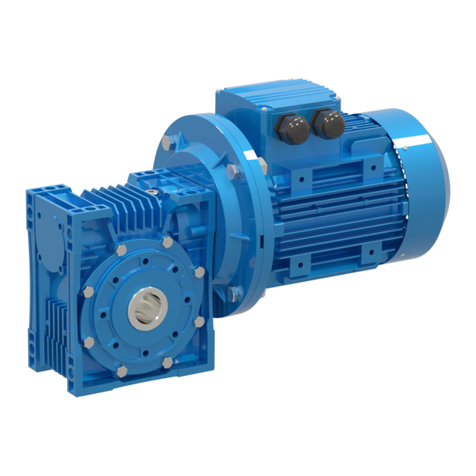

brevini Dana M Series Manual

®

Installation and Maintenance Manual

December 2022

IMM-0019EN

Gearmotors M/N Series

CONTENTS

The official language chosen by the Product manufacturer is English. No liability is assumed as a result of translations in

other languages not in compliance with the original meaning. In case of conflicting language versions of this document, the

English original prevails. Dana shall not be liable for any misinterpretation of the content here into. Photos and illustrations

might not represent the exact product.

© Copyright 2022 Dana Incorporated

All content is subject to copyright by Dana and may not be reproduced in whole or in part by any means, electronic or oth-

erwise, without prior written approval.

THIS INFORMATION IS NOT INTENDED FOR SALE OR RESALE, AND THIS NOTICE MUST REMAIN ON ALL COPIES.

DISCLAIMER

3IMM-0019EN - Installation and Maintenance Manual Dana Incorporated

CONTENTS

1 VERSION TRACKING ....................................................................................................................... 5

1.1 MANUAL APPLICABILITY AND SUPPORTED MODELS ..................................................................... 5

2 HOW TO USE THIS MANUAL .......................................................................................................... 6

3 UNIT DESIGNATION ......................................................................................................................... 7

3.1 DETAILED UNIT DESIGNATION ........................................................................................................... 7

3.2 NAMEPLATE UNIT DESIGNATION ...................................................................................................... 8

4 STANDARD TYPE GEARBOX PART LIST ....................................................................................... 9

4.1 M...TYPE 3 STAGES ............................................................................................................................. 9

5 N...TYPE 3 STAGES ........................................................................................................................ 10

5.1 M, N... ADDITIONAL STAGE FOR 4 STAGE TYPES .......................................................................... 11

5.2 M, N...MOTOR FLANGE FOR DIRECT COUPLED TYPES ................................................................. 12

5.3 M, N...TYPES B5, B14 MOTOR FLANGE ...........................................................................................12

5.4 M, N TYPES...INPUT BEARING HOUSING WITH SOLID INPUT SHAFT ........................................... 12

6 SAFETY ........................................................................................................................................... 13

6.1 INTENDED USE .................................................................................................................................. 13

6.2 IMPROPER USE ................................................................................................................................. 13

6.3 SAFETY INSTRUCTIONS ................................................................................................................... 14

6.3.1 GENERAL SAFETY INSTRUCTIONS................................................................................................... 14

6.4 TIGHTENING TORQUES .................................................................................................................... 15

6.5 CASE OF FIRE .................................................................................................................................... 16

6.5.1 SUITABLE EXTINGUISHING AGENTS, PROTECTIVE EQUIPMENT................................................... 16

6.5.2 UNSUITABLE EXTINGUISHING AGENTS ........................................................................................... 16

7 THINKS TO CHECK BEFORE THE GEAR UNIT OR GEARED MOTOR IS INSTALLED ............. 17

7.1 TRANSPORTATION ............................................................................................................................ 17

7.2 STORAGE ........................................................................................................................................... 18

8 INSTALLING THE GEAR UNIT ....................................................................................................... 19

8.1 BEFORE YOU START ......................................................................................................................... 19

8.2 CHECK THE SHAFT DIMENSIONS TO FIT ........................................................................................ 19

8.3 CHECK THE AMBIENT TEMPERATURE ............................................................................................ 19

