BREMA Maidaid M155-65 Operating instructions

241635 rev. 00 •It is strictly forbidden to reproduce this instruction manual or any part thereof.

M22-5 to M155-65

User & Installation Instructions

automatic

ice-cube

maker

E

EN

N

Directive:

2014/35/EU

Low Voltage Directive

2006/42/CE

Machinery Directive

2014/30/EU

Electro agnetic Co patibility Direct

ive

2011/65/UE Restriction of the use of certain hazardous substances in electrical and electronic

equip ent

Standard:

EN 60335

-

1

Household and si ilar electrical appliances

-

Safety

-

Part 1: General require ents

EN 60335-2-75 Household and si ilar electrical appliances - Safety - Part 2-75: Particular

require ents for co ercial dispensing appliances and vending achines

EN 62233 Measure ent ethods for electro agnetic fields of household appliances and

si ilar apparatus with regard to hu an expos

ure

EN 12100 Safety of achinery - Basic concepts, general principles for design - Part 1: Basic

ter inology, ethodology

EN 55014-1 Electro agnetic co patibility: require ents for household appliances, electric tools

and si ilar apparatus. E ission

EN 55014-2 Electro agnetic co patibility: require ents for household appliances, electric tools

and si ilar apparatus. I unity

–

product

fa ily standard

EN 61000-3-2 Electro agnetic co patibility. Li its. Li its for har onic current e issions

(equip ent wit

h input current up to and including

16A per phase)

EN 61000-3-3 Electro agnetic co patibility. Li its. Li itation of voltage changes, voltage

fluctuations and flicker in public low-voltage supply

syste s, for equip ent with rated current ≤ 16A per phase and not subjected to

conditional connection

EN 50581 Technical docu entation for the assess ent of electrical and electronic products

with respect to the restriction of hazardous substances

Regulations and technical specifications:

D.M. 21/3/73 Regulations covering hygiene of packaging, recipients, tools and equip ent,

designed to co e into contact with foodstuffs and substances for personal use

CE 1935/2004

Materials and articles intended to co e into contact with food

CE 2023/2006 Good anufacturing practice for aterials and articles intended to co e into contact

with food

Original copy and

infor ation folder available at

Legal Representative of the Manufacturer / Authorized Representative

EC DECLARATION OF CONFORMITY

The above- entioned apparatus is designed for the production of ice. We the undersigned declare under our own

exclusive responsibility that the ice aker referred to in this declaration is in full co pliance with the require ents of the

following European Directives, standard, regulations, technical specifications and subsequent odifications.

Dear Custo er, Congratulations on having chosen a quality product which will certainly fully eet your expectations. Thank you for having

purchased one of our products. Please read this instruction manual carefully before usin your new auto atic ice-cube aker.

TABLE OF CONTENTS

1 IMPORTANT ADVICE AND RECOMMENDATIONS

2 TECHNICAL SPECIFICATIONS

3 ADVICE ABOUT TRANSPORTATION

4 UNPACKING

5 INSTALLATION

5.1 CONNECTION DIAGRAM

5.2 POSITIONING

5.2.a POSITIONING FOR FLUSH-MOUNTING MODELS

5.3 CONNECTION TO WATER MAINS

5.3.a WATER SUPPLY

5.3.b DRAIN

5.4 CONNECTION TO THE ELECTRICITY MAINS

6 START-UP

6.1 CLEANING INTERNAL PARTS

6.2 START-UP

6.2.a STARTING-UP MODELS WITH CONTINUOUS DELIVERY

6.3 CLEANING THE STEEL PARTS

7 MAIN CAUSES OF OPERATING FAILURE

8 OPERATION

8.1 MODEL WITH CONTINUOUS DELIVERY

8.1.a ADJUSTING DISPENSED QUANTITY

8.2 MODEL WITH COLD WATER DISPENSER

9 MAINTENANCE

9.1 CLEANING THE FILTER OF WATER SUPPLY SOLENOID VALVE

9.2 AIR-COOLED MODELS

9.3 CLEANING AND SANITIZING OPERATIONS

10 AUTOMATIC CLEANING (OPTIONAL FUNCTION)

11 AUTOMATIC SANITIZING (OPTIONAL FUNCTION)

11.1 NOTE FOR ICE MAKER WITH CONTINUOUS DELIVERY

11.2 NOTE FOR ICE MAKER WITH ABS FINISHING

11.3 NOTE FOR ICE MAKER WITH DAILY PRODUCTION OF 21 kg

11.4 NOTE FOR ICE MAKER WITH COLD WATER DISPENSER

11.5 NOTE FOR ICE MAKER WITH VERTICAL EVAPORATOR SYSTEM

12 ELECTRONIC TIMER (OPTIONAL FUNCTION)

12.1 START

12.2 OPERATION

E

EN

N

13 NOTES FOR CLEANING OF PRODUCT WITH ELECTRONIC TIMER (OPTIONAL FUNCTION)

13.1 CLEANING

13.2 SANITIZING

14 PERIODS AT A STANDSTILL

The figures in this manual are of a general nature. Some details may therefore differ depending on the specific model.

The Manufacturer declines all liability for any inaccuracies in this manual due to printing or transcription errors. The Manufacturer also

reserves the right to make any modifications to the products that may be necessary or useful, also in the interests of the user, without

impairing the products’ essential features of functionality and safety.

1 IMPORTANT ADVICE AND RECOMMENDATIONS

Before installin and usin the appliance, read the advice and

recommendations contained in this instruction manual very

carefully. They are iven in order to ensure safe installation, use

and maintenance of the appliance.

Before to start, ake sure that the appliance is intact. If in doubt, do

not use it and contact the authorized technical assistance center.

The ice aker can only be put into operation if the installation has

been carried out in co pliance with local laws and regulations and

according to the instructions in this anual.

It is absolutely forbidden for the user to access the appliance's

cooling circuit, in case of necessity, call the authorized assistance.

WARNING: Do not use echanical devices such as

screwdrivers, sharp tools or other eans to speed up the defrosting

process.

WARNING: Keep the vents in the appliance casing or flush-

ounting fra e clear fro obstructions.

WARNING: Do not da age the refrigerant circuit.

WARNING: Do not use electrical apparatus in the ice

co part ents

WARNING: Do not keep explosive substances in the apparatus

co part ent, such as aerosol spray cans with fla able propellant

In the event of da age to the refrigerant circuit: switch off the

achine i ediately, disconnect it fro the power supply, ventilate

the environ ent, call authorized service.

This instruction manual forms an inte ral part of the automatic

ice-cube maker (also more simply called “appliance” in the text)

and must be kept for possible future consultation.

The user ust keep this docu entation intact to allow it to be

consulted throughout the useful life of the appliance.

Keep this anual safe and ensure that it is available for consultation

near the appliance.

