Breezair IWC 10 User manual

I n s t a l l a t i o n & O p e r a t i o n M a n u a l

®

I n d u s t r i a l W a l l C o n t r o l - I W C 1 0

( i n c o r p o r a t i n g S m a r t H u b a n d F a u l t I n d i c a t i n g f e a t u r e s )

SAFETY

Please read this manual carefully. Your failure to do so could result in injury to you or damage to the cooler and

property.

Disconnect electrical power at the fuse or circuit breaker box and turn OFF the isolating switch located inside the cooler

on the Electronics Module before you begin to install the cooler.

Always comply with your local laws and safety regulations.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use

of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

KIT COMPONENTS

1

Safety / Kit Components

1

ILL1344-A

ITEM

1

2

3

4

5

6

7

8

9

SEELEY

PART #

833880

833897

828527

828534

802329

114064

833873

805306

804644

VENDOR

PART #

-

-

-

614-047

-

-

-

-

-

QTY

1

1

1

1

2

1

1

1

1

DESCRIPTION

SENSOR CABLE ASSY 20M 6 PIN BOTH ENDS

DATA CABLE ASSY 40M 4PIN BOTH ENDS

INSTRUCTIONS - INSTALLATION & OPERATION

INSTRUCTIONS - APPLICATION NOTES

CABLE GLAND M16*1.5

INDUSTRIAL WALL CONTROL “IWC10”

SENSOR TEMP & HUMIDITY INDUSTRIAL

SCREW PAN PHIL 6ABX1” ZNP

WALL PLUG YELLOW 5MM

10 Bush 303-0740

Bush 802336 1

CABLE GLAND

ITEM 10

Locknut 303-0775

Locknut 802343

1

REMOTE SENSOR LOCATION

avoid

Mount the remote sensor in a central

location within the room or area where you

want the temperature to be controlled.

When selecting a position for the remote

sensor the following locations:

Direct sunlight

Outside walls

Direct heat sources

Direct cool air sources.

Mounting the sensor in a position near any

heat source or cool air source will affect its

ability to control temperature.

1

Locating the Sensor & Wall Control

2

3

ILL1331-A

INSTALLING THE WALL CONTROL

Install the Wall Control about 1.5 metres

above the floor in a place that is easily

accessible.

WARNING! -

WARNING! -

WARNING! -

DO NOT USE EXTERNAL

INPUTS FOR FIRE ISOLATION FOR THE

COOLER.

ALL CONNECTIONS TO BE

HIGH QUALITY INTEGRITY

CONNECTIONS

DO NOT RUN

COMMUNICATION CABLES WITH HIGH

VOLTAGE POWER CABLES.

2

ILL1337-A

4

ILL1336-A

To mount the Wall Control, follow template

and dimensions on the under-side of the

Wall Control box. Fix securely to the wall

(Fig 4 & 5).

