SureStep STP-MTRD-17 series User manual

Popular Engine manuals by other brands

Chiaravalli

Chiaravalli CHM Series Maintenance List

Torqeedo

Torqeedo Travel Translation of the original operating instructions

Saito

Saito FA-90R3 instruction manual

MJ Research

MJ Research PTC-0200 Operation manual

Toshiba

Toshiba EQP III 300 Series Brochure & specs

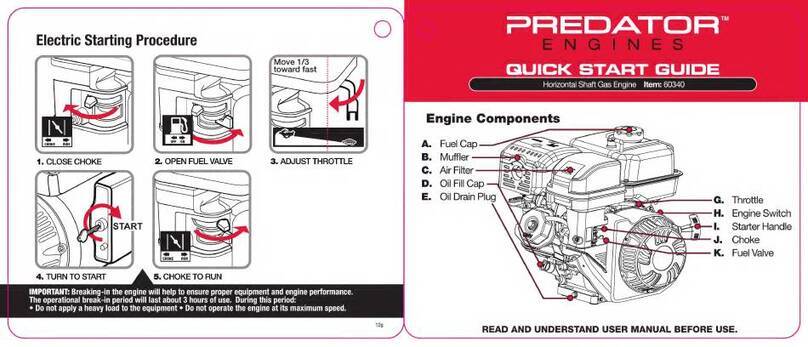

Predator Engines

Predator Engines 60340 quick start guide

Leroy-Somer

Leroy-Somer LSA 42.2 Installation and Maintenance

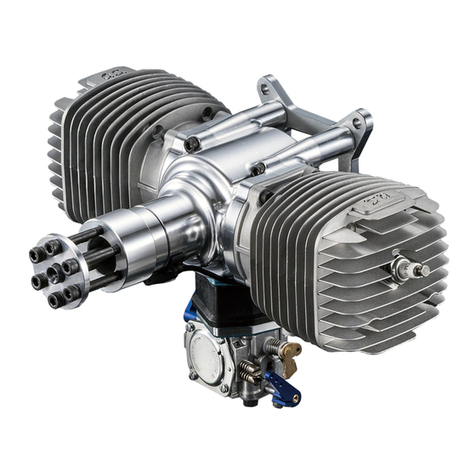

O.S. engine

O.S. engine GT120T instruction manual

FUTABA