If lost or destroyed ask for another copy fro the distributor,

indicating the serial nu ber and odel of the appliance.

The anual describes the state of the art at the ti e of supply of the

appliance, the distributor reserves the right to odify its appliances

when dee ed useful at any ti e, without having to update this

docu ent or docu ent relating to previous production batches.

The technical staff in charge of the activities perfor ed on the

appliance are responsible for the application of the safety

require ents laid down in this anual, and shall ensure that the

authorised staff:

-are qualified to perfor the required activities

-know and co ply with the instructions laid down in this

docu ent

E

EN

N

-know and apply the national safety require ents applicable to

this appliance

In the event of the appliance being sold or transferred to another

person, this anual ust be handed over to the new user, in order to

enable hi to beco e fa iliar with the operation of the equip ent

and the corresponding advice and reco endations.

•No use fla es and source of ignition and co bustion

•always re ove the plug fro the power socket before proceeding

with any cleaning or aintenance operations

•to ensure the appliance operates efficiently and correctly, it is

essential to co ply with the Manufacturer’s instructions and to

ake sure that aintenance is perfor ed by specially qualified

personnel

•do not re ove any of the panels or grilles

•do not rest objects on the appliance or in front of the ventilation

grilles

•always lift the appliance to ove it, even slightly. Do not push or

pull it

•any use of the appliance other than for the production of ice using

cold drinking water is to be considered as i proper use

•do not obstruct the ventilation and heat-dissipation grilles, since

poor aeration - in addition to reducing efficiency and causing poor

operation - ay also cause serious da age to the appliance

•if the appliance breaks down and/or operates in a faulty way, switch

it off by eans of the ain switch fitted during the installation

phase, re ove the plug fro the socket (if any), and turn off the

water tap. Do not ake any atte pt to repair the appliance

yourself. Contact only professionally qualified and authorized

personnel

•in addition to rendering any for of warranty null and void,

odifying (or atte pting to odify) this appliance is extre ely

dangerous

•open and close the door carefully without sla ing it

•do not use the ice container to cool or preserve food or drinks, as

these operations could cause the drain syste to beco e clogged,

thus leading to the container filling up and water leaking out

•in the event of a failure, contact the dealer who sold you the

appliance; he will be able to give you the address of your nearest

Authorized Technical Service Centre. Always insist on having

original spare parts ounted

•any specific infor ation or diagra s regarding particular odels

will be attached to this anual

Use of this electrical appliance requires co pliance with certain

funda ental rules; in particular:

• do not touch the appliance with wet or da p hands or feet

• do not use the appliance when you are barefoot

• do not use extensions in pre ises such as bathroo s or shower

roo s

• do not tug on the power supply cable to disconnect it fro the ains

• this appliance can be used by children aged fro 8 years and above

and persons with reduced physical, sensory or ental capabilities or

lack of experience and knowledge, if they have been given

supervision or instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children shall not play

with the appliance. Cleaning and user aintenance shall not be

ade by children without supervision

• supervise children to ensure that they do not play with the appliance

E

EN

N

Should you decide to scrap appliance, first disconnect the power

cable fro the ains, and then cut the cable off.

In addition, proceed as follows:

• break off and re ove the door in order to prevent the possible

danger of a child getting trapped inside

• do not allow the coolant gas and oil in the co pressor to disperse

into the environ ent

• dispose of or recover the various aterials according to the

provisions established by the current laws in force in your Country

This sy bol eans that this product should not be treated as a household waste. To prevent potential negative consequences for

the environ ent and health, be sure this product is correctly disposed of and recycled.

For infor ation on the disposal and recycling of this product, contact your Distributor or the Waste Treat ent Service.

This appliance does not contain coolant that dama es the

ozone layer. This appliance contains fluorinated reenhouse

ases covered by the Kyoto Protocol. This product is

hermetically sealed.

The Manufacturer shall not be liable for any dama e to the

environment, animals, persons or objects caused by incorrect

installation.

2 TECHNICAL DATA (Fi . 1)

The voltage and frequency are given on the data plate on the appliance. Refer to this data plate to check co pliance.

Voltage (1), power (2), odel (3), serial No. (4), Manufacturer (5).

The weighted equivalent continuous sound level A of this appliance is less than 70 dB(A). The easure ents were ade over an entire

production cycle, at a distance of 1 fro the surface of the appliance and at a height of 1.60 fro the floor.

The wiring diagra is stuck on the front counterpanel of the appliance.

In order to gain access thereto, unplug the appliance fro the power source, loosen screws holding the front panel, and slide it away after

first opening the door.

3 ADVICE ABOUT TRANSPORTATION

The net weight and the weight including packaging of the appliance are given on the cover of this anual. Please refer to the instructions

on the packaging in order to correctly transport and lift the appliance.

To prevent the oil in the co pressor fro flowing back into the coolant circuit, always ake sure that the appliance is kept upright during

transport, storage, and handling. Follow the instructions given on the packaging.

4 UNPACKING

The appliance must be installed by authorized personnel, in compliance with the current laws in force and the Manufacturer’s

instructions.

Once you have re oved the packaging according to the instructions on the box, MAKE SURE THAT THE APPLIANCE IS IN A

PERFECTLY GOOD CONDITION. IF IN DOUBT, DO NOT USE IT AND IMMEDIATELY CONTACT THE DEALER who sold it to you.

All the packa in items (plastic ba s, cardboard, polystyrene foam, nails, etc.) must be removed and put out of the reach of

children, as they are potential sources of dan er.

