Brecknell CP103 User manual

CP103

Thermal Mini Printer

User Instructions

AWT 35-501163

Issue AB

CP103 printer_u_en_501163.book

Brecknell is a trademark of the Illinois Tool Works group of companies whose ultimate parent company is

Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2013 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted in

any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

CP103 Thermal Printer User Instructions 1

Table of Contents

Chapter 1 General Information and Warnings ........................................................................................ 2

About this Manual ..............................................................................................................2

Special Messages ....................................................................................................... 2

Description ......................................................................................................................... 2

Package and Accessories .................................................................................................. 3

Warnings ............................................................................................................................ 3

Prepare the Printer for Use ................................................................................................ 3

Signal Light Status ............................................................................................................. 4

Power Light ................................................................................................................. 4

Feed Light ................................................................................................................... 4

Specifications ..................................................................................................................... 4

Paper Roll Specifications ................................................................................................... 5

Chapter 2 Communication ........................................................................................................................ 6

RS-232 Serial Interface ...................................................................................................... 6

CP103 Printer PS/2 Connector .......................................................................................... 6

Serial Cable Definition ....................................................................................................... 7

Chapter 3 Printer Self Test and Cleaning ................................................................................................ 8

Cleaning the Print Head ..................................................................................................... 8

Steps for Cleaning Print Head ..................................................................................... 8

Chapter 4 Programming ............................................................................................................................ 9

Communicate with the Printer .......................................................................................... 10

Select Printer Type .................................................................................................... 10

Select COM Port ....................................................................................................... 10

Check Printer Baud Rate ........................................................................................... 11

Select Baud Rate ...................................................................................................... 11

Make Changes to Printer Configuration ........................................................................... 12

Change Printer Baud Rate ........................................................................................ 12

Set the Printer Data Bits ............................................................................................ 13

Set the Printer Stop Bit .............................................................................................. 13

Set the Printer Parity ................................................................................................. 14

Restore Default Baud Rate ....................................................................................... 14

Time and Date ........................................................................................................... 15

Company Information ................................................................................................ 16

Underline Printing ...................................................................................................... 17

Inverse Font .............................................................................................................. 18

Line Feed .................................................................................................................. 18

Character Dot Choice ................................................................................................ 19

Font Choice ............................................................................................................... 19

Time and Date Display Mode .................................................................................... 20

Print Height and Width .............................................................................................. 20

Upside Down Printing ................................................................................................ 21

Printer Escape Command Code Definitions .............................................................. 21

Logo Download ......................................................................................................... 22

2 CP103 Thermal Printer User Instructions

1 General Information and Warnings

1.1 About this Manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.1.1 Special Messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional information or the relative

level of hazard.

1.2 Description

The CP103 Printer is a portable thermal printer which uses a power supply adapter.

The communication interface is via RS-232 Serial. The CP103 printer can be used for

a variety of instruments or handheld data printing.

