Brenell Mark 5 Series 2 User manual

OPERATING

INSTRUCTIONS

forthe

Brenell

Mark

5

Series

2

TAPE

RECORDER

IMPORTANT

Before

attempting

to

operate this

instrument,

be

sure

to

study careful

these

instructions.

In the

event

of

damage

to the

Recorder through

wrong connection

or

other misuse,

the

manufacturers

can

accept

no

responsibility.

Price:

Five

shillings

GENERAL

DESCRIPTION

includingrecording

and

playback

sequences,

together

with:

Hints

for

improving

recordings

............

Page

8

Incorporating

into

a

Hi-Fiinstallation

.........

Page

II

Maintenance

Page

14

Specification

Page

20

Glossary

Page

22

Fig.

I

Feed

Spool

Spool

Retaining

Screws

Take-upSpool

Guide

Pillar

Adjustable

TapeGuide

Revolution

Counter

Record

PlaybackSwitch

Record

Lock

Button

Pause

Control

Superimpose

Control

RewindSwitch

Speed

SelectorSwitch

Fixed

HeadCover

Clip-on

HeadCover

FUNCTION

SWITCH—Record,

Playback,

Amplifier

FREQUENCY

CORRECTION—IJ,

3|,

7f

15

RECORDING

LEVEL

INDICATOR—Magic

eyeor

meter

VOLUME

CONTROL—Operative

onall

functions

TONE

CONTROL—Bass

boost(clockwisemaximum)

MOUNTING

SCREWS—Fixing

amplifier

to

cabinet

EXTENSION

SPEAKER—Preferably

IS

ohms

MONITOR—For

highimpedance

headphones

INDICATOR

LAMP—Straight

amplifier

ZERO

CONTROL—When

meter

is

fitted

INDICATOR

LAMP—Playback

RADIO/GRAM.

INPUT—For

high-levelsignals

MICROPHONE

INPUT—For

low-level

signals

MAINS

CABLE

This

isa

three-cored

cable

which

is

stored

inthe

left-handrear

compartment(viewed

from

the

rear).

Choose

a

suitablethree-pin

mains

plug

and

connect

the

greenlead

tothe

earth

pin

(largest)

andthetwo

remaining

leads

tothe

smaller

pins.

If a

two-pin

plugmust

be

used,

the

green(earth)leadmust

be

leftdisconnected

and

suitablyinsulated.

MAINS

ADJUSTMENT

PLUG

This

is

situated

within

right-handrearcompartment

and

contains

the

mains

fuse

which

is

easily

renewed.

Ensure

that

the

plug

issettothe

correctvoltageposition

for

your

electricitysupply.

i.e.,

240V

for

mains

of

220V

to

250V

210

V for

mains

of200V to220V

*IIOVfor

mains

of

100

V

to

125V

(thepowerconsumption

is

approx.

100

watts).

*Use

ONLY

onthe

special model

fitted

with

117

V

motors

and

suitable

ONLY

for use on

100-125

V

A.C.

supplies.

DO NOT

operate

the

special model

on

higher

voltage

mains

supplies unless

a

suitable

step-

down

transformer

is

used.

A

converter

to

enable

the

machine

tobe

operated

from

D.C.mains

or a car

battery

can be

obtained

from

yourdealer.

The

mains

switch

is

mounted

on

thispanel

and

will

switchpower

to

both

deck

and

amplifiers.

Also

mounted

onthe

mainsadjust-

mentpanel

isa

device

known

asa

"

Humdinger."

This

control

is

preset

atthe

factory

and

further

information

onitmaybe

found

in

the

Glossary.

LOADING

THE

TAPE

Before

loading

the

tape

forthe

first

time,

remove

the

headcovers

in

order

to

familiarise

yourself

with

the

position

ofthe

components,

the

working

ofthe

pressure

pads

and

pinchwheel.

The

upper

half

of

headcover

isa

pressed

fit,

and

needs

only

tobe

lifted

from

its

retainingposts;

the

lowerhalf

is

held

in

position

bytwo

screws.

To

loadtape,

place

full

reel

on

left-handspindle

and

thread

as

shown

onthe

diagram(Fig.

2).

With

the

tapecorrectlythreaded,

give

the

deck

a

trial

run

preparatory

to

making

a

recording,thus

familiarising

yourself

with

the

switchingoperations.

When

the

right-handswitch

onthe

deck

is

operated(record/play-

back)

the

tape

will

be

transported

from

left

to

right

across

the

erase

and

record/playback

heads

ata

speed

dependent

onthe

size

of

capstan

sleeve

inuseandthe

setting

ofthe

speed

switch.

The

left-handknob

isfor

rewinding

or

winding

onthe

tape

at

high

speed,

and

will

onlyoperate

ifthe

record/playbackswitch

isinits

STOP

position.

Al,

A2,A3

Tapeguides

B

Erase

head

C

Tapecontactrelease

pin

Dl

Retainingposts

for

upperhalfheadcover

D2

Retainingposts

for

lower

halfheadcover

E

Record/playbackhead

F

Azimuth

adjustmentscrew

G

Capstanshaft

H

Capstansleeve

J

Adjustabletapeguide

AlC B

K

Pinchwheel

LI,L2

Pressure

Pads

M

Take-up

pin

N

Pressure

pad

operating

lever

O

Crescent-shapedlever

P

Pause

control

R

Superimpose

control

S

Pressure

pad

spring

V

-jV'

freemovement

W

Supplementaryguide

pillar

Fig.

2.

Head

layout

and

tape

lacing

diagram

SPOOL

RETAINING

SCREWS

Screws

are

supplied

for

retaining

the

tapespools

onthe

hubs.

Whilst

itisnot

essential

to

fit

these

screws

whenrecording,

or

replaying

the

tape,theyshould

be

used

whentransporting

the

machine

in

order

to

hold

the

spools

in

position.

Should

the

screws

be

omitted

duringfastwind

or

re-wind,

itis

inevitable

that

a

certainamount

of

vibration

ofthe

spool

will

occur.

Adjustable

tape

guide

In

order

to

enable

spools

of

variedtypes

tobe

used

without

the

edge

ofthe

spool

fouling

the

tape,

an

adjustableguide

is

fitted.