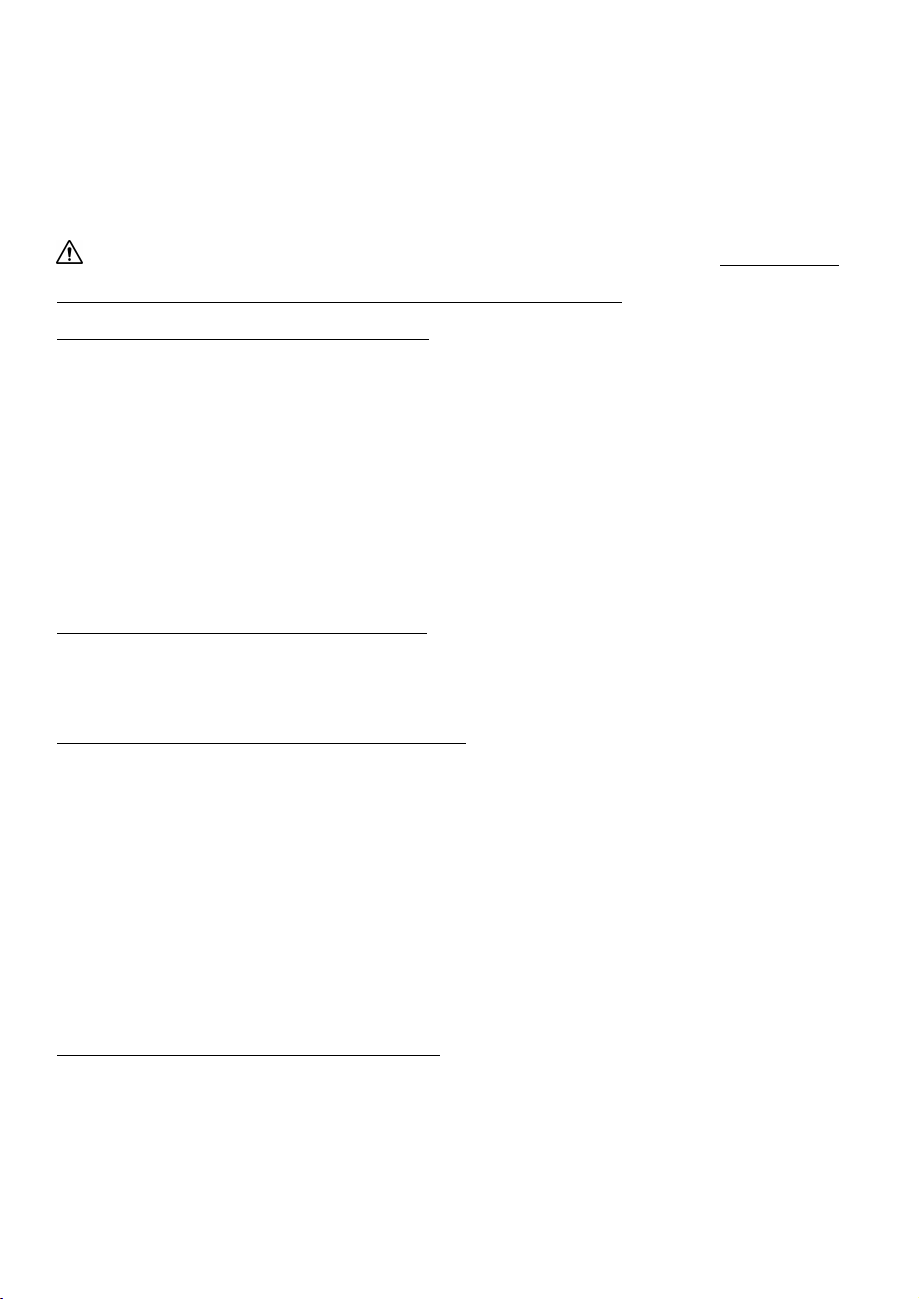

Rest the wooden pallet on the floor and, using a hex socket wrench, loosen and re ove the bolts (if any) that fix the appliance to the pallet

(Fig. 2).

Lift the appliance using equip ent fit to bear its weight. Separate the appliance fro the wooden pallet and fit the supplied legs into the

housings on the base plate provided for the purpose

(6 in Fig. 3).

Use a spirit level to ensure that the appliance is standing perfectly level. If necessary, adjust the legs.

5 INSTALLATION

5.1 CONNECTION DIAGRAM (Fi . 4)

7. electrical connection controlled by o nipolar circuit-breaker with residual current device

8. water tap

9. water supply pipe

10. water drainage pipe

5.2 POSITIONING

The appliance must be installed in a hy ienically clean location; it is advisable to avoid rooms like cellars and store-rooms,

because failure to meet hy iene requirements is likely to lead to the formation and proliferation of bacteria in the appliance.

The appliance can operate at an ambient temperature of between 10°C and 43°C.

The best performance will be obtained by installin the appliance in a place with an ambient temperature of between 10°C and

35°C and a water temperature of between 3°C and 25°C.

Avoid direct exposure to sunli ht and do not install near heat sources.

This appliance:

• must be installed in a place where it can be supervised by skilled personnel

• ust not be used outdoors

• ust not be installed in da p places or where it is liable to be sprayed with water

• ust not be cleaned with jets of water

• ust be allowed a clearance of least 5 c all around (this does not apply to the flush-mountin models)