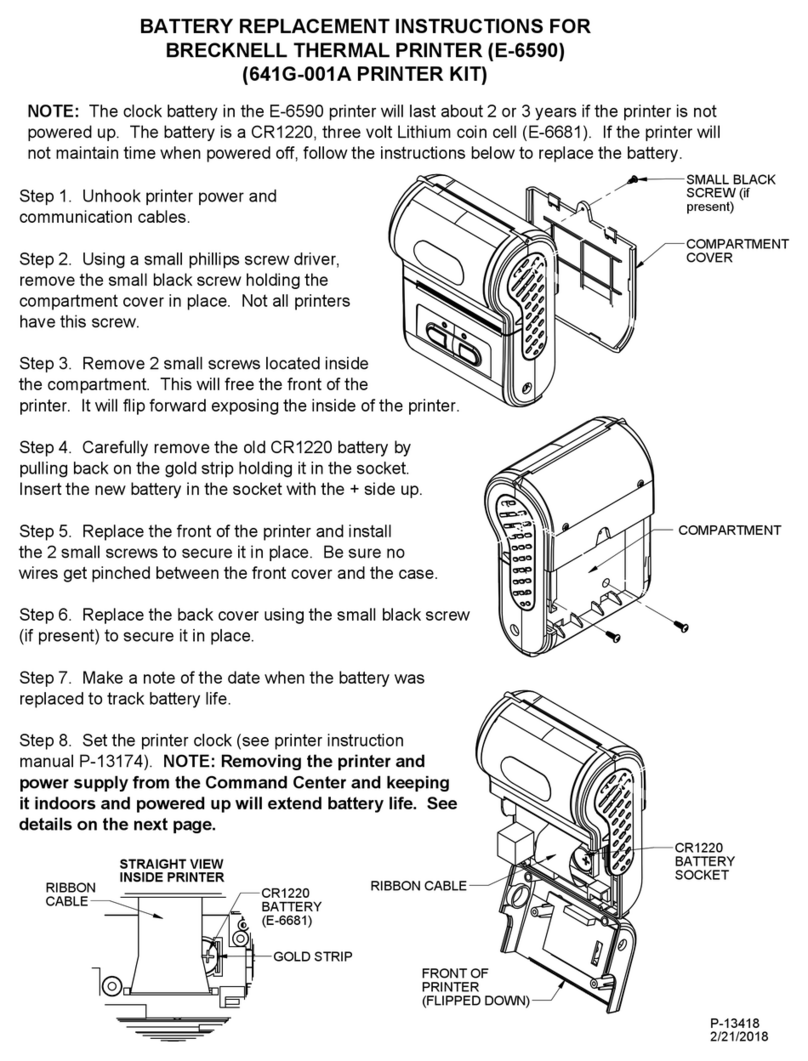

Figure 1.1 Printer Description

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

RS-232 Interface

Feed Button

Power Input

Power Button

Power Indicator Light

Paper Cutter

Feed Light

Paper Dispenser

CP103 Thermal Printer User Instructions 3

1.3 Package and Accessories

lPortable Thermal Printer

lRS-232 Serial Data Cable

lThermal Paper Roll

lDriver disc (for RS-232/USB)

1.4 Warnings

lRead all operating instructions carefully before use.

lAvoid lengthy exposure to extreme heat or cold. Your printer works best

when operated at normal room temperature.

1.5 Prepare the Printer for Use

1. Install a roll of thermal paper in paper dispenser by lifting the dispenser cover

and placing the paper in with the thermal side facing outward. Refer to Figure

1.1 for paper dispenser location.

1a. To test which side is thermal, run a fingernail across the paper. A mark should

show on the paper. If no mark appears, try the other side of the paper.

2. With about 1/2 inch of paper sticking out, close the paper dispenser cover.

3. Connect RS-232 cable by plugging the PS/2 end of the cable to the printer.

Refer to Figure 1.1 for PS/2 connector location.

4. Connect AC power adapter to the printer by plugging the adapter connector

into the printer power supply plug. Refer to Figure 1.1 for power input location.