Adjust

as

required

by

releasing

the

lower

milled

circular

nutand

raising

or

lowering

the

guide

by

rotating

the

upper

portion.

Finally,

ensure

that

the

lower

lockingscrew

is

re-tightened.

Speed-changeswitch

This

three-position

switch

gives

speeds

of:

(a)

with

largediameter

capstan

sleeve—IS,

7^,

3£

i.p.s.

(b)

with

smalldiameter

capstan

sleeve—7^-,

3£,

If

i.p.s.

Thisswitch

does

not

rotate

through

360°.

The

figures

above

the

switch

areforuse

with

the

smaller

sleeve

andthe

lower

with

the

larger

sleeve.

The

machine

is

supplied

with

the

large

capstan

sleeve

in

position

and

the

smallcapstansleeve

fitted

toW the

supplementaryguide

pillar.

The

sleeves

are

retained

onthe

capstan

shaft

with

grub

screws.

Ensure

screw

is

tight,

or

speed

fluctuations

will

occur.

(NOTE:

The

capstan

sleeve

should

be

fixed

with

the

grubscrewnear

the

deck

plate,allowing

£"

clearancebetween

endof

sleeve

and

deckplate.)

RECORDING

SEQUENCE

1

After

ascertaining

that

the

mainsadjustmentplug

atthe

rear

of

the

machine

is

correctly

setto

suityour

mains

voltage,

connect

the

machine

tothe

mains

supply

and

switch

on

(recorder

mains

switch

isonthe

same

panel

ofthe

power

unit

as

the

mains

adjustmentplug).

2Fit

reel

of

tape

to

left-hand(feed)spoolholder

and

lace

the

tape

asper

diagram(Fig.

2)tothe

emptytake-upspool

(right-

hand),ensuring

that

the

"

sensitive

"

side

ofthe

tape

faces

the

heads.

(Most

tapes

have

a

"

glossy

"

side

anda

"

dull

"

side—

itisthe

"

dull

"-side

which

is

coated

with

iron

oxide

andisthe

sensitive

side).

3

Select

recording

speed

and

adjust

the

frequencycorrection

switch

(B,

Fig.

I) to

match. (Thefaster

the

tape

speed

the

better

the

recordingquality.

If

quality

isnotso

important,

then

a

lower

speed

maybe

used

to

allowlongerrecording

periods

per

tape.)

4

Insertmicrophone

jack

plug

into

microphone

input

socket

or,

if

recording

from

radio,couple

the

radio

tothe

radio/gram

socket.

(See

special

noteregardinggramophonepick-ups

in

"

Hints

for

ImprovingRecording

"

section.)

5

Switchamplifier

to

record

and

adjust

the

volume

control

until

the

loudest(peak)signal

from

radio

or

microphone

causes

the

magic

eye

bars

to

justmeet

or,ifa

meter

is

fitted

in

lieu

ofeye

(seenote

on

zeroingmeter

inthe

Glossary—

"

Modulation

Level

Indicator

")

until

the

needle

rises

to

"

7

"

on

the

dial(i.e.

tothe

left-handedge

ofthered

portion

ofthe

scale).

6

Note

the

position

ofthe

volume

control

and

then

turn

it

fully

anti-clockwise

to

minimum.

7Now

depress

the

button

near

the

deckrecord/playback

switch

and

turn

thisswitch

tothe

"

Record

"

position.

8

Advance

the

volume

control

to

positionnoted

in6and

record-

ing

will

takeplace.

Ifthe

superimpose

control

is

inoperative,i.e.

itissetto

allow

the

erase

pressure

padto

press

the

tape

tothe

erase

head,

any

signals

which

have

beenpreviouslyrecorded

will

be

erased.

(See

note

on

"

Superimposing

"

inthe

Glossary.)

10

Onemay

hear

the

signalbeingrecorded

on

headphonescon-

nected

tothe

monitor

socket.

11

Asthe

recordingproceeds,

onemay

omit

certainitems,

for

example,

announcementsbetween

musical

items

ina

broad-

cast,

by

temporarilyhalting

the

tapemovement

by

operating

the

pause

control.

(Fade

outthe

signal

by

turning

down

the

volume

control—operate

pause

control

and

afterreleasing

this

control

forthe

continuance

ofthe

recording,

advance

the

volume

control

toits

originalsetting.)

12

To

stop

the

machine,

switch

rhe

deckrecord/playbackswitch

to

the

central

"

stop

"

position.

13

When

the

whole

ofthe

tape

has

passed

tothe

take-upspool,

thisreel

maybe

inverted

and

transferred

tothe

feed

side

in

order

that

a

further

recording

maybe

made.

(Seenote

on

"

Twin

Track

"

inthe

Glossary.)

PLAYBACK

SEQUENCE

1

Once

a

recording

has

beenmade

itmaybe

replayed

any

number

of

times

until

you

decide

to

erase

it.

(Erasure

is

auto-

maticallyaccomplishedwhen

another

recording

is

made

unless

superimposing

isin

operation.)

2

Place

the

recordedtape

onthe

feedspool

(orifyou

havejust

finished

a

recording

session,

rewind

the

tape

ontothe

feed

spool)

and

lace

itto

take-upspoolexactly

asfor

recording

purposes.

3

Switchamplifier

to

playback(playback

indicator

will

light).

Turn

volume

control

to

minimum.

Select

speed

of

deck

to

coincide

with

recording

speed

and

similarly

set

frequency

correction

switch.

4

Turn

the

deckrecord/playbackswitch

to

playback.Advance

volume

control

and

adjust

tone

control

as

required.

(The

frequency

correction

switch

maybe

adjusted

toany

position

desired

buta

"

flat

"

response

will

be

obtainedwhen

itisset

tothe

positioncoinciding

with

the

deckspeed.)

5

Shouldplayback

be

required

onan

external

speaker,simply

plug

the

externalspeaker

into

the

appropriate

socket

ofthe

amplifier.

(Internal

speaker

will

be

automaticallydis-

connected.)