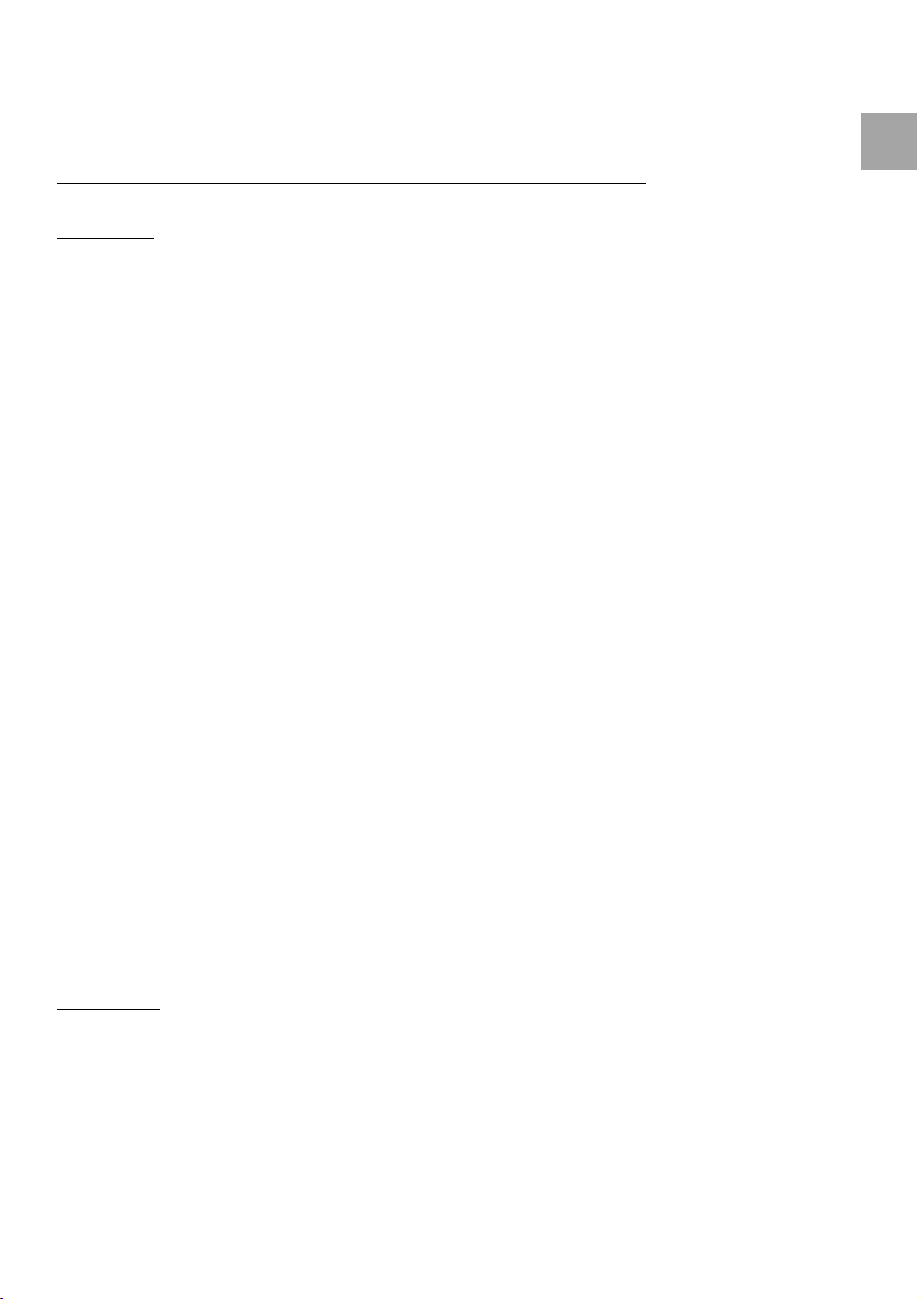

5.2.a POSITIONING FOR FLUSH-MOUNTING MODELS

Ventilation is ensured by the grille on the front panel; it is therefore not necessary to leave any gap, except to facilitate installation.

A hole ust be ade in the surface where the appliance is to be located so that the power cable, water supply pipe and the water drain

pipe can be passed through as shown in Fig. 5.

The plug and water supply and drain connections are accessible fro the front panel.

To access these, disconnect the appliance fro the power supply, unscrew the screws that hold the front panel in place and after

opening the door, pull out the panel fro above (Fig. 6).

Before fitting the appliance in place, the power cable ust be fixed to the base plate as shown in the diagra in Fig. 6:

• pass the plug and cable (11) through the hole (12) in the plate

• position the cable cla p (13) in its housing

Fit the front panel back in place after aking these connections.

5.3 CONNECTION TO THE WATER MAINS

IMPORTANT:

•the appliance ust be connected to the water ains by professionally qualified personnel in accordance with the Manufacturer’s

instructions

•this appliance ust be only be supplied with cold water for hu an consu ption (drinking water)

•the operating pressure ust be between 0.1 and 0.6 MPa

E

EN

N

•a tap ust be installed between the water ains and the feed pipe of the appliance, so that the water supply ay be shut off if

necessary

•where the feed water is particularly hard, you are advised to install a polyvalent cartridge filter. Any solid particles (e.g. sand) ay be

eli inated by installing a echanical filter, which ust be periodically inspected and cleaned. These devices ust co ply with the

standards in force in the Country of use

•Is forbidden install the machine to De-ionized or Reverse Osmosis Water

•never turn the water supply tap off when the appliance is working

•only new hose-sets supplied with the appliance are to be used to connect the appliance to water ains, old hose-sets should not be

reused

5.3.a FILLING WITH WATER (Fi . 7)

Insert the special seals provided (15) in the two threaded ring nuts (14) of the water supply pipe (9) supplied with the appliance.

Without exerting excessive force (otherwise the unions could crack), fir ly tighten one of the threaded ring nuts on the outlet of the

solenoid valve located in the rear of the appliance (front for the flush-mountin models). The other threaded ring nut ust be

screwed to the water tap (8); this too ust be provided with a thread.

5.3.b DRAIN (Fi . 7)

Fix the water drain pipe (10) in the housing provided on the rear of the appliance (front for the flush-mountin models). Make sure

that:

• the pipe is a hose

• the internal dia eter is 22 , as required

• the water drain hose is not throttled at any point throughout its length

• the drain hose slopes downwards by at least 15%

It is advisable to drain the water straight into an open drain trap.

5.4 CONNECTION TO THE ELECTRICITY MAINS

IMPORTANT:

•the appliance ust be connected to the electricity ains by professionally qualified personnel in accordance with the Manufacturer’s

instructions

•before connecting the appliance to the electricity ains, ake sure that the ains voltage rating corresponds to the value indicated on

the rating plate

•ake sure that the appliance is connected to an efficient earthing syste

•ake sure that the capacity of the power supply syste suits the axi u power value indicated on the rating plate of the appliance

•if the appliance co es supplied with a plug, prepare a socket controlled by an o nipolar circuit-breaker (7 in Fig. 4), with a contact-

opening gap of not less than 3 , that provides full disconnection under overvoltage category III conditions, in accordance with

national safety standards currently in force. This switch ust be equipped with fuses, with the associated residual current device

positioned in such a way as to be readily accessible. Insert the plug into the socket controlled by the switch (7 in Fig. 4)

•the plug ust only be replaced by professionally qualified and authorized personnel, and the new plug ust co ply with current

national safety standards

•if the appliance co es supplied without a plug and you wish to connect it per anently to the power supply, prepare an o nipolar

circuit-breaker (7 in Fig. 4), with a contact-opening gap of not less than 3 , that provides full disconnection under overvoltage

category III conditions, in accordance with national safety standards currently in force. This switch ust be equipped with fuses, with

the associated residual current device positioned in such a way as to be readily accessible. This operation must be carried out by a

specialized technician

•ake sure that you fully uncoil the power supply cable and check that it is not crushed in any way

•should the supply cable be da aged, it ust be replaced by a specialized technician using a special cable available fro the

Manufacturer or fro the Technical Service Centres

6 START-UP

6.1 CLEANING INTERNAL PARTS

The appliance will have already been cleaned in the factory. However, you are advised to wash the internal parts again before using the

appliance. Make sure that the power supply cable is unplugged before carrying out the above cleaning operation.

See cleanin and sanitizin manual for information re ardin cleanin operations.

For cleaning operations in general, use an ordinary detergent for washing dishes or a solution of water and vinegar. Rinse thoroughly with

plenty of cold water and re ove any ice that ay have been produced during the first 5 cycles after cleaning, together with any ice present

in the bin.

It is advisable to avoid using abrasive detergents or powders, since these ight da age the finish.

6.2 START-UP

When you start up the appliance the first time, or when you start it up a ain after a lon period at a standstill, fill the basin

manually with water (Fi . 8).

This filling operation ust be carried out by opening the door, raising the flaps (if any) and pouring the water directly into the internal basin.

In the cycles subsequent to the initial one, the appliance will be filled with water in a fully auto atic way.

Once the appliance has been correctly connected to the electricity ains, water ains and water drain syste , it can be started up as

follows:

a) turn on the water supply tap (8 in Fig. 4)

b) insert the plug (if any) in the socket and switch on the power supply by eans of the relative switch fitted during the installation phase

(7 in Fig. 4)

Switch on appliance by pressing the lu inous switch (16 in Fig. 3).

For appliances that are connected per anently to the electricity ains, turn on by eans of the switch on the outside of the appliance,

fitted during the installation phase.

