exterior box up and away

from the machine.

Table of Contents

16 of 127

4. Cut the packing/holding straps securing the machine to the box/

pallet. Remove any additional loose packaging, boxes, and foam

spacers.

5. Remove the black base cover from the machine and set it to the

side.

6. If not already completed, assemble the cart using the cart

instructions.

7. With two people, lift the machine using the hand holds located on

the bottom of the machine casting.

Do not attempt to lift the machine alone. Always move the machine

with two people.

Each person should use the hand holds on the bottom of either

side of the machine. When moving the machine, take care not to

apply pressure against the needle case.

Table of Contents

17 of 127

8. Depending on which option was purchased, place the machine on

the cart or bench-top pad. If the machine is placed on a cart, make

sure that it ts within the placement tabs.

9. Replace the black base cover on the machine.

Table of Contents

18 of 127

Install the Machine User Interface and X-Beam End Caps

1. Locate the box containing the user in-

terface and end caps. The box is labeled

with the image to the right.

2. Attach the user interface assembly.

Using the two screws and two lock washers that came with the

user interface assembly, attach the interface as shown in the image

using a 4mm hex wrench.

Route the network cable (shown in yellow) from under the right

side machine cover, under the user interface mounting bolt, and

plug into the back of the user interface assembly.

3. Insert the X-beam end caps on either side of the x-beam as shown

in the image below.

Table of Contents

19 of 127

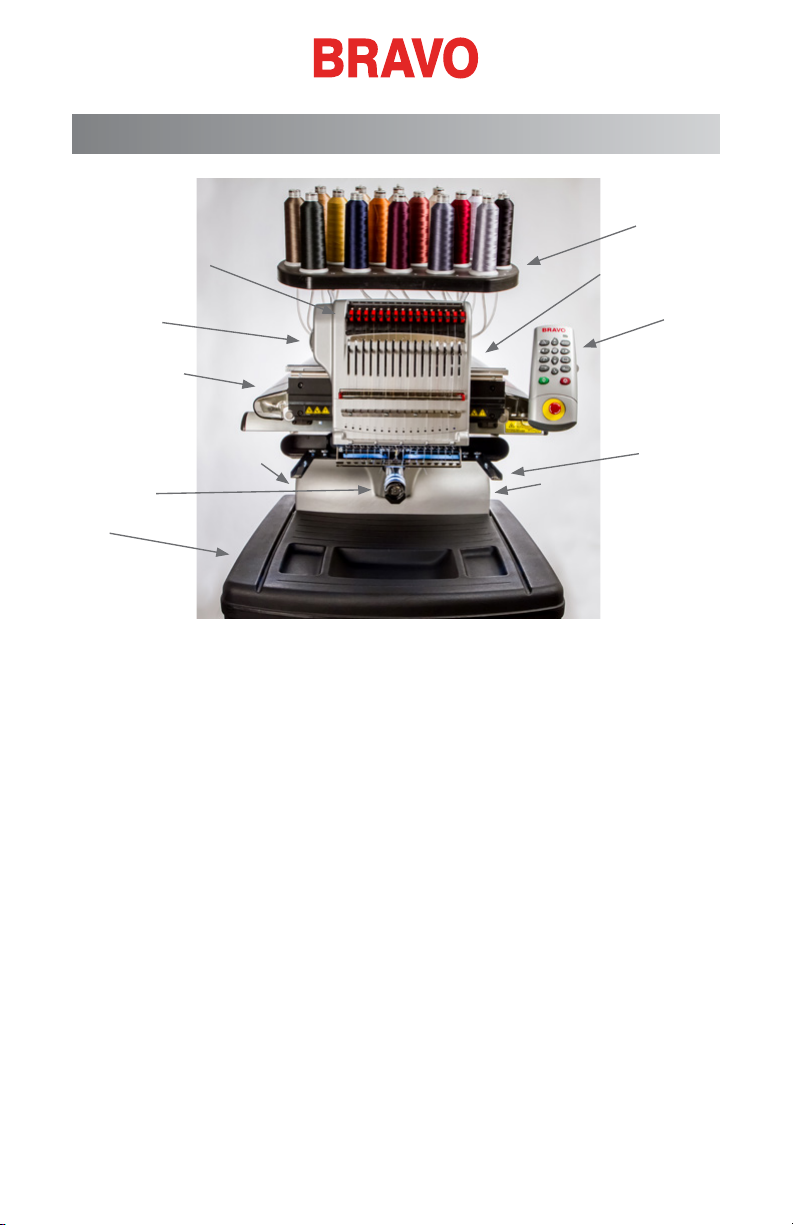

Machine Overview

Thread Tree

Keypad

Right Side Cover

Needle Case

Thread Feed Rollers

Left Side Cover

Network Connection (Back)