Connect the cables to the Wall Control

through the glands supplied

5

ILL1338-A

1

Installing the Wall Control

3

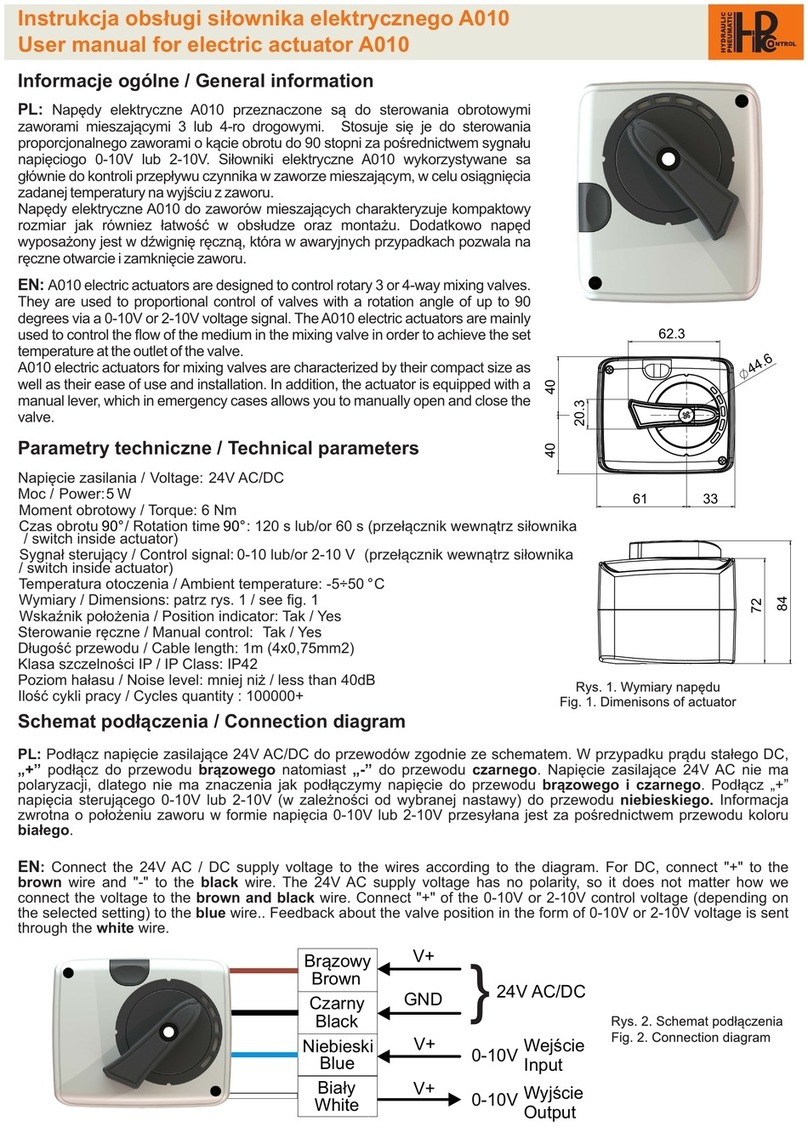

Connect cables, plugs and glands as indicated in the wiring

diagram (Fig 6 & 7).

Cables are to be a maximum of 1.5mm insulated for use

with the input and output control signals.

2

The Breezair communications cable (4 way plug) and the

Breezair sensor cable (6 way plug) will pass through

one gland. See Fig 6 for recommended cable entry

utilisation.

both

SYSTEM INPUTS:

SYSTEM OUTPUTS (each up to 40 mA, 40Vdc):

J4 - 1 Safety OFF Turns cooler OFF regardless of other external or internal commands.

- 2 F1 Selects fan speeds 1 or 2 or 3 using binary code from external source.

- 3 F2 As above.

- 4 Pump Turns pump ON and OFF from external source.

- 5 Com Common, negative.

J5 - 1 H.E. Enables humidity sensing to over-ride external commands and control pump.

- 2 Spd Cont Speed Control. 0-10Vdc, Off - Speed 10.

- 3 HD Disables humidity control of pump in Auto mode when inside T low and H low.

- 4 ON/OFF Remote location system ON/OFF switch (eg: Exit doorway, office or similar).

- 5 Com Common, negative.

J6 - 1 On System ON or OFF.

- 2 Fan Fan ON or OFF.

- 3 Pump Pump ON or OFF.

- 4 Ext External control active or in-active.

- 5 Com Common, negative.

J7 - 1 Fault Fault or No fault in system.

- 2 S.Hum Serial humidity % signal.

- 3 S.Temp Serial temperature signal.

- 4 Drain Signal appears after drain valve open and time delay expired.

0C

Terminals Legend

6

7

ILL1333-C

Sensor Cable

(6 Wire Flat)

Comm. Cable

(4 Wire Flat)

LOGIC INPUT

CONNECTION

All Commons connected

to Negative

4-32VDC

<=12mAmps D2

R1

Input

Common

D1

OUTPUT

CONNECTION

All Commons connected

to Negative

Common

Output

R3

D3

Q1

R2

Q2

NPN

RES-NTC

1.4-32VDC

<=40mAmp

(C) SEELEY INTERNATIONAL

AUSTRALIA 2004

J6

J4

J7

J5

J3

J2

RJ11 RJ12

CPMD

COMMS

REMOTE

SENSOR

OUT

OUT

IN

IN

1

2

3

4

5

1

2

3

4

5

Com

Com

In1

In2

In3

In4

Com

In5

In6

In7

In8

Com

Out1

Out2

Out3

Out4

Out5

Out6

Out7

Out8

Safety Off

F1

F2

Pump

H.E

HD

Spd Cont

ON/OFF

On

Fan

Pump

Ext

Fault

S.Hum

S.Temp

Drain

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

858746-A

ANALOGUE

INPUT

Common

20k

Spd Cont

Speed Control

Analogue Input

0 - 10Vdc

Off - Speed 10

DRYING TIME ENABLE

Parameter B6 allows the choice of enabling or disabling the Pad Drying Cycle.