5. When ready, plug the other end of the AC adapter into a wall socket.

6. Plug the RS-232 serial cable in the host device.

7. Press the [POWER] button to turn on the printer.

4 CP103 Thermal Printer User Instructions

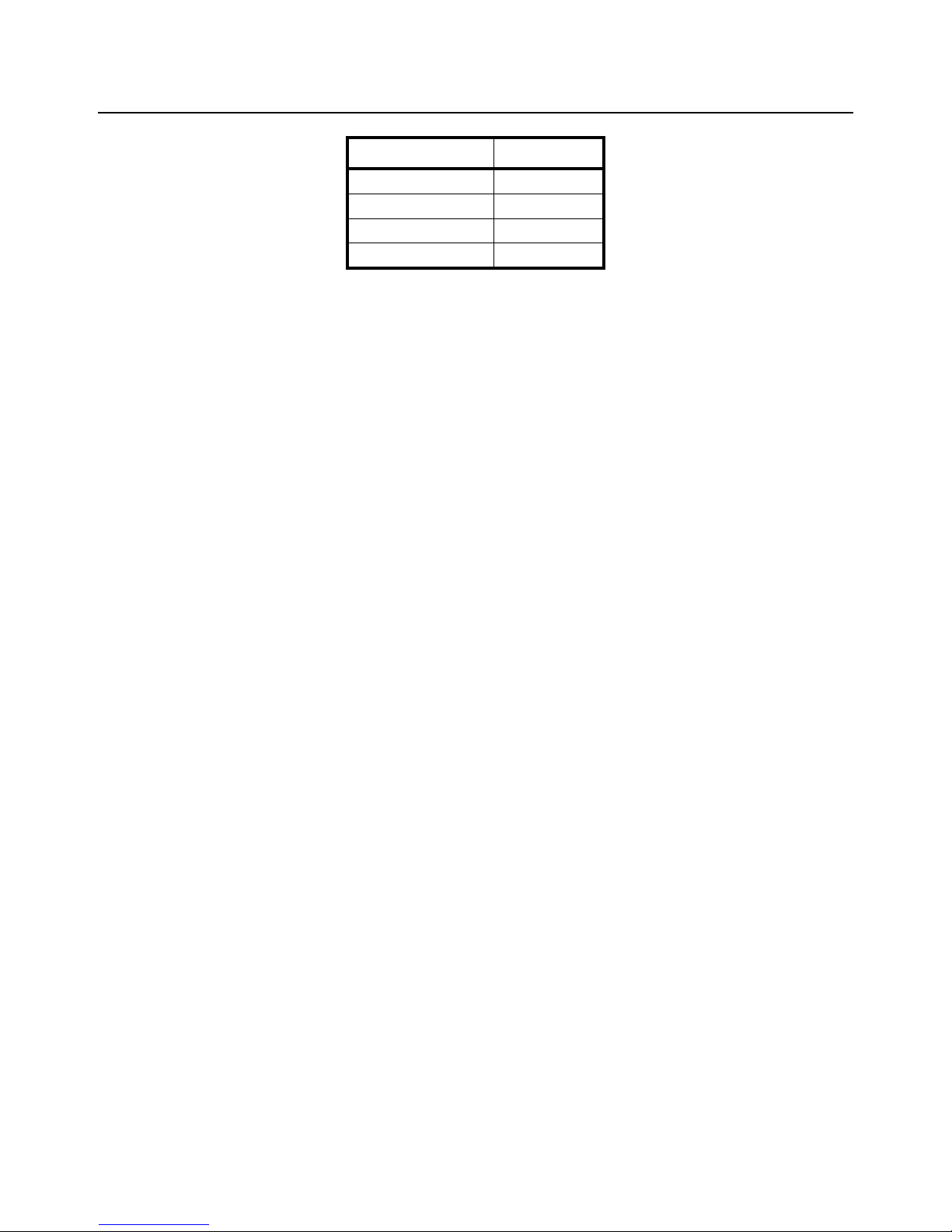

1.6 Signal Light Status

1.6.1 Power Light

1.6.2 Feed Light

1.7 Specifications

Power Light Light Color Printer Status Specification

Steady red light Red In the process of recharging battery

Red light blinks one time slowly every one second Red Battery power is low, recharge battery

Steady green light Green Battery voltage is good

Blinks between red and green light Red/Green Battery failure

Blinks 3 times between red and green light Red/Green Printing is finished or printer is in power on mode

No light None No power is detected

Feed light Light Color Printer status specification

Steady red light Red Feed paper or receiving data

Red light blinks quickly (2 times/sec) Red No paper

Red light blinks 3 times and then stops Red Printer parameter setting is finished and ok

Steady green light Green Printer status is ok but not connected bluetooth

Always alternating blink between red and green light Red/Green Printer dead, the buffer is full or temperature of

printhead is too high

Item Specification

Dimension (W×D×H) 104×75×48mm

Weight 145g (without battery and paper roll)

Print Width 58mm

Print Speed 90mm/s (MAX)

Memory 10K byte buffer and 8M byte flash

Interface RS-232 baud rate 4800 - 115200bps

Resolution 8 dot/mm (203dpi)

Language Support Figure, English characters, bit-image, bar code, curve

Character Size ANK: 12*24(dot), 1.5*3.0 (W*L, mm);

