PRD RK125W User manual

PRO RACING DESIGN

1

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLYAND

COMPLETELY BEFORE OPERATING THE ENGINE RK125W.07 FOR THE FIRST

TIME.

Congratulations on your purchase of the PRD RK125W high performance kart engine. The PRD

RK125W is the product of a thorough research, design and development program and employs the

latest in engine performance.

The PRD RK125W has been engineered to provide the user with trouble free operation and an

extended service life with a minimum of routine maintenance. Please read this booklet carefully so

that you can keep your engine in tip-top condition thus ensuring you have many satisfying hours of

performance racing.

Please note that due to PRD’s on-going development program there may be some data in this

booklet that will be upgraded from time to time. If this situation arises, we suggest you consult your

nearest PRD sales & service outlet for advice.

1. SPECIFICATIONS

1. MODEL: RK125W07 TAG

2. TYPE: 2 STROKE WATER COOLED SINGLE CYLINDER REED

VALVE INDUCTION

3. CAPACITY: 124cc

4. BORE: 53.70 ( FIRST PISTON 53.60)

5. STROKE 54mm

6. H.P./RPM 28H.P./15,800RPM

7. CARBURETOR: TILLOTSEN HL-360A

8. IGNITION: C.D.I (OPPAMA)

9. IGNITION TIMING: 2.20mm BTDC [STANDARD]

10. SPARK PLUG: NIPPON DENSO W27ESU [RUN IN ONLY]

W29ESU [RECOMMENDED RACING]

11. SPARK PLUG GAP: 0.60mm [0.024”]

12. FUEL OIL RATIO: 16:1 PREMIUM GRADE UNLEADED PETROL

13. PISTON TYPE: COATED PISTON

14. PISTON CLEARANCE: 0.10mm [STANDARD]

15. RING TYPE: DYKES STYLE (L RING)

16. RING GAP: 0.25mm [0.010”] MIN.

17. CYLINDER HEAD VOLUME: 10.2cc

18. COMPRESSION: 13 : 1

19. CRANKSHAFT: 2 PIECE, FORGED & INDUCTION HARDENED

20. CONROD: 100mm STEEL CNC MACHINED

PRO RACING DESIGN

2

2. FUEL / OIL

2.1 For Australia: Use only premium grade unleaded pump petrol.

2.2 Other Countries: Consult your karting controlling organizations for the appropriate legal fuel.

2.3 Oil: Use only high quality 2-stroke racing oil in a mix ratio of 16:1.

RECOMMENDED OILS: SILKOLENE CASTORENE R30 / CASTROL R30 / SHELL X100 SUPER M.

WARNING: DO NOTALLOW CASTOR OR OTHER VEGETABLE BASE

OIL MIXES TO STAND MORE THAN 8 HOURS OR LEAVE CONTAINERS

OPEN FOR PROLONGED PERIODS.

3. ENGINE RUN-IN

3.1 Ensure the engine is mounted to the chassis correctly, all mounting bolts and nuts are tight and the

drive chain is correctly aligned with the correct tension. Check all electrical & fuel line

connections are secure.

3.2 Ensure that the accelerator cable is correctly fitted and adjusted and the throttle valve in the

carburetor opens and closes correctly. For starting set the walbro high & low speed needle jets to

turn 1-1/4 HI & 1-3/4 LO.

3.3 The 45 minutes run-in period should be divided into 15 minutes periods.

3.4 Do not at any time allow the engine to overheat. If the engine shows signs of overheating abort

the session and allow the engine to cool down. Check for any obvious cause of overheating

before continuing. To excess heat may have simply been caused by an overlong on-track session

or incorrect carburetor setting.

3.5 TRACK SESSIONS 1 & 2:

Do not allow full throttle for prolonged periods. Round the engine in short bursts between 1/2 to

3/4 throttle. Do not allow the engine to labor nor remain on a constant throttle opening for any

prolonged period if using a tachometer limit engine RPM to 7500 [1/2] to 9000 [3/4] maximum.