Lower Arm

Hoop Arms

Power Connection (Back)

Base

Table of Contents

20 of 127

Software Activation & Deactivation

BRAVO OS can use a virtual security key as opposed to a physical one. This

means that if no physical security key is present when you initially launch

your software, you will be prompted to activate the product using the prod-

uct serial number.

If a physical security key is present and attached to a USB port, this screen

will be bypassed and the appropriate level of software will be launched.

BRAVO OS may be installed on multiple computers, but only one activated

software is allowed at one time. One activation is allowed per product serial

number at any given time.

Lite

If the product is not activated, it can run in Lite.

Lite is a version of the software that allows for the running of the machine,

but limits are applied to sew eld, sew speed, and various other settings. It

will also force the software into the advanced interface.

To run in Lite, click on the Lite button on the rst Product Activation page.

Product Activation

To activate the product:

1. In the initial activation page that comes up when you launch the

software, enter the following information:

• Product Serial Number - This

number is most likely found

on the software package.

Do not lose this number.

• Device Identication Number - This number will be generated

by the software and entered for you.

• Activation Code - If you are connected to the Internet, you

may attempt to automatically obtain this number by clicking

the Activate button. This is the fastest and easiest way to acti-

vate your software.

Table of Contents

Table of contents

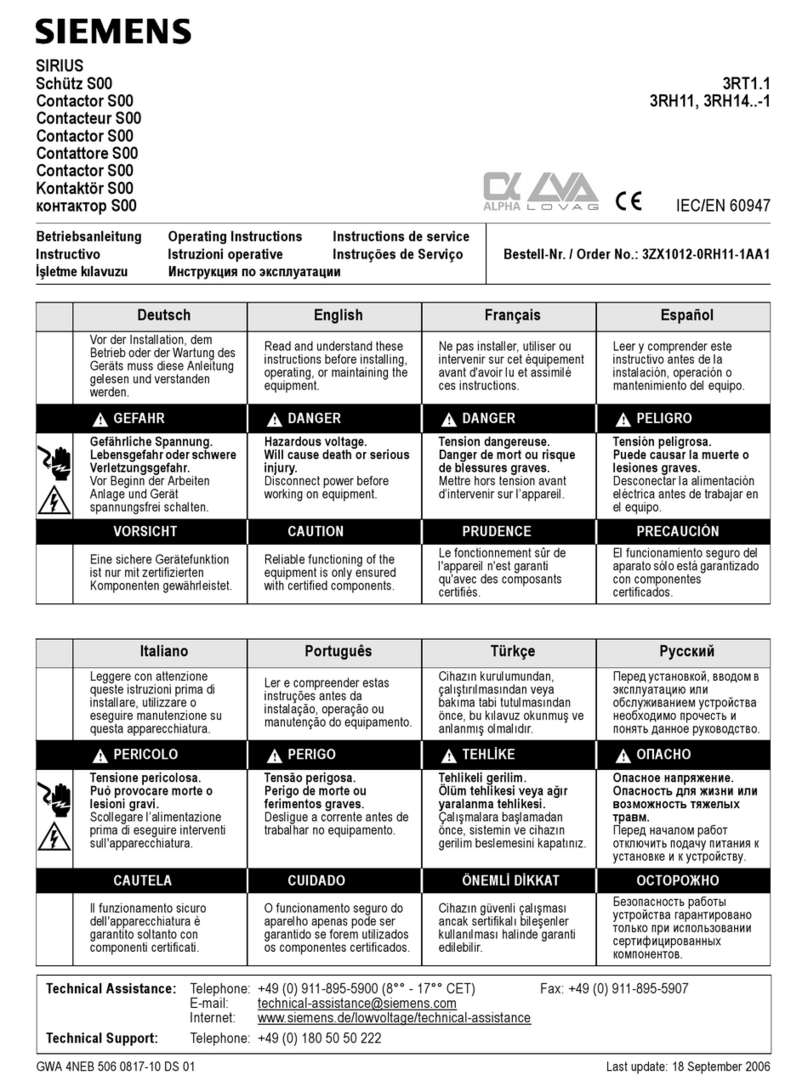

Popular Industrial Electrical manuals by other brands

Siemens

Siemens SIRIUS 3RH14 1 Series operating instructions

ZKTeco

ZKTeco BOL1219-A user manual

Murata

Murata GRM033R60J104ME19 Series Reference sheet

Murata

Murata GRM1885C2A5R1DA01 Series Reference sheet

Daniamant

Daniamant ODEO Strobe Installation and maintenance instructions

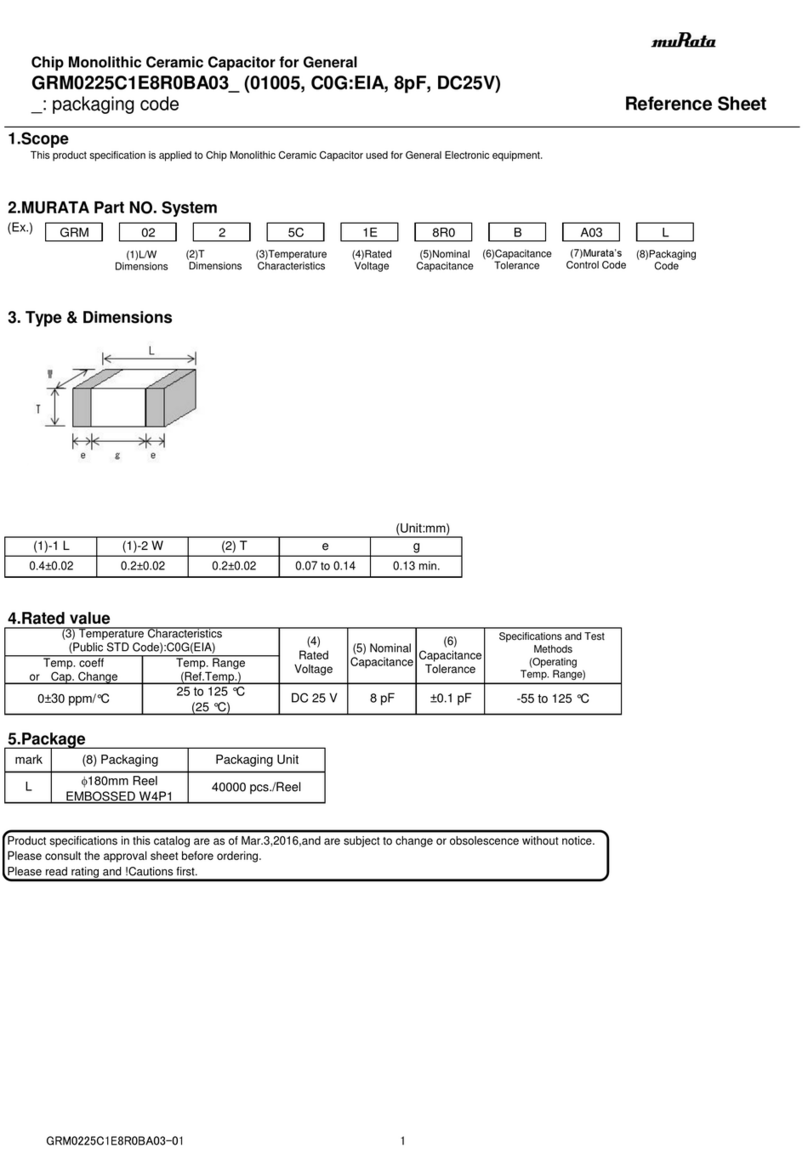

Murata