Access to the B6 parameter is achieved in the usual way for accessing all parameters; i.e. within 4

minutes of mains power being switched on, the Parameter programming mode must be entered

by pressing and holding the Auto button for at least 4 seconds; then while still holding the

Auto button, press and release the Down arrow and release the Auto button.

The display will show and (fig 10). Pressing the Down arrow again repeatedly

will cycle through the parameters until you reach and . Press Auto to accept

this screen and it will now show and . The value of 00 shows the Dry Cycle is

disabled - this is the factory default setting. Press the Up arrow to change the value to

to enable the Drying Cycle.

When enabled, the Drying Cycle will commence every time the clock stops the cooling system, in

Auto mode only. In the Drying Cycle the fan continues to run on speed 1 for 60 minutes to dry the

cooling pads, and the pump does not run.

Param A1.00

Param B6.00

Value B6:00

B6:01

1

Getting Started

4

Example of a 2 Hub

project that contains

Hub 0 & Hub 1.

PROG

AT POWER UP

1.

SERVICE

SERVICE

2.a

2.b

3.

When power is first applied to the Wall Control there are 3 possible responses depending on what

is connected to the Wall Control.

When the Wall Control is connected directly to an ICON cooler without any Hubs,

either on a single cooler installation or during individual cooler commissioning on a

multiple cooler installation, the Wall Control will display (Fig. 8).

Press and hold the button until the word disappears from the

display. This will take approximately 7 seconds. This transfers ICON specific

operating requirements to the Wall Control. To complete this transfer see

“CHANGING SPEED TABLE FOR COOLERS” below.

When one TBA cooler is connected the Wall Control will display the OFF state.

When a Hub (Kit #105949) is connected the Wall Control will display the OFF

state.

When one or more Smart Hubs (Kit #111070) are connected the Wall Control will

display the identity of every Smart Hub as it is detected by the Wall Control during

initialization (Fig. 9). The Wall Control starts at Hub 0 and can count up to

Hub 9, ie. a total of 10 hubs.

When the Wall Control has completed it's initialising function and the last Hub is displayed, press

the button to accept. The Wall Control now enters the OFF state and will display just the day

and the time.

Upon restoration of the power following subsequent power failures, the Wall Control will initialise

each time, but will automatically revert to the "OFF" state no changes have occurred

to the number of Smart Hubs.

ICON

provided that

CHANGING SPEED TABLE FOR COOLERSICON

When the Wall Control is connected to an ICON evaporative cooler a different speed table must

be selected. If this speed table is not selected the cooler will not operate at its optimum

performance. To select the correct speed table follow these steps:

1/

2/

3/ Value A2:00

4/ A2:01

5/

Within 4 minutes of mains power being switched on at the Electronics Module

must be entered by pressing and holding the button for at least 4

seconds, and then while still pressing the button press and release the button.

Press the button until the display shows and Fig. 11).

Press the button. The display will now show and (Fig. 12).

Press the button until the display shows and (Fig. 13).

Press the button to accept this new value, then after a delay of a few seconds press the

button

Parameter

Programming Mode

The

display will show and (Fig. 10).

(

Param A1:02

Param A2:00

Value

.

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

SERVICE

8

9

Param

Param

Value

Value

10

11

12

13

1

Getting Started

5

TURNING THE COOLER ON

PREPARING TO START

The Wall Control can be switched ON and OFF by pressing the button. The Wall Control will

remember the setting from when the cooler was last used.

Whenever you select AUTO mode or COOL in MANUAL mode, the cooler will take a few minutes

to start as it fills with water and saturates the cooling pads. This time will be decreased if the tank is

full or the cooler has only recently been turned OFF. During this time the and symbols

will flash on the display (Fig 16).

Start:

SETTING THE CLOCK

!

1/

2/

3/

Note:

IMPORTANT Please read the application notes before programming this controller.

When the Wall Control is first installed, it will show four flashing clock digits. Set the clock on the

Wall Control before proceeding with any other programming. Programming can only be done with

the Wall Control switched OFF.

Hold the button down for over 3 seconds, until the symbol flashes.

Press the button to accept. Four digits will show with the first digit flashing (Fig 14).