6An

external

amplifier

maybe

used

with

the

recorder

by

con-

necting

itto

either

the(a)

monitor

socket

and

adjusting

the

recordervolume

control

tothe

requiredlevel,

(b)

co-axial

socket

onthe

amplifier

chassis.

The

signal

at

this

socket

is

not

governed

bythe

recordervolume

control.

(Normally

this

socket

is

used

with

externalhigh

fidelity

pre-amplifiers

and

amplifiers

andis

situated

atthe

rear

to

enableunobtrusive

connection

tobe

madewhen

the

recordingamplifier

isin-

stalled

ina

"

permanent

"

hi-fi

installation.)

Ifitis

desired

to

mute

the

internal

loudspeaker

when

operating

as(a)

above,

insert

a

jack-plug

which

hasa

15

ohm

resistor

wired

across

it

into

the

external

speaker

socket.

WARNING—Do

not

mute

with

an

open-circuited

jack-plug

or

damage

will

be

caused

tothe

amplifier.

STRAIGHTAMPLIFIER

If

the

function

switch

is

turned

to

"

Amplifier

"

the

amplifier

only

will

be

available

for

reproducingsignals

from

radio

tuner,

pick-ups

and

microphones.

It

should

be

noted

that

when

a

microphone

is

used

in

close

proximity

toa

loudspeaker,

"

acousticfeed-back

"

(howling)

will

occur—therefore

alwaysensure

that

the

micro-

phone

and

speaker

area

considerabledistance

apart.

Hints

for

improving

recordings

MICROPHONES

Seldom

isanyone

type

of

microphone

suitable

for

every

circum-

stance

andwe

recommendthey

be

used

as

follows:

Ribbon:

For

highquality

"

live

"

musical

recording

(indoors).

Dynamic

(moving

coil)—For

indoor

and

outdoor

use:

speech,

music,etc.

Crystal—Principally

for

speech

recordings.

RECORDING

FROM

MICROPHONE

Avoidplacing

the

microphonenear

the

motor

ofthe

taperecorder.

Wedonot

recommend

that

the

microphone

be

placed

onthe

same

table

asthe

tape

recorder

whenrecording.Earth

the

machine

ifthe

microphone

is

used

with

a

longercablethan

that

supplied.

This

will

avoid

excessive

A.C.

hum.Only

use

screened

extension

cables

(co-axialcable

as

used

forTV

aerial

leads

is

suit-

able).Alwaysensure

that

microphonecable

is

correctly

connected

tothe

jack

plug—broken

leads

or

reversedconnections

will

give

loud

hum.

Ifa low

impedancemicrophone

is

used

a

matching

transformer

will

be

required.

Donotrubthe

hand

or

fingers

onthe

case

ofa

microphonewhilst

recordingotherwise

"

noise

"

will

be

recorded.

Endeavour

to

persuade

people

to

speak

oneata

time

andnotasa

group

because

a

microphonerecords

allit

"

hears

"

and

cannot

discriminate

ascanthe

humanear.

RECORDING

FROM

RADIO

The

bestrecordings

will

be

obtained

from

FM-VHFtransmissions.

Donot

record

from

a

radioreceiver

by

means

ofa

microphone

if

one

ofthe

following

methods

canbe

employed:

(a)

Record

from

extensionspeakersocketofradioreceiver.

(b)

Record

from

the

diode

output

ofthe

radio

receiver.Your

radio

may

requiremodification

ifno

diode

output

socket

is

fitted.

Your

localdealer

can

advise

you.

Always

use

screenedcable

to

coupleradio

to

tape

recorder.

Always

consultyourdealerbeforeusing

an

A.C./D.C.

radio

orTV

receiver

which

hasno

extensionspeakersocket.

The

recording

signal

source

may

requiremodification

to

enable

the

receiver

tobe

used

without

risk

of

electricshock.

Always

ensure

that

any

plugs

or

connections

are

secure

otherwise

intermittent

crackling

maybe

produced.

PAUSE

CONTROL

Immediately

prior

to

using

the

pause

control,

turn

down

the

volume

control.

Conversely,

revert

to

normalvolume

as

soon

as

pause

control

is

released.

A

little

practice

will

soon

enable

the

user

to

makerecordings

of

excellentquality

ata

uniformsound

level

with

all

unwantedmaterial

omitted.

CARE

OF

HEADS

AND

GUIDES

Any

accumulation

of

dirt

or

oxideparticles

from

the

tape

will

preventgoodrecordingsbeingmade.Periodically,therefore,

clean

the

working

surfaces

of

both

heads

with

methylatedspirit

applied

with

a

small

camel

hairbrush.Take

special

care

notto

scratch

the

surfaces

ofthe

heads.

The

tapeguides

and

capstan

shouldalso

be

periodicallycleaned

with

methylatedspirits

to

removeoxidedeposit.

Access

to

heads

and

tapeguides

is

available

merely

by

removing

the

mouldedcovers.

SELECTING

AN

EXTENSION

LOUDSPEAKER

The

choice

ofa

loudspeaker

isa

verypersonal

thing,

andwe

suggest

that

the

listenershouldendeavour

to

hear

a

variety

of

makes

(within

his

pricerange),

inuse

with

the

taperecorder.

Ifthe

speakers

canbe

heard

within

the

listener's

own

home,

so

much

the

better,

as

roomacousticsmust

be

taken

into

account.

RECORDING

FROM

GRAMOPHONE

PICKUP

It

should

be

borne

in

mind

that

moderngramophone

discs

are

deliberatelyrecorded

with

an

attenuated(reduced)

bass

response

and

an

accentuatedtreble

response

compared

with

the

original

sound.

Therefore,

if

satisfactorytaperecordings

aretobe

made,suitable

frequency

compensationmust

be

incorporatedbetween

the

gramophonepick-up

andthe

taperecordingamplifier

to

reverse

the

disc's

recordingcharacteristics.

Such

frequencycompensationcircuits

are

incorporated

in

high

fidelity

pre-amplifiers

and

thosepeople

possessing

such

equipment

should

record

from

gramophone

discs

onlyafter

the

signal

has

passed

through

their

hi-fi

pre-amplifiers.

