Benedini TBS Micro V2.0 User manual

Soundmodule TBS Micro V2.0 Page:1

RC - Soundunit TBS Micro V2.0

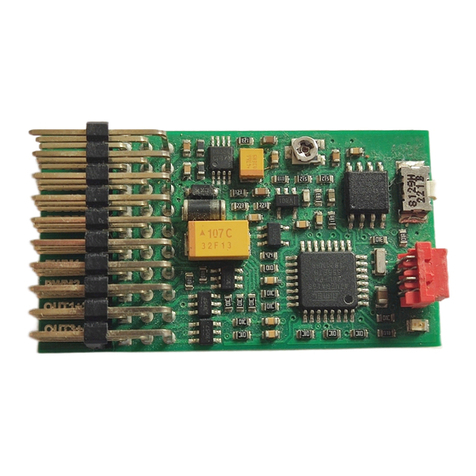

Technical datas:

Dimensions: 11 x 23,5 x 3,2mm (min.11x1 x3,2mm)

Voltage: 3V to max. 5V! (supplied by the receiver)

Current: app. 10mA without sound, app. 250mA at max. volume

Speaker: 8-32 Ohm

Output power: 1W at 8-Ohm at 5V, 0, W at 8-Ohm at 3V

Proportional inputs: Positiver Impuls 0,8ms bis 2,0ms

Sound quality: up to 22,05 kHz

Connections:

LS: Speaker or external amplifier

PROP_1: Prop.input for s eed controller

PROP_2: Prop.input for s ecial functions (configurable)

PROP_3: Prop.input for controlling.

Used for 12position encoder or two position toggle Switch.

LRN: Bridge to enter the learn mode.

Attention: Don’t solder wires at this contacts, because they are also used for

connecting the optional programming adaptor.

Prog: Connector for the optional programming adaptor

Note:

Prog cable must be connected with its BROWN wire at the outer (right) side

of the PCB (see last age)

Power is provided through the receiver by one of the PROP inputs.

Set controlmode at delivery:

O Encoder (→ see page 3) O Direct soundselect (→ see page 5)

O Indirekt soundselect (→ see page ) O Autostart (→ see page 7)

Loaded sound at delivery: _______________________________________

RC Connection

Speaker

Prop 1

Prop 2

Prop 3

Polarity: - + Sinal Learn Kontakte

NC A1 A2

A5

A4

A3

PWM2 PWM1 A9 A8 A7 A

Solder ads

Speaker

Ground

Prop1

Prop2

Prop3

+5V

Soundmodule TBS Micro V2.0 Page:2

1. Introduction

The digital sound unit TBS Micro can be used for any kind of RC-Model. It is connected directly

to the receiver outputs, in parallel to the speedcontroller. This ensures the ability to use the sound

unit in combination with brushless motors.

A 1W NF amplifier is already included.

Due to the dimensions and the weight of the unit, it is highly suitable for models in 1/87 scale and

electric planes.

The electrical connections to the receiver can be done by common servo cables, plugged into

sockets mounted on the PCB area at the left side of the TBS Micro. The power supply is provided

by the receiver.

Note the maximum su ly voltage of 5V!

In space critical applications, the PCB area for the sockets can be cut. In this case the servo

signals and the power supply must be connected to the copper spots beside the socket area. Good

solder skills are necessary!

The TBS Micro is delivered with unmounted sockets for the receiver cables. This ensures the

flexibility to use sockets or soldering the servo wires directly at the PCB or cutting the PCB area

off.

External am lifiers are available.

The volume can be adjusted remotely via the RC-transmitter or manually at the amplifier.

A optional programming adaptor is available to configure the sound unit at a common PC or to

install new sounds on it.

The free of charge configuration software TBS Flash is available at www.benedini.de, as well as

free of charge soundlibraries.

The soundunit can be controlled by a separate proportional channel or in “Autostart” mode.

Possible control modes:

●12 position encoder

●3 position switch for direct sound selection (only two sounds selectable)

●3 position switch for indirect sound selection (all sounds selectable)

●Autostart

The desired control mode can be selected by the programing adapter or manually.

Soundmodule TBS Micro V2.0 Page:3

2. Control modes

2.1. Controlling the sound unit by the 12- osition encoder

The most comfortable way of controlling the sound unit is using the socalled “12-position

encoder”. It consists of a 12 position rotary switch in combination with a push button. The

desired sound is selected by the rotary switch and is triggered by the push button.