3.6 TRACK SESSION 3:

Gradually increase throttle opening from 3/4 to full for short bursts full throttle can be used for

longer periods in the 4th & 5th sessions if using a tachometer limit engine RPM to 11,000

maximum when using full throttle.

3.6.1 It is advisable to run the engine “rich” during run-in to assist engine cooling. Care should be taken

not to foul the spark plug.

3.7 In the interval between on-track sessions check all engine & mounting bolts & other fasteners for

tightness as looseness can occur due to vibration.

PRO RACING DESIGN

3

3.8 Regularly check the spark plug tip for adverse discoloration and if necessary adjust the low &

high speed needle settings to compensate fuel input.

Use the Denso w24es-u spark plug as supplied for engine run-in only.

WARNING: Do not use the w24es-u spark plug under racing or prolonged full throttle operation.

We suggest the use of Denso 27ES-ZU [cold weather] & 29ES-ZU [hot weather] for racing.

Your choice of another quality brand of spark plug is acceptable provided the suitable heat range is

chosen for the prevailing weather conditions.

4. GOING RACING

In the previous section we dealt with the “run-in” period for your PRD engine. Once completed your

engine is now ready for racing. In this section we will give you some tuning “TIPS” and advice that

will help you successfully race your PRD.

It is highly recommended that you maintain a “Log Book” to record the vital data for each and every

time you race or test/practice at every race circuit.

This “Log Book” will assist you in duplicating the correct data for each race circuit thus allowing you

to minimize setup time & avoid choosing the wrong data for the circuit conditions.

PRD can assist you establish your “Log Book” by providing the main data you should include.

4.1.1 Carburetor Needle Jets: The carburetor is equipped with high and low speed adjustable jets. The

standard settings for these jets are.

HIGH SPEED 1-1/4 TURNSTILLITSON LOW SPEED 1-3/4 TURNS

Needle “Blow-Off” pressure is 10psi, holding 9psi.

Not every two stroke engine necessarily operates in the same way under the same conditions.

Your engine may not operate in the same way from one race track to another or under varying

atmospheric conditions. Therefore it may be necessary to adjust from standard the high and the

low speed needles to compensate for these changes. A driver’s level of skill can also be a

determining factor in changes to the jet settings.

Warning: Careful monitoring of the condition of the spark plug tip and engine

temperature readings [where a heat gauge is fitted] will be necessary to prevent and engine

malfunction due to insufficient fuel.

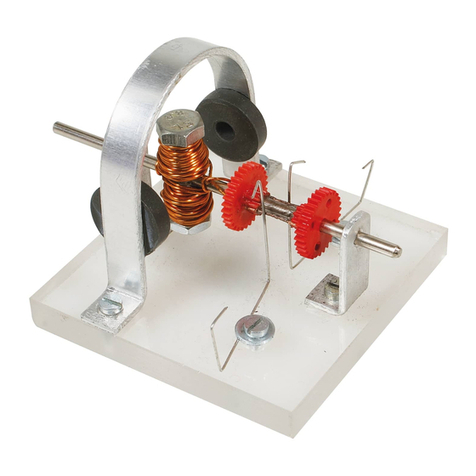

4.1.2 The metering lever [ref#7] will also influence the flow of fuel to the engine. This lever should

be set at a measurement of 1.00mm below the diaphragm mount [see illus]. Adjustment can be

made by carefully bending the lever.

PRO RACING DESIGN

4

Warning: If you are not confident or competent to carry out this task we suggest you have

this adjustment made by your local engine tuner.

4.2 Ignition: The standard ignition timing is 1.8mm BTDC. Your engine will provides satisfactory

performance at this setting. As you gain experience with your engine you may wish to

experiment with different settings. The PRD engine will provide crisp clean performance

between 1.8 to 2.2mm BTDC. We suggest you may care to experiment with these changes to

extract increased performance.

Warning:Any increase in ignition setting may result in an increase in engine heat.

Monitoring of spark plug tip condition and heat gauge temperatures should be made until

you are satisfied the changes are not detrimental to the engine performance.

