Brewer's EDGE 2 Series User manual

-1- -6-

READ CAREFULLY AND SAVE FOR FUTURE

REFERENCE

SAFETY

This appliance is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities.

•Never clamp down the lid when brewing, the clamps

are only to be used with an optional T500 compatible

distilling column (not included).

•This appliance should not be left unattended during

operation.

•The appliance should be operated on a flat stable

surface, NEVER on an incline.

•The unit must be plugged into a GFCI protected plug.

•Do not move when hot to prevent scalding.

•Do not run the pump without the recirculation arm

attached. Doing so can cause scalding! Keep the blue handle

closed when the recirculation arm is removed.

•If the supply cord or plug is damaged, it must be

replaced by a qualified electrician in order to avoid a hazard.

•DO NOT IMMERSE IN WATER - The base of the unit

is not waterproof and should not be immersed for cleaning.

The unit must be unplugged from power before cleaning.

• This appliance is intended for household use only,

and is not designed for commercial use.

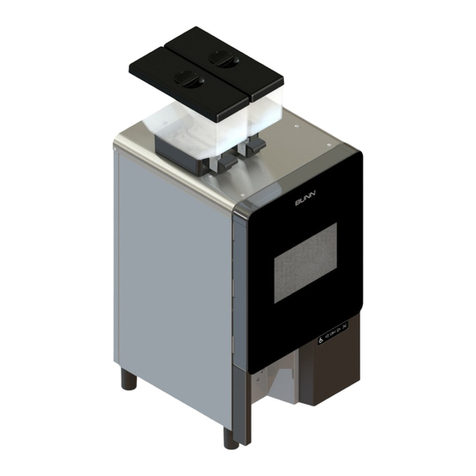

Recirculation

Arm

Stainless Steel

Faucet

LCD Display

On/Off

switch &

Power

Selection

Switches

Pump Switch

-3- -4-

BATCH SIZE: You can make either a 2½ gallon or 5 gallon

batch in the Mash & Boil.

STRIKE WATER CALCULATION: You will first need to

calculate your strike water. Use .30 gallons of water for

every pound of grain, with a minimum amount of 2 gallons,

regardless of batch size.

Examples:

2½ GALLON BATCH WITH 5 POUNDS OF CRUSHED GRAIN:

Instead of using (5 × .3) gallons to calculate strike water

which would be 1.5 gallons, use 2 gallons which is the

minimum.

5 GALLON BATCH WITH 11 POUNDS OF CRUSHED GRAIN:

Use (11 × .3)which is 3.3 gallons of strike water.

5 GALLON BATCH WITH 16 POUNDS OF CRUSHED GRAIN:

Use (16 × .3) which is 4.8 gallons of strike water (16 pounds

is maximum capacity).

STEP 1: Calculate your strike water for your batch and add

to the Mash & Boil. Insert the Sparging Basket and cover

with lid. Plug in the unit, set for 1600 W, and turn ON the

far right (red rocker) power switch. Now press ON/OFF on

the digital control, and press SET. The default strike water

temperature of 162° will flash. To change this, press the + or

– buttons, otherwise, press SET to agree to this strike

temperature (which results in a mash temperature of 152°

to 154° F.).

STEP 2: After setting the runtime, the TIMER value of 0:00

will flash. This means the unit will turn on as soon as you

press SET again as you have not entered a delayed start

time.

If you want to delay the start of the unit, enter the number

of hours you want to wait before the unit starts (enter 1 to

23 hours in whole hours only). For example, if you want the

unit to start 8 hours from now, enter a value of 8.

STEP 3: To agree to this and start the heating cycle for the

strike water (or TIMER countdown), press SET again to start

the strike water heat cycle.

STEP 4: Once the strike water has reached the target

temperature of 162° F., open the lid and start mixing in the

crushed grain with a long spoon. Mix in thoroughly for even

heat distribution until the mash develops a porridge like

consistency. If you find the mash is a little dry, pour a half

gallon of strike water from the bottom valve and mix it into

the top of the mash. Now with the lid removed, change the

set temperature to 152° F (down from 162° F.), by following

the instructions in step 1.

STEP 5: Now attach the recirculation arm and the short

piece of silicone tubing with the white plastic Sparge

Attachment (see picture). With the blue handled valve all

the way open (vertical) turn on the PUMP switch on the

side of the unit to start the pump. You will need to use the

valve to adjust the flow of recirculation so the unit

maintains about an inch of water above the grain bed

during the 1 hour mash.

Mashing, Sparging, and Boiling

-1- -6-

Too much flow, and the unit will run dry (you will hear a

sucking sound) and too little, and the needed 1” of liquid

above the grain will not be maintained. You will have to

play around with the valve adjustment a bit to maintain

about an inch of water above the grain bed as every mash is

different.

If your mash clogs, and is not flowing well enough for the

pump to function, you either have too fine a crush of the

grain in the mash, or too large a percentage of gummy

starches like flaked grains. Turn off the pump and put on

the lid, and let mash without recirculation if this happens.

Wait 1 hour for mashing to complete (but start preparing

your sparge water now, see below).

SPARGE WATER CALCULATION: You will need to calculate

the amount of hot 168° F. sparge water you will need at the

end of the 1 hour mash. Use your strike water calculation

amount and multiply by .75 to get the amount of sparge

water needed.

Examples:

2½ GALLON BATCH WITH 5 POUNDS OF CRUSHED GRAIN:

2 gallons of strike water multiplied by .75 = 1½ gallons of

sparge water needed.

5 GALLON BATCH WITH 11 POUNDS OF CRUSHED GRAIN:

Multiply your 3.3 gallons of strike water by .75 to get 2.48

gallons needed.