The encoder must be mounted in your transmitter and must be connected at a unused proportional

channel.

The encoder must be ordered separately!

After installation you should test the encoder by a common servo at the according receiver

channel. Keep the encoder push button pressed and move the rotary switch through all positions.

The attached serve must move to a new position at each rotary switch position. The total

movement of the servo should be about the same as at the normal joystick channels set to 100%.

The receiver encoder channel must be connected to Pro 3 of the TBS Micro.

The installation of the encoder in your transmitter is on your own risk

Pro er functionality is not guaranteed at ALL transmitter brands / ty es

Connect to an

unused channel.

trigger switch

Rotary switch for

sound selection

The total resistance of the encoder can be

adjusted to your TX by two solder bridges at

the rear side of the encoder pcb:

BOTH bridges Total resistance

open app. 22

KOhm

closed app. 5

KOhm

Soundmodule TBS Micro V2.0 Page:4

Teaching the sound unit for encoder control:

1. Power on transmitter and receiver. LED blinks fast -> normal mode

Bring all joysticks to neutral position. Model must not move.

2. Bridge LRN contact for about 0.5 seconds until one beep occurs -> LED cont. on.

At this moment all neutral/idle positions are stored.

3. Move throttle stick to your desired acceleration point (throttle stick position where idle

dead band stops and engine running sound starts) and push the button of the encoder.

-> A short sequence of acceleration is played

Now the dead (neutral) band of the speed channel is defined

4. Move throttle stick to full speed position and push the encoder button again

A short sequence of full speed is played.

5. Bring the encoder rotary switch to its first position and push the encoder button

-> Engine start/stop is stored to this position

. Bring the encoder rotary switch to the next position and push the encoder button.

-> Reeving up the engine is stored to this position

7. Repeat step until all 12 rotary switch positions are stored

8. The 12th position is usually set to volume control

After programming, the sound unit beeps 3x and is back in the normal operation mode.

Explanations:

1. Dead- or neutral band is the throttle/speed stick range in which no sound change will

occur.

2. The rotary switch of the encoder has no mechanical limits. It can be rotated multiple times

through all positions.

3. Position #1 can be located at any indexed position of the encoder

Soundmodule TBS Micro V2.0 Page:5

2.2. Direct sound selection by a 3 osition switch (toggle switch)

If you want to run only the engine sound and ONE special sound (f.e. MG), you can use this

simple control mode.

You need a proportional channel equipped with a 3 position switch with neutral position and

momentary contacts to both sides or a common joystick channel.

A attached servo must leave its middle/neutral position when the switch is pressed in one

direction and must return to its middle position when the switch is released. Pushing the switch in

the opposite direction causes the servo to move to the other side.

Please compare the very left and right positions of the servo with a common joystick channel.

They should be about the same.

This is the first test you should do before programming the sound unit.

The control channel must be connected to Pro 2 of the TBS Micro.

Teaching the direct sound selection

(similar to Autostart mode)

1. Power on transmitter and receiver. LED blinks fast -> normal mode

Bring throttle stick to idle. Motor must not move.

2. Bridge LRN contact for about 0.5 seconds until beep -> LED cont. on.

At this moment the idle position of the throttle stick is stored.

3. Move throttle stick to your desired acceleration point (throttle stick position where idle

dead band stops and engine running sound starts) and wait for a beep

Now the dead (neutral) band of the speed channel is defined.

4. Move the throttle stick to full speed position and wait for three beeps.

After this the sound unit is back in the normal operation mode.

During the rograming sequence:

If you leave the last stored throttle stick osition, a very short bee is layed. Since then,

you have about 2 seconds to adjust the new throttle stick osition to be stored next.

Soundmodule TBS Micro V2.0 Page:

2.3. Indirect sound selection by a 3 osition switch (toggle switch)

Another control mode is possible by using a toggle switch with neutral position (recommended),

or a common joystick at a available proportional channel.

A attached servo must leave its middle/neutral position when the switch is pressed in one

direction and must return to its middle position when the switch is released. Pushing the switch in

the opposite direction causes the servo to move to the other side.

Please compare the very left and right positions of the servo with a common joystick channel.

They should be about the same.

This is the first test you should do before programming the sound unit.

The control channel must be connected to Pro 3 of the TBS Micro.

Selecting a Sound:

The desired sound (f.e. sound #3) is selected by pushing the switch/stick 3 times from its neutral

position to one direction. The selected sound is triggered/ layed by pushing the switch/stick to

the other direction. The last selected sound can be triggered multiple times, without new

selection.

