Safety Instructions ..........................................................................................................................1

Read and Follow ALL Safety Instructions ...............................................................................1

Safety Overview .................................................................................................................1

Recognition .........................................................................................................................1

Different Types of Alerts ..........................................................................................................1

Safety Tips ................................................................................................................................1

Qualified Service Personnel ......................................................................................................2

Safety Precautions .....................................................................................................................2

Shipping And Storage ...............................................................................................................2

Unit Location ............................................................................................................................3

Power Cord ...............................................................................................................................3

Sound Levels .............................................................................................................................3

Machine Usage .........................................................................................................................3

Unit Cleaning ............................................................................................................................4

Grounding Instructions .............................................................................................................4

System Overview ............................................................................................................................5

Overview ...................................................................................................................................5

Features .....................................................................................................................................5

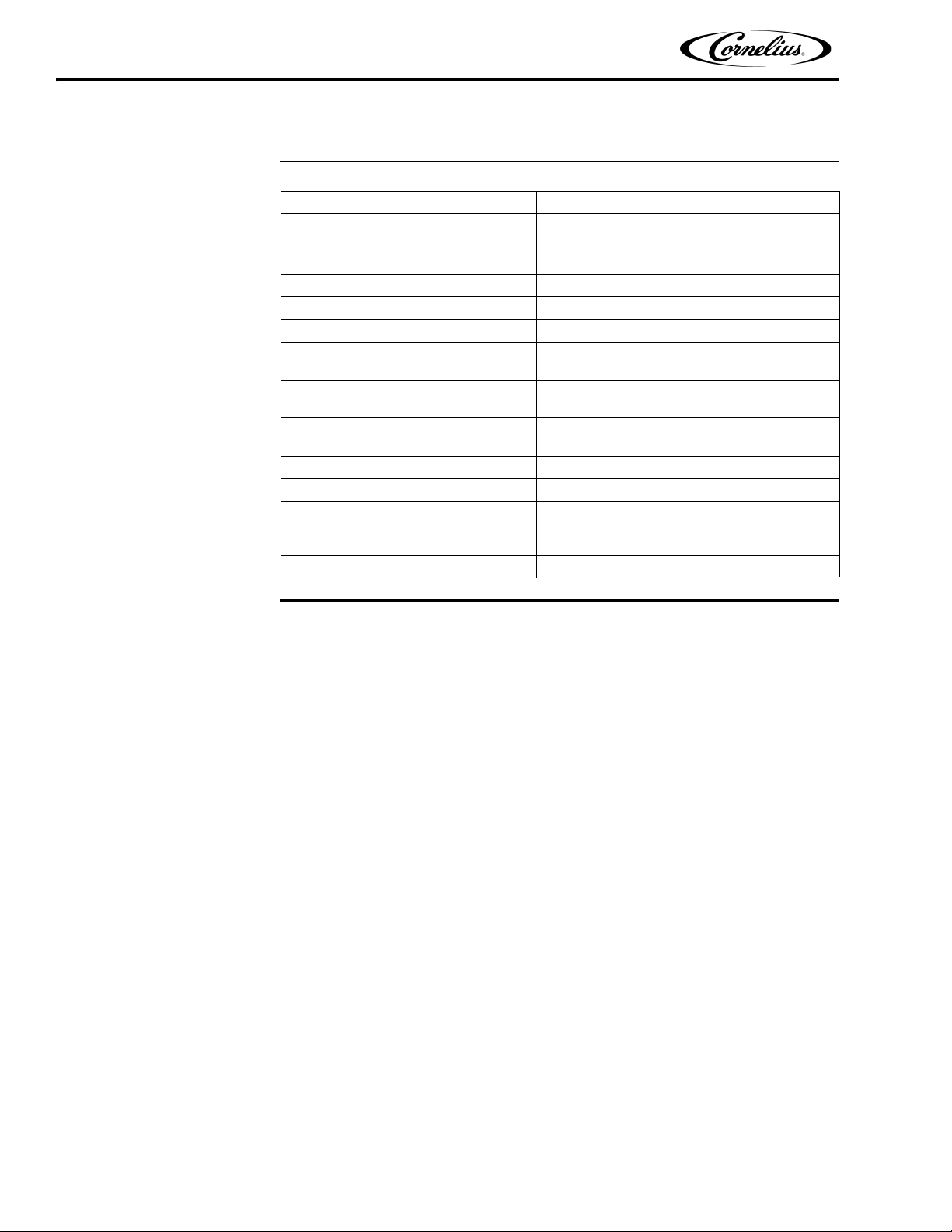

Specifications ............................................................................................................................6

Installation ......................................................................................................................................7

Delivery Inspection and Unpacking .........................................................................................7

Installation Kit ..........................................................................................................................7

Location ....................................................................................................................................7

Supply Connections ..................................................................................................................8

Electrical Requirements ......................................................................................................8

Line Voltage .................................................................................................................8

Power ............................................................................................................................9

Nitrogen Requirements .......................................................................................................9

Nitrogen Connections ...................................................................................................9

Initial Nitrogen Pressure Setup ...................................................................................10

Water Requirements .........................................................................................................10

Ventilation Requirements .......................................................................................................11

Freestanding Unit Installation .................................................................................................11

Under Counter Unit Installation .............................................................................................17

commissioning the Unit ................................................................................................................24

Initial Startup ..........................................................................................................................24

Connecting Power .............................................................................................................24

Unit Details .............................................................................................................................24

Cleaning Products .............................................................................................................24