6.2.a STARTING UP MODELS WITH CONTINUOUS DELIVERY (Fi . 9)

Carry out operations a) and b) described above; then:

• re ove the plug (17) on the front grille panel

• using a screwdriver turn the adjusting screw of the ti er clockwise until you hear a click and the water pu p stops

• repeat the previous operation three ti es consecutively at intervals of one inute each

• when this operation has ter inated, fit the plug (17) back on the front grille; the appliance will auto atically start producing ice

6.3 CLEANING THE STEEL PARTS

The appliance was cleaned initially in the factory. For subsequent cleaning operations on the steel parts of the achine, co ply with the

instructions below:

Do not allow saline solutions to dry or pool on the external steel co ponents of the achine, as this ay lead to corrosion.

Avoid contact with ferrous aterial (scourers, forks, ladles, scrapers, etc.) to prevent corrosion, conta ination fro ferrous particles

circulating in the receptacle.

Carefully clean the stainless steel parts with a da p cloth, water and soap or co on, non-abrasive chlorine or a onia based

detergents.

7 MAIN CAUSES OF OPERATING FAILURE

Should the appliance fail to produce ice, before calling on the Authorized Technical Service Centre, first check carefully that:

• the water supply tap (8 in Fig. 4), fitted during the installation phase, has been turned on

• electric power is reaching the appliance; the plug (if any) is properly inserted in the socket, the switch (7 in Fig. 4) is in the “ON” position,

and the push button (16 in Fig. 3) is lighted up

Further ore:

• if there is excessive noise, ake sure that the appliance is not touching furniture or sheet etal which can give rise to noise or vibrations

• should any trace of water appear, check the drain hole of the container to ensure that it is not clogged, that the water fill and drain pipes

are correctly connected and are not throttled or da aged

• ake sure that the te perature of the air or water does not exceed the installation li it values (see paragraph 5.2)

• ake sure that the water inlet filter is not clogged (see paragraph 9.1)

• ake sure that the spray nozzles are not clogged with scaly deposits

If the fault still persists after the above inspections have been ade, turn off the electric power source by eans of the switch fitted during

the installation phase, pull out the plug fro its socket, turn off the tap connecting the appliance to the water ains, and contact the

nearest Authorized Technical Service Centre.

To obtain a faster and ore efficient reply when you call the Centre, state the odel of the appliance precisely, together with its serial

nu ber or anufacturing nu ber. This infor ation is given on the serial N° plate (Fig. 1) affixed to the rear of the appliance and on the

cover of this anual.

8 OPERATION

The appliance has a ther ostat probe in the ice bin, which stops ice production when the ice accu ulated in the bin reaches the probe

connected to the ther ostat.

When ice is taken fro the bin, the ther ostat will auto atically reactivate ice production, thus creating a new supply of ice.

8.1 MODEL WITH CONTINUOUS DELIVERY (Fi . 10)

E

EN

N

The appliance is equipped with an ice-cube dispenser (18) on the front.

To take the required quantity of ice, place a glass or a suitable container under the dispenser and press the button (19) to turn on the

supply.

8.1.a ADJUSTING DISPENSED QUANTITY (Fi . 11)

IMPORTANT:

• the operations described below ust be perfor ed by a specialized technician, and only after disconnecting the appliance fro the

electricity ains

• all operations that require handling of parts ade of etal plate ust be carried out wearing suitable gloves to prevent cuts

The appliance is provided with an electronic device for adjusting the quantity of ice dispensed each ti e.

To increase or decrease the dispensing ti e and the proportionate quantity of ice dispensed, proceed as follows:

• re ove the basin (20)

• slacken off the screws (21) on the front panel using a Phillips screwdriver

• pull out the front panel fro above

• turn the knob (22) on the electronic device clockwise to increase the quantity of ice dispensed whenever the button is pressed, and

anti-clockwise to reduce the quantity

8.2 MODEL WITH COLD WATER DISPENSER (Fi . 12)

The appliance is provided with a cold water dispenser located beside the ice bin.

To obtain cold water, place a glass under the outlet and gently press the button (23) to turn on the water tap. Release the button to stop

the flow of cold water.

If the appliance is already provided with a filter located on the cold water supply circuit, read the instructions on the filter label carefully and

follow the anufacturer’s reco endations regarding the replace ent schedules.

9 MAINTENANCE

9.1 CLEANING THE FILTER OF WATER SUPPLY SOLENOID VALVE (Fi . 13)

All the operations described in this para raph must be carried out only after the electric power and water supplies have

been disconnected, as described previously, by professionally qualified and authorized personnel.

At least every two onths, clean the filter (24) located on the water inlet solenoid valve, proceeding as follows:

• switch off the electric power supply by eans of the switch (7 in Fig. 4), fitted during installation, and disconnect the plug of the

appliance fro its socket (if any)

• shut off the water supply by turning the tap (8 in Fig. 4) fitted during installation

• unscrew the threaded ring nut (14) of the water feed hose, located at the outlet of the solenoid valve at the rear of the appliance (front

for the flush-mountin models). For the built-in odel, first re ove the panel as indicated at point 5.2.a

• using a pair of pliers, re ove the filter (24) fro its seat without da aging the water feed pipe connector

• place the filter under a strong jet of water to re ove residue, but replace the filter if it is excessively dirty

After having carried out the cleaning operations, refit the filter and hose pipe taking the necessary precautions described earlier in the

anual.

When the operations have terminated, turn on both the electricity supply and water supply.

9.2 AIR-COOLED MODELS (Fi . 14)

For air-cooled odels, it is very i portant to keep the finned condenser and its external filter

(if any) clean.

Have the finned condenser cleaned at least once every two onths by an Authorized Technical Service Centre, which can include this

operation in the scheduled aintenance progra e.

The external filter (if any) ust be cleaned at least once a onth, as follows:

• switch off appliance and cut off power supply with the switch (7 in Fig. 4) fitted at the installation stage

• open plastic grille

• re ove filter and keep it at a distance for the appliance

• re ove dust fro filter by blowing with co pressed air

• replace filter in its seat and close plastic grille

9.3 CLEANING AND SANITIZING OPERATIONS

A cleanin and sanitizin kit specifically desi ned for this appliance is available from your dealer.

Do not use corrosive substances to remove limescale from the appliance, because this will invalidate the warranty, and may

cause serious dama e to the materials and components of the appliance.

Do not use jets of water to clean the appliance.

All cleanin operations must be carried out only after the electric power and water supplies have been disconnected, as

described previously, by professionally qualified and authorized personnel.

Follow the instructions iven in the cleanin and sanitizin manual supplied with the appliance.

IMPORTANT:

All the ice produced durin the first 5 cycles after cleanin and sanitizin operations, and any ice already in the container, must

be eliminated.