Use the and buttons to change the first digit and the button to enter. Repeat this

for each digit to set the 24-hour time. The (Monday) symbol will then start flashing (Fig 15).

After replacing the battery reset the clock time.

4/ Use the and buttons to change the day of the week and press the button again to

enter the OFF mode. While the cooler is OFF it will display the current time and day.

PROG

AUTO

AUTO

M

AUTO

MANUAL MODE

Man

AUTO MODE

Auto

With the Wall Control switched ON, press the button until is shown on the display

(Fig 17).

You may then press the button to switch between COOL and VENT (where fresh air is

being delivered but not cooled).

To increase or decrease the fan speed, press either the or button.

To select the AUTO mode press the button until is shown on the display (Fig 18).

In AUTO mode the cooler will remember the last setting used and try to achieve this setting.

Operation may vary depending on ambient conditions. Pressing the and buttons will have

no effect when the cooler is in AUTO mode. (See Temperature Control Program on the following

page).

When COOL or VENT has been selected, the Wall Control will maintain a constant fan speed as

shown by the bar graph on the display.

AUTO

COOL

AUTO

Man

Auto

Start:

Man

M

14

15

16

17

18

16

Programming Wall Control

PROGRAMMING THE WALL CONTROL

The Wall Control can only be programmed in the OFF mode. If the control is ON, press the

button to enter OFF mode.

To enter the PROGRAM mode hold the button down for over 3 seconds. The symbol will

start flashing. Use the and buttons to scroll through the clock, temperature, humidity,

time and drain signal delay programs and press the button to select any one.

24 HOUR CLOCK PROGRAM

To program the clock press the button when the symbol is flashing (Fig 19).

Refer to page 5 for instructions on setting the current time and day.

PROG

AUTO

AUTO

TEMPERATURE CONTROL PROGRAM

The Wall Control can monitor the room temperature and adjust the operation of the cooler to hold

a set temperature. To do this, hold down the button for over 3 seconds to enter PROGRAM

mode. Press the or button until the symbol is flashing, then press the button.

or will flash. Select the desired temperature scale using the and buttons and press

.

The current temperature setting will flash (Fig 20).

Adjust the setting to the desired temperature level by pressing or holding down the and

buttons.

Press the button to accept the temperature setting and return to the OFF mode.

When the cooler is in AUTO mode, it will adjust the fan speed and cooling to achieve the new

temperature setting. The MANUAL mode ignores any temperature settings.

PROG

AUTO

AUTO

AUTO

C

0

F

0

HUMIDITY CONTROL PROGRAM

Humidity Control has 2 modes.

:

1/

A1:02 Param

2/ B6:0X Param

B5:00 Param B4:00

Param

3/ B4:00 Value

B4:01 Value B4:01 Param

4/

MODE 1:

MODE 2:

Humidity Mode 1 and Mode 2

The default mode provides a maximum Humidity Limit per the set point within the Wall

Control. In this mode the AUTO control function will respond to the temperature sensor to achieve

comfort conditions in the building according to the temperature set point in the Wall Control. However

the pump will stop (and therefore no moisture is added) when the room humidity rises to the humidity

set point in the Wall Control.

The alternative mode allows the cooler to attempt to satisfy both temperature and humidity,

with humidity over-riding temperature when the temperature is satisfied but the humidity is not.

The choice of which mode to use is made by changing parameter B4. See instructions below. In the

MANUAL mode no humidity control is enabled.

Disconnect power to the cooler, then reconnect power. Then, while the IWC10 is in the OFF state,

press and hold the button for 3 seconds and continue to hold whilst you press the button.

Display will now show and .

Press the button. Display will now show and . Press the button again.

Display will now show and . Press the button again. Display will now show

and .

Press . Display will now show and . Press the button. Display will now show

and . Press to set the value. Display will show and .

Press the button to enter the OFF state. Full humidity control is now enabled according to Mode

2 above.

To change between

AUTO

AUTO

AUTO

19

0

C

20

17

Programming Wall Control

When full temperature and humidity control is selected via parameter B4, the cooler will

function as follows in AUTO: When the room temperature falls below the temperature

set point the fan and pump will normally stop. But if the room humidity is below the

humidity set point, they will remain ON to add moisture to the room to satisfy the

humidity requirement. The function of the fan and pump under this condition is shown in

Fig. 22.