8.4 CHECK THE VOLTAGE SUPPLY ....................................................................................................... 20

8.5 CHECK THE MOUNTING POSITION .................................................................................................22

8.6 USE THE BREATHER PLUG .............................................................................................................. 22

8.7 CHECK THE OIL LEVEL ..................................................................................................................... 22

8.8 CHECK SHAFT ENDS AND MOUNTING FACES ............................................................................... 22

8.9 COVER ABRASIVE AMBIENT ............................................................................................................. 23

8.10 CHECK ACCESSIBILITY TO FILLING, BREATHER AND DRAIN PLUGS .......................................... 23

9 MECHANICAL INSTALLATION ...................................................................................................... 24

9.1 FITTING OUTPUT SHAFT ELEMENTS ...............................................................................................25

9.2 CORRECT POSITION OF OUTPUT SHAFT ELEMENTS .................................................................... 25

9.3 FITTING COUPLINGS ........................................................................................................................ 26

10 MAINTENANCE & INSPECTION .................................................................................................... 27

11 LUBRICATION ................................................................................................................................ 28

11.1 OIL TYPES .......................................................................................................................................... 28

11.2 CHANGING THE OIL .......................................................................................................................... 29

11.3 OIL LEVELS, PLUGS AND QUANTITIES ............................................................................................ 30

11.4 MOUNTING POSITIONS .................................................................................................................... 36

4

CONTENTS

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

12 TROUBLESHOOTING GUIDE ........................................................................................................37

13 DISPOSAL ....................................................................................................................................... 40

13.1 DISPOSAL OF OIL .............................................................................................................................. 40

13.2 DISPOSAL OF SEALING .................................................................................................................... 40

13.3 DISPOSAL OF METAL ........................................................................................................................ 40

5Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

1 VERSION TRACKING

1.1 MANUAL APPLICABILITY AND SUPPORTED MODELS

File name Revision Date Changes description

IMM-0019EN_Rev.00 Gearmotors MN

Series 00 17/10/2022 - Changed layout

IMM-0019EN_Rev.01 Gearmotors MN

Series 01 07/12/2022 - Updated "Use the breather plug" page 22

Models

Gearmotors M/N Series

6Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

2 HOW TO USE THIS MANUAL

Take attention to the following safety and warning signs for proper understanding and quick reference.

Table 1:

Hazard pictograms

Table 2:

The operating instructions contain important information to ensure;

• Trouble-free operation

• Fulfilment of any rights to claim under guarantee

The operating instruction must be kept close to the gearbox and must be available in case it is needed.

This operating instruction is written for M/N series gear units and is applicable only for M/N series. If any different type of gear-

box is used please ask Dana Motion Systems Italia S.r.l. for the operating instructions of that type.

This instruction can be used only for standard type geared units of Dana Motion Systems Italia S.r.l.. For special application

and modified gear units ask Dana Motion Systems Italia S.r.l. for validity.

This manual does not cover 94/9/EC compatible gearboxes. For 94/9/EC contact Dana Motion Systems Italia S.r.l..

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates an imminently hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a situation which, if not avoided, may result

in damage to components.

Indicates information which may make product service

easier to perform.

NOTE:

Important Information.

General danger

Electric current

Moving parts

NOTE:

EC Machinery Directive:

Within terms of the EC machinery directive 2006/42/EC, the gearboxes are considered as not autonomous machine, but

as a component to install in machines.

Operation is prohibited within the area of validity of the EC directive, until it has been determined that the machine, in

which this product is installed, corresponds to the regulations within this directive.