Co plete sanitizing can only be carried out only by the Authorized Technical Service Centres, and ust be done regularly depending on

the conditions of use of the appliance, the che ical and physical features of the water, and after every period in which the appliance has

re ained at a standstill for any length of ti e.

You are advised to ask your dealer to draw up a scheduled aintenance contract that will cover the following:

• cleaning the condenser

• cleaning the filter located on the water supply solenoid valve

• cleaning the ice container

• checking the charge of coolant gas

• checking the operating cycle

• sanitizing the appliance

10 AUTOMATIC CLEANING (OPTIONAL FUNCTION)

The frequency of cleaning and sanitizing operations can vary, depending on:

• te perature and environ ental conditions

• te perature and quality of water (hardness, presence of grit, etc.)

• quantity of ice produced, or ti e of use of ice-cube aker

• periods of non-use of ice-cube aker

TO ENSURE CORRECT CLEANING AND SANITIZING OF THE ICE-CUBE MAKER, PERFORM THE OPERATIONS DESCRIBED IN

THIS MANUAL AT LEAST ONCE A MONTH.

IMPORTANT:

• the operations described in this anual ust only be perfor ed by skilled, authorised personnel

• the appliance ust be installed in a hygienically clean location; avoid pre ises such as cellars and storeroo s, because poor hygiene

pro otes the for ation and proliferation of bacteria in the ice-cube aker

• a cleaning and sanitizing kit specifically designed for this appliance is available fro your dealer

• do not use corrosive substances to re ove li estone fro the appliance, because this will invalidate the guarantee, and ay cause

serious da age to the aterials and co ponents of the appliance

• gloves suitable to protect against cuts ust be worn when perfor ing all operations involving handling of sheet etal parts in particular

• Gloves suitable to protect the skin against the substances used ust be worn when perfor ing all cleaning and sanitizing operations

• wear suitable goggles during cleaning and sanitizing operations to protect the eyes against splashes of the substances used

• take care not to spill water or solutions on the wiring or the power cable

1. wait for ice cubes to drop, switch off appliance, disconnect fro the electricity ains supply and open door

2. re ove all ice fro container

3. re ove flag support asse bly (1 in Fig. 15) and ice-cube slide (2 in Fig 2. 15) and extract overflow pipe (3 in Fig 2. 15) to drain water

present in basin

4. reposition overflow pipe and fill basin with a 25% solution of water and white vinegar. Refer to the table for the a ount of solution

required, depending on daily output (Fig. 16)

5. reposition ice-cube slide and flag support asse bly

6. close door and operate appliance for five one- inute periods, with a five- inute interval between each

IMPORTANT: The pump must be in operation durin cleanin cycles (check that water is sprayed). If it is not, immediately

adjust the timer re ulation screw by turnin it clockwise until the indicator on the pin exits from the zone marked DEFROST.

To reach ti er, loosen screws in front panel with a Phillips screwdriver, re ove front panel by pulling it upwards, and regulate ti er with a

flat-head screwdriver (Fig. 17).

7. switch off achine and disconnect it fro electricity ains and water supply

E

EN

N

8. re ove top of appliance by lifting rear part and releasing it fro front hooks (Fig. 18). NOTE: on so e odels the top is secured to

the rear panel of the appliance with a screw, which ust be re oved before lifting the top and repositioned when cleaning and

sanitizing operations are finished

9. re ove evaporator cover panel (Fig. 19) and clean top part of evaporator, bin, evaporator cover panel and door with water and

vinegar solution

10. re ove any sedi ent fro evaporator and evaporator cover panel using a brush with soft bristles and a non-abrasive sponge

11. pour plenty of cold water onto the evaporator and with the aid of the brush, direct the sedi ent re oved into the basin beneath, taking

care not to obstruct the holes in the base of the evaporator.

During cleaning of evaporator, take care:

• not to bend coils

• not to detach water supply pipes

• not to re ove evaporator ther ostat

12. re ove (Fig. 15) and clean with ordinary washing-up liquid:

• flag support asse bly (1)

• ice-cube slide (2)

• overflow pipe (3)

• sprayer bank (4), taking care to re ove side caps (5)

• sprayer bank feed pipe (6)

• pu p filter (7)

13. clean with the sa e washing-up liquid:

• evaporator cover panel

• inner basin

• bin

• door

14. thoroughly rinse previously cleaned parts with cold water

15. rinse and refit (Fig. 15):

• pu p filter (7)

• sprayer bank feed pipe (6)

• sprayer bank (4), after repositioning side caps (5)

• overflow pipe (3)

• evaporator cover panel (Fig. 5)

16. prepare to perfor the sanitizing operations described in the next chapter

11 SANITIZING

Use a 200 g/l solution of sodiu hypochlorite and water (or a solution of ½ ounce of nor al bleach to 1 gallon of water) or one of the

solutions co only used to disinfect babies’ feeding bottles; in this case, check that the sanitizing product is:

• authorized by your country’s Ministry of Health

• suitable for use with food achines

• not har ful to the aterials and co ponents of this appliance

For the directions for use and concentrations, please refer to those shown on the packaging and reco ended by the anufacturer. We

reco end using the solution at the te perature of 25°C.

1. fill basin with sanitizing solution. Refer to the table for the a ount of solution required, depending on daily production (Fig. 2)

2. refit ice-cube slide (2 in Fig. 1) and flag support asse bly (1 in Fig. 15)

Before connectin the appliance to the mains electricity supply, ensure that all cables and electrical wirin are perfectly

dry.

3. operate ice aker for five one- inute periods, with a five- inute break between the

IMPORTANT: The pump must be in operation durin sanitizin cycles (check that water is sprayed). If it is not, immediately

adjust timer re ulation screw by turnin it clockwise until the indicator on the pin exits from the zone marked DEFROST.

To reach ti er, loosen screws in front panel with a Phillips screwdriver, re ove front panel by pulling it upwards, and regulate ti er with a

flat-head screwdriver (Fig. 17).

4. switch off achine and disconnect it fro the ains electricity and water supply

5. re ove evaporator cover panel (Fig. 19)

6. pour sanitizing solution onto top part of evaporator, distribute with a brush, and rinse thoroughly with cold water

7. re ove (Fig. 1) and i erse in sanitizing solution for 30 inutes:

• flag support asse bly (1)

• ice-cube slide (2)

• overflow pipe (3)

• sprayer bank (4) and side caps (5), after re oving the fro the bank

• sprayer bank feed pipe (6)

• pu p filter (7)

• evaporator cover panel (Fig. 19)

8. wipe container walls and door with sanitizing solution using a sponge and brush

9. drain sanitizing solution re aining in pu p body by introducing pressurised water into the suction pipe and checking that the water

exits fro the delivery pipe (Fig. 20)

10. thoroughly rinse inner basin, door and container with cold water

11. thoroughly rinse ice-cube slide, evaporator cover panel, sprayer bank and the corresponding side caps, flag support asse bly,

overflow pipe, pu p filter and sprayer bank feed pipe under running water

12. refit parts previously re oved

13. reposition top, securing it to rear panel with the screw, if present

The ice-cube aker can now be reactivated as specified in the instruction anual.