Chinese Character: 24*24 (dot), 3.0*3.0 (W*L, mm)

Print Commands ESC/POS compatible command set

Other Features Paper auto-detection, power detection, thermal protection, with machine charging, automatic sleeping mode

Working Conditions Temperature: 0° - 50°, Humidity 20% - 85%

Storage Conditions Temperature: -20° - 70°, Humidity 5% - 95%

CP103 Thermal Printer User Instructions 5

1.8 Paper Roll Specifications

Item Specification

Roll Width: 58mm

Roll Diameter: ≤43mm

Paper Thickness 0.06 - 0.08mm

Paper Type Thermal

6 CP103 Thermal Printer User Instructions

2 Communication

The CP103 Mini Thermal Printer uses a RS-232 serial interface connection with the

host communication. If a serial port is unavailable on the host device, it is possible to

use a serial / USB converter.

2.1 RS-232 Serial Interface

RS-232 is developed according to the EIA standard asynchronous transmission serial

interface. The specifications are as following:

lData transmission: serial interface

lSynchronization: asynchronous

lSignal Level: RS-232 level, logic 1:-5.4v, logic 0: +5.4v

lHardware Flow Control: optional

lBaud rate: 1200 bps to 115200 bps (NOTE: At 1200 baud, continous

printing mode of data sending from Host is not supported)

lData word length: 8 bits

lStop bit: 1bit

lParity: None

The printer self-testing page will show the current baud rate. The default baud rate is

115200bps. Refer to Chapter 3for details on the Printer Self Test.

2.2 CP103 Printer PS/2 Connector

The following drawing illustrates the PS2 socket pinout located on the CP103 printer.

This connection is used for RS-232 communication with an indicator or computer and

requires the PS2 to RS-232 interface cable (serial cable).

Pin Description

1 TXD - data output

2 no connection

3GND

4 no connection (12V DC- IN is optional)

5 RXD - data input

6 no connection (12V DC- IN is optional)