PICKUPS

Disc

recordings

from

domesticradiogramsshould

be

taken

from

the

extension

speaker

sockets

ofthe

radiogram

in

order

to

take

advantage

ofany

frequencycorrectioncircuitsincorporated

therein.

Shouldyourradiogram

or

recordplayer

NOT

have

extension

speaker

sockets,

donot

attempt

touseitin

conjunction

with

your

tape

recorder

before

consulting

a

qualified

electrician

or

dealer.Many

record

players

are

dangerous

touse

unless

fitted

with

isolatingtransformers

to

preventelectricalshocks.

Mostmanufacturers

of

gramophonepick-ups

will

supply,

on

request,details

of

frequency

correction

circuits

foruse

with

their

products—and

to

avoid

any

misunderstanding,

one

should

quote

the

sensitivities

and

impedances

ofthe

amplifier

with

which

a

pick-up

istobe

used

whenapplying

for

information.

Inthe

case

ofthe

BrenellMark

5

Series

2,

quote:

"

2

mV

into

I

megohm

"

and

"

80mV

into

220k

ohms."

Please

note

that

permissionmust

be

obtained

from

the

gramo-

phonerecordmanufacturerbeforetaperecordings

are

made

from

discs.

Failure

to

obtain

permission

isa

breach

of

copyright.

-~T

-

~

~

When

stopping

the

tape,

the

re-wind

switch

must

be

brought

quickly

tothe

central

position

in

order

to

allow

instantaneous

action

by

both

brakes.

(An

alternative method

isto

switch—very

quickly

indeed—from

the

re-wind

to the

wind position

(or

vice

versa), thus

transferring

the

power from

one

motor

to

the

other

and

achieving

a

gradual

slowing

down

of the

tape,

then,

just

as the

tape

movement

is

about

to

change,

turn

the

sw'tch

to the

central

'stop'

position. This

method requires a little practice but is

mentioned

at the

request

of

a.number

of

people, who, having learned

to use

it,

prefer

it to the

abrupt arresting

of

the

tape

movement.)

Fig.

3

POWER

SUPPLY

COMPENSATED

LOW-LEVEL

OUTPUT

SOCKET

10

Incorporating

the

Mark

5

Series

2

Recorder

into

a

permanent

Hi-Fi

installation

The

Mark

5

Series

2

taperecorder

is

oftensold

inthe

threemain

units:

tapedeck

amplifier

power

unit

foruse

with,

andfor

installation

into,

a

high

fidelity

console.

As

all

three

units

are

coupledtogether

by

means

of

non-reversible

plugs

and

sockets

(no

solderingrequired)

the

addition

of

tape

recording

facilities

to

exisingequipment

is

greatlysimplified.

DECK

MOUNTING

(Masksize

isfx

12

)

The

tapedeckshould

be

mounted

HORIZONTALLY

for

best

results.

An

aperture

of

I4"x

10^"

ina

mountingboard

will

allow

the

deck

to

"

drop

through

"

until

the

deckplaterests

onthe

board.

Rubbergrommets

or

other

rubbercushioningshould

be

fitted

between

the

deckplate

andthe

mountingboard.

(Beforeactuallymounting,remove

the

mask

from

the

deck

to

gain

access

tothe

four

holes

for

fixingpurposes.)

The

deckshould

be

mountedapproximately

£•"

clear

ofthe

board

to

facilitateventilation.Clearancebelow

the

deckplatemust

beat

least

5".

8^"

reels

of

tape

will

overlap

the

deckplate

IJ"

tothe

rear

and

Ij"

on

both

sides.

AMPLIFIER

MOUNTING

(Masksize

151

x41)

An

aperture

I2j"x4"

will

enable

the

amplifier

to

"

drop

through

"

a

mounting

board

until

the

maskrests

onthe

board.

Fixing

isby

means

oftwo

screws

through

the

mask.

The

amplifier

maybe

mounted

atany

angle.

POWER

UNIT

MOUNTING

The

power

unit

is

separate

from

the

amplifier

in

order

that

itmay

be

sited

to

induce

the

minimum

A.C.

hum

into

the

heads

andthe

II

amplifier.Therefore,aftermounting

the

deck

and

amplifier,

the

three

units

will

be

coupled

together,

a

loudspeakerattached

and

the

power

unit

movedaround

until

the

position

for

minimum

hum

is

found.(See

note

on

"

Hum.")

Fixing

is

thenaccomplished

by

means

of

screws

through

the

holesprovided.

HUM

It

should

be

noted

that

hummaybe

introduced

from:

a

mains

transformer

"

earth

"

loops

and

thereforecertainprecautionsmust

be

taken

and

experiments

made

should

excessive

humbe

encountered.

Hum

from

mainstransformers

maybe

introduced

into:

the

tape

heads

the

recording/playbackamplifier

the

cables

from

heads

to

amplifier

the

cables

carrying

the

signals

toand

from

the

amplifiers.

The

Mark

5

Series

2

power

unit

hasa

special

low

A.C.radiation

mains

transformer.

Beforescrewing

the

unit

into

a

permanent

position

the

deck,amplifier

and

power

unit

should

be

coupled

together

(deck

and

amplifier

in

permanentpositions),

anda

loud-

speaker

plugged

into

the

amplifier.

Now

connect

the

equipment

tothe

mains

supply,switch

the

amplifier

to

playback

andsetthe

volume

and

tone

controls

to

maximum.

Adjust

the

humdinger

onthe

power

unit

for

minimum

hum—if

no

definite

position

canbe

ascertained,

setit

mid-way.Move

the

power

unit

(beingcareful

notto

touch

any

components

ora

shock

may

be

received)

toa

position

in

which

the

minimum

humis

heard

from

the

loudspeaker,thenscrew

the

power

unit

down

in

this

position.

(If

thisposition

is

inconvenient

forthe

operation

ofthe

mains

switch,

putthe

switch

tothe

"

ON

"

position

and

instal

anotherswitch

ina

moreconvenientposition,

such

asonthe

deck

mounting

board.)

