3

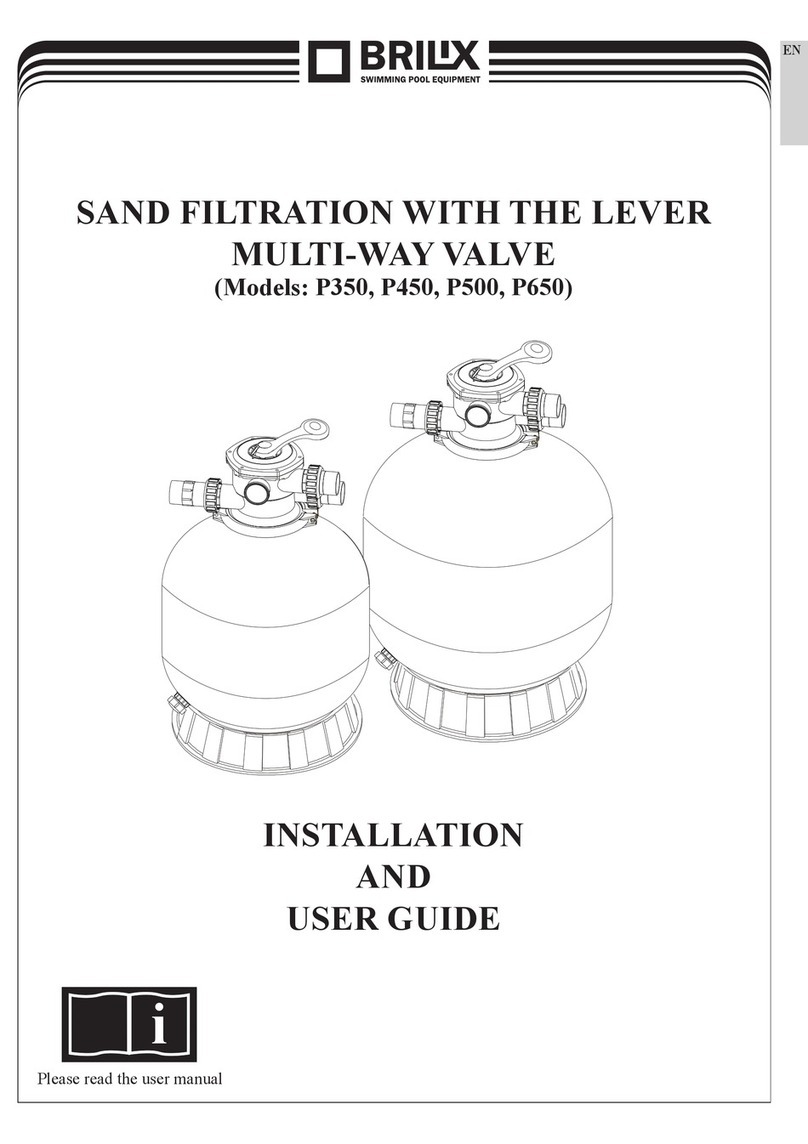

I. Function

The filter uses a special filtration sand to capture the dirt components from the pool water. A filter container,

operating as a permanent dirt collector, is filled with the filtration sand. When the regulating valve remains

in the position “FILTER“, the pool water containing the dirt, sucked through the system of hoses, is auto-

matically forced in the regulating valve with patented filter and it is led from this place to the top part of the

filtration container. The water, pushed through the sand, removing the fine dirt, is taking back to the bottom

part of the container. Through the regulating valve, the water comes back to the pool by hoses. The whole

process is continuous and automatic. It ensures the complete re-circulation of the pool water through the

filter and the hose system.

After some time of operation, the dirt accumulated in the filter may cause upsetting of water conduit through

the sand and reduce he flow through the filtration unit. This process indicates to the fact that the filter should

be cleaned. If you set the valve bar in the position BACKWASH, the water flow will automatically return,

so it will flow from the bottom of the container through the filtration sand from which it rinses the sedimen-

tary dirt to the waste pipe. If the filter is rinsed, set the bar in set the bar in the position RINSE and activate

the pump for a half to one minute; then set up the valve stick back to the position FILTER to re-initiate the

standard filtration.

II. Installation

• Assemble the filtering system, including the pump, the filtering tank and the six-way valve.

• The filtering system should be fitted as close to the pool as possible, possibly 0.5 metre under the water

level in the pool. Make sure that water can run off from the place where the filter is installed.

PUMP

1. The pump and the electric power line should only be installed by qualified and authorized persons. All

pumps are supplied with 230 V power.

2. Remember to fit in a closing valve in the suction line.

FILTERING TANK AND SIX-WAY VALVE

1. Filling of the sand filtering medium: The sand filtering medium is filled through the filter’s upper

opening.

a. Release the tank branch plastic plugs.

b. Protect the inner tube against infiltrating sand using a plastic cover.

c. We recommend that you fill in the tank with water up to a half to ensure a damping effect after filtering

sand is filled in. This will protect the bottom drainage duct against an excessive impact.

d. Carefully fill in adequate quantity and type of filtering sand. Make sure that the central tube is in the

middle of the opening. The sand surface should be levelled and should reach up to approximately a half

of the filtering sand. Remove the plastic cover from the inner tube.

2. Connect the control valve to the filtering tank.

a. Insert the control valve (with a correctly fitted sealing ring) to the tank nozzle and ensure that the central

tube connects to the opening in the bottom part of the valve.

b. Place two plastic plugs on the valve flange and the tank nozzle, and tighten them to ensure that the valve

can rotate on the tank for the purpose of the final adjustment in a permanent position.

EN