IMPORTANT: All the ice produced durin the first five cycles after cleanin and sanitizin operations must be discarded.

THE FOLLOWING ADDITIONAL OPERATIONS ARE REQUIRED FOR SOME SPECIAL MODELS:

11.1 NOTE FOR ICE MAKER WITH CONTINUOUS DELIVERY

To access the inner parts, re ove top of appliance (Fig. 18), then re ove front upper panel as shown in Fig. 21.

In addition to the operations described in chapters 10 and 11, the following steps ust be taken when cleaning and sanitizing the ice

collecting bin (Fig. 21):

1. tilt appliance towards the front by positioning a shi at least 4 c thick under the back legs

2. position a basin under the ice-cube dispenser pipe (8)

3. raise outlet pipe until it is higher than the appliance

4. pour water and vinegar solution onto ice-cube conveyor screw until solution exits fro ice-cube dispenser pipe (8)

5. leave solution in bin for at least 30 inutes, then drain solution and return outlet pipe to its original position

6. wipe ice-cube collection bin walls and conveyor screw with a water and vinegar solution using a sponge and brush; avoid rotations

which could da age the drive otor

7. repeat operations 3 to 6 using the sanitizing solution

8. thoroughly rinse walls of ice collection bin with cold water

9. rinse ice-cube conveyor screw and botto of bin with cold water, allowing it to flow along the ice dispenser pipe (8)

10. drain water re aining on botto of bin and return outlet pipe to its original position

11.2 NOTE FOR ICE MAKER WITH ABS FINISHING (Fi . 23)

To access inner basin, evaporator and ti er regulation screw:

• re ove screw cover

• re ove screws with a Phillips screwdriver

• open front door and re ove ABS shell

11.3 NOTE FOR ICE MAKER WITH DAILY PRODUCTION OF 21 k

Perfor cleaning and sanitizing operations as described in chapters 10 and 11.

To reach pu p filter (Fig. 24):

• re ove flag support asse bly (1) and ice-cube slide (2) and extract overflow pipe (3) to drain water present in the basin

• disconnect pu p connection pipes (10) and sprayer bank (11)

• unscrew the filter threaded ring nut (9)

To access pu p side of inner basin:

• re ove rear panel by loosening fixing screws and extracting it upwards (Fig. 25)

• re ove pu p connector pipe (10 in Fig. 24)

• release pu p wiring (12 in Fig. 26) and re ove pu p asse bly located on right-hand side of evaporator by lifting it out of its seating,

taking care not to da age the wiring (Fig. 26)

• wipe pu p container walls with a water and vinegar solution and sanitizing solution using a sponge; take care not to wet the electrical

parts

• at the end of cleaning and sanitizing operations on the basin, refit pu p, taking care to connect sprayer bank connector pipe (10 in Fig.

24) and pu p connector pipe (11 in Fig. 24) correctly and to re-secure pu p wiring

(12 in Fig. 26)

11.4 NOTE FOR ICE MAKER WITH COLD WATER DISPENSER

Perfor cleaning and sanitizing operations as described in chapters 10 and 11, also re oving the following co ponents for cleaning and

sanitizing operations (Fig. 27):

• water cooling coil (13)

• coil cover grille (14)

Thoroughly rinse inside of cooling coil by circulating pressurised cold water through it.

Clean and sanitize cold-water dispenser area.

To access ti er regulation screw in odels with a 21 kg/24h output (Fig. 28):

• re ove screw connecting top to rear panel

• raise rear part of top and release it fro front hooks

• regulate ti er with a flat-head screwdriver

E

EN

N

To access pu p filter and pu p side of inner basin, see chapter 6.

11.5 NOTE FOR ICE MAKER WITH VERTICAL EVAPORATOR SYSTEM

Perfor cleaning and sanitizing operations as described in chapters 10 and 11, in accordance with the following instructions:

• to re ove evaporator cover (15) and ice-cube slide (2) and extract overflow pipe (3), see Fig. 29

• to re ove sprayer bank (4) and the corresponding side caps (5), see Fig. 30

• to clean and sanitize pu p filter (7), see Fig. 30

• clean front and back of evaporator using a brush with soft bristles

• clean and sanitize tilting panel (16) shown in Fig. 30

12 ELECTRONIC TIMER (OPTIONAL FUNCTION)

12.1 START

Once the appliance has been correctly connected to the electricity ains, water ains and water drain syste , it can be started up as

follows:

a) turn on the water supply tap (8 in Fig. 4)

b) insert the plug (if any) in the socket and switch on the power supply by eans of the relative switch fitted during the installation phase

(7 in Fig. 4)

Switch on appliance by pressing the lu inous switch (1).

For appliances that are connected per anently to the electricity ains, turn on by eans of the switch on the outside of the appliance,

fitted during the installation phase.

12.2 OPERATION

The appliance has a ther ostat probe in the ice bin, which stops ice production when the ice accu ulated in the bin reaches the probe

connected to the ther ostat.

When ice is taken fro the bin, the ther ostat will auto atically reactivate ice production, thus creating a new supply of ice.

FUNCTIONS

D

W

DEFR.

WASH

ON/OFF PUSH BUTTON: used to turn on and turn off the appliance - GREEN LED

DEFR. PUSH BUTTON: allows to start the defrost cycle - YELLOW LED

WASH PUSH BUTTON: allows to start and/or finish the washing cycle - BLUE LED.

FUNCTIONS

Pressing the ON/OFF push button, at the appliance’s start-up, the green LED start to flash for 3 inutes,

during this ti e the water is charged in the appliance’s basin.

After the 3 inutes have elapsed, the appliance starts a defrost cycle: green LED and yellow LED are lit.

Once the defrost is over, the appliance starts the ice production: green LED is lit.

It is possible to start at any ti e the defrost cycle pressing the DEFR. push button, the yellow LED is lit.

This operation ust be perfor ed by professional and qualified technical person.

Pressing the WASH push button, the appliance starts the washing cycle: the blue LED starts to flash.

ATTENTION:

To Push “W” (washin ) use only a plastic tool with rounded toe applyin a sli ht pressure. (fi . 3).

Please not use a screw or similar tools.

The washing cycle is ade by the following phases:

•defrost (yellow LED lit + green LED lit + blue LED flashing)

•30 inutes when only the water pu p is operating (green LED lit + blue LED flashing);

•60 inutes when the water inlet valve and water pu p are operating (green LED lit + blue LED flashing)

GREEN LED

YELLOW

LED

BLU

E LED

ON/OFF PUSH

BUTTON

DEFR. PUSH

BUTTON

WASH PUSH

BUTTON

D

W

DEFR.