4.2.1 Rotor Air Gap: The air gap between rotor and stators is 0.30 to 0.50mm. Adjust if necessary

using a feeler gauge. Ensure the gap is uniform at top and bottom pole positions of the stator.

4.3 Exhaust Length: The overall length of the exhaust will have an influence on engine

performance. The PRD engine is supplied as standard with a connector tube of 85mm.

A decrease in length will improve top-end performance.

An increase in length will improve bottom end performance.

4.4 Gear Ratio: The PRD engine is supplied standard with a 10 or 11 teeth engine sprocket. The

choice of final drive ratio will be dependant upon a number of variables and may alter from race

track to race track. Only detailed testing and analysis of lap times will allow you to determine

the correct final drive ratio for any given set of track conditions.

As a guide, we suggest the following procedure:

Selection of the secondary reduction ratio

Secondary reduction ration =Number of Axle sprocket teeth

Number of engine sprocket teeth

Preconditions: For instance if 90T is axle sprocket and 10t is engine sprocket then secondary reduction

ratio is 9:1

For fast course with long straight sections: Reduce the Axle sprocket.

For course with many curves and short straight sections: Increase the Axle sprocket.

Warning: The maximum kart speed will be developed towards the end of the straight sections and care

must be taken not to over-rev the engine.

PRO RACING DESIGN

5

5. ROUTINE ENGINE MAINTENANCE

This section has been provided to allow the owner to carry out sample maintenance tasks to

ensure his engine runs smoothly & reliably. We suggest for the repair & service of a more

serious nature that the owner consults his nearest PRD sales & service outlet.

5.1 Carburetor: The carburetor should be removed and cleaned after each race meeting or test

session. Partial disassembly should be undertaken to the diaphragm area. Dirt or foreign matter

should be removed by washing with a safe cleaning solvent and carefully blow with compressed

air.

5.1.1 Diaphragms and gaskets should be checked for damage and replaced if necessary. [PRD

recommends the use of walbro diaphragm repair kit #350-800 or PRD part #EPY669C where

unleaded fuel is used]

Re-assemble the diaphragms and gaskets in the carburetor body in the reverse order of

disassembly.

5.1.2 High & Low Speed Needles: The carburetor contains 2 adjustable needles. These needles

control the fuel mixture. Carefully remove both of the high & low speed needles, washers &

o-rings. Carefully below the fuel passageways clean with compressed air and refit needles &

other parts in reverse order of disassembly

Needle Adjustment: Turn In Leans mixture

Turn Out: Richens mixture

IMPORTANT:

The needle adjustment should be undertaken in 1/8th turn increments to prevent excessive adjustment

that may result in engine malfunction or failure.

Always adjust the LOW speed needle before adjusting the HIGH speed needle.

Symptoms of improper settings:

If your kart exhibits one or more of the symptoms below it may need some carburetor tuning adjustments.

Before attempting any changes make sure that everything else is in good condition and tuned and

operating correctly. Check the condition of the Spark Plug and ensure the ignition timing is correct.

If your kart is TOO RICH, it will: Accelerate poorly

Misfire

Smoke excessively

Foul the Spark Plug

Have a “deep rumbling”exhaust note

If your kart is TOO LEAN, it will: Ping or rattle **

Accelerate erratically

Act like it is running out of fuel

Run extremely hot

PRO RACING DESIGN

6

** If your kart pings or rattles and the carburetor are not too lean then check that your fuel is fresh and

you have purchased the correct octane rating petrol / gasoline.

5.1.3 Needle & Seat: The maintenance of the correct blow-off pressure is essential to reliable

carburetor performance. The owner can carry out this task with a suitable test gauge such as the

TILLOTSON #243-504 gauge. The needle & seat should be removed and cleaned.As should

the diaphragms etc., prior to carrying out this task. Blow-off pressure should be set at 10psi as

standard and holding 9psi. If your carburetor fails to operate efficiently at this pressure, we

suggest you consult your nearest PRD sales & service outlet.