The external humidity and temperature sensor requires air moving freely through

the sensor housing to maintain accurate readings of the temperature and humidity. The

sensor should be periodically checked to ensure that the air inlets are not clogged up by

dust. If they are, try to clear the dust away but do open the sensor housing.

NOTE:

PLEASE ALSO REFER TO APPLICATION NOTES PAGE 2 FOR COMPLETELY

DISABLING HUMIDITY CONTROL.

not

22

PUMP

STATUS

FAN

STATUS

Room Humidity

minus Set

Humidity (%RH)

-20% or less

-10% to -20%

0% to -10%

+10% to 0%

ON

OFF OFF

ON

ON

Speed 3

Speed 2

Speed 1

PROG

7-DAY TIMER PROGRAM

1/

2/

3/

4/

5/

6/

7/

8/

In order for the cooler to run according to the global settings on any day, the day must be

programmed ON, and the start and stop times must be set to 00.00.

The cooler can be programmed to operate at specific times throughout the week.

The cooler must be in the OFF mode to be programmed. If the cooler is ON, press the button to

enter OFF mode. Hold down the button for over 3 seconds to enter PROGRAM mode.

Press the or buttons until the display shows and is flashing (Fig 23).

Press the button to select the TIMER mode. (Monday) will flash. Select the day you

want to program, using the and buttons and press .

Use the and buttons to select or and press the button (Fig 24).

If you select you can either select another day to program, or exit PROGRAM mode by

pressing the button. If you select , will show with the first digit flashing. Refer to

page 5 for instructions on how to set the time for the cooler to start operating.

Repeat this process when shows to set the time for the cooler to stop operating.

After setting the time, or will flash. Refer to page 6 for instructions on how to set the

temperature and humidity settings for the cooler operation.

Once you have set the humidity, either select another day using the , and buttons or

press the button to exit PROGRAM mode.

When the cooler is on, the display will show a rectangle around all days which have a TIMER

program (Fig 25).

On days in which no settings are programmed, the cooler may run according to the global settings

programmed into the IWC10. In order for the cooler to be run in AUTO on any day, the day must be

programmed ON.

When any day is programmed to OFF, the cooler will run in AUTO. The cooler can be run in

MANUAL at any time, regardless of the programs set.

not

AUTO

AUTO

Start:

M

AUTO

Start:

Stop:

AUTO

C

0

F

0

Start:

F

23

24

%

21

HUMIDITY CONTROL PROGRAM (continued)

:

1/

2/

3/

4/

To change the Humidity Set Point

Hold down the button for over 3 seconds to enter PROGRAM mode.

Press the or button until the symbol is flashing, then press the button. The

current humidity setting will flash as two digits on the clock (Fig 21).

Adjust the setting to the desired humidity level by pressing or holding down the and

buttons. Press the button to accept the humidity setting.

Press the button to return to the OFF state.

AUTO

AUTO

PROG

F

Auto

25

DRAIN SIGNAL DELAY PROGRAM

The cooler will periodically drain itself of water in order to ensure clean operating conditions.

When it does, it sends a signal allowing a scavenger pump or other control to begin operating

(terminal J7-4). The drain delay feature allows time for the drained water to travel from the cooler

to the scavenger pump before the scavenger pump begins to operate.

To set a delayed drain mode, enter the PROGRAM mode and press the or button until

flashes on the clock display (Fig 26).

Press the button to confirm.The current time delay will flash as four digits on the clock.

Adjust the time delay using the and buttons up to a maximum of ten minutes. Press the

button to lock the time delay and return the cooler to the OFF mode. Disconnect and

reconnect the power for this change to take effect.

AUTO

AUTO

18

Programming Wall Control

LOW BATTERY WARNING

The "Battery Low" message will appear on the Wall Control screen when power resumes

after a very long power OFF period in which the battery voltage has fallen below a functional

level. (Fig. 29). In this event, Then start the plant. The plant will not re-start

until the clock has been reset. It may not be necessary to change the batteries at this time.

Should the "Battery Low" message appear repeatedly after short duration power failures, then

replace the battery.

first reset the clock.

The battery:

IT IS NOT A POWER FAILURE BACK-UP

BATTERY AND IS NOT ON TRICKLE CHARGE.

The lithium battery in the Wall Control is a long life device that powers the real-time

clock only, during prolonged power "Off" periods.

Under normal conditions the battery should

have a life of about 10 years.