Murata GRM0225C1E8R0BA03 Series Reference sheet

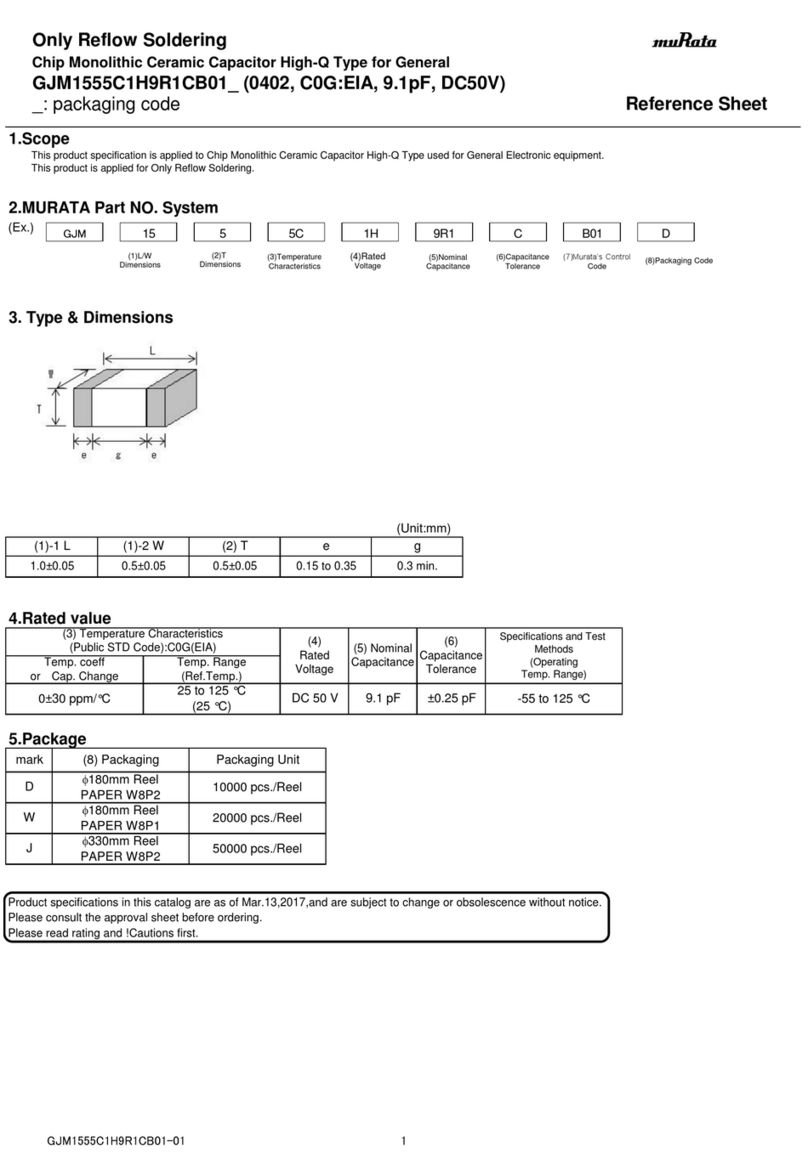

Murata

Murata GJM1555C1H9R1CB01 Series Reference sheet

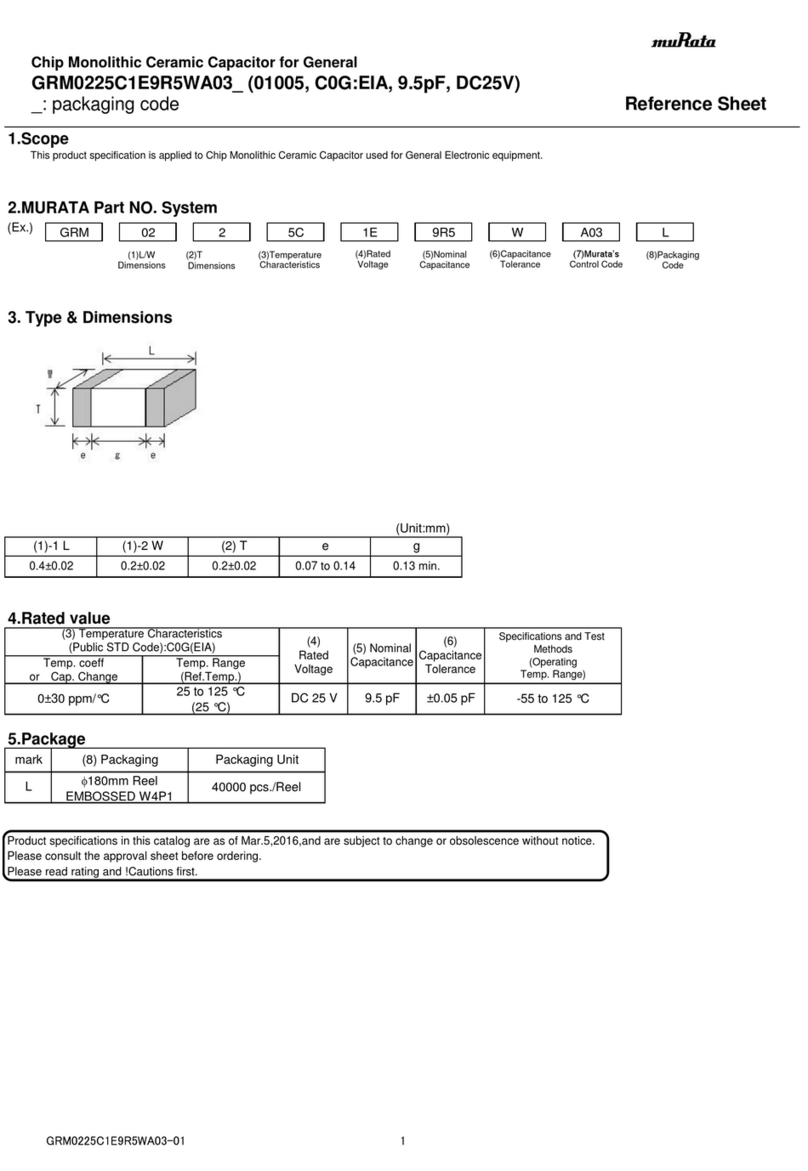

Murata

Murata GRM0225C1E9R5WA03 Series Reference sheet

Murata

Murata GRT31CR60J476KE13 Series Reference sheet

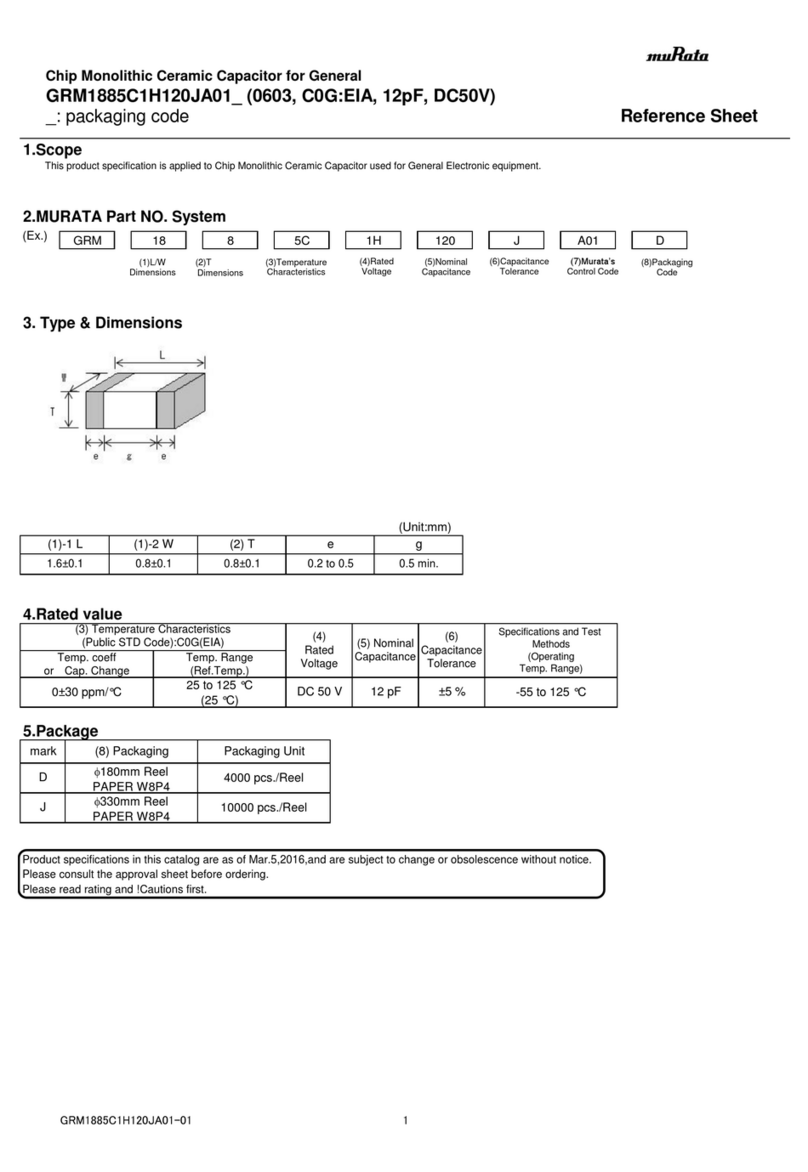

Murata

Murata GRM1885C1H120JA01 Series Reference sheet

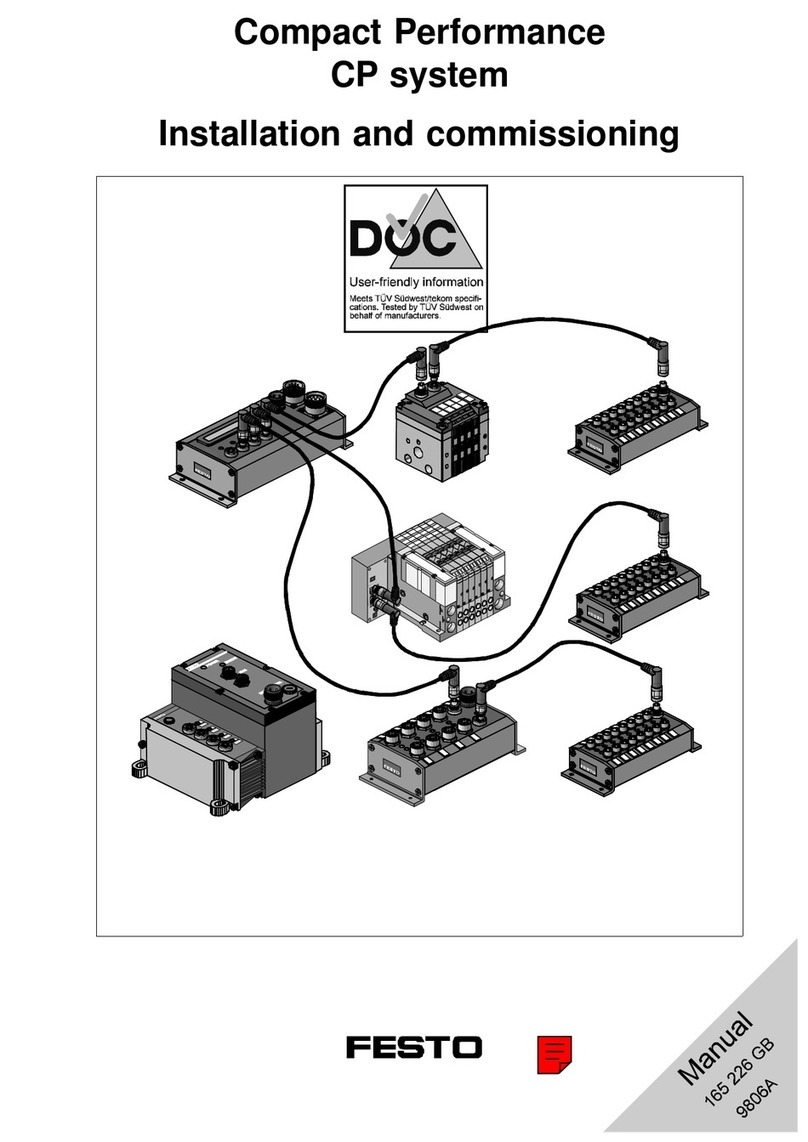

Festo

Festo Compact Performance System Installation and commissioning

Nitchi

Nitchi MH-5 Service manual