5 GALLON BATCH WITH 16 POUNDS OF CRUSHED GRAIN:

Multiply your 4.8 gallons of strike water by .75 to get 3.6

gallons needed.

STEP 6: Prepare your sparge water. Heat the calculated

amount of water in a separate vessel to 168° F., so it will be

ready for use at the end of the 1 hour mash period. It is

okay to mash for longer than 1 hour if your sparge water is

not quite ready yet.

STEP 7: Time to sparge. Now unscrew and detach the

recirculation arm and pull the mashing basket straight up,

and then twist to set its 4 legs on the upper wire support.

Be careful not to drop the full basket on the floor, as the

legs may bend under the weight of the wet grain. Change

the set temperature to 218° F. by following the instructions

in step 1 to boil.

STEP 8: While the temperature is rising, the malt sugar is

dripping into your Mash & Boil from the Sparging Basket.

Now it is time to add the 168° F. sparge water you have

prepared, to wash the malt sugars into the boiler. Sparge

until you have 5½ to 6 gallons of wort.

-3- -4-

IF USING 7 POUNDS OF CRUSHED MALT OR LESS

If you are using 7 pounds of crushed malt or less, you will

first need to push the wet crushed malt up so it covers the

side perforations of the basket to prevent splashing down

the sides when you add strike water. When using this small

amount of grain, only add a quart of sparge water at a time

to prevent splashing out the sides.

Brewer’s Edge® offers an optional Small Batch Adapter,

item J11, that covers the side holes. This is recommended if

you do a lot of small 2½ gallon batches.

IF USING 8 TO 16 POUNDS OF CRUSHED MALT

Add a half gallon of 168° F. sparge water at a time to the top

of the basket, let the basket drain, and add more sparge

water as needed until the 5½-6 gallon mark is reached. It is

helpful to use a flashlight and shine it across to the gallon

marker side to make the markers more visible. Keep doing

this until you have 5½-6 gallons, and then lift the Sparging

Basket off when it has finished draining. Turn up the

thermostat to 217° F and wait for the boil to begin.

IMPORTANT - Do not clamp the lid when boiling, leave the

clamps loose to prevent steam burns! We recommend

leaving the lid off when the unit comes to a boil.

STEP 9: Boiling will be

reached in about 50

minutes. Boil for 1 hour,

adding hops and brewing

your usual way. Do not

run the pump during the

boil. Consider using a hop

spider if you intend on

pumping through a wort

chiller at the end of the

boil to reduce the chance

of pump clogging.

STEP 10: After the boil,

use the chiller of your

choice to chill the wort.

Once cool, transfer into

your designated

fermenter. We

recommend using the

valve rather than using

the pump to pump out, as

the pump can sometimes

clog on hop particles after

the boil.

CLEARING A CLOGGED PUMP

The pump can become clogged occasionally, particularly

when large amounts of pellet hops are used. To clear a

-1- -6-

pump clog, turn the pump off and remove the recirculation

arm. Add a half gallon of water to the unit. Open the blue

valve handle and blow vigorously on the side pipe, and also

suck to loosen any clog. Whole hops

should not be used.

FOR USE IN DISTILLING

The Mash & Boil lid is distilling ready.

If you plan to use your Mash & Boil

to distill, you will need a standard

Turbo 500 type distilling column

that fits in a 47mm lid hole.

Unscrew the handle from the Mash

& Boil lid with a screwdriver to

reveal a 47mm hole, and install your column. Be sure to

clamp the lid to seal when distilling, and release clamps

when done.

CLEANING THE UNIT

Always unplug before cleaning. Clean your Mash & Boil

interior with a scrub sponge and then rinse with water.

Now plug it back in and add a gallon of clean water.

Reattach the recirculation arm and run the pump for a few

seconds until the water runs clear. Now unplug the unit,

remove the recirculation arm, and leave the unit upside

down to dry between uses.

DO NOT REMOVE THE VALVE FOR CLEANING!

Doing so will void the warranty and may cause leaks

between the double walls. Open the valve and rinse with

water to clean. The heat of the next boil will effectively

sanitize the valve.

ERROR CODES & THE

RESET BUTTON:

ER1: Thermostat error,

usually caused by the

red thermostat cable

plug coming loose from

the top left corner of

the internal power

board.

ER4: Thermostat overheating protection. This can happen

when the heating element and thermostat are covered by a

hop or grain bag. It can also be caused by heavy trub

deposits resulting from too fine a grain crush, or malt

extract or honey being poured into the unit, coating the

thermostat. Reset by unplugging, and pressing the reset

button on the bottom center of the unit.

1 YEAR WARRANTY & SERVICE

(do not return to store)

A one year warranty from date of purchase is provided by

Brewer’s Edge®. This applies to household use only,

commercial use will void this warranty.

Warranty is valid in the United States only, and only applies

to units purchased from authorized sellers, which are home

brewing dedicated retailers and online home brew stores.

Proof of purchase in the form of a receipt for store or online

purchase is required for warranty service.

Email info@brewersedge.com with a copy of your proof of

purchase for warranty service information. You can also go

to brewersedge.com for the latest tips on use, and check

the Facebook Mash & Boil user group.

-3- -4-

brewersedge.com • Item B95

Popular Brewing System manuals by other brands

ESPRO

ESPRO ULTRALIGHT COFFE AND TEA PRESS quick start guide

Franke

Franke Bkon Craft Brewer Operation manual

Toddy

Toddy ARTISAN quick start guide

Grainfather

Grainfather G Series quick start guide

BRAVILOR BONAMAT

BRAVILOR BONAMAT Aurora Single High troubleshooting guide

Curtis

Curtis D500GT12A000 user guide