DANGER

WARNING

CAUTION

NOTICE

7Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

3 UNIT DESIGNATION

3.1 DETAILED UNIT DESIGNATION

Motor Size

Brake

L-220V

P-24V

S-220 V

Z-24 V

01-10 Nm

02-25 Nm

04-40 Nm

05-50 Nm

Gearbox Type

M Series

N Series

Input Type

R :With Motor

N :IEC B5 / B14 Flanged without Motor

V : IEC B5 / B14 Flanged with Motor

T : Without Motor

RF : With Motor and Output Flange, Foot Mounted (M Type)

RB : With Motor, Agitator Neck at Output (N Type)

TF : Without Motor and Output Flange, Foot Mounted (M Type)

Housing Size

1...9

Revision Number

M R 4 7 3 - 90S / 4 - L02

10-100 Nm

20-200 Nm

30-300 Nm

40-400 Nm

Stage

2 Stages

3 Stages

4 Stages

5 Stages

6 Stages

For MV / NV Types

90S / 4

For MN / NN types

A06 :63 B5 A09 : 90 B5 A13:132 B5 A25: 250 B5

B06 :63 B14 B09 : 90 B14 B13:132 B14 A28: 280 B5

A07 :71 B5 A10 :100 B5 A16:160 B5 A31: 315 B5

B07 :71 B14 B10 :100 B14 A18:180 B5

A08 :80 B5 A11 :112 B5 A20:200 B5

B08 :80 B14 B11 :112 B14 A22:225 B5

Pole Number

Frame Lenght

8

NAMEPLATE UNIT DESIGNATION

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

3.2 NAMEPLATE UNIT DESIGNATION

A sample name plate for M Series

Abreviations:

Serial N.: Serial Number

M.Pos.: Mounting Position

A - Type

B - Motor Size

Serial Number: 100658986

NOTE:

Nameplate unit designation is a short abbreviation from the detailed designation.

M. Pos.:

:Oil

Ratio:

:Type

rpm.:Speed

Power : kW

MADE IN TURKEY

Serial N.:

Oil Qty : lt.

MR473-90 S / 4B

100658986

1,1 219

6,6 M1

ISO VG 320

(Mineral) 4

AB

MR473 90 L / 4

9Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

4 STANDARD TYPE GEARBOX PART LIST

4.1 M...TYPE 3 STAGES

A - Only in gearboxes with 3 stages

NOTE:

Standard M type 3 stages basic part diagram. Parts may differ for special applications.

1

2

3

4

5

6

7

9

11

8

12

13

16

17

18

19

20

21 22

14

15

23

10

24 25

26

28

29 30

27

31

A

32 33

34

35

36

Parts List

1Housing

2Oilplug

3Circlips

4Bearing

5Spacer

6 Gear

7Bearing

8Key

9 Gear

10 Bearing

11 Circlips

12 Cover

13 Output shaft

14 Key

15 Key

16 Seal

17 Circlips

18 Bearing

19 Spacer

20 Gear

21 Bearing

22 Circlips

23 Cover

24 Circlips

Parts List

25 Bearing

26 Gear

27 Key

28 Gear

29 Bearing

30 Circlip

31 Oil plug

32 Bolt

33 Eye Bolt

34 Oil plug

35 Top Side Cover

36 Screw Pin

Parts List

10 Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

5 N...TYPE 3 STAGES

A - Only in gearboxes with 3 stages

NOTE:

Standard N type 3 stages basic part diagram. Parts may differ for special applications.

1

2

3

4

5

6

7

9

11

8

12

16

18

19

20

21

22

23 24

15

17

25

10

26 27

28

30

31 32

29

34 35

36

37

38

33

A

14

13

Parts List

1Housing

2Oilplug

3Circlips

4Bearing

5Spacer

6 Gear

7Bearing

8Key

9 Gear

10 Bearing

11 Circlips

12 Cover

13 Output Flange

14 Bolt

15 Key

16 Output Shaft

17 Key

18 Seal

19 Circlips

20 Bearing

21 Spacer

22 Gear

23 Bearing

24 Circlips

25 Cover

26 Circlips

27 Bearing

28 Gear

Parts List

29 Key

30 Gear

31 Bearing

32 Circlips

33 Oil plug

34 Bolt

35 Eye bolt

36 Oil plug

37 Top side cover

38 Screw Pin

Parts List

M, N... ADDITIONAL STAGE FOR 4 STAGE TYPES

11Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

5.1 M, N... ADDITIONAL STAGE FOR 4 STAGE TYPES

NOTE:

M, N additional stage for 4 stage types part diagram. (Standard)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

4

Parts List

1Circlips

2Bearing

3 Gear

4Oilplug

5Bearing

6Circlips

7Shaft

8Seal

9 Gear

10 Circlips

11 Key

12 Key

13 Bolt

14 Additional Housing

15 Screw Pin

12

M, N...MOTOR FLANGE FOR DIRECT COUPLED TYPES

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

5.2 M, N...MOTOR FLANGE FOR DIRECT COUPLED TYPES

5.3 M, N...TYPES B5, B14 MOTOR FLANGE

5.4 M, N TYPES...INPUT BEARING HOUSING WITH SOLID INPUT SHAFT

1

2

3

4

5

6

7

8

10

9

Parts List

1Shaft

2 Circlips

3Bearing

4 Circlips

5Flange

6Key

7Gear

8 Circlips

9Nut

10 Key

1

2

3

4

5

6

7

8

10

9

Parts List

1Shaft

2 Circlips

3Bearing

4 Circlips

5 B5 / B14 Flange

6Seal

7Gear

8 Circlips

9Nut

10 Key

1

2

3

4

5

6

7

8

9

11

10

Parts List

1Seal

2Nut

3Flange

4Shaft

5Bearing

6Bearing

7 Circlips

8Gear

9 Circlips

10 Key

11 Key

13Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

6 SAFETY

6.1 INTENDED USE

The gear reducer is designed for use in industrial machines. Please refer to our catalogue or our web page for the maximum

permitted torques and speeds. The most important maximum permitted values are indicated on the nameplate of the product.

But the whole data can be found on our product catalogues. Using the product out of the product catalogue / nameplate's per-

mitted ranges will cancel the warranty/manufacturer declaration and Dana Motion Systems Italia S.r.l. will not take any respon-

sibility.

The gear units are intended for industrial machines and may only be used in accordance with the information provided in this

manual the product catalogue and the nameplate of the gearbox. They comply with the applicable standards and regulations

and meet the requirements of the directive 2006/42/EC. The gearbox must be started up, maintained and operated according

this manual. The gearbox most be incorporated with 2006/42/EC confirming parts/machines.

6.2 IMPROPER USE

The operation of the gear reducer is prohibited if:

• It was not mounted/installed according to regulations and this manual

• The gear reducer is very soiled

• It is operated without lubricant

• It is operated out of the permitted values provided on catalogues and/or nameplate.

NOTE:

A motor connected to the gear unit is only allowed to be operated in the frequency entries so that the data provided on

nameplate/catalogue of the gear unit is not exceeded and is accordance with the nameplate/catalogue. The speed

range will be provided on the name plate if Dana Motion Systems Italia S.r.l. is informed that the gear unit will be used

with frequency inverter. If not informed the nameplate will have a single fixed speed and only this speed is allowed.

The electric motor and frequency inverter must be in accordance with 2006/42/EC.

NOTE:

If the gear units input is used with variable speed gear unit, this must be informed to Dana Motion Systems Italia S.r.l.

before ordering and on the nameplate the allowed maximum and minimum speeds (speed range) will be provided. If not

mentioned by ordering the gear units speed will be a fixed single input speed and only this speed is allowed.

NOTE:

If the gear unit will be driven by belt / coupling / chain drive etc. the gear unit is only allowed to be used according the

nameplate/catalogue entries. Different speed, higher motor power, higher radial/axial loads etc. than nameplate/cata-

logue is not allowed.

NOTE:

The ambient temperature must be between +5 - +40 ºC and no abrasive media must attack the paint and seals. If differ-

ent working conditions this must be informed to Dana Motion Systems Italia S.r.l. before ordering.

The gearbox maintenance (oil change / check ) must be done according this manual.

NOTE:

Every usage which exceeds the limits stated above, the nameplate and catalogue of the product (especially higher

torques and speeds) is not compliant with the regulations, and thus prohibited.