EXTERNAL CONTROL

Some of the functions of the Wall Control can be controlled by an external device, such as a PLC

or Building Management System. In this case will show on the display (Fig 27). In

EXTERNAL mode, all temperature and timer settings will be ignored. Humidity settings will be

ignored unless the external system enables humidity control. External systems may also control

the fan speed of the cooler. The bar chart on the Wall Control will show the equivalent speed

setting.

External systems may remotely switch the cooler OFF. If the cooler is in the Safety Off mode,

then, the symbol will be displayed (Fig 28). When the symbol is displayed, the IWC will

not respond to any other control input.

SAFETY OFF

EXTERNAL

R

EXTERNAL

26

27

28

29

7-DAY TIMER PROGRAM (continued)

Any day that has start and stop times set and the day switched ON will show brackets for the

day. Any day that has start and stop times set and the day switched OFF will show no brackets.

Any day that has start and stop times set to 00.00 will show no brackets.

These programs will be ignored if the cooler is in MANUAL or EXTERNAL mode during the

programmed times. This feature allows different settings for every day - start/stop, temperature &

humidity.

REMOTE ON/OFF

This input is used to turn the cooling system ON or OFF from a remote location.

The input must be in the form of a momentary pulse (provided by the installer) for both ON and

OFF functions. Any repeated pulses received within 2 seconds of the first pulse will be ignored.

When a pulse is received during cooling system operation (whether AUTO or MANUAL) the

control will save the current state of the system and the system will enter a stand-by state and

shut down.

When the next pulse is received at Input 8, the cooling system will start up again in the same

mode in which it was last shut down.

In the event that the cooling system is re-started manually during the standby state, the next

pulse received at input 8 will shut down the system into standby mode.

SERVICE MODE - SINGLE COOLER INSTALLATION

SERVICE

SERVICE

SERVICE

When a fault has been recognised by the Wall Control the word appears on the screen

(Fig 30). When is displayed it may be necessary for you to phone your Service Agent.

However, before doing so, turn the Wall Control OFF. You will notice a number flashing at the

bottom of the screen (Fig 31). This number indicates the cause of the fault. See “Service Guide

CMPD” for fault codes.

Please write this number down, then push the button to turn the cooler back on. If after a short

time is again shown on the display, turn the Wall Control OFF and check if the flashing

number is the same. If so check the following possible problems. However, we do suggest that any

checks be carried out by an authorised dealer or service agent.

Check that the water supply tap to the cooler is turned on.

Check that your local water supply is on.

If your cooler is fitted with a drain valve, check that the drain is not blocked.

Check to ensure that the temperature and humidity sensor is plugged in.

Check the interconnecting cable for faults.

If the problem continues contact your Dealer or Service Agent. You will need to quote the flashing

number that you wrote down.

If ‘02’ is displayed

If ‘04’ is displayed

If ‘09’ is displayed

19

Programming Wall Control

SERVICE MODE - MULTIPLE COOLER INSTALLATION

This section ONLY applies to any new installations commissioned since January 2006, in

which IWC05’s (part no. 111087) and Smart-Hubs (part no. 111070) are installed. Installations

prior to that date do NOT have any fault indicating features when multiple Breezair coolers

are connected to original hubs.

Identification labels “IWC05” and “Smart-Hub” are attached to the new devices.

SERVICE

!

When a fault occurs in any cooler, the word appears on the Wall Control display (Fig.

32). The system will continue normal operation.

In cases where Smart-Hub kits are installed (and only in such cases) the fault location can be

viewed by either pressing the button or switching the wall control OFF (Fig. 33). The fault

location display shows the Hub number (0 - 9) and the cooler number (1 - 5) on that hub.

If more than one fault exists, pressing the or buttons shows other fault locations.

Fault codes that identify the nature of the fault will not be shown; however the nature of the

fault can be found at the faulty cooler(s) on their CPMD Electronic Module(s).

Note

DRAIN MODE

Pressing the and buttons at the same time will open the drain valve and empty the water

in the tank. The Wall Control will display on the screen. Draining the water will leave the tank

clean and dry until it is next used. The drain valve will remain open until the cooler is re-started.

POWER FAILURES

Momentary power failures (less than 1

second) may restart automatically when power is restored.

Any power failure of any duration will shut down the air cooling system and will require manual re-

start. Power failure means a complete loss of mains power to the air cooling system. It may be

caused by external factors over which you have no control, or it may be caused during the

commissioning procedure by the deliberate action of the technician.