CP103 Thermal Printer User Instructions 7

2.3 Serial Cable Definition

Wire Colors PS2 Connector Pinout

male

Pin Description DB9 Pinout

female

white 1 TXD 2

blue 2 Null 8

black 3 GND 5

yellow 4 12 V Input 7

red 5 RXD 3

green 6 12 V Input 6

51

96

432

87

8 CP103 Thermal Printer User Instructions

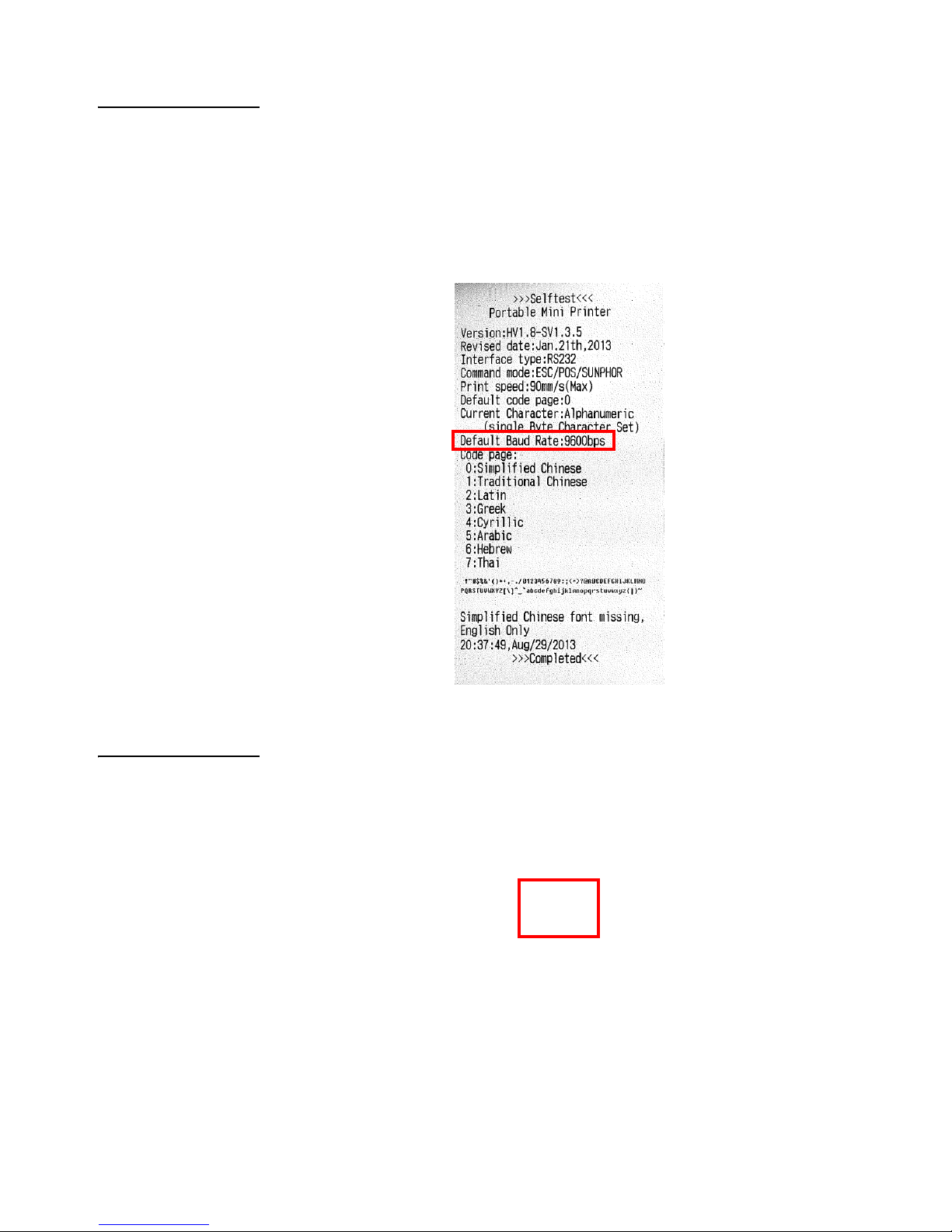

3 Printer Self Test and Cleaning

With the printer off, press and hold the [POWER] button until the printer begins to print

a self-testing page and then release the [POWER] button.

The page gives specific information regarding version of firmware, interface type, print

speed, default baud rate, etc.

3.1 Cleaning the Print Head

When the printer displays the following symptoms the print head should be cleaned:

lThe printer does not print clearly and the thermal paper is good

lThe page-test printing is not crisp and clear

lPaper feed is noisy

3.1.1 Steps for Cleaning Print Head

1. Turn off the power to the printer and open the paper dispenser cover. Remove

the thermal paper roll.

1a. If the printer was just printing then wait for the print head to cool down.

2. With a soft cotton cloth dipped in rubbing alcohol (make sure there is no

dripping), wipe the thermal printer head gently and remove any dust or debris.

3. Wait for the rubbing alcohol to evaporate completely and then place the

thermal paper roll back in the printer. Close the paper dispenser cover and

print a test page.

CP103 Thermal Printer User Instructions 9

4 Programming

It is possible to make changes to the operation of the CP103 printer such as baud rate,

company name and address, time and date. A communication utility program is needed

and can be downloaded to a PC.

1. Connect the printer to the computer with the provided serial cable.

2. Open the PC communication utility program.

Figure 4.1 Communication Utility Program

Refer to the following sections to perform certain changes to the CP103 Thermal

Printer setup.

10 CP103 Thermal Printer User Instructions

4.1 Communicate with the Printer

4.1.1 Select Printer Type

From the Set parameters tab under Select Printer Type, choose “Serial”.

4.1.2 Select COM Port

Select the PC communication port the printer is connected to.

Under Set Serial Port choose the correct COM port from the drop down choices.

CP103 Thermal Printer User Instructions 11

4.1.3 Check Printer Baud Rate

Before selecting the baud rate in the communication utility, verify the baud rate of the

printer if it is not know. The baud rate of the printer and computer need to match.