5.2 Piston & Ring: The piston & ring should be checked after 3 race meeting or extended test

session. Carefully remove the cylinder head & cylinder and inspect the piston & ring for any

obvious signs of damage. Replace if necessary. Evidence of detonation on piston crown can be

an indication of excess ignition advance and ignition timing should be checked and adjusted if

necessary.

5.2.1 Carefully remove ring & place in top of cylinder and measure gap. If gap exceeds 0.25mm and

you wish to maintain top performance then replace ring. If the ring is distorted and not sealing

perfectly then replace.

When re-installing the ring ensure the ring is correctly positioned in the piston ring groove and

the gap in the ring is located either side of the piston ring peg.

NOTE:

The ring, if not damaged, may continue to be used where measurement exceeds 0.25mm but engine

performance will be decreased.

5.2.2 Inspect the piston for any visible signs of damage and replace if necessary.

Inspect for cracks in piston surface of other surface damage or signs of detonation on crown of

piston. Minor surface imperfections such as piston seizure damage can be removed by solvent

and wet & dry sandpaper working in a crisscross pattern carefully and not excessively.

Carbon Deposits:

Deposits on piston crown can be carefully removed with fine grade [#600-800] wet & dry

sandpaper. Deposits in ring groove can be carefully removed with wet & dry sandpaper or very

fine miniature file.

PRO RACING DESIGN

7

Piston to Cylinder Clearance:

If piston to cylinder measurement exceeds maximum tolerance – replace piston.

WARNING:

If it is necessary to remove the piston from the conrod to carry out these procedures then care

must be taken to prevent the piston pin circlips or any other foreign object falling into the

crankcase of the engine.

Do not use excessive force to remove the piston pin.

Whilst disassembled inspect piston pin and bearing for wear or abnormality, replace if necessary.

As a precaution on reassembly, replace old circlips with new.

5.3 Cylinder head and cylinder should be inspected for any damage or abnormality.

5.3.1 Carbon deposits in the cylinder head can be removed with #600-800 wet & dry sandpaper.

Carbon deposits in the exhaust ports of the cylinder can be carefully removed with a round edge

scraper and wet & dry sandpaper.

5.3.2 The cylinder should be inspected for any damage to the liner and if damage is evident and

cannot be removed by wet & dry sandpaper the cylinder should be re-bored. The cylinder

should be measured for concentricity and if any out-of-roundness is detected, the cylinder

should be re-bored and a new piston and ring fitted. Measurement should be taken by either and

inside micrometer or a cylinder bore gauge.

IMPORTANT:

When refitting the cylinder assembly,

care must be taken that you compress the piston ring with one hand and gently lower the cylinder

onto the piston with the other hand.

Care must be taken that the ring is correctly located in the piston groove during this procedure.

5.4 Spark Plugs:

The heat range of a spark plug refers to the classification of a spark plug’s ability to transfer heat

from the firing tip of the insulator to the cylinder head.

The engine manufacturer through testing has determined the heat range appropriate to the

engine. However, variables such as atmospheric conditions, carburetor tuning and engine

modifications can have an influence on the recommended heat range.

WARNING:

When selecting a spark plug with a hotter or colder heat range then do so carefully and cautiously.

A spark plug with TOO HOT a heat range may lead to pre-ignition and possible engine damage.

A spark plug with TOO COLD a heat range may lead to fouling of the plug and failure to start or

erratic poor performance.

PRO RACING DESIGN

8

The “reading”of a spark plug is an acquired skill.

The following table is a guide.

Reference should be made to the photos in the plug manufacturers specification booklet to assist in

determining the correct visual appearance when “reading”a spark plug.

TABLE

Insulator Color Decision

Medium to light tan Normal

Whitish color Lean fuel mixture or

plug too hot

Blackish color Rich fuel mixture or

plug too cold

The insulator color is normally the indicator for the HIGH speed time of the engine.

The plug base color is normally the indicator for the LOW speed time of the engine.

5.5 Gaskets: It is recommended that gaskets be replaced at each partial or complete engine

disassembly.

THIS CONCLUDES OUR BRIEF OUTLINE OF PROCEDURES

This manual suits for next models

2

Table of contents

Other PRD Engine manuals