Teaching the sound unit for toggle switch / joystick control

1. Power on transmitter and receiver. LED blinks fast -> normal mode

Bring throttle stick to minimum and control the center position of the toggle switch

2. Bridge LRN contact for about 0.5 seconds until beep -> LED cont. on.

At this moment all neutral positions are stored.

3. Move throttle stick to your desired acceleration point (throttle stick position where idle

dead band stops and engine running sound starts) and push the switch/joystick of the

control channel once

-> A short sequence of acceleration is played

Now the dead (neutral) band of the speed channel is defined

4. Move the throttle stick to full speed position and push the switch/stick of the control

channel again (like pos.3)

-> A short sequence of full speed is played.

After this the sound unit is back in the normal operation mode. All special sounds can be

controlled as mentioned above.

Soundmodule TBS Micro V2.0 Page:7

2.4. Autostart

If you only want to play the engine sound, the “autostart” mode can be selected. The engine starts

automatically, as soon as the model is accelerated the first time.

If the engine is more than 20s idle, it shuts down automatically.

No s ecial sounds can be played in this mode!

Teaching the autostart mode:

3. Power on transmitter and receiver. LED blinks fast -> normal mode

Bring throttle stick to idle. Motor must not move.

4. Bridge LRN contact for about 0.5 seconds until beep -> LED cont. on.

At this moment the idle position of the throttle stick is stored.

3. Move throttle stick to your desired acceleration point (throttle stick position where idle

dead band stops and engine running sound starts) and wait for a beep

Now the dead (neutral) band of the speed channel is defined.

4. Move the throttle stick to full speed position and wait for three beeps.

After this the sound unit is back in the normal operation mode.

During the rograming sequence:

If you leave the last stored throttle stick osition, a very short bee is layed. Since then,

you have about 2 seconds to adjust the new throttle stick osition to be stored next.

2.5. Changing a already set control mode

It is possible to change the adjusted control mode without the optional programing adaptor:

1. Bridge the LRN contact DURING powering the soundmodule

2. Remove the LRN contact

3. Close LRN contact momentary and wait for the “Beep-Code”

4. Repeat closing the LRN contact until the desired control mode is signalized by the

according “Beep-Code”

5. Switch soundmodule off and on again

„Bee -Code“

1 x Beep -> Autostart

2 x Beep -> Toggle switch

3 x Beep -> 12 position encoder

Soundmodule TBS Micro V2.0 Page:8

3. Connecting the USB rogramming cable

4pole USB cable 3pole USB cable

!! Black or Brown lead of the prog. cable must be plugged on the OUTER edge of the board !!

In some cases the pins of the USB programming cable must be bended SLIGHTLY for having

good contact to the sound unit. Tilting the inserted plug SLIGHTLY is also possible.

Do not move the plug while programming!

The free of charge configuration software TBS Flash is available at www.benedini.de, as well

as free of charge soundlibraries.

Disclaimer

1. www.benedini.de provides the equipment solely to be used by each purchaser in

accordance with the specific instructions supplied with each Sound Module and that the

purchaser undertakes that the Sound Module and any associated equipment e.g. Amplifier,

Speakers, etc. will be operated within the parameters contained therein.

2. www.benedini.de accepts no liability for any damage to any Sound Module if it is

determined that the damage has been caused by either non adherence to the instructions or due

to any malfunction by any cause or reason whatsoever within the model or its equipment and

thereby outside of the control of www.benedini.de.

3. www.benedini.de supplies each Sound Module on the strict undertaking that it will be used

in such a manner to comply with the laws of the purchaser’s country of residence.

4.www.benedini.de has no control over the final assembly, no liability shall be assumed nor

accepted for any damage resulting from any use by user of the final assembled product, the

user accepts all resulting liability.

Technical changes reserved

No suited for children

Thomas Benedini, Müllergasse 15, 52159 Roetgen, Germany

Mail: [email protected] Web: www.benedini.de

Table of contents

Other Benedini Recording Equipment manuals

Popular Recording Equipment manuals by other brands

BENDIXKing

BENDIXKing AeroPanel 100 System installation and operation manual

Fairlight

Fairlight Fame 2 user guide

Clear One

Clear One XAP TH2 Installation & operation manual

digi-tech

digi-tech TSR6 owner's manual

Konan Labs

Konan Labs KSP-FS4 owner's manual

Blackmagicdesign

Blackmagicdesign HyperDeck Studio Installation and operation manual