D

W

WASH

E

EN

N

Once the washing cycle is over, the appliance resu es its operation at the sa e point it was when the WASH

push button was pressed.

It is possible to exit at any ti e the washing cycle by pressing the WASH or the DEFR. push button.

13 NOTES FOR CLEANING OF PRODUCT WITH ELECTRONIC TIMER (OPTIONAL FUNCTION)

To carry out the cleaning and the sanitizing operations, follow the directions below:

13.1 CLEANING

1. wait for ice cubes to drop and re ove all ice fro container

2. re ove flag support asse bly (1 in Fig. 15) and ice-cube slide (2 in Fig 2. 15) and extract overflow pipe (3 in Fig. 15) to drain water

present in basin

3. reposition overflow pipe and fill basin with a 25% solution of water and white vinegar. Refer to the table for the a ount of solution

required, depending on daily output (Fig. 16)

4. reposition ice-cube slide and flag support asse bly

5. with plastic tool, push the “W” button (wash position) through dedicated hole below “ON/OFF” button. (Fig 17)

The blue LED starts to flash. The appliance will carry out a co plete washing and rinsing cycle

6. Once the washing cycle is over, re ove flag support asse bly (1 in Fig. 15) and ice-cube slide (2 in Fig 15) and extract overflow pipe

(3 in Fig 2. 15) to drain water present in basin

7. switch off achine and disconnect it fro electricity ains and water supply

8. re ove evaporator cover panel (Fig. 19) and clean top part of evaporator, bin, evaporator cover panel and door with water and

vinegar solution

9. re ove any sedi ent fro evaporator and evaporator cover panel using a brush with soft bristles and a non-abrasive sponge

10. pour plenty of cold water onto the evaporator and with the aid of the brush, direct the sedi ent re oved into the basin beneath, taking

care not to obstruct the holes in the base of the evaporator.

During cleaning of evaporator, take care:

• not to bend coils

• not to detach water supply pipes

• not to re ove evaporator ther ostat

11. re ove (Fig. 15) and clean with ordinary washing-up liquid:

• flag support asse bly (1)

• ice-cube slide (2)

• overflow pipe (3)

• sprayer bank (4), taking care to re ove side caps (5)

• sprayer bank feed pipe (6)

• pu p filter (7)

12. clean with the sa e washing-up liquid:

• evaporator cover panel

• inner basin

• bin

• door

13. thoroughly rinse previously cleaned parts with cold water

14. rinse and refit (Fig. 15):

• pu p filter (7)

• sprayer bank feed pipe (6)

• sprayer bank (4), after repositioning side caps (5)

• overflow pipe (3)

• evaporator cover panel (Fig. 19)

15. prepare to perfor the sanitizing operations described in the next chapter

13.2 SANITIZING

Use a 200 g/l solution of sodiu hypochlorite and water (or a solution of ½ ounce of nor al bleach to 1 gallon of water) or one of the

solutions co only used to disinfect babies’ feeding bottles; in this case, check that the sanitizing product is:

• authorized by your country’s Ministry of Health

• suitable for use with food achines

• not har ful to the aterials and co ponents of this appliance

For the directions for use and concentrations, please refer to those shown on the packaging and reco ended by the anufacturer. We

reco end using the solution at the te perature of 25°C.

1. re ove flag support asse bly (1 in Fig. 15) and ice-cube slide (2 in Fig 2. 15) and extract overflow pipe (3 in Fig. 15) to drain any

water that ay be present in the basin

2. fill basin with sanitizing solution. Refer to the table for the a ount of solution required, depending on daily production (Fig. 16)

3. refit ice-cube slide (2 in Fig. 15) and flag support asse bly (1 in Fig. 15)

4. with plastic tool, push the “W” button (wash position) through dedicated hole below “ON/OFF” button. (Fig 17)

The blue LED starts to flash. The appliance will carry out a co plete washing and rinsing cycle

5. switch off achine and disconnect it fro electricity ains and water supply

6. re ove evaporator cover panel (Fig. 19)

7. pour sanitizing solution onto top part of evaporator, distribute with a brush, and rinse thoroughly with cold water

8. re ove (Fig. 15) and i erse in sanitizing solution for 30 inutes:

• flag support asse bly (1)

• ice-cube slide (2)

• overflow pipe (3)

• sprayer bank (4) and side caps (5), after re oving the fro the bank

• sprayer bank feed pipe (6)

• pu p filter (7)

• evaporator cover panel (Fig. 19)

9. wipe container walls and door with sanitizing solution using a sponge and brush

10. drain sanitizing solution re aining in pu p body by introducing pressurised water into the suction pipe and checking that the water

exits fro the delivery pipe (Fig. 20)

11. thoroughly rinse inner basin, door and container with cold water

12. thoroughly rinse ice-cube slide, evaporator cover panel, sprayer bank and the corresponding side caps, flag support asse bly,

overflow pipe, pu p filter and sprayer bank feed pipe under running water

13. refit parts previously re oved

14. reposition top, securing it to rear panel with the screw, if present

The ice-cube aker can now be reactivated as specified in the instruction anual.

IMPORTANT: All the ice produced durin the first five cycles after cleanin and sanitizin operations must be discarded.

14 PERIODS AT A STANDSTILL

If you do not intend to use the appliance for a certain period of ti e, proceed as follows:

• switch off the electric power source by eans of the switch (7 in Fig. 4), and re ove the plug of the appliance fro its socket (if any)

• shut off the water supply by turning off the water supply tap (8 in Fig. 4)

• carry out all the operations envisaged for scheduled aintenance of the appliance (see chapter 9)

• e pty the internal basin by raising the flaps (if any) and re oving the overflow pipe

• e pty out the pu p body by blowing co pressed air into the pipe that supplies water to the sprayer bank

• clean filter of water supply solenoid valve as described in chapter 9.1

• clean filter of air condenser (if any) as described in chapter 9.2

This manual suits for next models

1

Table of contents

Other BREMA Ice Maker manuals

Popular Ice Maker manuals by other brands

Follett

Follett L77091 Installation, operation and service manual

Hoshizaki

Hoshizaki IM-200BAA Service manual

Manitowoc

Manitowoc S0850M Service manual

Rancilio

Rancilio ICEBOX IBS specification

Bosch Thermotechnology

Bosch Thermotechnology MUZ5EB2 instruction manual

U-Line

U-Line UHRI124-SS01A User guide & service manual

Summit Classic Collection

Summit Classic Collection BIM45 owner's manual

Hoshizaki

Hoshizaki FM-750AKE-N installation manual

Follett

Follett Horizon Elite HCD1010RHT installation instructions

HOMCOM

HOMCOM 800-157V90 user manual

Maxx Ice

Maxx Ice MIM50-0 instruction manual

Viking

Viking Professional VUIM150D Use & installation guide