Now

switch

onthe

mainamplifyingequipment

you

will

be

using

with

the

taperecordingequipment

and

listen

forhuminthe

speaker

connected

tothe

playback

amplifier.

Should

thehum

level

rise

with

the

switching

onofthe

mainamplifyingequipment,

it

will

be

necessary

to

move

the

unit

in

which

the

mainstransformer

is

situated

(or

move

the

tapedeckand/or

amplifier).

COUPLINGAMPLIFIER

TO

HI-FI

EQUIPMENT

The

co-axialsocket

onthe

rear

ofthe

Brenellamplifiershould

be

coupled

tothe

appropriate

input

socket

ofthe

hi-fi

pre-amplifier

using

goodqualityco-axialcable.

It

should

be

noted

that

the

signal

from

the

co-axialsocket

is

frequency

corrected

and

must

notbefed

into

a

"

tape

input

"

socket

inthe

hi-fi

pre-amplifierwhich

is

designed

for

direct

connec-

tion

to

a

tape

head.

Ifthe

onlysocketmarked

"

tape

"

is

unsuitable,

12

couple

tothe

"

extra

"

or

"

auxiliary

"

socketdesigned

to

receive

a

"

flat

"

or

compensatedsignal.

Should

the

strength

ofthe

signal

from

the

Mark

5

amplifier

betoo

high

and

there

isnota

presetgain

control

incorporated

inthe

hi-fi

pre-amplifier,

the

signal

must

befedviaa

screened

volumecontrol

(value

50k to

100

k

ohms)

or

attenuator.

(a)

To

Record

Follow

the

earlierinstructions

on

thissubject

in

thisbooklet,

bearing

in

mind

that

a

signal

for

recordingpurposes

maybe

obtained

from

either

the

loudspeaker

output

ofthe

hi-fi

amplifier

or

from

the

"record"

socket

ofthe

hi-fi

pre-amplifier

(most

pre-amplifiers

have

thisprovision).Microphones

will

be

plugged

directly

into

the

recordingamplifier.

(b)

To

Replay

Tape

recordings

maybe

replayed

via

hi-fi

amplifyingequipment

by

connectingeither

(a)the

co-axialsocket

or (b) the

monitor

socket

onthe

Mark

5

Series

2

amplifier

tothe

hi-fi

pre-

amplifier,

ifthe

outputfrom

(a)is

insufficient.

Output

level

of(b)

will

dependupon

the

adjustment

ofthe

playback

amplifier'svolume

control.

EARTH

LOOPS

Hum may be

introduced

into

amplifyingequipment

by

having

too

many

earthpotentiallinking

cables

anditis

thereforesometimes

necessary

to

ensure

that

only

one

piece

ofthe

installation

is

con-

nected

tothe

earthterminal

ofthe

mains

supply

installation—

one

mustexperiment

by

removing

all

earth

return

leads

and

con-

necting

oneata

time

to

find

which

gives

the

condition

of

minimum

hum.

These

testsshould

be

carried

out

with:

all

equipmentswitched

on

tape

amplifierlinked

to

externalamplifier

for

playback

purposes

volume

levels

set

high,

butnotat

maximum.

The

cable

used

for

linking

the

tapeamplifier

and

mainamplifier

or

pre-amplifiershould

bea

goodquality

co-axial

type

as

used

for

TV

aerial

leads.

The

signal

from

the

co-axial

socket

onthe

Mark

5

Series

2

amplifier

is

not

affected

bythe

volume

control

setting

of

thisamplifier

and

thereforethisvolume

control

should

besetto

minimum.