1. Perform a printer self test by turning off the printer with the [POWER] button.

2. With the printer off, press and hold the [POWER] button until the printer begins

to print a self-testing page and then release the [POWER] button.

3. The “default baud rate” designates the current baud rate of the printer.

4.1.4 Select Baud Rate

Select the baud rate within the utility that matches the baud rate of the printer.

Under Set Serial Port choose the correct baud rate from the drop down choices and

press Open.

12 CP103 Thermal Printer User Instructions

4.2 Make Changes to Printer Configuration

Strings of data can be entered to make certain changes to the printer.

Figure 4.2 Change Baud Rate Example

4.2.1 Change Printer Baud Rate

Change the baud rate of the printer to match the host device.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+CHANGE BAUD:n

Where nis the number associated with the desired baud rate.

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

nBaudRate

0 9600 (default)

1 14400

2 19200

3 38400

4 57600

5 115200

6 4800

7 1200

CP103 Thermal Printer User Instructions 13

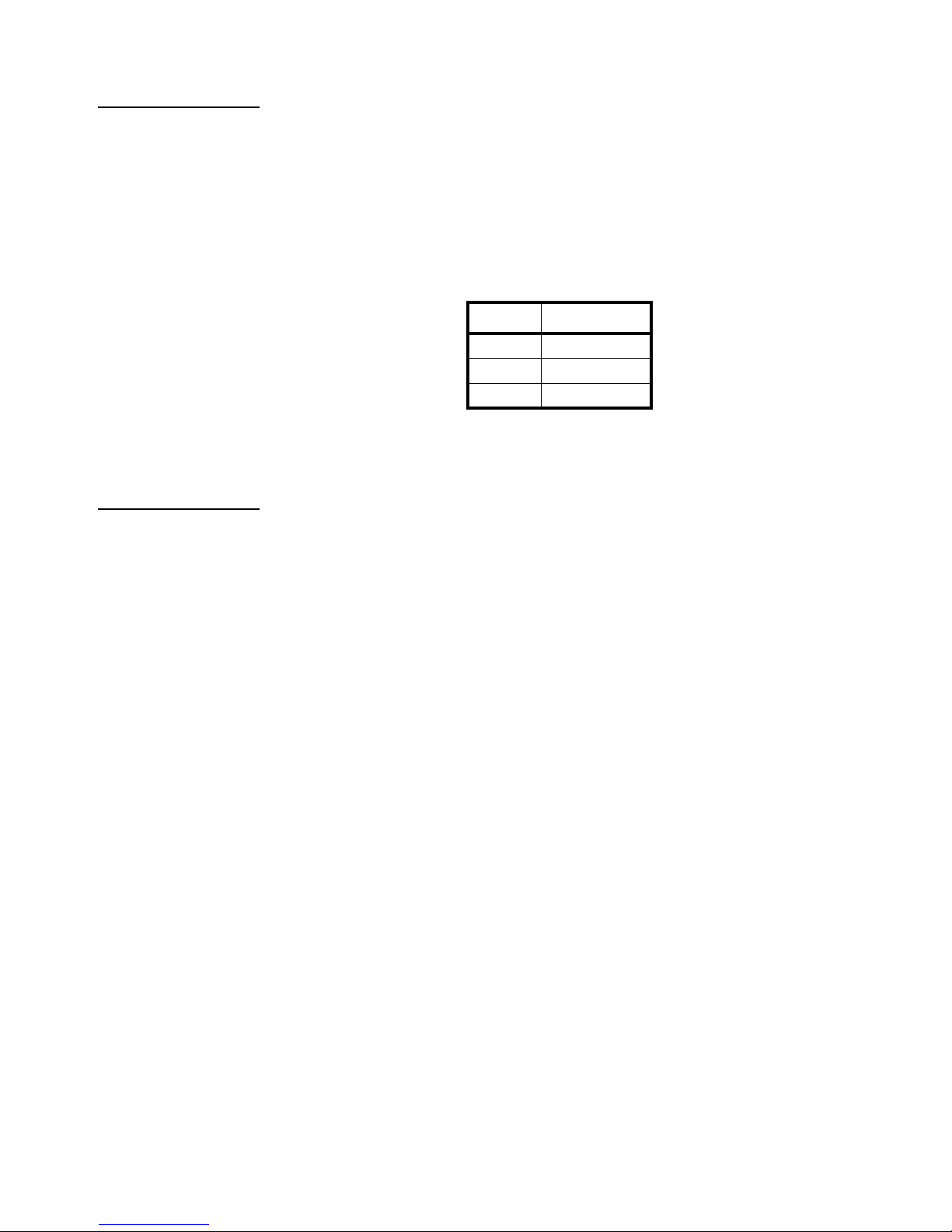

4.2.2 Set the Printer Data Bits

Change the data bits of the printer to match the host device.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+UART LEN:n

Where nis the number associated with the desired data bits

Note: Dont change the paramter if possible. If set n=1, must set parity of COM.

4.2.3 Set the Printer Stop Bit

Change the stop bit of the printer to match the host device.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+UART STOP:n

Where nis the number associated with the desired stop bit

n Data Bits

0 8 bit (default)

19bit

nStopBit

0 1 (default)

11.5

22

14 CP103 Thermal Printer User Instructions

4.2.4 Set the Printer Parity

Change the parity of the printer to match the host device.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+UART CRC:n

Where nis the number associated with the desired parity

NOTE: Only changed if the Data Bit has been changed to 9.

4.2.5 Restore Default Baud Rate

Set factory default baud rate.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

1f 40

3. Click on the box to the left of HEX.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

nParity

0 none (default)

1even

2 odd

CP103 Thermal Printer User Instructions 15

4.2.6 Time and Date

Make changes to time and date settings

Check Current Time and Date

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+TIME

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

Time and Date Setting

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+TIME: year-month-day,hour-minute-second

For example:+TIME:2013-09-22,15:20:07

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

Set Time and Date Position on Page

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+PRINT TIME ADD:n

Where nis the number associated with the desired time and date location.

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