14

SAFETY INSTRUCTIONS

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

6.3 SAFETY INSTRUCTIONS

6.3.1 GENERAL SAFETY INSTRUCTIONS

6.3.1.1 Working on the gear reducer

6.3.1.2 Operation

6.3.1.3 Maintenance

WARNING

Inappropriately executed work can lead to injury or damage.

Make sure that the gear reducer is only installed, maintained and dismantled by trained technicians.

WARNING

Foreign bodies spinning through the air can cause grave injury.

Before putting the gear reducer into operation, check that there are no foreign bodies or tools near the gear reducer

WARNING

Touching hot surfaces can lead to burns.

Do not touch the gear reducer if their operation temperatures are too high, or use suitable safety equipment like gloves.

WARNING

Rotating machinery can lead to injuries. There is danger of being trapped or pulled in!

Keep a sufficient distance and make safeguarding to rotating machinery. See relevant norms EN349+A1, EN13857.

WARNING

An unintentional start of the machine during maintenance work can lead to serious accidents.

Make sure no one can start the machine while you are working on it.

WARNING

Even a brief running of the machine during maintenance work can lead to accidents if the safety devices are not operating.

Make sure that all safety devices are mounted and active.

TIGHTENING TORQUES

15Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

6.3.1.4 Lubricant

6.3.1.5 Ambient Conditions

6.4 TIGHTENING TORQUES

All screwed connections for which a tightening torque is specified, must on principle be tightened with a calibrated torque

wrench and checked. Use the following torques for the threaded bores over the gear unit housing. For connecting elements

refer to the mechanical installation part.

Table 3:

WARNING

Extended, intensive contact with oils can lead to skin irritations.

Avoid extended contact with oil, and clean oil off skin thoroughly.

WARNING

Hot oil can cause scalding.

When changing oil, protect yourself against contacting hot oil.

DANGER

If the gear unit will be used in outdoor applications the gear unit must be prevented from rain snow and dust. Entering sub-

stances inside the gear unit from seals can damage the gear unit. Observe the safety instructions for outdoor use

EN12100:2010.

WARNING

Standard gearboxes are allowed to work in ambient temperatures between +5 to +40ºC unless differently specified on the

nameplate. Using the gear unit out of this range can cause damage to the gear unit or environment. Over +40 ºC ambient

conditions the gear unit surface temp could be so high causing burns when touched.

Bolt Size Class Tightenning Torque [Nm]

M8 8.8 23

M10 8.8 43

M12 8.8 77

M16 8.8 190

M20 8.8 370

M24 8.8 640

16

CASE OF FIRE

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

6.5 CASE OF FIRE

The gear reducer itself is not combustible. However, it usually contains a synthetic or mineral gear oil.

Please observe the following if the gear reducer is situated in a burning environment

6.5.1 SUITABLE EXTINGUISHING AGENTS, PROTECTIVE EQUIPMENT

Always keep suitable extinguishing, protective equipment like carbon dioxide, powder, foam, fog easily accessible around the

gear unit.

6.5.2 UNSUITABLE EXTINGUISHING AGENTS

WARNING

-High temperature produce irritating steam.

Use a protective breathing apparatuses.

WARNING

Do not spray with water!

17Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

7 THINKS TO CHECK BEFORE THE GEAR UNIT OR GEARED MOTOR IS INSTAL-

LED

Before you install the gearbox you have to be sure that the gearbox is arrived with the all necessary equipment and without

damage. Points to take into consideration before you start to install the unit;

• You have received the correct operation manual of the your product.

• The gearbox and all its parts are transported without damage.

• The gearbox is stored correctly according the instructions in this manual

• You have the latest product catalogue or you have access to our web page

7.1 TRANSPORTATION

When the goods arrive, first check for any damage. If some damage observed, immediately contact the transport company and

inform about the damage. Contact Dana Motion Systems Italia S.r.l. for the damage and do not start to install the unit until it is

agreed that the damage has no affect of operation.

NOTE:

If geared motors are used, please also refer to the manual of the motor manufacturer.

DANGER

Falling or hard placement can damage the gear unit.