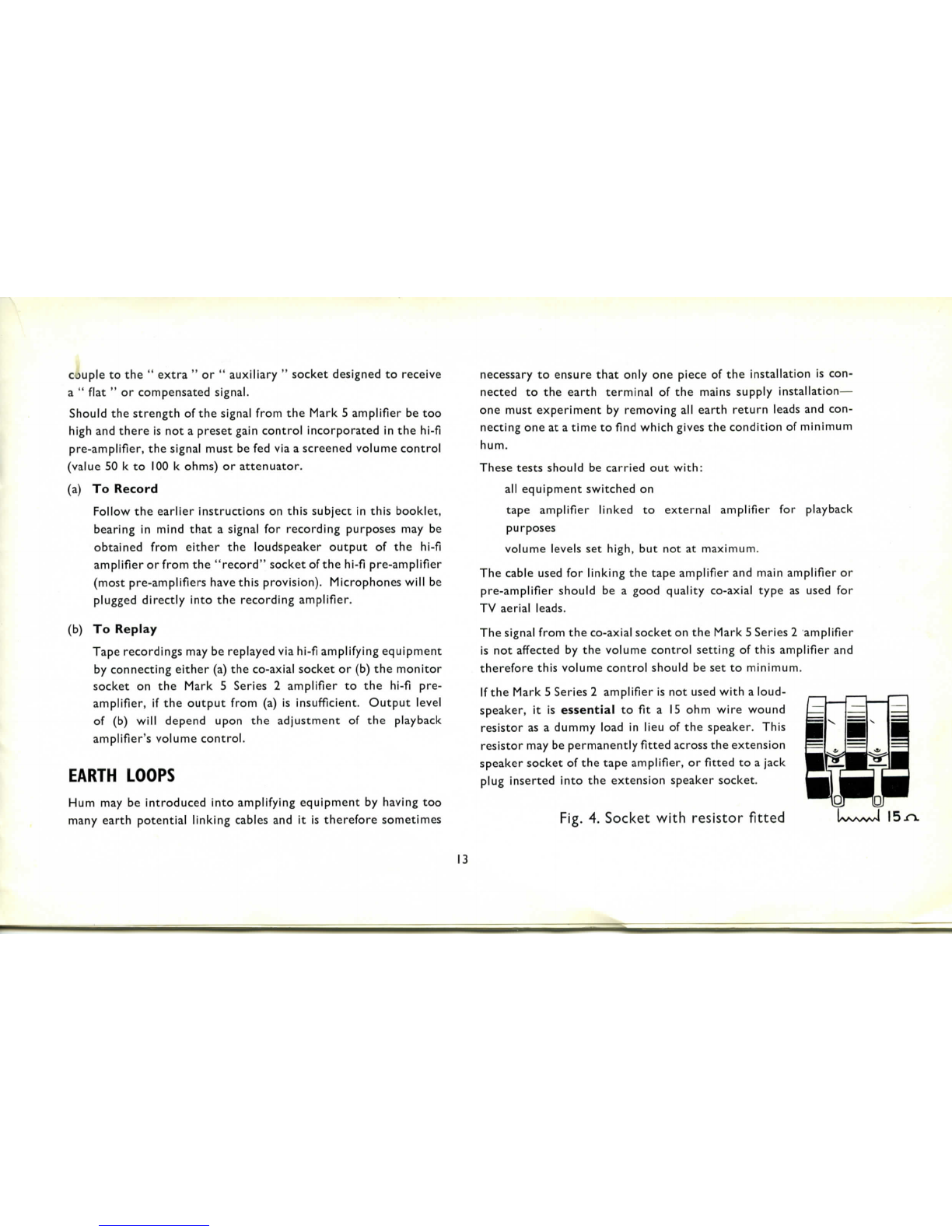

Ifthe

Mark

5

Series

2

amplifier

isnot

used

with

a

loud-

speaker,

itis

essential

to

fit

a

15

ohm

wire

wound

resistor

asa

dummyload

in

lieu

ofthe

speaker.

This

resistor

maybe

permanently

fitted

across

the

extension

speaker

socket

ofthe

tapeamplifier,

or

fitted

toa

jack

plug

inserted

into

the

extension

speaker

socket.

Fig.

4.

Socket

with

resistor

fitted

15

J~\.

13

Maintenance

TO

CLEAN

For

the

continuedefficientoperating

ofthe

machine,

itis

essential

to

ensure

that

the

heads,

pinchwheel

and

tapeguides,

are

clean

and

freefromtapeoxide.

A

very

thin

film

of

dirt

or

oxide

onthe

heads

will

seriously

mar

the

frequencyresponse

and

reduce

the

volumelevel,

whilst

oxide

onthe

pinchwheel

and

guides

may

cause

tape

slipping—apparent

tothe

listener

asa

variable

change

in

pitch

ofthe

recordedsounds.

We

recommend

the

cleaning

kit

marketed

by

Messrs.

METRO-

SOUND

M.F.S.

Co.

Ltd.,

I9a

BuckinghamRoad,London,N.I,

and

known

as

KLENZATAPE.This

kit

will

enable

the

heads

tobe

quickly

and

efficientlycleaned.

The

tapeguides

and

pinchwheelshould

be

cleaned

with

methy-

latedspirits,

but

careshould

be

taken

to

prevent

this

spirit

being

spilt

onthe

plastic

head

covers.Methylatedspirits

may

also

be

used

ona

lightlydampenedlinen

cloth

for

cleaning

the

heads.

REMOVAL

OF

AMPLIFIER

Two

domedscrews

FI-F2

(Fig.

I)are

used

to

hold

the

amplifier

inthe

cabinet,

andthe

removal

of

thesescrews

will

enable

the

amplifier

tobe

lifted

from

the

cabinet

for

examinationand,

if

necessary,

operation

whilst

"

live."

Donot

disconnect

the

amplifier

from

the

power

unit

unless

the

mains

switch

isOFF

otherwise

excessive

voltage

will

build

upinthepower

unit

and

damage

will

occur.

REMOVAL

OF

DECK

The

deck

is

covered

bya

steelmaskwhichmust

be

removed

to

gain

access

tothe

four

boltswhichclamp

the

deck

tothe

mounting

brackets.

DONOT

remove

the

four

screws

from

the

sides

ofthe

cabinet—

these

screws

retain

the

deckmountingbrackets

in

position.

The

mask

maybe

lifted

from

the

deckafterremoval

ofthe

deckknobs,

adjustable

guide,plastic

head

covers

andthetwo

smallscrews

near

the

spoolholders.

When

lifting

the

deck,careshould

be

taken

to

avoiddamaging

the

cables

coupling

amplifier

and

deck.

REMOVAL

OF

POWERUNIT

After

removal

ofthe

amplifier

and

deck,

the

power

unit

will

be

14

readily

accessible

andmaybe

entirely

removed

from

the

cabinet

by

removing

the

clampingscrews.

(Be

sure

to

replace

spacers

when

refitting.)

The

power

unit

must

notbe

operated

unless

loaded

bythe

amplifier,

otherwise

high

voltages

will

build

upand

cause

damage.

OILING

The

motors,

flywheel,

idler

wheel

and

pinchwheel

are

fitted

with

the

"

oilite

"

oil-retaining

bearings

and

therefore

will

seldom

require

oiling.

Not

morethan

one

drop

of

thin

machine

oil

will

be

needed

to

each

bearing

per

1,000

hours'use.

Oil

must

notbe

allowed

to

contaminate

the

rubbertyres

ofthe

idler

and

pinchwheels.

Oilonthe

periphery

ofthe

flywheel

will

cause

the

tape

speeds

to

become

erratic.

BRAKES

Mechanical

braking

is

employed;

cork-lined

levers

act

upon

the

spoolholderdrums.

BRAKE

ADJUSTMENT

Should

tapespillageoccur(whenusingreels

of

equal

size)

check

adjustment

of

brakes,whichshould

beas

follows:

With

rewind

and

record/playbackswitches

to

"

STOP,"adjust

the

gap

betweenbrakelevers

andthe4

B.A.

adjustablescrews

in

actuatingbar,

to

-^".

Adjustment

of

thesescrews

canbe

carried

out

after

releasing

the

lock-nuts.Always

tighten

lock-nutsafterwards.

Should

spillageoccurwhen

thegapis

correct,

shorten

the

brake

spring

by

approximately

£".

(NOTE

that

when

using

reels

of

unequal

size,centrifugalforces

will

be

unequal

and

tapespillage

may

occur.)

STABILISER

BRAKE

This

isa

smallbrakewhichoperates

onthe

feed-spoolholder

drum

to

stabilise

the

tapefeed

on

record

and

playback.