n Description

0 put date and time in page head (default)

1 put date and time in page end

16 CP103 Thermal Printer User Instructions

4.2.7 Company Information

Enter company specific information.

Open or Close Auto-print Company Information

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+SELECT COMPANY:n

Where nis the number associated with the desired time and date location.

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

Set Company Name

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+COMPANY:NAME

NAME is company name. Maximum is 12 bits

For example input: +COMPANY: Major Technology

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

n Description

0 do not print company information (default)

1 print company information

2 only print address

3 only print telephone number

4 print company and address

5 print company and telephone number

6 print address and telephone number

7 print company, address and telephone number

CP103 Thermal Printer User Instructions 17

Set Company Address

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+ADDRESS:address

address is company the address. Maximum is 12 bits

For example input: +ADDRESS: 222 Main Street

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

Set Company Telephone Number

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

+TELEPHONE:NUM

NUM is telephone number. Maximum is 12 bits

For example input: +TELEPHONE:123-456-7890

3. Click on the box to the left of SendNewLine.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

4.2.8 Underline Printing

Enable or disable all characters printed with an underline.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

1f 2d n

Where nis the number associated with enable or disable underline printing.

3. Click on the box to the left of HEX.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

n Description

00 disable underline printing (default)

01 enable all character in underline printing mode

18 CP103 Thermal Printer User Instructions

4.2.9 Inverse Font

Enable or disable inverse font printing.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

1f 49 n

Where nis the number associated with enable or disable inverse font printing.

3. Click on the box to the left of HEX.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

4.2.10 Line Feed

Enable or disable line feed after printing.

1. Go to the Testing tab.

2. Under the CMD Testing window (the top window) enter the following command

string:

1f 19 n

Where nis the number associated with enable or disable inverse font printing.

3. Click on the box to the left of HEX.

4. Click the [SEND] button. The typed in command string will be displayed in the

bottom window if the command was sent.

n Description

00 disable inverse font printing (default)

01 enable inverse font printing

n Description

00 automatically feed 2 lines after printing (default)

01 no line feed after print

Table of contents

Other Brecknell Printer manuals