Only use hoisting and securing equipment which is permitted for the size / weight of your gear unit. Ensure that the load is

slowly and carefully handled and placed.

DANGER

Use the supplied eyebolts or lifting holes for lifting up the gear unit. The eyebolts are capable to carry the weight of

gearboxes only. Do not hang additional loads. Use suitable hoisting equipment which is capable to hold the gear

units weight. Refer to the catalogue for various types weights. See drawing bellow for hoisting point.

DANGER

Do not stay beneath / under the lifting/hoisting equipment which may cause serious injuries by falling down objects, accidental

movements, unexpected accidents.

18

STORAGE

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

7.2 STORAGE

If the geared unit or geared motor will be stored up to 3 years refer to the following instructions;

With Packing;

Use corrosion protection oil for the output shaft and connection surfaces like flange surface or foot assembling surface. Seal

the unit in a plastic wrap and pack it in container. A moisture indicator should be placed around the container to observe the

moisture. Relative atmospheric humidity should not exceed 50%. The container should be kept under roof which protects from

snow and rain. Under this condition the gear unit can be stored up to 3 year with regular check. The ambient temperature should

be between -5 to 60 ºC.

Without Packing;

Use protection oil for the output shaft and connection surfaces like flange surface or foot assembling surface. If no packing is

used and the gearbox is stored without packing, the ambient temperature should be between 5 to 60 ºC. The gearbox must be

kept under enclosed roof with constant temperature and constant humidity not exceeding 50%. The storage should be free of

dust and dirt and ventilated with filter. If the gearbox is stored without packing it is recommended not to store more than 2 years

and regular check during this time is recommended.

If stored in open protect against insect damage.

19Dana IncorporatedIMM-0019EN - Installation and Maintenance Manual

8 INSTALLING THE GEAR UNIT

8.1 BEFORE YOU START

• Observe the gear unit for damages of storage or transportation. If any damage please contact Dana Motion Systems Italia

S.r.l..

• Be sure that you have all the equipment necessary for installing like; Spanners, torque wrench, shims and distance rings,

fixing devices for input and output elements, lubricant, bolt adhesive etc.

8.2 CHECK THE SHAFT DIMENSIONS TO FIT

Table 4:

8.3 CHECK THE AMBIENT TEMPERATURE

The ambient temperature must be between +5 ºC to +40 ºC for standard type gear units. If different contact Dana Motion Sys-

tems Italia S.r.l. for special solutions.

NOTE:

This manual is not for 94/9/EC (ATEX) conforming gear units. For 94/9/EC conforming gear units refer to the ATEX range

manual. ATEX conforming gear units have name plates indicating the zone and the temperature class and are different

from standard type geared units. Therefore Standard units can not be installed on Potentially explosive atmospheres.

Type Output

Shaft

Diameter

Output Shaft Tolerance

(DIN748)

Up to 50mm k6

Over 50mm m6

Flange Centering Shoulder

Diameter (for N Serie)

Centering Shoulder Tole-

rance (g6) (for N Serie)

M/N...002/003.. 20 +0.02

095 -0.01

-0.03

M/N...102/103... 25 +0.02

0110 -0.01

-0.03

M/N...172/173... 25 +0.02

0110 -0.01

-0.03

M/N...202/203... 30 +0.02

0130 -0.01

-0.04

M/N...272/273... 35 +0.02

0130 -0.01

-0.04

M/N...282/283... 35 +0.02

0180 -0.01

-0.04

M/N...372/373... 40 +0.02

0180 -0.01

-0.04

M/N...472/473... 50 +0.02

0230 -0.02

-0.04

M/N...572/573... 60 +0.03

+0.01 250 -0.02

-0.04

M/N...672/673... 70 +0.03

+0.01 300 -0.02

-0.05

M/N...772/773... 90 +0.04

+0.02 350 -0.02

-0.06

M/N...872/873... 110 +0.04

+0.02 450 -0.02

-0.06

M/N...972/973... 120 +0.04

+0.02 550 -0.02

-0.06

20

CHECK THE VOLTAGE SUPPLY

Dana Incorporated IMM-0019EN - Installation and Maintenance Manual

8.4 CHECK THE VOLTAGE SUPPLY

The standard geared motors are supplied with 230/400 V 50/60 Hz up to 3 kW including 3 kW and 400/690 V 50/60 Hz over 3

kW and is indicated on the motors name plate unless it is differently ordered.