Itis

essential

that

thisbrakeshould

have

very

light

pressure

onthe

feed

spoolholderotherwise

thewow

content

will

rise

asthe

tape

nears

the

centre

ofthe

reel.

The

pressureshould

be

justsufficient

to

prevent

a

full

reel

of

tape

unwindingjerkilyduringrecordandplayback.

MOTORS

Threemotors

are

employed

onthe

Mark

5

Series

2

deck—

hysteresis

synchronoustype

for

driving

the

capstan,

5

watt

shaded

pole

for

rewinding,

and3

watt

shaded

pole

for

take-up.

15

MOTOR

TEMPERATURE

These

motors

are

designed

to

operate

at

high

temperatures—

50°C

plus

ambient.

SPEED

CHANGE

SWITCH

This

three-positionswitch

gives

speeds

of:

(a)

with

I"

diameter

capstan

sleeve—IS,

7^,

3J

i.p.s.

(b)

with

j"

diameter

capstan

sleeve—7\

3|,

IJ

i.p.s.

(See

note

on

"

Capstan

sleeves.")

Important:

should

the

user

desire

to

dispense

with

the

15

i.p.s.

and

permanently

usethe

small

capstan

sleeve,

giving

speeds

of

IJ,

3f

and

7^

i.p.s.,

the

cable

between

speed

switch

and

resistor

RSI

should

be

removed;this

will

enable

the

take-up

motor

to

operate

at

a

lowertemperature

inthe

highest

speed

position.

(NOTE:

At

15

i.p.s.

full

mains

power

is

applied

tothe

take-up

motor

to

givefaster

initial

take-up

and

preventtapespillage.)

CAPSTAN

SLEEVES

Two

sleeves

are

provided

of

approximately

I"

and

^"

diameter.

The

I",

used

in

conjunction

with

speed

switch,

gives

speeds

of

15,

7j

and

3J

i.p.s.,

whilst

the

\"

isfor

speeds

of

7^,

3|

and

IJ

i.p.s.

(See

note

on

"

Speed

ChangeSwitch

")

The

sleeves

are

retained

onthe

capstan

shaft

with

grub

screws.

Ensure

screw

is

tight,

or

speed

fluctuations

will

occur.

(NOTE:

The

capstan

sleeve

should

be

fixed

with

the

grubscrew

near

the

deck

plate,allowing

£"

clearance

between

endof

sleeve

and

deckplate.)

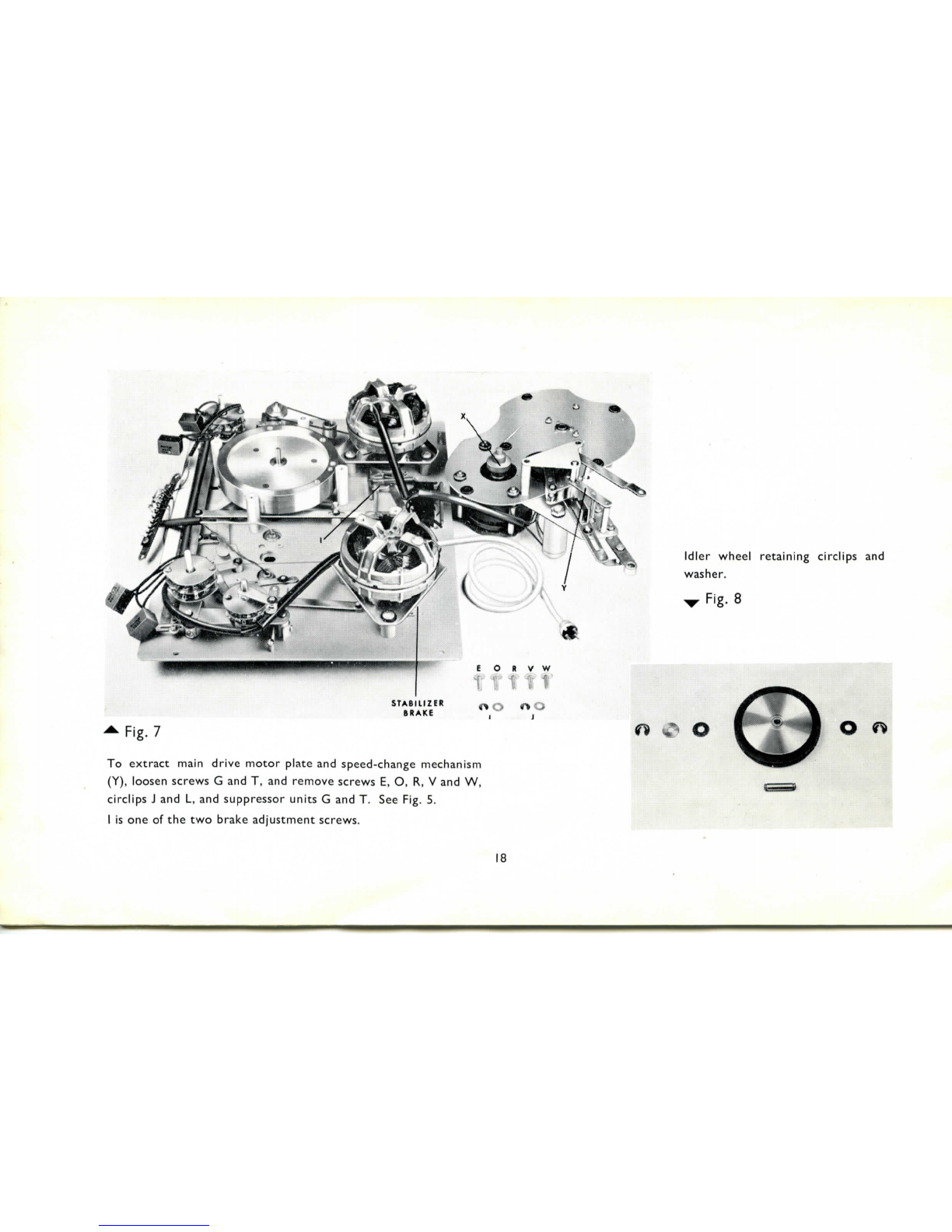

These

illustrationsshow

how

simple

itisto

gain

access

toall

parts

ofthe

BrenelI

Mark

5

Series

2

deck

simply

by

removing

the

maindrive

motor

plate.