FUTABA HPS-A700 quick start guide

3T-Components

3T-Components 3T-MOTORS 3T45-20 Installation & operating instructions

Generac Power Systems

Generac Power Systems MITSUBISHI GAS ENGINE 0G2832 Service manual

DLE

DLE DLE20 user manual

Vittorazi Motors

Vittorazi Motors Moster 185 Factory R Maintenance manual

Mercury

Mercury HP 500 EFI Bravo XR/XZ/III user guide

O.S. engine

O.S. engine GT120THU instruction manual

SOMFY

SOMFY LS40 404R2 installation instructions

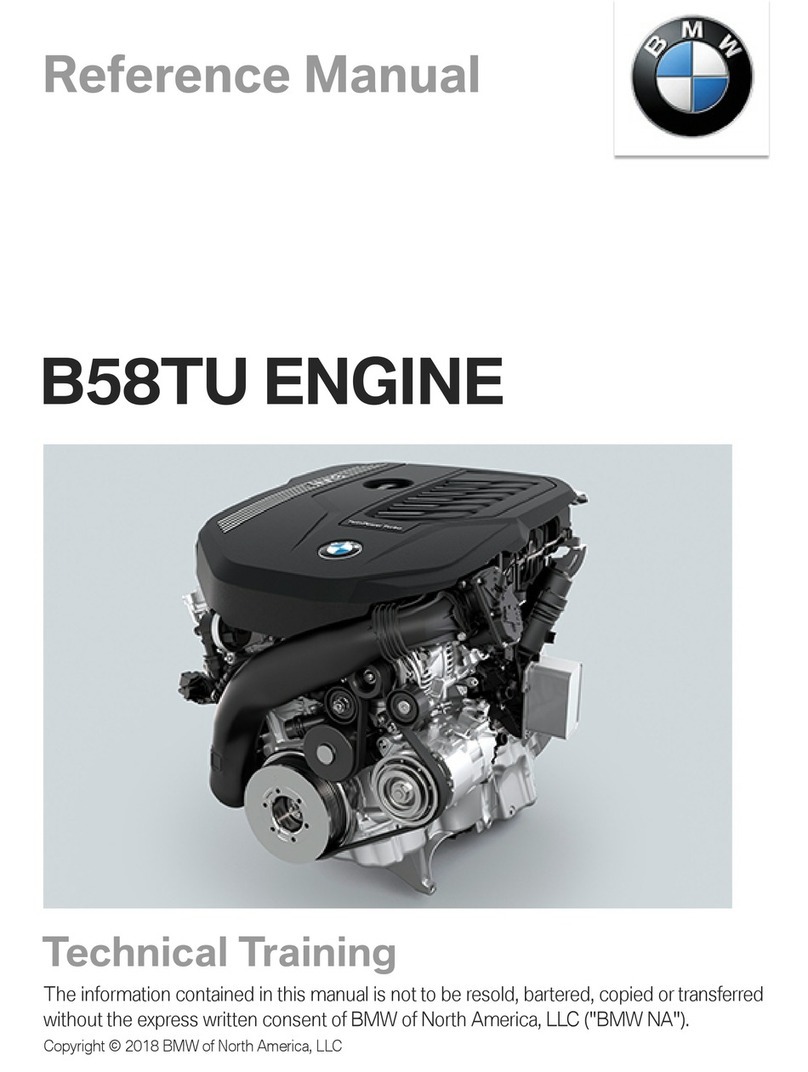

BMW

BMW B58TU Reference manual

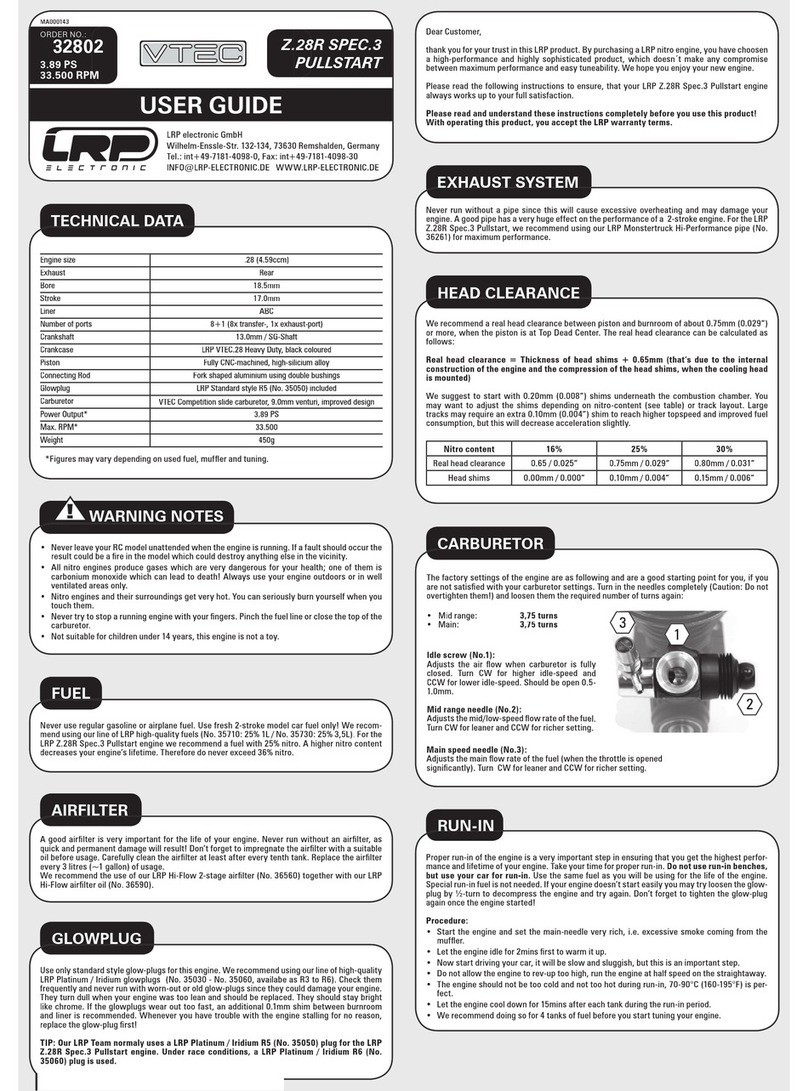

LRP electronic

LRP electronic Z.28R Spec.3 Pullstart user guide