In case of only gear unit is supplied from Dana Motion Systems Italia S.r.l. please observe the name plate of the electric motor

and the instructions of the supplier. Check the basic electric connection diagrams below. Use experienced electric technician.

The following wiring diagram is for standard 230/400 V 50 Hz AC electric motors. For different voltages please contact Dana

Motion Systems Italia S.r.l.. For gear units supplied without motor, refer to the motor manufacturers user manual.

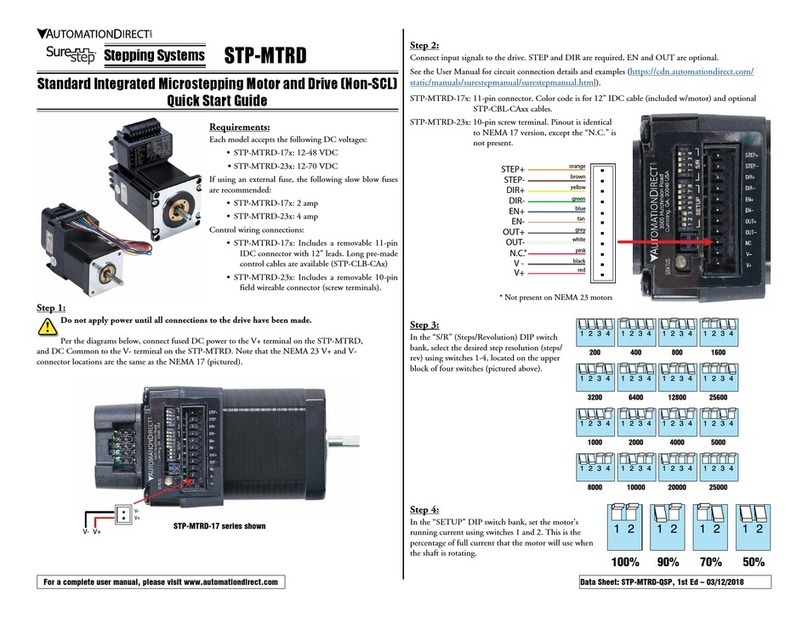

Table 5:

Basic motor connection wiring diagram

DANGER

Using wrong connection or voltage can damage the electric motor or environment.

DANGER

The electric connection must be done by experienced electric technician.

The gearbox, the motor and the brake must be grounded to prevent potential differences of earth and gearbox/mo-

tor.

Pole Number

Nominal Powers at 400V, 50Hz

230V ( D ) / 400 V ( Y ) 400V ( D )

2 or 4 ≤3 kW ≥4 kW

6≤2,2 kW ≥3 kW

8≤1,5 kW ≥2,2 kW

Starting Principle Direct Direct or Y/D

I =

L2L1

U1

W2

W2

ph

U1

W1V1

L3

W1

V2U2

V2

(230V)

U2

I1

I

3

U

L1

(230V)

U =U

U

I2

V1

I3

ph

(230V)

U

L2 L3

V2

L1 L2

U1 V1

I =I

ph

U1

W2 U2

U2

W1

L3

W1

V2

W2

I1 I2

V1

(400V)

L1

U

L2

I3

U

U =

ph

3

(400V)

U

L3

(400V)

U

This manual suits for next models

74

Table of contents

Other brevini Engine manuals

Popular Engine manuals by other brands

Canaline Engines

Canaline Engines Canaline 30 Operator's handbook

DR

DR 5.8 HP Safety & Operating Instructions

Marathon Electric

Marathon Electric imPower Installation & operation instructions

Rotax

Rotax 125 MAX evo Installation instructions and operators manual

Kubota

Kubota GR1600EU Workshop manual

Himax

Himax HA3618 Series manual