A

Take-up

motor

C

Maindrive

motor

D500

ohms

10

watt

resistor

F

Feed

motor

G

Suppressorunits

16

To

gain

access

to

idler

pulley

(Z)

remove

screws

N andBand

swing

speed-changing

mechanism

so

that

idler

is

clear

of

motor

plate.

Xisthe

steppedpulley.

Uisthe

lower

bearing

forthe

capstan

spindle.

Fig-

6

v

H

Mechanicalbrake

K

Speed

changeswitch

M

Rewindswitch

P

Flywheel

Fig.

5

^

Q

Headleads,anchoring

strip

S

Recordplayback

switch

T

Suppressor

units

U

Lower

bearing—capstan

spindle

17

Fig.

7

To

extract

main

drive

motor

plate

and

speed-changemechanism

(Y),loosenscrews

G andT,and

removescrews

E,O,R,V andW,

circlips

J andL,and

suppressorunits

G andT.See

Fig.

5.

1

isoneofthetwo

brakeadjustmentscrews.

Idler

wheel

retaining

circlips

and

washer.

v

Fig.

8

18

PRESSURE

PAD

RELEASE

MECHANISM

An

adjustablecrescent-shapedlever(seeFig.

2)

controls

the

move-

ment

ofthe

leverreleasing

the

pressure

pads

(Nin

Fig.

2).

This

is

carefully

setup

before

the

deck

leaves

the

works,

butin

case

adjustment

is

required

the

following

setting-upprocedure

should

be

adopted:

With

I"

diametercapstan

sleeve

in

position,

switch

to

playback

and

adjust

the

crescentlever

so

that

when

the

pressure

pads

meet

the

headfaces,approximately

-fa"

freemovement

ofthe

releasing

baris

possible(see

V on

Fig.

2).

ERRATIC

TAPE

SPEED

Will

be

caused

ifOILis

allowed

to

accumulate

onthe

flywheel,

idler

or

motor

pulley.

FAULT

FINDING

Loss

oftop

response

and/or

output

from

record/playback

heads

and

incompleteerasure:

The

above

condition

canbe

caused

bythe

tapebeingunable

to

make

intimate

contact

with

the

face

ofthe

record/playbackhead

orthe

erasehead

owing

toa

build-up

of

oxidedust.

REMEDY:

Cleanhead

faces

with

soft,clean

cloth

dampened

with

methylatedspirits(NOTPETROL).

Atthe

same

time

clean

the

tapeguides,tensioningpins

and

capstan

sleeve.

Check

for

distortion

of

pressure

pads

and/orarms.Check

springtension

of

arms.

The

armsshouldmovefreely

on

their

posts.

WOWAND

FLUTTER

Listed

below

are

some

ofthe

possible

causes

ofwowand

flutter:

(a)

Driving

members

dirty

and/or

greasy

(b)

Eccentricpinchwheel

(c)

Stabiliserbrakeunder

too

great

tension

(d)

Idler

wheel

fouling

steppedpulley

(e)

Loose

capstan

sleeve

(f)

Tight

bearings

of

flywheel,pinchwheeland/or

idler.

19

REMEDIES

FORWOWAND

FLUTTER

(a)

Clean

with

soft

cloth

dampened

with

methylated

spirits:

the

flywheel

rim

capstan

sleeve

tape

guides

head

faces

stepped

motor

pulley.

(b)

Changepinch-wheel;avoidcontact

with

oil.

(c)

Adjust

the

pressure

ofthe

stabiliserbrake

tothe

minimum

amountrequired

to

prevent

the

tapespoolunwinding

ina

jerkymannerduring

the

record

or

playbackoperations.

Adjustment

is

effected

by

releasing

the4

B.A.

fixing

nutand

resetting

the

position

ofthe

brakelever.

(d)

Adjust

height

of

steppedpulley

to

ensureonly

one

section

is

operativeaccording

to

speed

in

use.

(e)

Ensure

that

fixing

screw

is

tight.

(0

Usually

dueto

dirt—clean

and

lightly

oilthe

bearings.

Specification

TAPE

SPEEDS:

l|,

3|,

7^

and

IS

i.p.s.

MOTORS:

Three(SynchronousHysteresistype

for

driving

capstan).

WOWAND

FLUTTER:

Less

than0.05%

at

15

i.p.s.

0.1%

at

7±

i.p.s.

0.15%

at

3f

i.p.s.

0.25%

at

IJ

i.p.s.

Please

note,

thesefigures

arefor

Record/Replay

andNOT

Record

only.

RECORD/PLAYBACK

FREQUENCY

RESPONSE:

15

i.p.s.

40 c/s to

over

15

kc/s

±2

dB

7£

i.p.s.

40c/sto

14

kc/s

±3dB

3|

i.p.s.

40c/sto

11

kc/s

±3dB

IJ

i.p.s.

40c/s

to

6

kc/s

±3dB

Measured

at

Ext.

Amp

Socketacross

47k ohm

load.

AMPLIFIER

RESPONSE:

40c/sto20

kc/s

±3dB.

BASS

CONTROL:

9 dB

variation

at65

c/s.

SIGNAL/NOISE

RATIO:

Unweighted—including

hum—45

dB.

SENSITIVITIES:

FOR

PEAK

MODULATION

A

MINIMUM

SIGNAL

OF:

MICROPHONE:

2.0

mV

(Impedance

I

Megohm).

RADIO:

80mV

(Impedance

220k

ohms).

20

Table of contents

Popular Recording Equipment manuals by other brands

Roland

Roland Camm-1 CX-24/12 manual

Bespoke

Bespoke Scoreboards Play cricket scorer pro Set up and operating instructions

Korg

Korg Tone Works Pandora PX4D owner's manual

GRASS VALLEY

GRASS VALLEY K2 HD-00 quick start guide

Lexicon

Lexicon REFLEX - user guide

Kurzweil

Kurzweil MIDIBOARD - MUSICIAN S BOARD manual