Whatever caused the power failure, and whatever mode the cooling system is set to (MANUAL or

AUTO), the system will require manual restarting.

EXTERNAL control mode will

resume automatically after power has been restored if the external commands are present. The

lithium battery will maintain the clock during prolonged power OFF periods.

REFER TO COOLER MANUAL FOR TROUBLE SHOOTING GUIDE.

PROG

SERVICE

SERVICE

F

Auto

SERVICE

SERVICE

Man

33

32

31

30

1

Exploded View of the Wall Control

10

34

ILL1342-B

8

No. Description Seeley Part no.

1

2

3

4

5

6

7

PCBB Terminal

Ribbon Cable ASM

PCBA Control

LCD Assembly

Plate Facia

Window Facia Screen

Decal Facia

670164

833941

670157

841328

822327

859029

841311

8Battery +3V CR 2032

(stamped on battery)

(replacements not

supplied by Seeley)

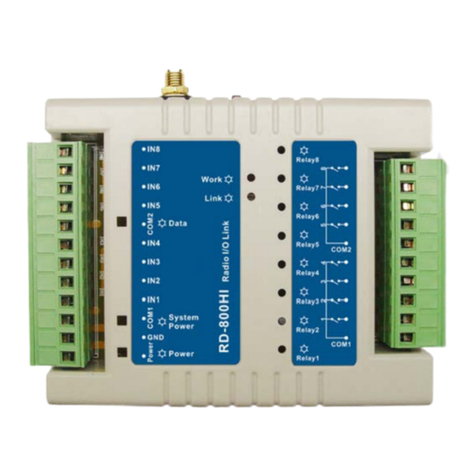

60m.

CPMD

HUB 1

HUB 2

SENSOR

Industrial Wall

Industrial Wall

Control

Control SENSOR

CPMD

CPMD

CPMD

20m.Any length

OK up to combined

length of 140m from

IWC to CPMD.

Any length

OK up to combined

length of 200m from

IWC to CPMD.

60m.

CPMD

CPMD

CPMD

CPMD

CPMD

max 40m !

max 40m !

max 40m !

max 40m !

max 40m ! max 40m !

max 40m !

max 120m !

max 120m !

max 140m !

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Coolers are supplied with 20m data cable in

accessories kit

Hubs are supplied with 20m data cable in kit.

Industrial Wall Controls (IWC) are supplied with 20m

Sensor cable in kit

60m Sensor cable on reel available

20m data cable in re-sealable bag available

40m data cable on reel available

60m data cable on reel available

80m data cable on reel available

100m data cable on reel available

4-way in-line joiners available to extend data cable to

maximum lengths shown on diagram

Data cables may be shortened or lengthened (to

maximums shown), using ONLY correct RJ

connectors and crimping tools

Cables supplied by Breezair are 26AWG, 7/016, 4

core & 6 core flat

ALWAYS route cables at least 300mm away from

regular power cables and high power machines.

Cross over power cables at right angles.

Where maximum data cable and sensor cable lengths

are exceeded, or cables are not routed in accordance

with our recommendations Seeley technical support is

not available and the product warranty may be voided.

Breezair Control System

Cable Lengths

Industrial Wall Control

824130-A 0703

MASTER

MASTER

MASTER

SLAVE 1

SLAVE 1 SLAVE 2

SLAVE 3

SLAVE 3

SLAVE 2

Any length

OK up to combined

length of 200m from

IWC to CPMD.

828527-J AU 1011

ILL1331-A

S

E

E

L

E

Y

S

E

R

V

I

C

E

Evaporative Cooling Control Manual. Seeley International Pty Ltd, Adelaide, South Australia. ACN 054 687 035.

As the policy of the company is one of continuous product improvement, all specifications are subject to change without notice.

Table of contents

Other Breezair Controllers manuals

Popular Controllers manuals by other brands

Duff-Norton

Duff-Norton TracMaster 6415 Series manual

YASKAWA

YASKAWA MP2000 Series troubleshooting manual

Alpha Group

Alpha Group OutBack Power FLEXmax Series owner's manual

Delta Electronics

Delta Electronics Programmable Logic Controller DVP-EH2-L instruction sheet

Cypress

Cypress F2MC-8FX Series Setup guide

Bollfilter

Bollfilter 2200 Operating and installation instructions